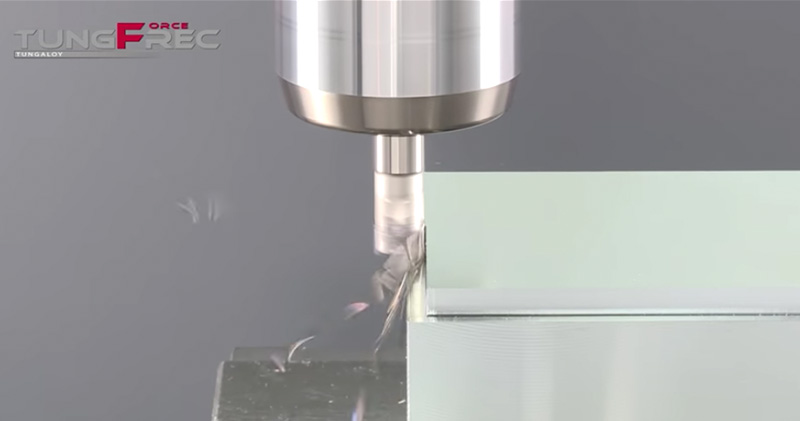

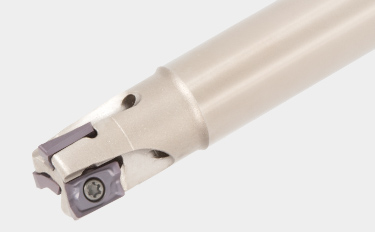

Versatile shoulder milling cutter with unique V-shaped insert bottom for maximum productivity

TungForce-Rec, a new miniature shoulder milling series, features a unique clamping system offering exceptional stability in machining small pockets and slots

Applications & Features

Applications

Features

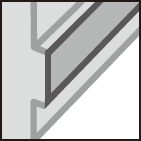

1. Strong cutter body design

• V shape insert design enables the cutter to have a thick core and insert backing.

• Ensures high productivity and stability.

2. Extremely secure insert clamping

• V shape design prevents insert movement during machining.

• Eliminates premature insert failure, while providing machining stability.

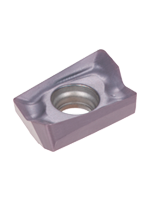

2. Sharp and strong cutting edge for increased productivity

• High productivity and stability are achieved with the unique cutting edge design.

Large rake angle and obtuse fl ank surface provide low cutting force and anti-chipping performance.

Large rake angle off ers low cutting force but small cross section area leads to chipping on the edge.

Inserts & Grades

Inserts

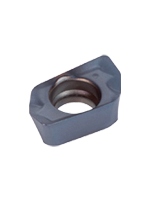

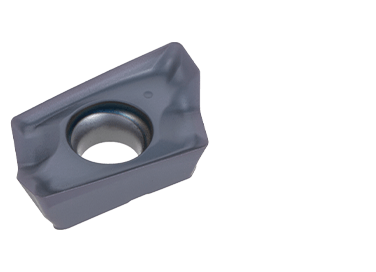

AV*T04

- Maximum depth of cut: 4 mm

- Unique V-shape insert for high precision shoulder milling

AV*T06

- Maximum depth of cut: 6 mm

- Unique V-shape insert for high precision shoulder milling

AV*T12

- Maximum depth of cut: 11.5 mm

- Unique V-shape insert for high precision shoulder milling

AVGW12

- Maximum depth of cut: 4.5 mm

AV*T18

- Maximum depth of cut: 16.5 mm

- Unique V-shape insert for high precision shoulder milling

Main Grades

AH120

![]()

![]()

![]()

![]()

- Good balance between wear and fracture resistance

- Suitable for machining steel, stainless steel, and cast iron under general cutting conditions

AH3135

![]()

![]()

- High fracture resistance

- Suitable for machining steel and stainless steel under general cutting conditions

AH3225

![]()

![]()

- Good balance between wear and fracture resistance

- Suitable for steel and stainless steel

Cutter bodies

Practical examples

Example #1

| Part: | Machine parts |

| Material: | SUS304 / X5CrNiMo18-9 |

| Cutter: | EPAV04M008C08.0R02 (ø8 mm, z=2) |

| Insert: | AVMT040204PPER-MM |

| Grade: | AH3225 |

| Cutting conditions: | Vc = 150 (m/min) fz = 0.08 (mm/t) Vf = 895 (mm/min) ap = 1.429 (mm) ae = 8 (mm) Application: Slotting Coolant: Air blast Machine: Vertical M/C, BT50 |

Example #2

| Part: | Machine parts |

| Material: | SS400 / E275A |

| Cutter: | EPAV06M014C12.0R03 (ø14 mm, z=3) |

| Insert: | AVGT060302PBER-MJ |

| Grade: | AH3225 |

| Cutting conditions: | Vc = 264 (m/min) fz = 0.125 (mm/t) Vf = 1,500 (mm/min) ap = 6 (mm) ae = 3 (mm) Application: Shoulder milling Coolant: Wet (External) Machine: Vertical M/C, BT40 |

Example #3

| Part: | Machine parts |

| Material: | Cast aluminum |

| Cutter: | TPAV12M050B22.0R12 (ø50 mm, z = 12) |

| Insert: | AVGT120408PDFR-AM |

| Grade: | KS05F |

| Cutting conditions: | Vc = 950 (m/min) fz = 0.15 (mm/t) Vf = 11,000 (mm/min) ap = 6(mm) ae = 35 (mm) Application: Face milling Coolant: Wet (External) Machine: Vertical M/C, BT50 |

Standard cutting conditions

TungForce-Fec 04

| ISO | Workpiece materials | Hardness | Priority | Grades | Cutting speed Vc (m/min) | Feed per tooth fz (mm/t) | |

|---|---|---|---|---|---|---|---|

|

Low carbon steel S15C, SS400, etc. C15E, C15E4, E275A, etc. |

– 200 HB | First choice | AH3225 | 100 – 300 | 0.05 – 0.12 | |

| Carbon steel and alloy steel S55C, SCM440, etc. C55, 42CrMo4, etc. |

– 300 HB | First choice | AH3225 | 100 – 250 | 0.05 – 0.12 | ||

| Prehardened steel NAK80, PX5, etc. |

30 – 40 HRC | First choice | AH3225 | 100 – 200 | 0.05 – 0.1 | ||

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

– | First choice | AH3225 | 80 – 180 | 0.05 – 0.1 | |

|

Grey cast iron FC250, FC300, etc. GG25, GG30, etc. 250, 300, etc. |

150 – 250 HB | First choice | AH120 | 100 – 300 | 0.05 – 0.12 | |

| Ductile cast iron FCD400, FCD600, etc. GGG60, 600-3, etc. |

150 – 250 HB | First choice | AH120 | 100 – 250 | 0.05 – 0.12 | ||

|

Titanium alloys Ti-6AI-4V, etc. |

– | First choice | AH3225 | 20 – 60 | 0.04 – 0.07 | |

| Superalloys Inconel 718, etc. |

– | First choice | AH120 | 20 – 40 | 0.04 – 0.07 | ||

|

Hardened steel | SKD61, X40CrMoV5-1, etc. |

40 – 50 HRC | First choice | AH120 | 50 – 150 | 0.04 – 0.07 |

| SKD11, X153CrMoV12, etc. |

50 – 60 HRC | First choice | AH120 | 40 – 70 | 0.04 – 0.07 | ||

TungForce-Fec 06

| ISO | Workpiece materials | Hardness | Priority | Grades | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|

|---|---|---|---|---|---|---|---|

|

Low carbon steel (S15C / C15E / C15E4, SS400 / E275A, etc.) |

– 200 HB | First choice | AH3225 | 100 – 430 | 0.04 – 0.12 | |

| Carbon steel and alloy steel (S55C / C55, SCM440 / 42CrMo4, etc.) |

– 300 HB | First choice | AH3225 | 100 – 350 | 0.04 – 0.12 | ||

| Prehardend steel (NAK80, PX5, etc.) |

30 – 40 HRC | First choice | AH3225 | 100 – 230 | 0.04 – 0.12 | ||

|

Stainless steel (SUS304 / X5CrNi18-9, SUS316 / X5CrNiMo17-12-3, etc.) |

– | First choice | AH3135 | 80 – 220 | 0.04 – 0.1 | |

|

Grey cast iron (FC250 / GG25 / 250, FC300 / GG30 / 300, etc.) |

150 – 250 HB | First choice | AH120 | 100 – 330 | 0.04 – 0.12 | |

| Ductile cast iron (FCD400, FCD600 / GGG60 / 600-3, etc.) |

150 – 250 HB | First choice | AH120 | 100 – 240 | 0.04 – 0.12 | ||

|

Aluminium alloys (Si < 13%) | – | First choice | DS2005, KS05F | 300 – 1000 | 0.04 – 0.12 | |

| Aluminium alloys (Si ≥ 13%) | – | First choice | DS2005, KS05F | 100 – 230 | 0.04 – 0.12 | ||

|

Titanium alloys (Ti-6AI-4V, etc.) | – | First choice | AH130 | 20 – 90 | 0.04 – 0.1 | |

| Superalloys (Inconel718, etc.) | – | First choice | AH130 | 20 – 65 | 0.04 – 0.09 | ||

|

Hardened steel | (SKD61 / X40CrMoV5-1, etc.) |

40 – 50 HRC | First choice | AH120 | 50 – 70 | 0.04 – 0.08 |

| (SKD11 / X153CrMoV12, etc.) |

50 – 60 HRC | First choice | AH120 | 40 – 65 | 0.04 – 0.06 | ||

TungForce-Fec 12

| ISO | Workpiece materials | Hardness | Priority | Grades | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|

|---|---|---|---|---|---|---|---|

|

Low carbon steel S15C, SS400, etc. C15E, C15E4, E275A, etc. |

– 200 HB | First choice | AH3225 | 100 – 300 | 0.06 – 0.22 | |

| – 200 HB | Wear resistance | T3225 | 200 – 400 | 0.06 – 0.18 | |||

| Carbon steel and alloy steel S55C, SCM440, etc. C55, 42CrMo4, etc. |

– 300 HB | First choice | AH3225 | 100 – 250 | 0.06 – 0.22 | ||

| – 300 HB | Wear resistance | T3225 | 200 – 400 | 0.06 – 0.18 | |||

| Prehardened steel NAK80, PX5, etc. |

30 – 40 HRC | First choice | AH3225 | 100 – 200 | 0.06 – 0.22 | ||

| 30 – 40 HRC | Wear resistance | T3225 | 200 – 400 | 0.06 – 0.15 | |||

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

– | First choice | AH3225 | 80 – 180 | 0.07 – 0.2 | |

|

Grey cast iron FC250, FC300, etc. GG25, GG30, etc. 250, 300, etc. |

150 – 250 HB | First choice | AH120, AH8015 | 100 – 300 | 0.05 – 0.18 | |

| 150 – 250 HB | Wear resistance | T1215 | 200 – 400 | 0.05 – 0.12 | |||

| Ductile cast iron FCD400, FCD600, etc. GGG60, 600-3, etc. |

150 – 250 HB | First choice | AH120, AH8015 | 100 – 250 | 0.05 – 0.18 | ||

| 150 – 250 HB | Wear resistance | T1215 | 150 – 300 | 0.05 – 0.12 | |||

|

Aluminium alloys (Si < 13%) | – | First choice | DS2005, KS05F | 300 – 1,500 | 0.05 – 0.32 | |

| – | Wear resistance | DX160 | 500 – 2,000 | 0.05 – 0.2 | |||

| Aluminium alloys (Si ≥ 13%) | – | First choice | DS2005, KS05F | 100 – 200 | 0.05 – 0.32 | ||

| – | Wear resistance | DX160 | 200 – 800 | 0.05 – 0.2 | |||

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | First choice | AH3225, AH8015 | 20 – 60 | 0.04 – 0.15 | |

| Superalloys Inconel 718, etc. |

– 40 HRC | First choice | AH120, AH8015 | 20 – 40 | 0.04 – 0.15 | ||

|

Hardened steel | SKD61, X40CrMoV5-1, etc. |

40 – 50 HRC | First choice | AH120, AH8015 | 50 – 150 | 0.04 – 0.07 |

| SKD11, X153CrMoV12, etc. |

50 – 60 HRC | First choice | AH120, AH8015 | 40 – 70 | 0.04 – 0.07 | ||

TungForce-Rec 18

| ISO | Workpiece materials | Hardness | Priority | Grades | Cutting speed Vc (m/min) |

Feed per tooth: fz (mm/t) | |||

|---|---|---|---|---|---|---|---|---|---|

| MM | MT | AM | |||||||

|

Low carbon steel S15C, SS400, etc. C15E, C15E4, E275A, etc. |

– 200 HB | First choice | AH3225 | 100 – 300 | 0.06 – 0.22 | 0.07 – 0.28 | – | |

| Carbon steel and alloy steel S55C, SCM440, etc. C55, 42CrMo4, etc. |

– 300 HB | First choice | AH3225 | 100 – 250 | 0.06 – 0.22 | 0.07 – 0.28 | – | ||

| Prehardened steel NAK80, PX5, etc. |

30 – 40 HRC | First choice | AH3225 | 100 – 200 | 0.06 – 0.22 | 0.07 – 0.28 | – | ||

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

– | First choice | AH3225 | 80 – 180 | 0.07 – 0.2 | 0.07 – 0.25 | – | |

|

Grey cast iron FC250, FC300, etc. GG25, GG30, etc. 250, 300, etc. |

150 – 250 HB | First choice | AH8015 | 100 – 300 | 0.05 – 0.22 | 0.06 – 0.28 | – | |

| 150 – 250 HB | Wear resistance | T1215 | 200 – 400 | 0.05 – 0.18 | – | – | |||

| Ductile cast iron FCD400, FCD600, etc. GGG60, 600-3, etc. |

150 – 250 HB | First choice | AH8015 | 100 – 250 | 0.05 – 0.22 | 0.06 – 0.28 | – | ||

| 150 – 250 HB | Wear resistance | T1215 | 150 – 300 | 0.05 – 0.18 | – | – | |||

|

Aluminium alloys Si < 13% |

– | First choice | DS2005 KS05F |

300 – 1500 | – | – | 0.05 – 0.32 | |

| Aluminium alloys Si ≥ 13% |

– | First choice | DS2005 KS05F |

100 – 200 | – | – | 0.05 – 0.32 | ||

|

Titanium alloys Ti-6Al-4V, etc. |

– | First choice | AH8015 | 20 – 60 | 0.04 – 0.15 | – | – | |

| Superalloys Inconel 718, etc. |

– | First choice | AH8015 | 20 – 40 | 0.04 – 0.15 | 0.05 – 0.18 | – | ||

|

Hardened steel | SKD61, X40CrMoV5-1, etc. |

40 – 50 HRC | First choice | AH8015 | 50 – 150 | 0.04 – 0.07 | 0.05 – 0.1 | – |

| SKD11, X153CrMoV12, etc. |

50 – 60 HRC | First choice | AH8015 | 40 – 70 | 0.04 – 0.07 | 0.05 – 0.1 | – | ||

For more information about this product, visit our online e-catalog or download the product report: