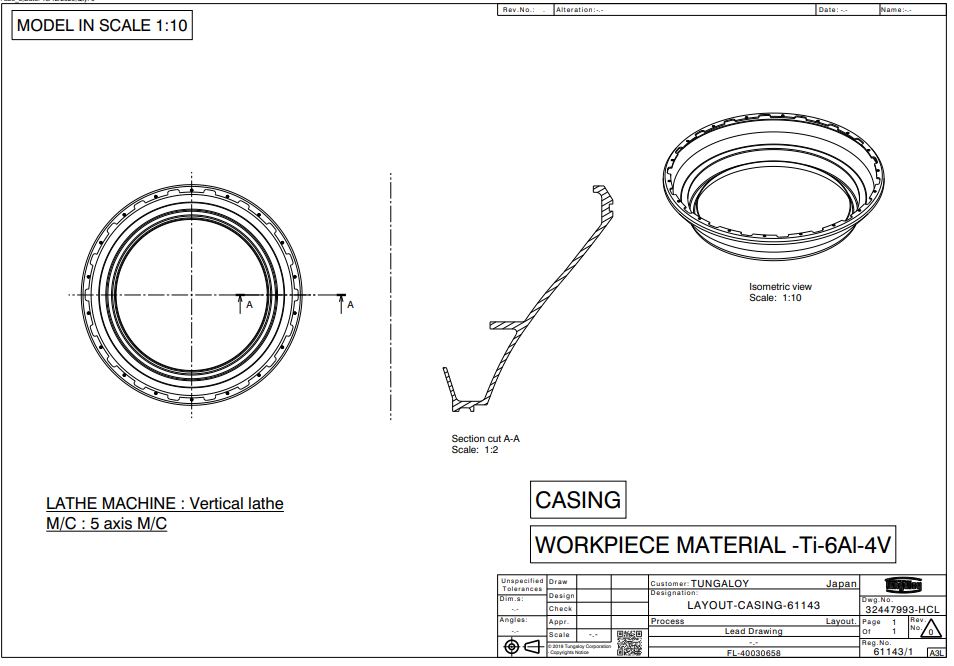

Aerospace – Casing

Aircraft engines commonly utilize a variety of titanium alloys for their notable strength and lightness. These engines often feature stationary parts with intricate shapes, typically made from cast materials. An aircraft engine works by injecting fuel into compressed air from turbines, facilitating continuous combustion to generate high-temperature gases. The engine casing, designed to draw in air, is characterized by its complex geometry. Selecting the right cutting tools, which are specifically tailored for the machining process and the part’s shape, becomes essential. Tungaloy leverages its unique technology and extensive expertise to provide optimal cutting tool designs and solutions, adept at machining parts with complex geometries made from materials that are typically difficult to cut and prone to rapid tool wear.

Tooling concepts

- Providing solutions for high-efficiency rough machining in titanium.

- Optimizing tool proposals for machining complex-shaped parts, including machining paths and special tool shapes.

- Ensuring stable accuracy by suppressing machining distortion through robust cutting edges and extending tool life, combined with reduced resistance.

Featured process

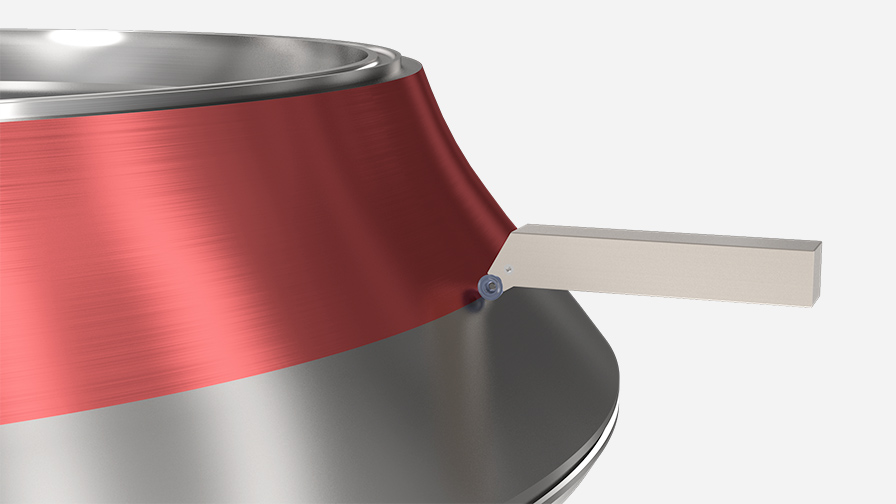

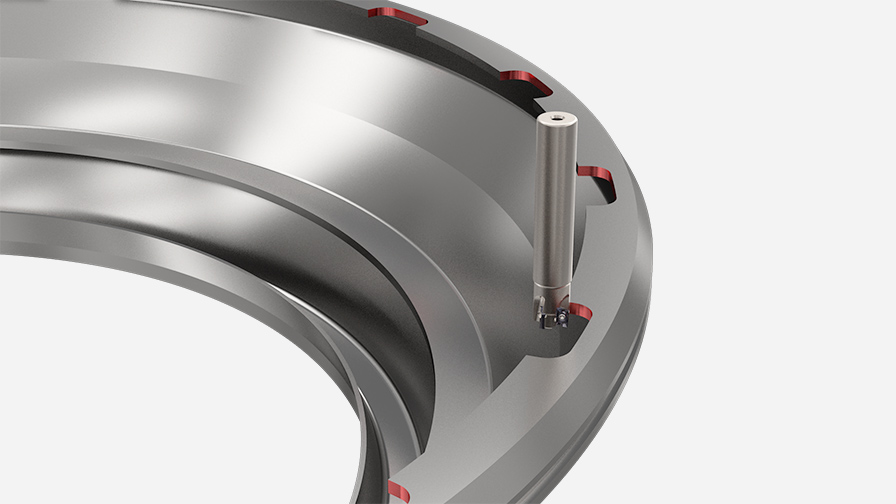

Process 1: OD Rough turning

Benefits

- For OD rough machining for the component, round inserts with high edge strength are the first choice.

- Round inserts are also suitable for profiling. By machining to a shape close to the final form during rough machining, the finishing margin is minimized.

- RS chip breaker, designed exclusively for round inserts, ensures stable chip control and extends tool life.

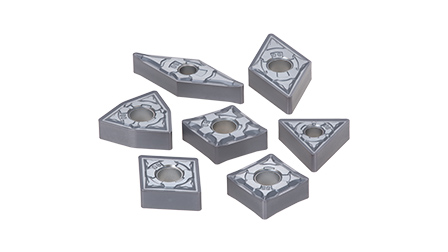

AH8005

- Prevents boundary wear which is a problem in titanium alloy turning

- High wear resistance due to high hardness coating film

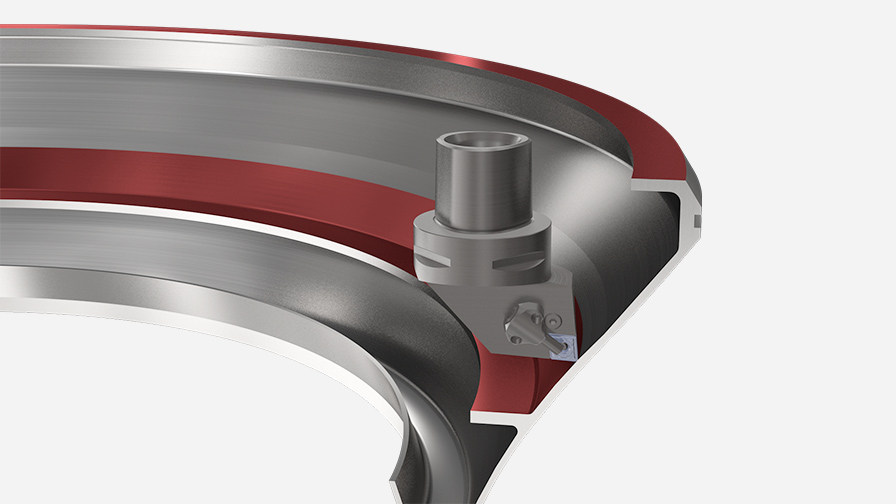

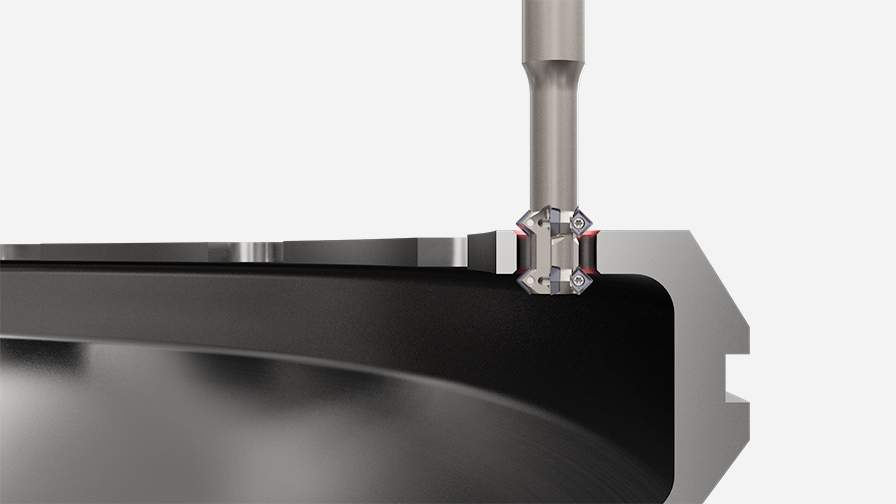

Process 2: End face Rough turning / ID Rough turning

Benefits

- HRM breaker is a breaker specialized for machining difficult-to-cut materials such as titanium alloys and heat-resistant alloys, achieving stable chip control and extended tool life.

- By using the TungTurn-Jet holder, coolant is supplied near the cutting edge, enhancing the cooling of the cutting edge. This is particularly effective in extending tool life for titanium alloys, which often experience higher cutting temperatures.

AH8015

- Prevents boundary wear which is a problem in heat-resistant alloy turning

- Excellent balance between wear resistance and fracture resistance

AH8005

- Prevents boundary wear which is a problem in titanium alloy turning

- High wear resistance due to high hardness coating film

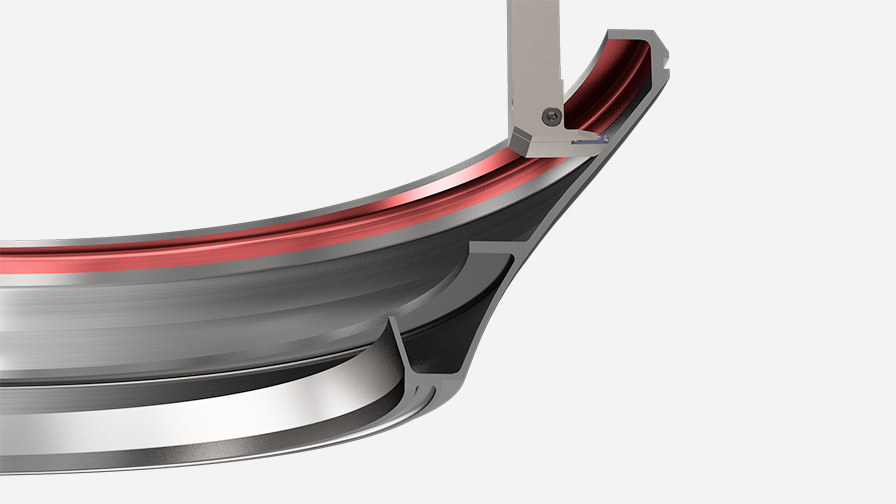

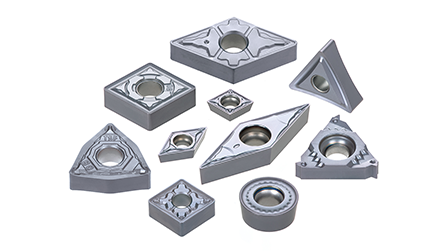

Process 4: Rough/Finish shoulder milling

Benefits

- TungForce-Rec’s unique V-shaped insert design provides a larger core thickness and superior body rigidity.

- The high rigidity of the body suppresses chatter, even in groove machining where it is prone to occur, ensuring stable machining.

- Due to its superior performance in maintaining wall accuracy, TungForce-Rec is also well-suited for finishing operations.

- Demonstrates high wear and chipping resistance in the machining of Titanium alloy or heat-resistant alloys

- Remarkable reliability in wet machining