Solid carbide boring bar for small-diameter turning

Extra-fine cutting edge offers high-precision machining for a wide range of internal applications

Applications & Features

Applications

Features

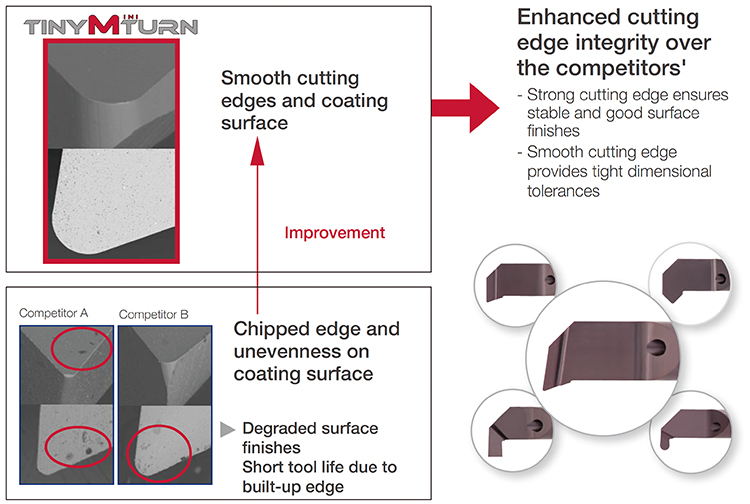

1. Strong cutting edge

Optimized geometry and coating surface.

2. Enhanced lineup for a variety of turning operations of small-diameter holes

Full lineup with 146 items of solid carbide boring bars – Minimum boring diameter : øDm = 0.6 mm

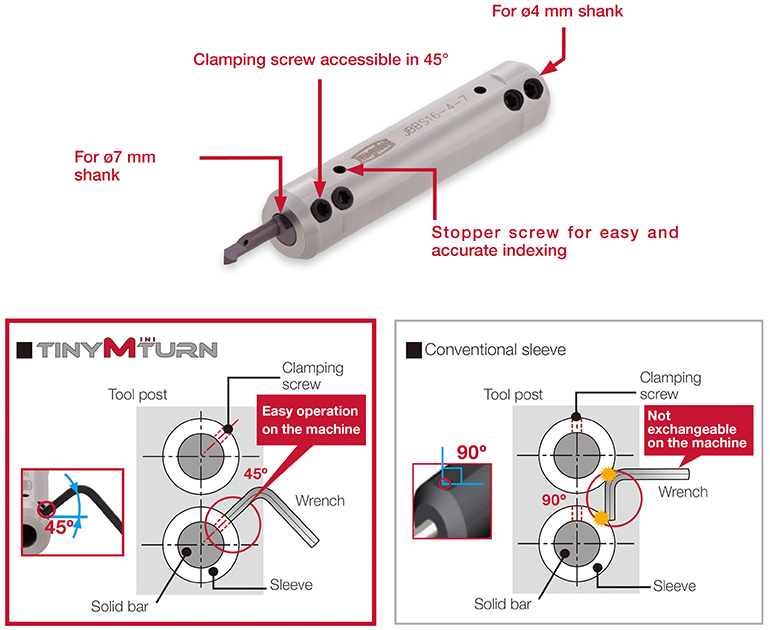

3. High precision collet chuck sleeves

Functional TinyMiniTurn sleeves ensure stability in boring of small-diameter holes.

Solid Carbide Boring Bars & Grades

Solid Carbide Boring Bars

Grades

SH725

![]()

![]()

- P20 – P30 / M20 – M30

- High wear resistance

- Designed for machining steel and stainless steel

BX310

![]()

- H01 – H10

- High wear resistance

- Designed for high-speed continuous cutting of hardened steel

Inserts & Grades

Inserts

Main Grades

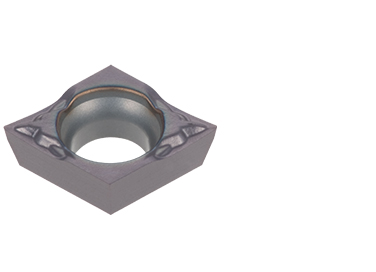

SH7025

![]()

![]()

- P20 – P30 / M20 – M30

- The latest grade with sharp cutting edge designed for small part machining.

- A combination of a columnar-structured TiCN coating and multilayered TiAlN coating provides superior surface quality and process security.

SH725

![]()

![]()

- P20 – P30 / M20 – M30

- High wear resistance

- Designed for machining steel and stainless steel

GH110

![]()

![]()

![]()

![]()

![]()

- P10 – P20 / M10 – M20 / K10 – K25 / N05 – N15 / S10 – S20

- High wear resistance

J740

- Ultra-fi ne-grain cemented carbide coated with TiN-based compoundF

GT9530

![]()

![]()

- High wear resistance

- Excellent surface quality in finishing

NS9530

![]()

![]()

- High fracture resistance

- Suitable for finishing to medium cutting of steel

TH10

![]()

![]()

![]()

![]()

- P10 / M10 / K10 / N10

- Uncoated Cemented Carbide

BX310

![]()

- H01 – H10

- High wear resistance

- Designed for high-speed continuous cutting of hardened steel

BX470

![]()

- Excellent sharpness

- Suitable for ferrous sintered metal

Indexable Toolholders

Sleeves

Practical Examples

Standard cutting conditions

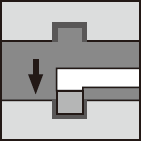

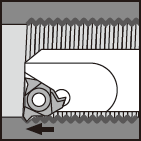

Boring, profi ling, chamfering, back boring

| ISO | Workpiece materials | Grade | Cutting speed Vc (m/min) | Feed f (mm/rev) |

|---|---|---|---|---|

|

Low carbon steels S15C, S25C, etc. C15E, C15E4, etc. |

SH725 | 40 – 140 | 0.01 – 0.08 |

| Carbon steels, Alloy steels S55C, SCM440, etc. C55, 42CrMo4, etc. |

SH725 | 40 – 140 | 0.01 – 0.08 | |

| Prehardened steels NAK80, PX5, etc. |

SH725 | 40 – 140 | 0.01 – 0.08 | |

|

Stainless steels SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

SH725 | 40 – 140 | 0.01 – 0.08 |

|

Grey cast irons FC250, FCD300, etc. GG25, 250, GG30, 300, etc. |

SH725 | 30 – 100 | 0.01 – 0.08 |

| Ductile cast irons FC450, FCD600, etc. GGG60, 600-3, etc. |

SH725 | 30 – 100 | 0.01 – 0.08 | |

|

Aluminium alloys, Copper alloys Si < 12% |

SH725 | 90 – 200 | 0.01 – 0.08 |

|

Titanium alloys Ti-6AI-4V, etc. |

SH725 | 30 – 100 | 0.01 – 0.08 |

| Superalloys Inconel718, etc. |

SH725 | 30 – 100 | 0.01 – 0.08 | |

|

Hardened steel | BX310 | 15 – 100 | 0.01 – 0.1 * |

* Set the D.O.C. and feed according to the tool’s corner radius (RE).

Threading (metric thread)

| ISO | Workpiece materials | Grade | Cutting speed Vc (m/min) |

Number of passes Pitch (mm) |

||||

|---|---|---|---|---|---|---|---|---|

| 0.5 | 0.75 | 1 | 1.25 | 1.5 | ||||

|

Low carbon steels S15C, S25C, etc. C15E, C15E4, etc. |

SH725 | 40 – 140 | 6 – 8 | 8 – 10 | 10 – 12 | 12 – 15 | 15 – 18 |

| Carbon steels, Alloy steels S55C, SCM440, etc. C55, 42CrMo4, etc. |

SH725 | 40 – 140 | 6 – 8 | 8 – 10 | 10 – 12 | 12 – 15 | 15 – 18 | |

| Prehardened steels NAK80, PX5, etc. |

SH725 | 40 – 140 | 6 – 8 | 8 – 10 | 10 – 12 | 12 – 15 | 15 – 18 | |

|

Stainless steels SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

SH725 | 40 – 140 | 8 | 10 | 12 | 15 | 18 |

|

Grey cast irons FC250, FCD300, etc. GG25, 250, GG30, 300, etc. |

SH725 | 30 – 100 | 7 | 9 | 12 | 14 | 17 |

| Ductile cast irons FC450, FCD600, etc. GGG60, 600-3, etc. |

SH725 | 30 – 100 | 7 | 9 | 12 | 14 | 17 | |

|

Aluminium alloys, Copper alloys Si < 12% |

SH725 | 90 – 200 | 6 | 8 | 10 | 12 | 15 |

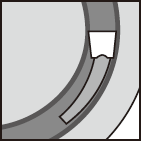

Internal grooving

| ISO | Workpiece materials | Grade | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|

|

Low carbon steels S15C, S25C, etc. C15E, C15E4, etc. |

SH725 | 40 – 140 | 0.01 – 0.03 |

| Carbon steels, Alloy steels S55C, SCM440, etc. C55, 42CrMo4, etc. |

SH725 | 40 – 140 | 0.01 – 0.03 | |

| Prehardened steels NAK80, PX5, etc. |

SH725 | 40 – 140 | 0.01 – 0.03 | |

|

Stainless steels SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

SH725 | 40 – 140 | 0.01 – 0.03 |

|

Grey cast irons FC250, FCD300, etc. GG25, 250, GG30, 300, etc. |

SH725 | 30 – 100 | 0.01 – 0.03 |

| Ductile cast irons FC450, FCD600, etc. GGG60, 600-3, etc. |

SH725 | 30 – 100 | 0.01 – 0.03 | |

|

Aluminium alloys, Copper alloys Si < 12% |

SH725 | 90 – 200 | 0.01 – 0.03 |

|

Titanium alloys Ti-6AI-4V, etc. |

SH725 | 30 – 100 | 0.01 – 0.03 |

| Superalloys Inconel718, etc. |

SH725 | 30 – 100 | 0.01 – 0.03 |

Face grooving

| ISO | Workpiece materials | Grade | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|

|

Low carbon steels S15C, S25C, etc. C15E, C15E4, etc. |

SH725 | 40 – 140 | 0.01 – 0.05 |

| Carbon steels, Alloy steels S55C, SCM440, etc. C55, 42CrMo4, etc. |

SH725 | 40 – 140 | 0.01 – 0.05 | |

| Prehardened steels NAK80, PX5, etc. |

SH725 | 40 – 140 | 0.01 – 0.05 | |

|

Stainless steels SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

SH725 | 40 – 140 | 0.01 – 0.05 |

|

Grey cast irons FC250, FCD300, etc. GG25, 250, GG30, 300, etc. |

SH725 | 30 – 100 | 0.01 – 0.05 |

| Ductile cast irons FC450, FCD600, etc. GGG60, 600-3, etc. |

SH725 | 30 – 100 | 0.01 – 0.05 | |

|

Aluminium alloys, Copper alloys Si < 12% |

SH725 | 90 – 200 | 0.01 – 0.05 |

|

Titanium alloys Ti-6AI-4V, etc. |

SH725 | 30 – 100 | 0.01 – 0.05 |

| Superalloys Inconel718, etc. |

SH725 | 30 – 100 | 0.01 – 0.05 |

For new indexable boring bar (EPG*04 / EPG*03 insert)

| ISO | Workpiece material | Grade | Cutting speed Vc (m/min) |

|---|---|---|---|

|

Low carbon steels S15C, S25C, etc. C15E, C15E4, etc. Carbon steels S45C, S55C, etc. C45, C55, etc. Alloy steels SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

SH7025 | 10 – 200 |

| SH725 | 10 – 200 | ||

| SH730 | 10 – 150 | ||

| J740 | 10 – 100 | ||

| NS9530 | 150 – 300 | ||

| GT9530 | 150 – 300 | ||

|

Stainless steels SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

SH7025 | 10 – 200 |

| SH725 | 10 – 200 | ||

| SH730 | 30 – 150 | ||

|

Grey cast iron FC250, GG25, 250, etc. |

TH10 | 30 – 100 |

|

Aluminium alloys Si < 12% |

TH10 | > 100 |

| DX140 | > 500 | ||

| Aluminium alloys Si > 12% |

TH10 | > 100 | |

| DX140 | > 400 | ||

| Copper alloys | TH10 | > 100 | |

| DX140 | > 500 | ||

|

Hardened materials | BX310 | 30 – 150 |

| Powder metal | Sintered powder metals | BX470 | 100 – 300 |

For more information about this product, visit our online e-catalog or download the product report: