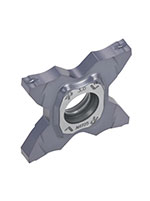

Grooving tools with 4 cutting-edge insert

Ground insert clamps into unique insert pocket and provides high rigidity as well as repeatability

Applications & Features

Applications

Features

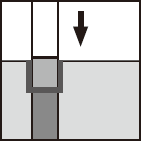

1. Unique 3-point clamping system

The unique pocket design provides accurate indexing repeatability of the cutting edge height.

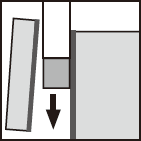

2. Ground or molded chip breakers

Enhanced lineup for greater flexibility.

3. Expedited delivery service for special grooving inserts

Inserts & Grades

Inserts

TetraMini-Cut Grooving and Parting-off Inserts (Grooving width 0.33 – 3.0 mm)

- For precise grooving operation with uniquely designed insert, mainly in swiss and small lathes

TetraForce-Cut Grooving and Parting-off Inserts (Grooving width 0.5 – 4.0 mm)

- Suitable for accurate grooving with ground 4-edged inserts for wide range of components

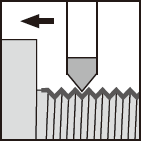

TetraMini-Cut Threading Inserts (Pitch 0.4 – 3.0 mm)

- Threading insert with 4 cutting-edges

Grades

SH7025

![]()

![]()

![]()

![]()

- P20 – P30 / M20 – M30

- The latest grade with sharp cutting edge designed for small part machining

- A combination of a columnar-structured TiCN coating and multilayered TiAlN coating provides superior surface quality and process security

AH7025

![]()

![]()

![]()

- P20 – P30 / M20 – M30 / S15 – S25

- Excellent wear resistance and high rigidity

- First choice for grooving of various materials

AH725

![]()

![]()

![]()

![]()

- P15 – P30 / M15 – M30 / K25 – K30 / S15 – S25

- Good balance between wear and chipping resistance

- Suitable for machining steel and stainless steel under general cutting conditions

SH725

![]()

![]()

![]()

![]()

![]()

![]()

- P20 – P30 / M20 – M30

- High wear resistance

- Designed for machining steel and stainless steel

AH8015

![]()

![]()

![]()

![]()

![]()

- M01 – M20 / S10 – S20

- Good balance between wear and fracture resistance

- First choice for machining heat-resistant alloy under general cutting conditions

AH8005

![]()

![]()

![]()

- M01 – M10 / S01 – S10 / H10 – H20

- Good resistance to wear and adhesion

- Excellent performance in machining heat-resistant alloy at high speed

AH6235

![]()

![]()

- P30 – P40 / M30 – M40

- Provides high reliability in interrupted cutting with large depths of cut

NS9530

![]()

![]()

- P20 – P30 / M20 – M30 / K10 – K20

- High fracture resistance

- Suitable for finishing to medium cutting of steel

TH10

![]()

![]()

![]()

![]()

Toolholders

Grooving & Parting & Threading

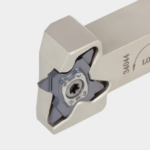

TetraMini-Cut Toolholders

Grooving and threading toolholder for swiss and small lathes

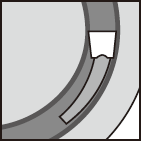

Face grooving toolholder

Grooving & Parting & Threading

TetraForce-Cut Toolholders

Grooving and threading toolholder for general lathes

Grooving & Parting & Threading

TetraForce-Cut / TetraMini-Cut modular blade

Modular type toolholder with square shank and PSC connection

Practical examples

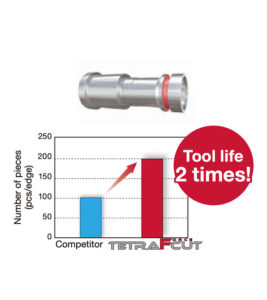

Example #1

General Engineering

| Part: | Shaft stator |

| Material: | S45C / C45 |

| Toolholder: | STCR2525-27 |

| Insert: | TCS27-200-020 |

| Grade: | AH725 |

| Cutting conditions: | Vc = 210 (m/min) f = 0.15 (mm/rev) CDX = 2 (mm) CW = 2 (mm) Application: External grooving Coolant: Wet Machine: NC lathe |

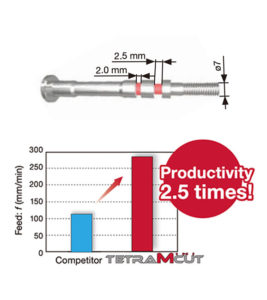

Example #2

Automotive Industry

| Part: | Input shaft |

| Material: | SCr420 / 20Cr4 |

| Toolholder: | STCR2525Z18 |

| Insert: | TCG18R150-020 |

| Grade: | AH7025 |

| Cutting conditions: | Vc = 100 (m/min) f = 0.08 (mm/rev) CDX = 2.1 (mm) CW = 2 (mm) Application: External grooving Coolant: Wet Machine: NC lathe |

Example #3

Miniature / Electronic Industry

| Part: | Spool shaft |

| Material: | S45C / C45 |

| Toolholder: | STCR1010X18 |

| Insert: | TCP18R200F-010 |

| Grade: | SH725 |

| Cutting conditions: | Vc = 43 (m/min) f = 0.10 (mm/rev) CDX= 1.5 / 1.1 (mm/min) CW = 2 / 2.5 (mm) Application: External grooving Coolant: Wet Machine: Swiss lathe |

Standard cutting conditions

TCL18R/L, TCS18R/L (3D chipbreaker), TCG18R/L (honed edge), TCG18R/L (Full R)

| ISO | Workpiece materials | Grades | Cutting speed Vc (m/min) |

Feed: f (mm/rev) | ||

|---|---|---|---|---|---|---|

| TCL18 | TCS18 | TCG18 | ||||

| Carbon steel S45C / C45, etc. |

AH8005 | 100 – 300 | 0.03 – 0.12 | 0.04 – 0.16 | 0.04 – 0.14 | |

| AH7025 | 100 – 200 | |||||

| AH6235 | 80 – 120 | |||||

| NS9530 | 120 – 250 | |||||

| Alloy steel SCM435 / 34CrMo4, etc. |

AH8005 | 80 – 250 | 0.03 – 0.12 | 0.04 – 0.16 | 0.04 – 0.14 | |

| AH7025 | 50 – 180 | |||||

| AH6235 | 50 – 100 | |||||

| NS9530 | 100 – 200 | |||||

| Stainless steel SUS304 / X5CrNi18-9, etc. |

AH8005 | 100 – 150 | 0.03 – 0.12 | 0.04 – 0.16 | 0.04 – 0.14 | |

| AH7025 | 80 – 120 | |||||

| AH6235 | 50 – 120 | |||||

| Grey cast iron FC250 / 250, etc. |

AH8005 | 80 – 250 | 0.03 – 0.12 | 0.04 – 0.16 | 0.04 – 0.14 | |

| AH7025 | 50 – 180 | |||||

| AH6235 | 50 – 100 | |||||

| NS9530 | 50 – 180 | |||||

| Ductile cast iron FCD400 / 400-15, etc. |

AH8005 | 80 – 180 | 0.03 – 0.12 | 0.04 – 0.16 | 0.04 – 0.14 | |

| AH7025 | 50 – 120 | |||||

| AH6235 | 50 – 80 | |||||

| NS9530 | 50 – 180 | |||||

| Titanium alloys Ti-6Al-4V, etc. |

AH8005 | 50 – 70 | 0.03 – 0.12 | 0.04 – 0.16 | 0.04 – 0.14 | |

| AH7025 | 30 – 60 | |||||

| Superalloys Inconel718, etc. |

AH8005 | 40 – 60 | 0.03 – 0.12 | 0.04 – 0.16 | 0.04 – 0.14 | |

| AH7025 | 20 – 50 | |||||

TCP18R/L (lightly honed edge) / TCP18R/L-F (sharp edge)

| ISO | Workpiece materials | Grades | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|

| Carbon steel S45C / C45, etc. |

SH7025 | 80 – 180 | 0.01 – 0.08 | |

| AH725 | 80 – 180 | 0.03 – 0.1 | ||

| Alloy steel SCM435 / 34CrMo4, etc. |

SH7025 | 80 – 180 | 0.01 – 0.08 | |

| AH725 | 80 – 180 | 0.03 – 0.1 | ||

| Stainless steel SUS304 / X5CrNi18-9, etc. |

SH7025 | 50 – 120 | 0.01 – 0.08 | |

| AH725 | 50 – 120 | 0.03 – 0.1 | ||

| Grey cast iron FC250 / 250, etc. |

AH725 | 50 – 180 | 0.03 – 0.1 | |

| SH7025 | 50 – 180 | 0.01 – 0.08 | ||

| Ductile cast iron FCD400 / 400-15, etc. |

AH725 | 50 – 180 | 0.03 – 0.1 | |

| SH7025 | 50 – 180 | 0.01 – 0.08 | ||

| Titanium alloys Ti-6Al-4V, etc. |

SH7025 | 30 – 80 | 0.01 – 0.08 | |

| AH725 | 30 – 80 | 0.03 – 0.1 | ||

| Superalloys Inconel718, etc. |

SH7025 | 20 – 60 | 0.01 – 0.08 | |

| AH725 | 20 – 60 | 0.03 – 0.1 |

TCF18L (Face grooving)

| ISO | Workpiece materials | Grades | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|

| Carbon steel S45C / C45, etc. |

SH7025 | 30 – 100 | 0.01 – 0.04 | |

| Alloy steel SCM435 / 34CrMo4, etc. |

SH7025 | 30 – 100 | 0.01 – 0.04 | |

| Stainless steel SUS304 / X5CrNi18-9, etc. |

SH7025 | 30 – 100 | 0.01 – 0.04 | |

| Grey cast iron FC250 / 250, etc. |

SH7025 | 30 – 100 | 0.01 – 0.04 | |

| Ductile cast iron FCD400 / 400-15, etc. |

SH7025 | 30 – 100 | 0.01 – 0.04 | |

| Titanium alloys Ti-6Al-4V, etc. |

SH7025 | 20 – 40 | 0.01 – 0.04 | |

| Superalloys Inconel718, etc. |

SH7025 | 10 – 30 | 0.01 – 0.04 |

TCT18R/L / TCT18FR

| ISO | Workpiece material | Hardness | Grade | Cutting speed Vc (m/min) |

|---|---|---|---|---|

| Steel / Alloy steel S45C, SCM440, etc. C45, 42CrMoS4, etc. |

< 200HB | AH8015 | 80 – 180 | |

| AH725 | 60 – 150 | |||

| SH7025 | 60 – 150 | |||

| > 200HB | AH8015 | 60 – 160 | ||

| AH725 | 60 – 150 | |||

| SH7025 | 60 – 150 | |||

| Stainless steel SUS304, etc. X5CrNi18-9, etc. |

– | AH8015 | 50 – 130 | |

| – | AH725 | 50 – 80 | ||

| – | SH7025 | 50 – 80 | ||

| Cast iron FC250, FC300, etc. 250, 300, etc. |

– | AH8015 | 60 – 150 | |

| – | AH725 | 50 – 100 | ||

| – | SH7025 | 50 – 100 | ||

| Superalloys Ti-6AI-4V, Inconel718, etc. |

– | AH8015 | 20 – 80 | |

| – | AH725 | 20 – 80 | ||

| – | SH7025 | 20 – 80 |

TCL27, TCS27, TCM27, TCG27, TCL38

| ISO | Workpiece materials | Grades | Cutting speed Vc (m/min) |

Feed: f (mm/rev) | Depth of cut for profiling (with full radius insert) |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Grooving, Parting off |

Parting off (with hand) |

Profiling (with full radius insert) |

|||||||||

| TCL | TCS | TCM | TCG | TCS | TCS | TCM | |||||

| Carbon steel S45C / C45, etc. |

AH8005 | 100 – 300 | 0.03 – 0.12 | 0.05 – 0.15 | 0.05 – 0.25 | 0.03 – 0.1 | 0.04 – 0.12 | 0.05 – 0.1 | 0.05 – 0.15 | 0.5 | |

| AH7025 | 100 – 200 | ||||||||||

| AH6235 | 80 – 120 | ||||||||||

| NS9530 | 120 – 250 | ||||||||||

| Alloy steel SCM435 / 34CrMo4, etc. |

AH8005 | 80 – 250 | 0.03 – 0.12 | 0.05 – 0.15 | 0.05 – 0.25 | 0.03 – 0.1 | 0.04 – 0.12 | 0.05 – 0.1 | 0.05 – 0.15 | 0.5 | |

| AH7025 | 50 – 180 | ||||||||||

| AH6235 | 50 – 100 | ||||||||||

| NS9530 | 100 – 200 | ||||||||||

| Stainless steel SUS304 / X5CrNi18-9, etc. |

AH8005 | 100 – 150 | 0.03 – 0.12 | 0.05 – 0.15 | 0.05 – 0.2 | 0.03 – 0.1 | 0.04 – 0.12 | 0.05 – 0.1 | 0.05 – 0.15 | 0.5 | |

| AH7025 | 80 – 120 | ||||||||||

| AH6235 | 50 – 120 | ||||||||||

| Grey cast iron FC250 / 250, etc. |

AH8005 | 80 – 250 | 0.03 – 0.12 | 0.05 – 0.15 | 0.05 – 0.25 | 0.03 – 0.1 | 0.04 – 0.12 | 0.05 – 0.1 | 0.05 – 0.15 | 0.5 | |

| AH7025 | 50 – 180 | ||||||||||

| AH6235 | 50 – 100 | ||||||||||

| NS9530 | 50 – 180 | ||||||||||

| Ductile cast iron FCD400 / 400-15, etc. |

AH8005 | 80 – 180 | 0.03 – 0.12 | 0.05 – 0.15 | 0.05 – 0.2 | 0.03 – 0.1 | 0.04 – 0.12 | 0.05 – 0.1 | 0.05 – 0.15 | 0.5 | |

| AH7025 | 50 – 120 | ||||||||||

| AH6235 | 50 – 80 | ||||||||||

| NS9530 | 50 – 180 | ||||||||||

| Titanium alloys Ti-6Al-4V, etc. |

AH8005 | 50 – 70 | 0.03 – 0.12 | 0.05 – 0.15 | 0.05 – 0.15 | 0.03 – 0.1 | 0.04 – 0.12 | 0.05 – 0.1 | 0.05 – 0.1 | 0.5 | |

| AH7025 | 30 – 60 | ||||||||||

| Superalloys Inconel718, etc. |

AH8005 | 40 – 60 | 0.03 – 0.12 | 0.05 – 0.15 | 0.05 – 0.15 | 0.03 – 0.1 | 0.04 – 0.12 | 0.05 – 0.1 | 0.05 – 0.1 | 0.5 | |

| AH7025 | 20 – 50 | ||||||||||

1QP-TCX18R/L (Widening external grooves)

| ISO | Workpiece materials | Hardness | Grades | Cutting speed Vc (m/min) |

Feed: f (mm/rev) | Depth of cut: ae (mm) | ||

|---|---|---|---|---|---|---|---|---|

| RE = 0.1 | RE = 0.2 | RE = 0.1 | RE = 0.2 | |||||

| Hard material · Hardened steel SCM435 / 34CrMo4, SUJ2 / B1 etc. |

> 50 HRC | BX360 | 80 – 150 | 0.02 – 0.05 | 0.03 – 0.1 | 0.15 – 0.3 | 0.15 – 0.5 | |

For more information about this product, visit our online e-catalog or download the product report:

Metric

Imperial

- Main product report_No. 416-US

- Expansion full R inserts_No. 416S1-US

- Expansion Face grooving insert_No. 416S2-US

- Expansion TCL38 inserts_No. 416S3-US

- Expansion TCS18L, TCL18L inserts_No. 416S4-US

- Expansion Wide cutting edge inserts and dedicated

toolholders_No. 416S5-US - Expansion Introducing the latest PVD grade SH7025_No. 416S8-US