Rowkowanie

Machining grooves with accurate width and surface finish is possible only if the chips are controlled in its confined groove width; and managing chips in such a narrow space is a big challenge. Tungaloy’s advancements in geometry designs for grooving inserts are a key factor to solve this challenge while maintaining the highest standards in productivity and efficiency for grooving applications.

MiniV-LockGroove

High precision grooving and threading tool series for CNC automatic lathes

Grooving width 0.33 – 1.0 mm

CDX Max 4 mm

DuoForceCut

flexible turning tool series for CNC automatic lathes and cam-driven lathes

Grooving width 0.5 – 1.0 mm

CDX Max 3.5 mm

AddForceCut

Grooving and parting-off tool series with optimally rigid self-clamping system

Grooving width 2 – 8 mm

CDX Max 60 mm

DuoJust-Cut

Stable parting-off operations due to unique clamping system

Grooving width 0.6 – 2 mm

CDX Max 10.5 mm

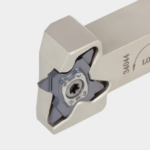

TetraForce-Cut / TetraMini-Cut

Noże do nacinania rowków z 4-ostrzowymi płytkami

Grooving width 0.33 – 4.00 mm

CDX Max 10 mm

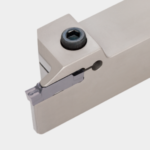

TungCut / TungShortCut

Wielofunkcyjny system do różnorodnych potrzeb w zakresie nacinania rowków

Grooving width 1.2 – 8 mm

CDX Max 55 mm

GTGN

The best solution for external and internal shallow groove machining

Grooving width: 1.00 – 2.25 mm

CDX Max 1.8 mm

EasyMulti-Cut

Najbardziej wydajne narzędzie do nacinania głębokich rowków czołowych.

Cutting width 4, 5, 6 mm

CDX Max 65 mm

TungHeavyGroove

Unkalny system narzędzi do nacinania szerokich rowków i profili

For wide groovingGrooving width 10 – 25 mm

Blanks for wide profi le groovingGrooving width 10.2 – 25.5 mm

CDX Max 40 mm

Hi, I'm Gabby.

Tungaloy's AI assistant. I'm here to help you find the most suitable grooving & parting solution. How can I assist you today?