Medical – Artificial Hip Joint and Bone Screw

Artificial hip joints generally consist of four independent parts: stem, ball, socket (or cup), and ultra-high-molecular-weight polyethylene liner that fits into the socket. As a joint prosthesis, the materials must have high strength, reliable chemical stability and safety, low friction but high wear resistance, and outstanding biocompatibility; therefore, difficult materials such as medical grade and surgical stainless steel, titanium, or cobalt-chrome are widely used.

Tungaloy presents a broad range of unique tooling and optimal technical solutions for CNC machining centers and Swiss-type machines to effectively and competitively machine difficult materials used in the medical industry.

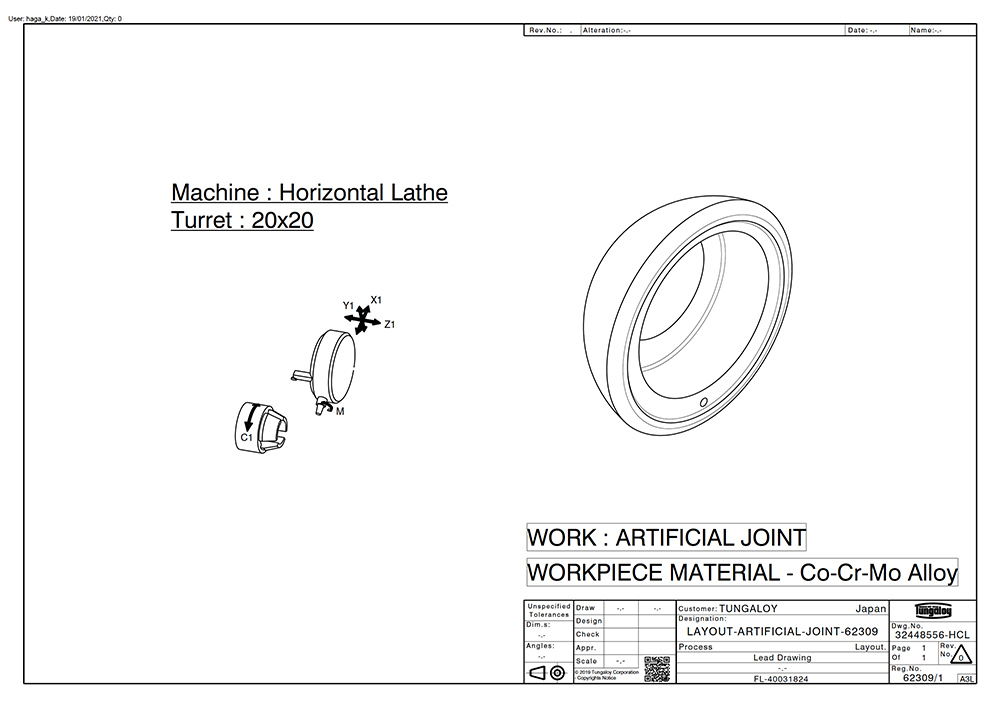

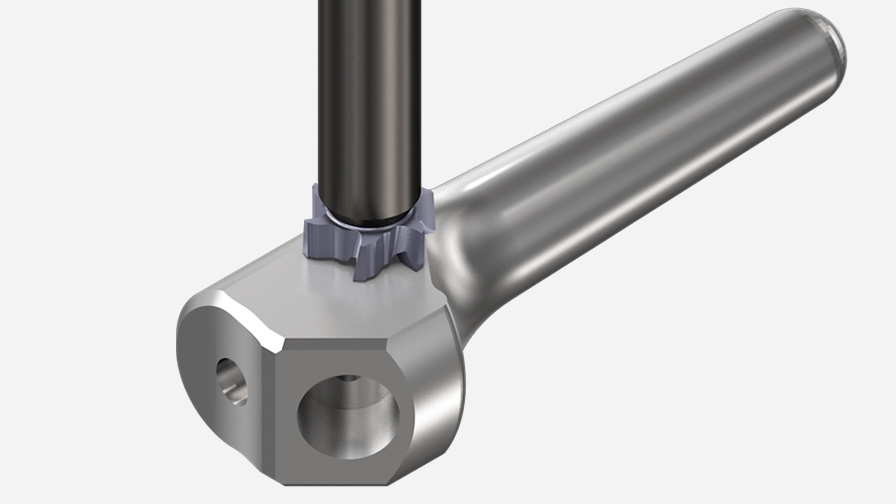

The Socket

General Challenges

- To increase machining efficiency

- To secure process based on increase tool life and wear predictability

- To minimize vibration using long overhang and challenging part fixturing for a high grade of surface finish

Key Points

1.Process security based on better wear predictability and tool life

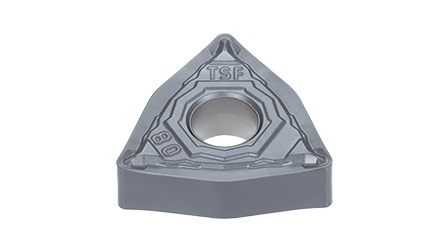

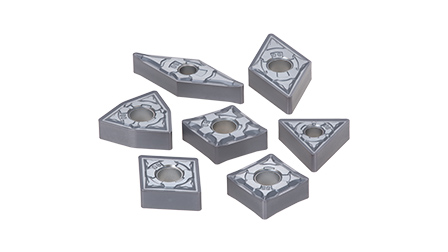

AH8000 grade series is PVD-coated carbide grades featuring AlTiN nano-multilayer coating with high aluminum content developed specifically for machining exotic parts.

- AH8015 is the first-choice grade that provides a good combination of wear resistance and fracture toughness

- AH8005 boasts superior wear resistance during machining of exotic materials at elevated cutting speeds with an excellent resistance to built-up edge

Using these grade inserts in combination with proper through-coolant delivery system such as TungTurn-Jet or StreamJet-Bar can heighten process security through increased tool life and better wear prediction.

2.Increased tool reliability, surface finish quality, and cost efficiency

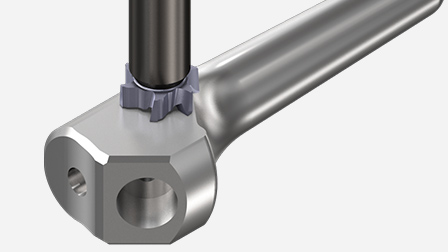

MiniForce-Turn features cost-efficient double-sided positive insert with unique dovetail profile that securely interlocks with the matching profile of the insert seat for maximum insert reliability and process security.

Designed to maintain sharp cutting edge over an extended period of time, MiniForce-Turn insert generates low cutting force and excellent surface quality, while the double-sided feature offers increased number of usable cutting edges per insert for improved insert economy.

Machining Solutions

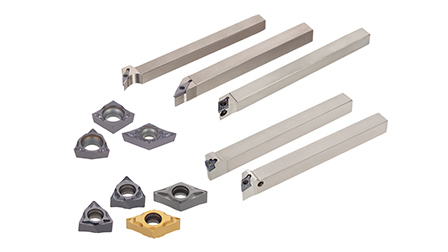

Turning

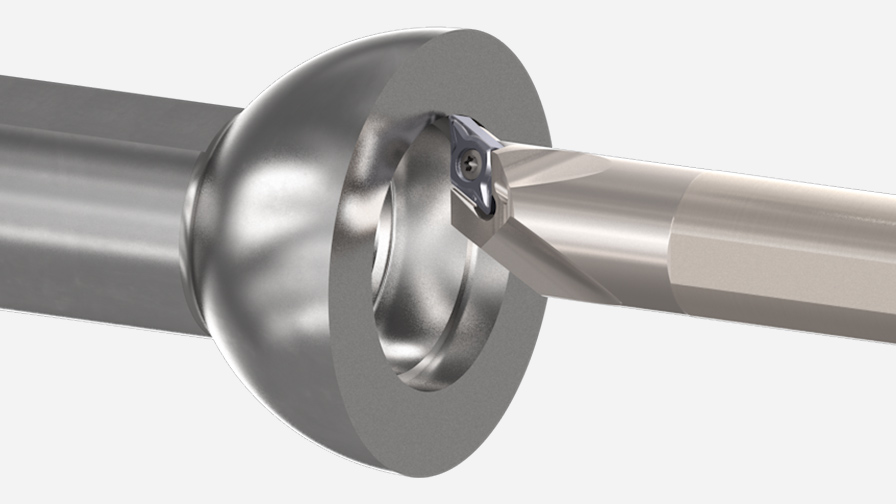

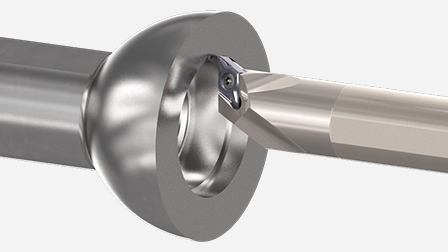

TungTurn-Jet system

- Through-coolant toolholder series with precision coolant delivery system

- Delivers two streams of coolant jets through the holder precisely to the optimal positions – close to the cutting point

- Improved chip control by lifting the chip away from the rake face and reducing the heat load. Longer tool life and drastically increased cutting parameters to be applied

- Improved insert performance and part quality, as well as prevention of built-up edge formation typical in exotic part machining, for extended tool life and better wear prediction

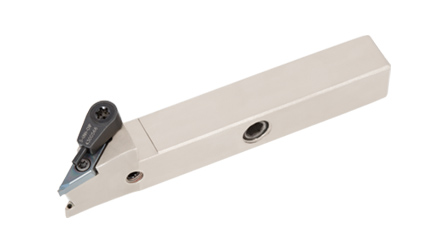

MiniForce-Turn

- Economical double-sided positive insert

- Highly rigid insert clamping enabled by unique dovetail interlocking design provides process security for machining small parts

- Light cutting geometry for low cutting force and high quality surface finish

StreamJet-Bar

- ID turning holders with minimum tool deflection

- Through-coolant and optimal chip pocket design for effective chip evacuation

- For small bores as small as ø4.5 mm (ø.177″)

- Inserts with 00 and 01 nose radii are also available

Hole making

GigaMiniDrill

- Extra small diameter solid carbide drill line in a diameter range from 0.1 to 3.0 mm (.004″ to .118″)

- Available in 0.01 mm increments

Grooving / Parting

TungCut

- Highly rigid insert clamping design for extra stability and accuracy

- High-pressure through-coolant system for effective chip control and process security

- Inserts are available in a variety of geometries and grades for high efficiency machining

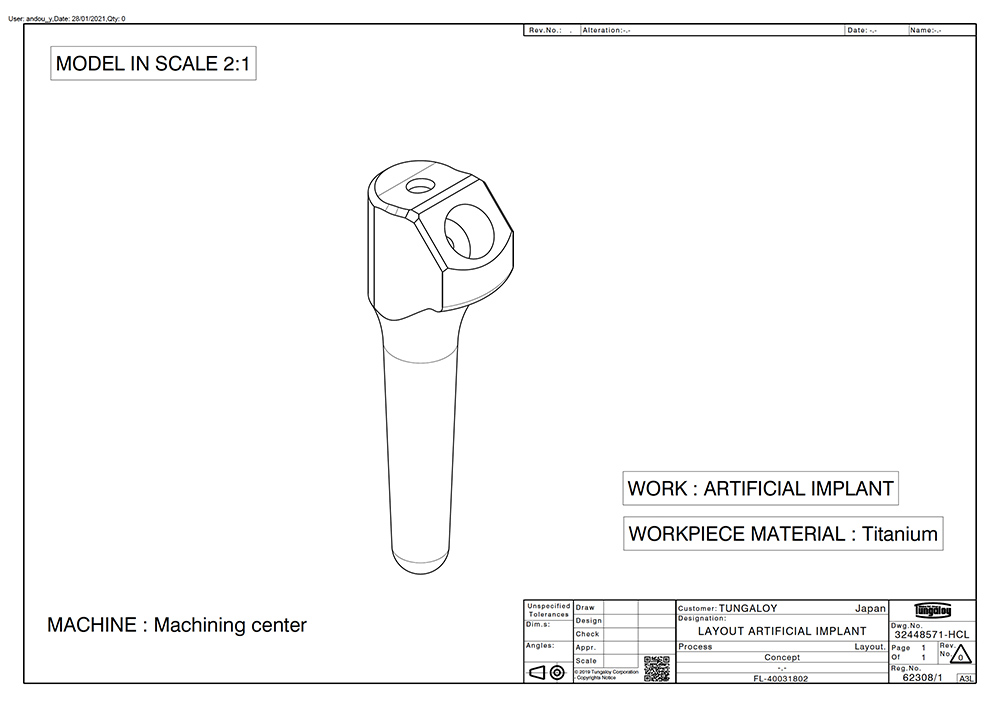

The Stem

General Challenges

- To increase machining efficiency

- To secure process based on increase tool life and wear predictability

- To improve surface finish quality

- To minimize cutting forces for reduced vibration due to challenging workpiece shape and workpiece fixture

- To maintain close tolerances of holes and part sizes

Key Points

-

Improved surface quality

TungMeister exchangeable-head end mill system offers more than 13,000 possible head-shank combinations, enabling quick, easy, and accurate tool changes between various applications.

- VFM style milling head is developed for efficient face milling of small parts, featuring six cutting edges with built-in wiper that provides excellent surface finish at elevated feeds. When combined with highly rigid VSSD toolholder, VFM minimizes vibration for excellent surface finish and process security.

SolidMeister solid carbide end mill series offers a wide variety of sizes and geometries with sophisticated features.

- FeedMeister has a large radius cutting edge configuration that enables highly stable milling at greatly increased feed rates – even with long overhang. This 4 flute tool design exhibits excellent performance on stainless steel, titanium and nickel based alloys.

- VariableMeister consists of variable-pitch, variable-helix design. Reduced vibrations for high quality surface finish and process security.

- FinishMeister boasts a sophisticated configuration that allows roughing and finishing operations at the same time, allowing the ability to apply roughing machining conditions, while providing excellent surface finish.

- FinishMeister VARIABLE PITCH, a new generation of solid carbide end mill, integrates the remarkable advantage of FinishMeister with a variable pitch design — a “2-in-1” version of FinishMeister. The tool dramatically increases productivity, while reducing production cost and inventory.

Machining Solutions

Milling

TungForce-Feed

- Small-diameter indexable end mill for high feed milling application

- Two types of inserts are interchangeable: radius or high feed

TungForce-Rec

- Strong inserts and high density cutter body design provide process security

- High precision inserts and their sophisticated orientations provide high wall accuracy equal to solid endmills

Hole Making and Threading

DrillMeister

- Exchangeable-tip drill tool series that offers variable drill tip shapes, geometries, and sizes in grades that works in all material groups including difficult materials

- DMF-style flat-edge drill tip streamlines counterboring process with a flat hole bottom

- No setup time

- Reduced inventory and production cost

GigaJet-Drill (standard/special solid drills)

- Fine tuning of drill tip profiles is possible for high precision hole making

SolidThread – ThreadMilling tool series

- Thread milling tool series is available in solid, exchangeable head, and indexable insert styles

- Allows full threads close to the bottom of the hole

- Generates very small, manageable chips

- Adjustments for tolerance and wear can be done easily

- Broken tool can easily be changed

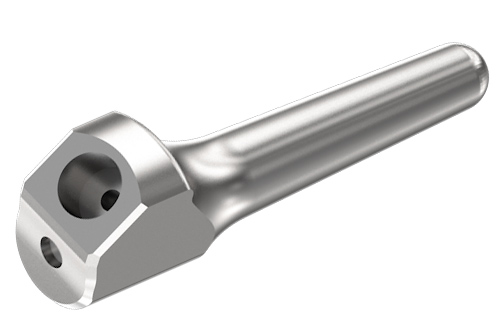

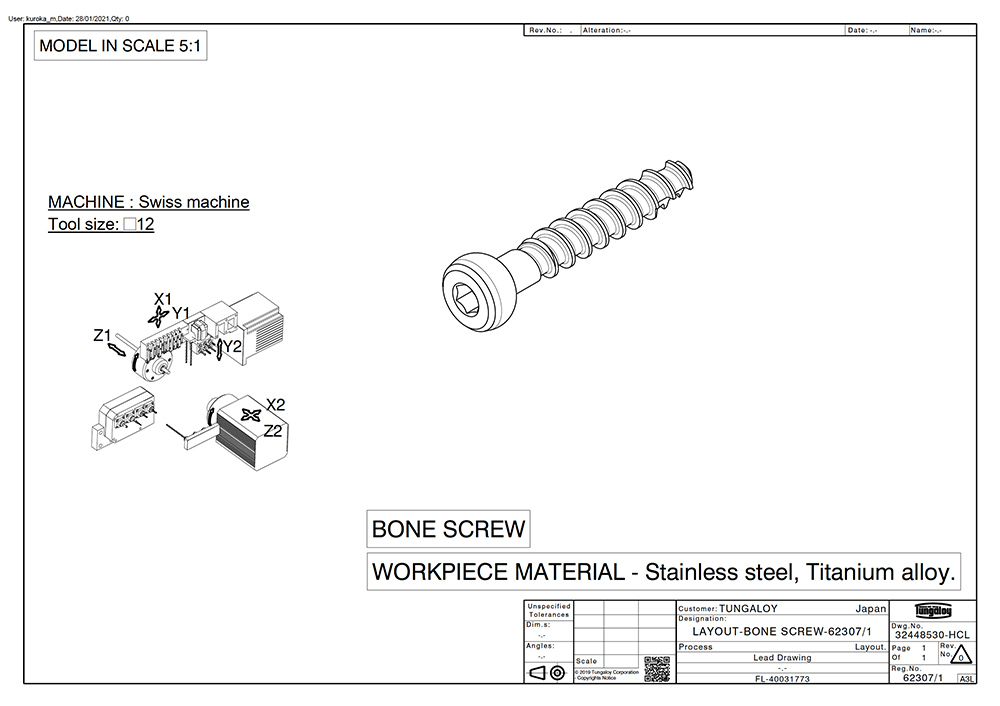

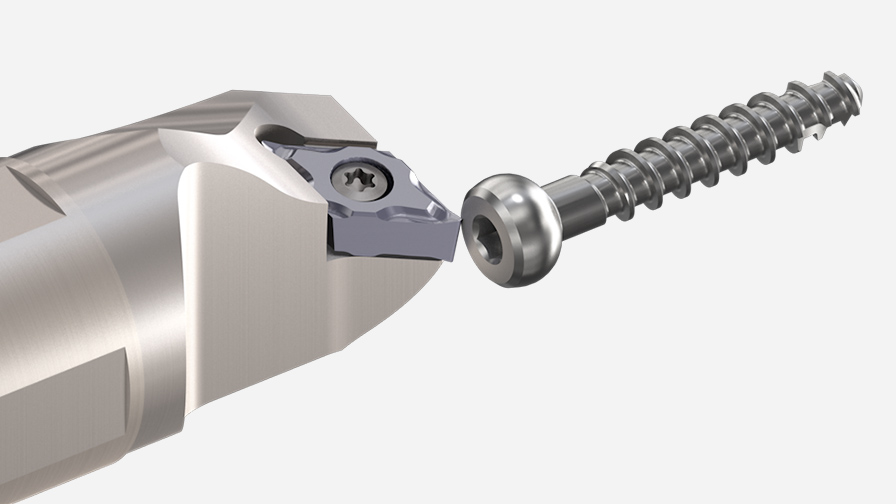

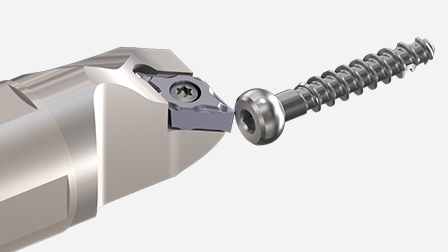

The Bone Screw

Bone screws are one of the most ubiquitous orthopedic implants. Most bone screws are made of stainless steel or titanium alloys due to stringent requirements for good mechanical strength and biocompatibility and come in various sizes with different thread designs, thread pitches, and thread lengths.

Despite its seemingly simple structure, bone screws have a surprising amount of complexity in its design. To meet this challenge, precision CNC Swiss-style machining is the method often used to accomplish the designs that give bone screws the proper features and functionality for their end uses.

General Challenges

- To increase process security

- To increase tool life in difficult materials

- To achieve high part tolerances and precisions

- To provide full line tool solution to Swiss machine applications

- To maximize machine uptime

Key Points

-

Process security through insert reliability and machining stability

SH725, a PVD-coated carbide grade, is developed specifically for Swiss-type machining methods. Improved coating-substrate adhesion and hard coating layer provide the insert with excellent wear resistance and edge line security.

TungTurn-Jet toolholder system with precision through-coolant delivery capability enables coolant supply close to the cutting point, providing better chip control and longer tool life during the machining of difficult materials, while also allowing the application of significantly increased cutting parameters.

MiniForce-Turn features double-sided positive insert with sharp cutting edges. AH725 grade enhances the insert’s edge-line security and wear resistance, generating light cutting with long tool life. Tool stability ensured by innovative dovetail interlocking provides this challenging machining with process security, as well as cost efficiency.

Machining Solutions

OD Turning

J-Series

- Extensive turning tool series for Swiss machines

- Allows flexible tooling to address various profile turning needs

AH8000 series

- PVD-coated carbide grade series featuring AlTiN nano-multilayer coating with high aluminum content developed specifically for machining difficult parts:

- AH8015 is the first-choice grade that provides a good combination of wear resistance and fracture toughness

- AH8005 boasts superior wear resistance during machining of exotic materials at elevated cutting speeds, while also providing an excellent resistance to built-up edge

Thread Turning

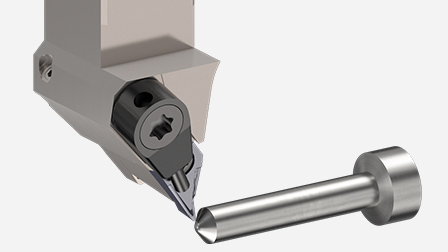

TetraForce-Cut (with special insert)

- Rigid and secure insert holding provides tool reliability

- Cost efficient four-edged insert for grooving, parting, or threading works

- Unused cutting edges are protected during machining, assuring all four edges to be used to their full capacities

- Customized inserts tailored for various groove/thread profile needs are also available

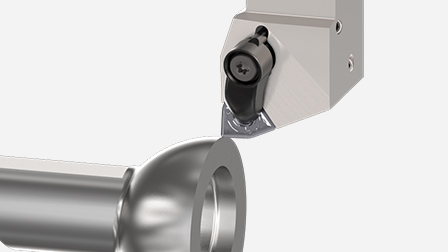

Parting

DuoJust-Cut

- Rigid insert clamping for increased tool reliability

- Dual-rake insert enables effective chip control and evacuation

- Available with a variety of cutting edge geometries

Pocket Milling (for Self-Tapping Flutes)

TungForce-Rec

- Strong inserts and high density cutter body design provide process security

- High precision inserts and their innovative orientations provide high wall accuracy equal to solid endmills

- The insert has sharp cutting corners for precision

GigaMini-Drill (standard/special solid drills)

- Fine tuning of drill tip profiles is possible for high precision hole making

Solid Broaching Tool (special)

- Special customized tools tailored for your specific needs