Reducing Setup Time and Optimizing Tool Overhang for Swiss-Type Automatic Lathes with Head Exchangeable Tools

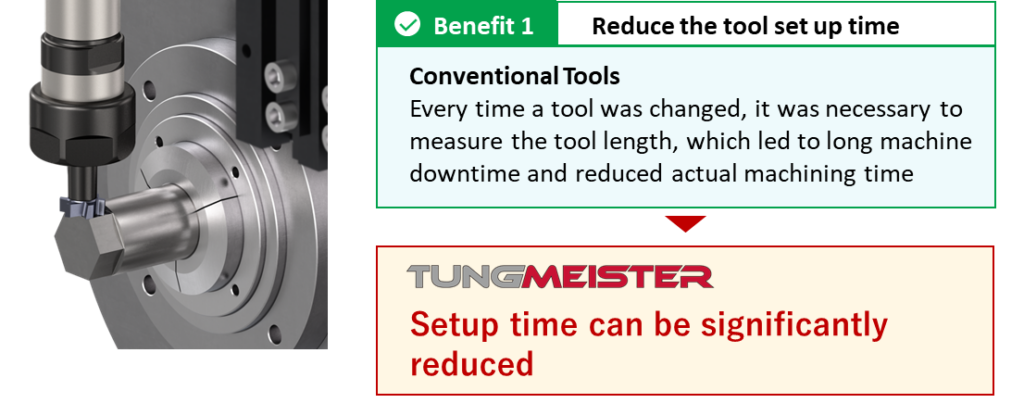

In Swiss-type automatic lathe machining, reducing setup time is a crucial challenge directly linked to improving productivity. Reducing tool setup time and increasing machine uptime are extremely important for improving efficiency in the manufacturing field.

When using conventional solid endmills, tool overhang tends to be long, which reduces rigidity during machining and can lead to chatter. Additionally, measuring tool length is necessary every time the tool is replaced, resulting in extended machine downtime.

These issues have a direct impact on machining efficiency and quality, becoming a significant bottleneck in the manufacturing process.

Tungaloy proposes the “TungMeister” head exchangeable tool to reduce setup time and optimize tool overhang for Swiss-type automatic lathe machining.

Reduction of Setup Time:

Easy tool replacement without the need for readjustment significantly reduces setup time.

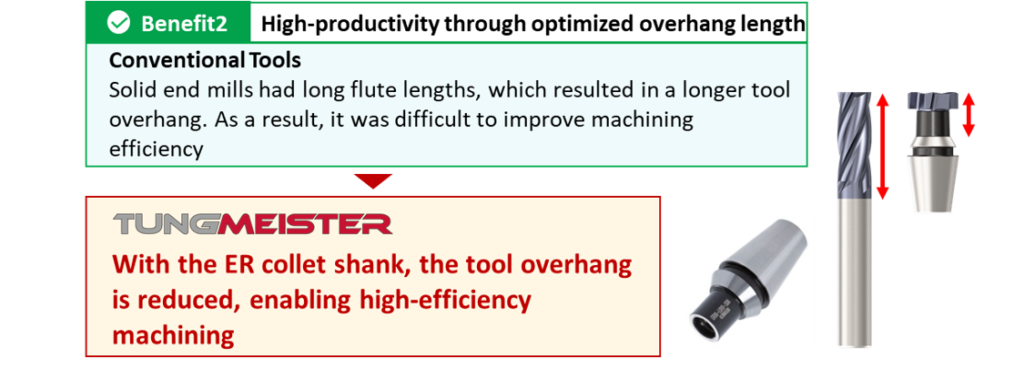

Optimization of Tool Overhang:

Optimization of tool overhang using ER collet specification shank, suppressing chatter.

Achieving high-efficiency machining and improved production efficiency.

Specific Effects

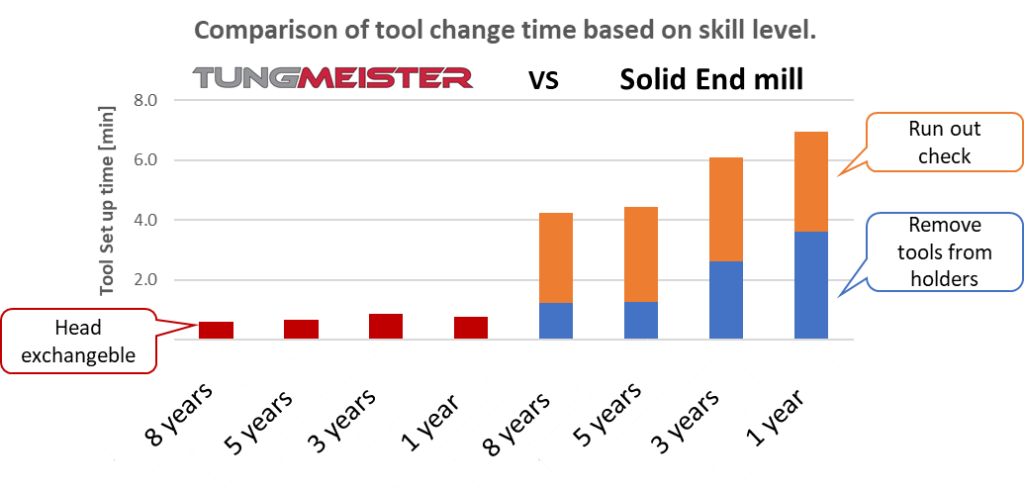

Effect 1: Significant Reduction in Tool Change Time

With the head exchangeable tool, the entire tool does not need to be removed during tool replacement; only the head part is replaced. This significantly reduces tool change time, eliminates the need for readjustment, and reduces machine downtime. As a result, setup time is reduced, and machine uptime is improved. In addition, tool replacement time becomes consistent regardless of the operator’s skill level.

Effect 2: High-Efficiency Machining by Optimizing Tool Overhang

By adopting an ER collet specification shank, tool overhang is optimized, suppressing chatter. With a shorter overhang, tool rigidity is enhanced, resulting in improved stability during machining. This allows for high-efficiency machining, leading to improved product quality and increased production efficiency.

Recommended Cases

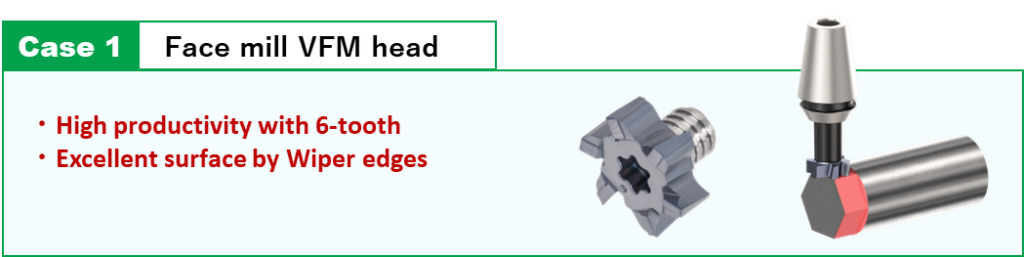

CASE 1: Face mill VFM head

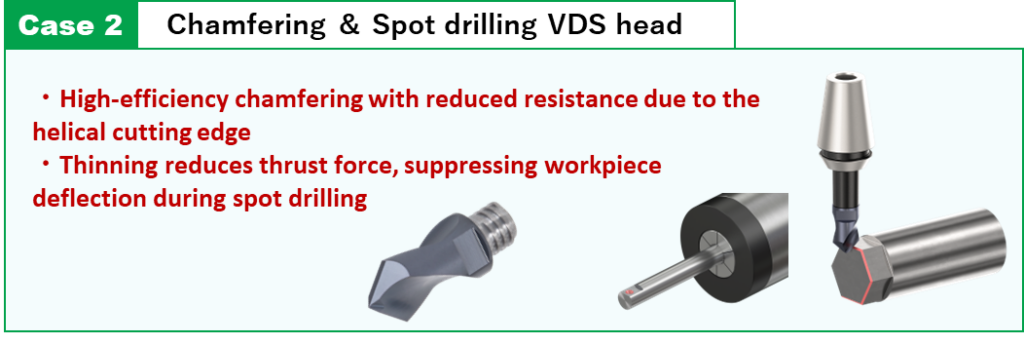

CASE 2: Chamfering and Spot Drilling VDS head

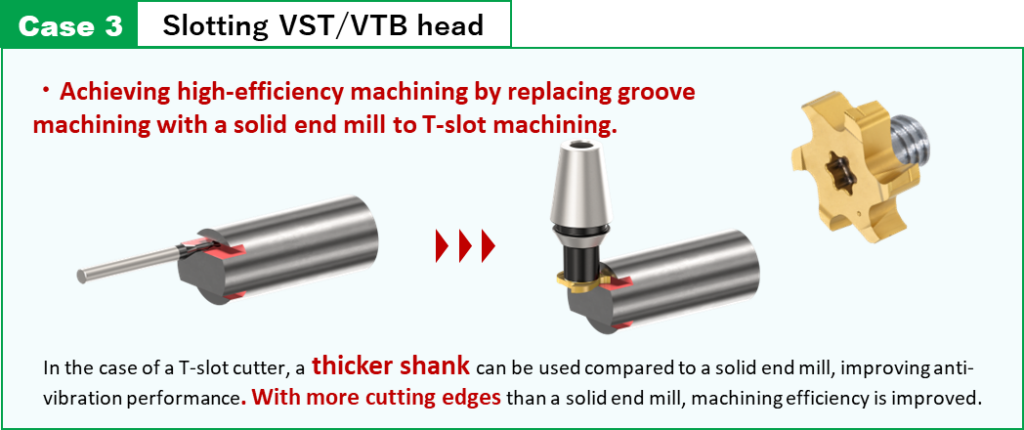

CASE 3: Slotting VST/VTB head

Summary

The “TungMeister” head exchangeable tool enables reduction of setup time and optimization of tool overhang in Swiss-type lathe machining, allowing for increased uptime and high-efficiency machining.