Broca cañón de plaquita intercambiable con una eficiencia excepcional

DeepTri-Drill, la serie de brocas de plaquita intercambiable fáciles de usar, ofrece un rendimiento sobresaliente, una eficacia y una estabilidad excepcionales en el taladrado de agujeros profundos

Aplicaciones y características

Aplicaciones

Características

1. Amplia gama de opciones para diversas operaciones de taladrado profundo

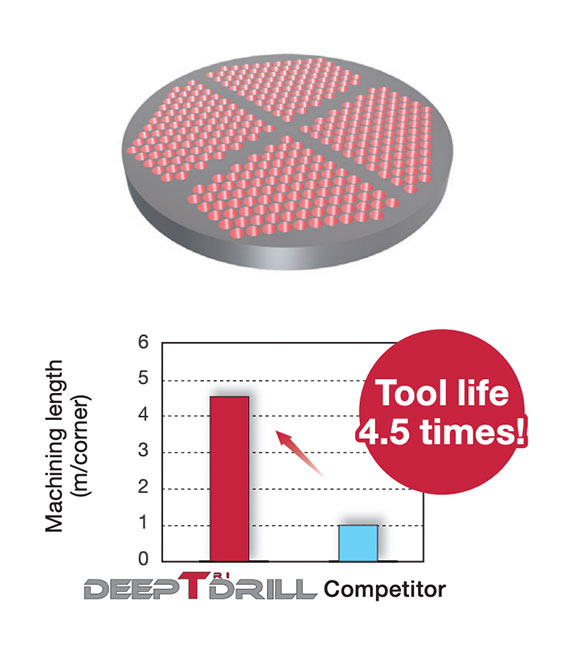

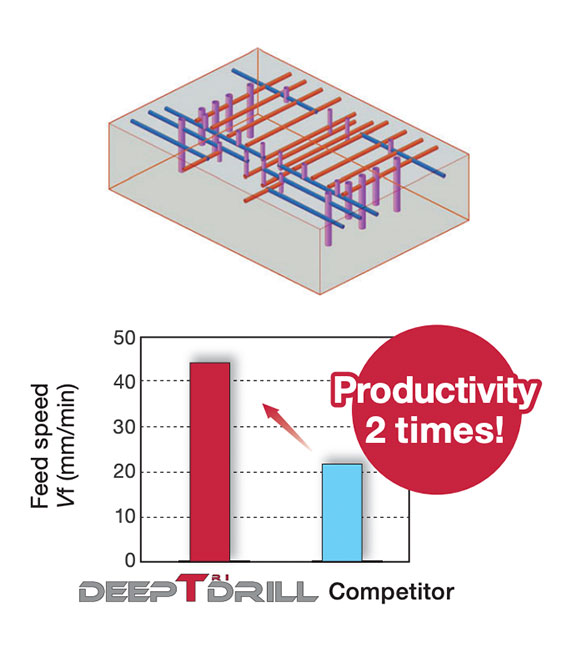

2. Máxima eficiencia

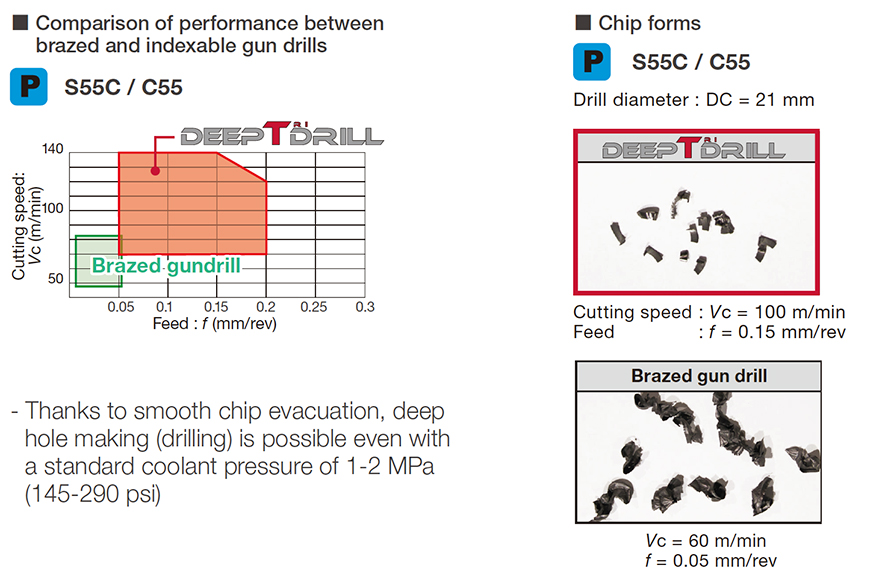

- El exclusivo rompevirutas y divisor de virutas en la arista de corte permite un impresionante control de viruta en cualquier velocidad de avance, especialmente en los avances más altos

- Gracias a la suave evacuación de viruta, es posible realizar agujeros profundos (taladrado) incluso con una presión de refrigerante estándar de 1-2 MPa (145-290 psi)

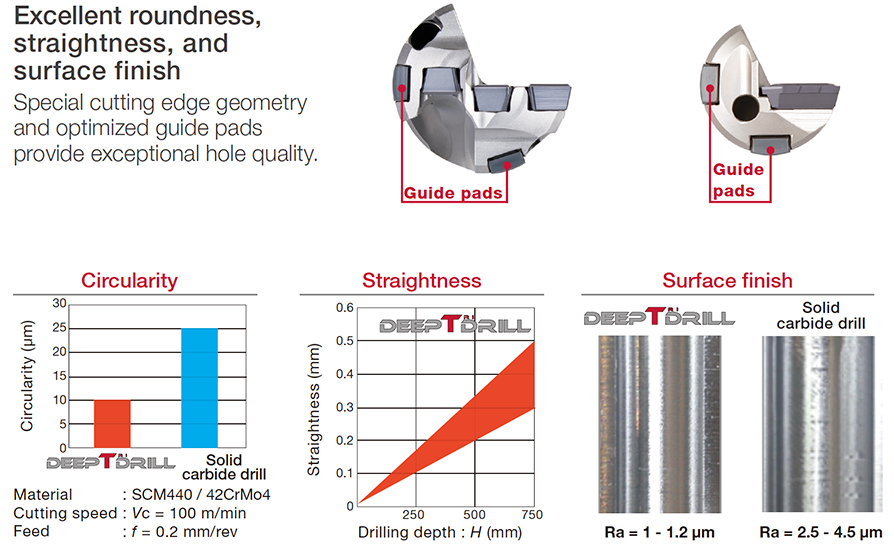

3. Excelente redondez, rectitud y acabado superficial

- La geometría especial de la arista de corte y los patines guía optimizados proporcionan una calidad de agujero excepcional.

Plaquitas y calidades

Plaquitas

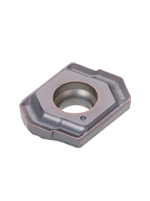

TOHT-NDJ/NDL

- 3 aristas de corte con separador de virutas

LOGT-NDJ

- 2 aristas de corte con separador de virutas

ZSGT-NDJ

- 1 arista de corte con separador de virutas

FBM/FBH

- Diseño optimizado del rompevirutas para el taladrado de agujeros profundos

Patín guia

Calidades principales

AH9130

![]()

![]()

![]()

![]()

- P15 – P35 / M25 – M35 / K10 – K25 / S15 – S30

- Gran resistencia al desgaste

- Diseñada para el taladrado de diversos materiales

AH725

![]()

![]()

![]()

![]()

- P15 – P30 / M15 – M30 / K25 – K30 / S15 – S25

- Buen equilibrio entre la resistencia al desgaste y al astillado

- Adecuada para el mecanizado de acero y acero inoxidable en condiciones de corte estándar

FH3125 (Para patines guia)

- Primera opción

- Gran durabilidad de la herramienta gracias a un sustrato y a un recubrimiento único

FH3135 (Para patines guia)

- Gran resistencia a la rotura

- Primera opción cuando se utiliza un refrigerante soluble en agua

Cuerpos de broca

Taladrado en general

MCTR (ø8 – ø40 mm)

• Para tornos y centros de mecanizado

• L/D = 8 – 45

Ejemplos prácticos

Ejemplo #01

Indústria energética

| Pieza: | Tubo |

| Material: | SUS304 / X5CrNi18-9 |

| Broca: | MCTR20.00XM32-10 |

| Plaquita: | TOHT090305R-NDL |

| Calidad: | AH725 |

| Condiciones corte: | Vc = 80 (m/min) f = 0.04 (mm/rev) Vf = 53 (mm/min) H = 200 (mm) Refrigeración: Taladrina Máquina: Horizontal M/C |

Example #2

Molde y matriz

| Pieza: | Molde de plástico |

| Material: | SKD61 / X40CrMoV5-1 (45 HRC) |

| Broca: | TRLGCH18.00X1500-36A |

| Plaquita: | TOHT080305R-NDJ |

| Calidad: | AH725 |

| Condiciones corte: | Vc = 62 (m/min) f = 0.04 (mm/rev) Vf = 44 (mm/min) H = 700 (mm) Refrigeración: Taladrina Máquina: Horizontal M/C |

Ejemplo #03

Industria automovilística

| Pieza: | Eje |

| Material: | SCM420H |

| Broca: | MCTR12.00XM20-20 |

| Plaquita: | LOGT060204R-NDJ |

| Calidad: | AH725 |

| Condiciones corte: | Vc = 150 (m/min) f = 0.13 (mm/rev) Vf = 517 (mm/min) øDc = 12 (mm) H = 233 (mm) Refrigeración: Taladrina Máquina: Vertical M/C |

Condiciones de corte estándar

Drill diameter: DC = ø7.94 – ø9.99 mm

| ISO | Workpiece material | Chip-breaker | Grade | Cutting speed Vc (m/min) |

Feedf (mm/rev) |

|---|---|---|---|---|---|

| Low carbon steel (C < 0.3) SS400, SM490, S25C, etc. E275A, C25, etc |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | |

| Carbon steel (C > 0.3) S45C, S55C, etc. C45, C55, etc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.14 | |

| Low alloy steel (C < 0.3) SCM415, 18CrMo4, etc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | |

| Alloy steel (C > 0.3) SCM440, SCr420, 42CrMo4, 20Cr4, etc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.14 | |

| Stainless steel (Austenitic) SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

NDJ | AH9130 | 60 – 80 | 0.05 – 0.08 | |

| Stainless steel (Martensitic, Ferritic) SUS430, SUS416, etc. X6Cr17, X12CrS13, etc. |

NDJ | AH9130 | 60 – 80 | 0.05 – 0.08 | |

| Stainless steel (Precipitation hardening) SUS630, X5CrNiCuNb16-4, etc. |

NDJ | AH9130 | 60 – 80 | 0.05 – 0.08 | |

| Grey cast iron FC250, GG25, 250, etc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.2 | |

| Ductile cast iron FCD700, 700-2, etc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.2 | |

| Aluminium alloys | NDJ | AH9130 | 60 – 100 | 0.05 – 0.18 | |

| Heat-resistant alloys Inconel 718, etc. |

NDJ | AH9130 | 20 – 50 | 0.04 – 0.06 | |

| Titanium alloys Ti-6Al-4V, etc. |

NDJ | AH9130 | 30 – 60 | 0.04 – 0.1 | |

| Hardened steel ≥ 40HRC |

NDJ | AH9130 | 20 – 50 | 0.04 – 0.06 |

*Coolant recommendations for drilling stainless steel:

– Oil coolant is first priority

– Water soluble coolant requires at least 20% oil concentration

Drill diameter: DC = ø10 – ø28 mm

| ISO | Workpiece material | Priority | Chip-breaker | Grade | Cutting speed Vc (m/min) |

Feed:f (mm/rev) | |||

|---|---|---|---|---|---|---|---|---|---|

| ø10 – ø11.8 | ø11.81 – ø13.99 | ø14 – ø18 | ø18.01 – ø28 | ||||||

| Low carbon steel (C < 0.3) SS400, SM490, S25C, etc. E275A, C25, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.1 | 0.03 – 0.1 | |

| First choice | NDJ | AH9130 | 80 – 140 | 0.05 – 0.08 | 0.05 – 0.1 | 0.06 – 0.12 | 0.08 – 0.16 | ||

| Carbon steel (C > 0.3) S45C, S55C, etc. C45, C55, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.1 | 0.03 – 0.12 | |

| First choice | NDJ | AH9130 | 80 – 140 | 0.05 – 0.14 | 0.05 – 0.16 | 0.07 – 0.18 | 0.08 – 0.2 | ||

| Low alloy steel (C < 0.3) SCM415, 18CrMo4, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.12 | 0.08 – 0.1 | |

| First choice | NDJ | AH9130 | 80 – 140 | 0.05 – 0.08 | 0.05 – 0.1 | 0.06 – 0.12 | 0.08 – 0.16 | ||

| Alloy steel (C > 0.3) SCM440, SCr420, 42CrMo4, 20Cr4, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.1 | 0.03 – 0.12 | |

| First choice | NDJ | AH9130 | 80 – 120 | 0.05 – 0.14 | 0.05 – 0.16 | 0.07 – 0.18 | 0.08 – 0.2 | ||

| Stainless steel (Austenitic) SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.06 | 0.03 – 0.06 | |

| First choice | NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.05 – 0.12 | ||

| Stainless steel (Martensitic, Ferritic) SUS430, SUS416, etc. X6Cr17, X12CrS13, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.06 | 0.03 – 0.06 | |

| First choice | NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.05 – 0.12 | ||

| Stainless steel (Precipitation hardening) SUS630, X5CrNiCuNb16-4, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.06 | 0.03 – 0.06 | |

| First choice | NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.05 – 0.12 | ||

| Grey cast iron FC250, GG25, 250, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.15 | 0.05 – 0.18 | |

| First choice | NDJ | AH9130 | 80 – 140 | 0.05 – 0.2 | 0.05 – 0.25 | 0.05 – 0.25 | 0.05 – 0.3 | ||

| Ductile cast iron FCD700, 700-2, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.15 | 0.05 – 0.18 | |

| First choice | NDJ | AH9130 | 80 – 140 | 0.05 – 0.2 | 0.05 – 0.25 | 0.05 – 0.25 | 0.05 – 0.3 | ||

| Aluminium alloys | Lower feed | NDL | AH725 | 80 – 160 | – | – | 0.03 – 0.15 | 0.03 – 0.15 | |

| First choice | NDJ | AH9130 | 100 – 200 | 0.05 – 0.18 | 0.05 – 0.2 | 0.08 – 0.22 | 0.1 – 0.25 | ||

| Heat-resistant alloys Inconel 718, etc. |

Lower feed | NDL | AH725 | 20 – 50 | – | – | 0.03 – 0.06 | 0.03 – 0.08 | |

| First choice | NDJ | AH9130 | 20 – 50 | 0.04 – 0.06 | 0.04 – 0.08 | 0.04 – 0.08 | 0.04 – 0.1 | ||

| Titanium alloys Ti-6Al-4V, etc. |

Lower feed | NDL | AH725 | 30 – 60 | – | – | 0.03 – 0.1 | 0.03 – 0.12 | |

| First choice | NDJ | AH9130 | 30 – 60 | 0.04 – 0.1 | 0.05 – 0.13 | 0.05 – 0.13 | 0.05 – 0.15 | ||

| Hardened steel ≥ 40HRC |

Lower feed | NDL | AH725 | 40 – 100 | – | – | 0.03 – 0.08 | 0.03 – 0.08 | |

| First choice | NDJ | AH9130 | 50 – 100 | 0.04 – 0.06 | 0.04 – 0.08 | 0.04 – 0.08 | 0.04 – 0.1 | ||

The use of NDL chipbreakers is recommended for cross hole drilling with low feed conditions.

*Coolant recommendations for drilling stainless steel:

– Oil coolant is first priority

– Water soluble coolant requires at least 20% oil concentration

Drill diameter: DC = ø28.01 – ø40 mm

| ISO | Workpiece material | Priority | For central | For intermediate | For peripheral | Cutting speed Vc (m/min) |

Feedf (mm/rev) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Chip-breaker | Grade | Chip-breaker | Grade | Chip-breaker | Grade | ø28.01 – ø40 | ||||

| Low carbon steel (C < 0.3) SS400, SM490, S25C, etc. E275A, C25, etc. |

Lower feed | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.25 | ||

| Carbon steel (C > 0.3) S45C, S55C, etc. C45, C55, etc. |

Lower feed | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.12 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.3 | ||

| Low alloy steel (C < 0.3) SCM415, 18CrMo4, etc. |

Lower feed | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.25 | ||

| Alloy steel (C > 0.3) SCM440, SCr420, 42CrMo4, 20Cr4, etc. |

Lower feed | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.12 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 80 – 120 | 0.1 – 0.3 | ||

| Stainless steel (Austenitic) SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

Lower feed | G | AH8015 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| First choice | G | AH8015 | G | AH8015 | G | AH8015 | 60 – 100 | 0.1 – 0.15 | ||

| Stainless steel (Martensitic, Ferritic) SUS430, SUS416, etc. X6Cr17, X12CrS13, etc. |

Lower feed | G | AH8015 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| First choice | G | AH8015 | G | AH8015 | G | AH8015 | 60 – 100 | 0.1 – 0.15 | ||

| Stainless steel (Precipitation hardening) SUS630, X5CrNiCuNb16-4, etc. |

Lower feed | G | AH8015 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| First choice | G | AH8015 | G | AH8015 | G | AH8015 | 60 – 100 | 0.1 – 0.15 | ||

| Grey cast iron FC250, GG25, 250, etc. |

Lower feed | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.14 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.35 | ||

| Ductile cast iron FCD700, 700-2, etc. |

Lower feed | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.14 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.35 | ||

| Aluminium alloys | Lower feed | G | AH725 | DL | AH725 | G | AH725 | 80 – 160 | 0.03 – 0.2 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 100 – 200 | 0.1 – 0.3 | ||

| Heat-resistant alloys Inconel 718, etc. |

Lower feed | G | AH8015 | DL | AH725 | G | AH725 | 20 – 50 | 0.03 – 0.08 | |

| First choice | G | AH8015 | G | AH8015 | G | AH8015 | 20 – 50 | 0.06 – 0.13 | ||

| Titanium alloys Ti-6Al-4V, etc. |

Lower feed | G | AH725 | DL | AH725 | G | AH725 | 30 – 60 | 0.03 – 0.1 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 30 – 60 | 0.1 – 0.18 | ||

| Hardened steel ≥ 40HRC |

Lower feed | G | AH8015 | DL | AH725 | G | AH725 | 40 – 100 | 0.03 – 0.1 | |

| First choice | G | AH8015 | G | AH8015 | G | AH8015 | 50 – 100 | 0.06 – 0.13 | ||

The use of NDL chipbreakers is recommended for cross hole drilling with low feed conditions.

*Coolant recommendations for drilling stainless steel:

– Oil coolant is first priority

– Water soluble coolant requires at least 20% oil concentration

Para más información sobre este producto, visita nuestro catálogo online o descarga el catálogo de producto:

Métrico

Cuerpo de broca

Patín guia

Imperial

Cuerpo de broca

Cómo ajustar el diámetro de DeepTri-Drill con placas de ajuste

Ver vídeo