CBN insert with new brazing technology for high efficiency hardened steel machining

Robust as ever! For outstanding performance in hard turning applications.

Applications & Features

Applications

Features

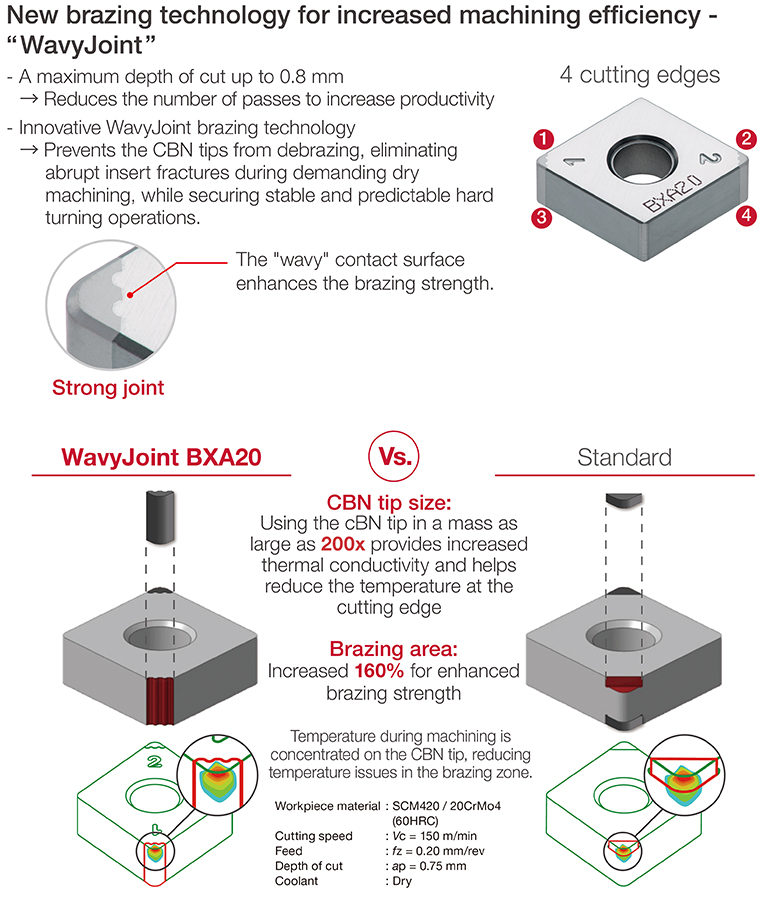

1. New brazing technology for increased machining efficiency “Wavy Joint”

• A maximum depth of cut up to 0.8 mm

– Reduces the number of passes to increase productivity

• Innovative WavyJoint brazing technology

– Prevents the CBN tips from debrazing, eliminating abrupt insert fractures during demanding dry machining, while securing stable and predictable hard turning operations.

Inserts & Grades

Inserts

Main Grades

BXA20

![]()

- First choice for light to heavy interrupted cuts

- For Vc = 180 m/min or less

BXA10

![]()

- First choice for continuous to light interrupted cuts of hardened steel turning

- For cutting speed = 230 m/min or less

Practical examples

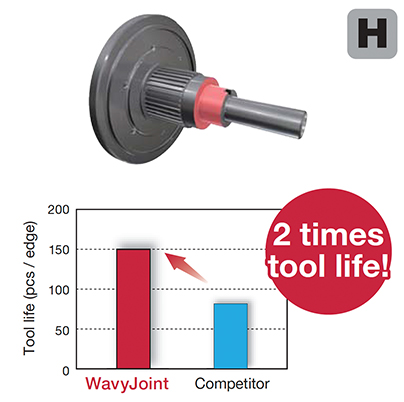

Example #1

Automotive Industry

| Part: | Automotive part |

| Material: | SCM420 / 20CrMo4 (60HRC) |

| Insert: | 4QS-CNGA120412 |

| Grade: | BXA20 |

| Cutting conditions: | Vc = 100 (m/min) f = 0.1 – 0.2 (mm/rev) ap = 0.7 – 1.0 (mm) Coolant: Dry |

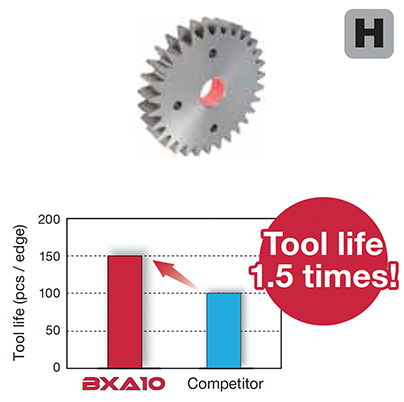

Example #2

General Engineering

| Part: | Gear part |

| Material: | SCM420 / 18CrMo4 (60HRC) |

| Insert: | 6QS-WXGQ040304SPL |

| Grade: | BXA10 |

| Cutting conditions: | Vc = 70 (m/min) f = 0.03 (mm/rev) ap = 0.1 (mm) Coolant: Dry |

Standard cutting conditions

For more information about this product, visit our online e-catalog or download the product report: