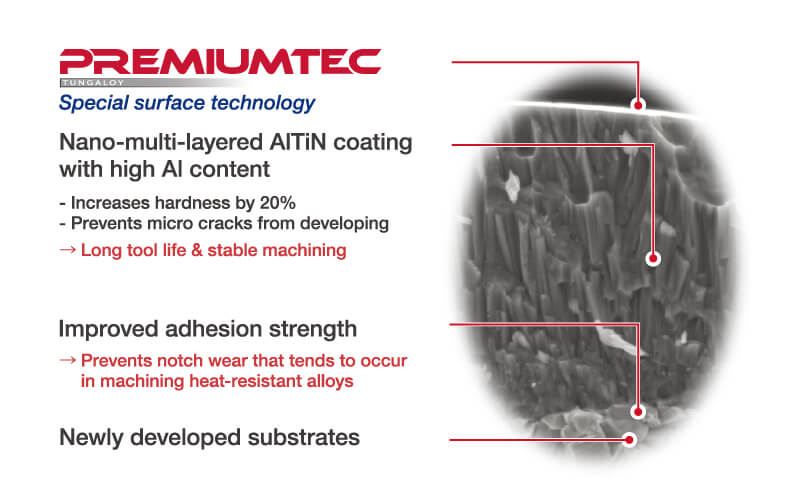

PVD grades for heat-resistant alloys

Incredible reliability in turning of heat-resistant alloy due to Nano-multi-layered AlTiN coating with high Al content

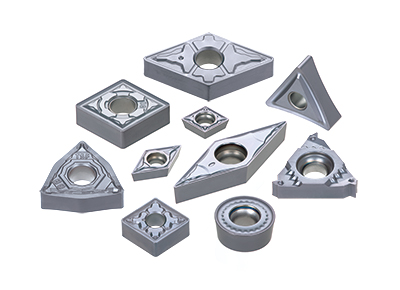

Applications & Features

Applications

Features

1. AH8000 series

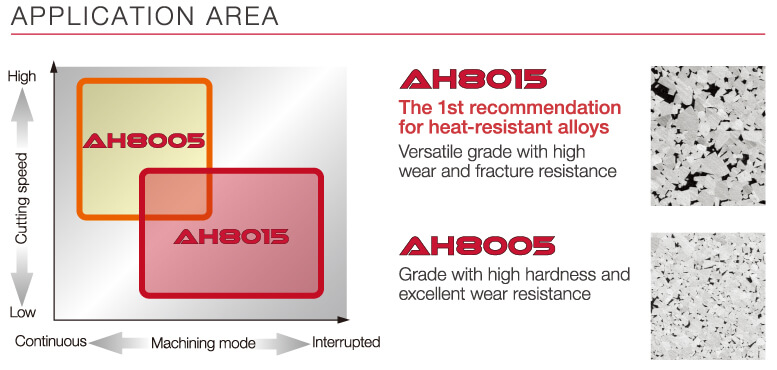

2. Application area

Main Grades

AH8005

- M01 – M10 / S01 – S10

- Good resistance to wear and adhesion

- Excellent performance in machining heat-resistant alloy at high speed

AH8015

![]()

![]()

![]()

![]()

![]()

- M01 – M20 / S10 – S20

- Good balance between wear and fracture resistance

- First choice for machining heat-resistant alloy under general cutting conditions

Practical examples

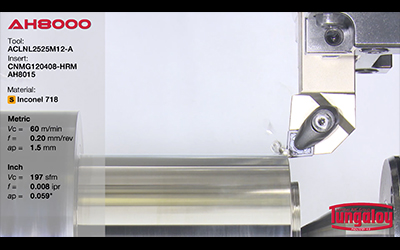

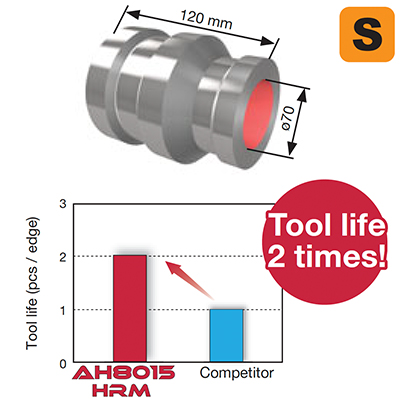

Example #1

Aerospace Industry

| Part: | Aircraft parts |

| Material: | Inconel 718 |

| Insert: | CNMG120408-HRM |

| Grade: | AH8015 |

| Cutting conditions: | Vc = 40 (m/min) f = 0.22 (mm/rev) ap = 2.0 (mm) Coolant: Wet |

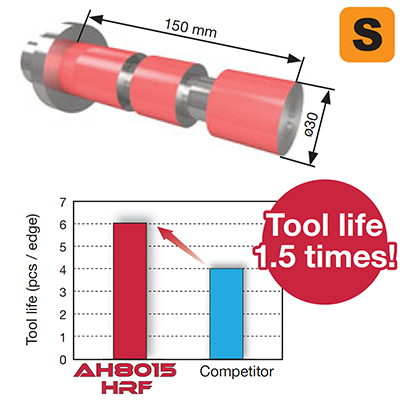

Example #2

Aerospace Industry

| Part: | Aircraft parts |

| Material: | Inconel 909 |

| Insert: | CNMG120412-HRF |

| Grade: | AH8015 |

| Cutting conditions: | Vc = 55 (m/min) f = 0.30 (mm/rev) ap = 0.5 (mm) Coolant: Wet |

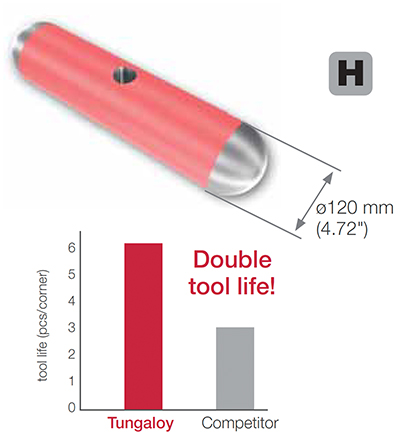

Example #3

General Engineering

| Part: | Toggle pin |

| Material: | Tool steel (49 HRC) |

| Insert: | CNMG190616-HRM |

| Grade: | AH8005 |

| Cutting conditions: | Vc = 66 (m/min) f = 0.6 (mm/rev) ap = 1.25 (mm) Application: External turning Coolant: Dry Machine: NC lathe |

Standard cutting conditions

Chipbreakers for negative inserts

| ISO | Chipbreaker | Corner radius RE |

Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | |

|---|---|---|---|---|---|---|

| AH8005 | AH8015 | |||||

|

HRF | 0.4 | 0.2 – 1.5 | 0.05 – 0.23 | 40 – 100 | 20 – 80 |

| 0.8 | 0.2 – 1.5 | 0.05 – 0.25 | 40 – 100 | 20 – 80 | ||

| 1.2 | 0.2 – 1.5 | 0.07 – 0.27 | 40 – 100 | 20 – 80 | ||

| HRM | 0.4 | 0.5 – 4.0 | 0.05 – 0.30 | 40 – 100 | 20 – 80 | |

| 0.8 | 0.5 – 4.0 | 0.07 – 0.33 | 40 – 100 | 20 – 80 | ||

| 1.2 | 0.5 – 4.0 | 0.10 – 0.35 | 40 – 100 | 20 – 80 | ||

| 1.6 | 0.5 – 4.0 | 0.15 – 0.40 | 40 – 100 | 20 – 80 | ||

| 28 | 0.4 | 0.5 – 3.0 | 0.08 – 0.20 | 40 – 100 | 20 – 80 | |

| 0.8 | 0.5 – 3.0 | 0.10 – 0.30 | 40 – 100 | 20 – 80 | ||

| 1.2 | 0.5 – 3.0 | 0.10 – 0.30 | 40 – 100 | 20 – 80 | ||

| SDM | 0.4 | 1 – 4 | 0.2 – 0.3 | 40 – 100 | 20 – 80 | |

| 0.8 | 1 – 4 | 0.2 – 0.5 | 40 – 100 | 20 – 80 | ||

| 1.2 | 1 – 4 | 0.2 – 0.5 | 40 – 100 | 20 – 80 | ||

Chipbreakers for positive inserts

| ISO | Chipbreaker | Corner radius RE |

Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | |

|---|---|---|---|---|---|---|

| AH8005 | AH8015 | |||||

|

PSF | 0.4 | 0.05 – 0.5 | 0.02 – 0.20 | 40 – 100 | 20 – 80 |

| 0.8 | 0.05 – 0.5 | 0.02 – 0.30 | 40 – 100 | 20 – 80 | ||

| PSS | 0.4 | 0.3 – 2.0 | 0.02 – 0.20 | 40 – 100 | 20 – 80 | |

| 0.8 | 0.3 – 2.0 | 0.03 – 0.30 | 40 – 100 | 20 – 80 | ||

| 1.2 | 0.3 – 2.0 | 0.05 – 0.30 | 40 – 100 | 20 – 80 | ||

| PS | 0.4 | 0.5 – 2.5 | 0.02 – 0.20 | 40 – 100 | 20 – 80 | |

| 0.8 | 0.5 – 2.5 | 0.03 – 0.30 | 40 – 100 | 20 – 80 | ||

| 1.2 | 0.5 – 2.5 | 0.05 – 0.30 | 40 – 100 | 20 – 80 | ||

| All-round | 0.4 | 0.5 – 3.0 | 0.08 – 0.20 | 40 – 100 | 20 – 80 | |

| 0.8 | 0.5 – 3.0 | 0.08 – 0.30 | 40 – 100 | 20 – 80 | ||

| 1.2 | 0.5 – 3.0 | 0.08 – 0.30 | 40 – 100 | 20 – 80 | ||

| RS | 0.5 – 1.5 | 0.03 – 0.30 | 40 – 100 | 20 – 80 | ||

| 61 | 0.5 – 2.0 | 0.20 – 0.60 | 40 – 100 | 20 – 80 | ||

RS chipbreaker with RCMT turning inserts size

| ISO | Workpiece material | Chipbreaker | Size | Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speedVc (m/min) | |

|---|---|---|---|---|---|---|---|

| AH8005 | AH8015 | ||||||

|

Stainless steel SUS303, SUS304, etc. X10CrNiS18-9, X5CrNi18-9, etc. |

RS | RCMT06… | 0.5 – 2 | 0.2 – 0.6 | 100 – 220 | 90 – 200 |

| RCMT08… | 0.5 – 2 | 0.2 – 0.6 | |||||

| RCMT10… | 1 – 2.5 | 0.2 – 0.6 | |||||

| RCMT12… | 1 – 2.5 | 0.2 – 0.6 | |||||

| RCMT16… | 1.5 – 3 | 0.5 – 1 | |||||

| RCMT20… | 1.5 – 3 | 0.5 – 1 | |||||

| RCMT25… | 1.5 – 5 | 0.5 – 1 | |||||

|

Superalloys Inconel718, etc. |

RS | RCMT06… | 0.5 – 2 | 0.2 – 0.6 | 40 – 100 | 20 – 80 |

| RCMT08… | 0.5 – 2 | 0.2 – 0.6 | |||||

| RCMT10… | 1 – 2.5 | 0.2 – 0.6 | |||||

| RCMT12… | 1 – 2.5 | 0.2 – 0.6 | |||||

| RCMT16… | 1.5 – 3 | 0.5 – 1 | |||||

| RCMT20… | 1.5 – 3 | 0.5 – 1 | |||||

| RCMT25… | 1.5 – 5 | 0.5 – 1 | |||||

JS chipbreaker

| ISO | Workpiece materials | Chipbreaker | Grade | Cutting speed Vc (m/min) |

Depth of cut ap (mm) |

Feedf (mm/rev) | |||

|---|---|---|---|---|---|---|---|---|---|

| RE < 0.05 | RE < 0.1 | RE < 0.2 | RE < 0.4 | ||||||

|

Superalloys Inconel718, etc. |

JS | AH8015 | 20 – 80 | 0.5 – 3 | 0.02 – 0.03 | 0.02 – 0.05 | 0.02 – 0.1 | 0.05 – 0.2 |

For more information about this product, visit our online e-catalog or download the product report: