Turning

Chip control and tool life are major Turning application challenges. Tungaloy’s latest technology develops new generations of grades and optimized chip breakers designed for superior performance while maintaining long tool life improving efficiency and productivity.

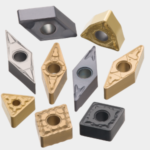

Carbide/Cermet/Ceramic Grades

Grades and Chip breakers

PCD/CBN Inserts & Grades

PCD/CBN grades and chip breakers

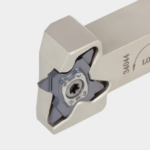

C-SDNCN-Y, C-STECN-Y

Y-axis turning tool with PSC connection for multitasking machines

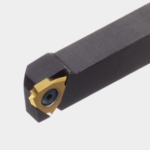

J*DJ2X, J*VJ2X, J*WL2X, JS-S*UX, JS*JX, JSWLX

Economical double-sided positive insert

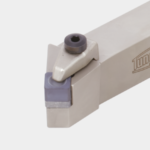

ACLNR/L-Eco, ADJNR/L-Eco, ADQNR/L-Eco

Cost effective: Identical cutting performance, only smaller

CCLN, CDJN, CDNN, CHSN, CSSN, CVVN

Ceramic insert with dimple for high-feed turning of cast iron

C-D**-L***-9D-C, C-SH-CHP, D-L-4D-SH, D/G-L

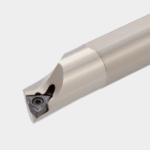

Vibration-Free Solution for Deep-Hole Boring

Minimum Bore dia. ø16 mm –

A/E-SCLX, A/E-SDXX, A/E-SDZX, A/E-SWLX

Economical double-sided insert with sharp cutting edge

A-PCLN, A-PDUN, A-PDZN, A-PSKN

Highly rigid internal toolholder with excellent chip evacuation

A-ACLN, A-ADUN, A-ASKN, A-ATFN, A-AVUN, A-AWLN

Highly rigid double clamping system with high repeatability

QC-JSDJ2XR, QC-JSDJ2XR-Y, QC-JSDNXR

Economical double-sided insert with sharp cutting edge

CAE, CGE, CGP, CTE, CGEU, CGIU, CTFV, CTIF, CTIR, JCTE, JTTE

Multi-functional system for diverse grooving needs

Cutting width 2 – 8 mm

CDX Max 55 mm

STC, JS-STC, JS-STCF, STCFV

Grooving tool with 4 cutting-edge insert

Cutting width 0.33 – 4 mm

CDX Max 10 mm

JSXX, JS-SXX

Stable parting-off operations due to unique clamping system

Cutting width 0.6 – 2 mm

CDX Max 10.5 mm

JSXX

Flexible turning tool series for CNC automatic lathes and cam-driven lathes

Cutting width 0.5 – 0.6 mm

CDX Max 3.5 mm

SVE

High precision grooving and threading tool series for CNC automatic lathes

Cutting width 0.33 – 1 mm

CDX Max 4 mm

A/E-SM

Small internal grooving and threading tool

Cutting width 1 – 2 mm

CDX Max 2 mm

B-S/CE, BC-SE, CE, JS-SE, JS-TTL3, JSE2, JSTT, CN, SN

Effective threading tools for CNC lathes, Swiss-type lathes, and multitasking machines