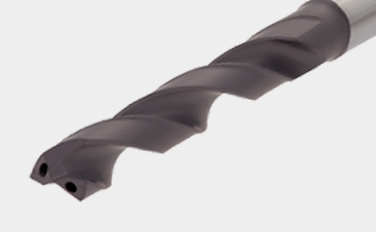

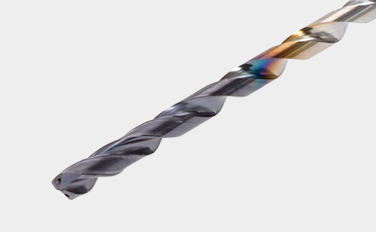

Coated solid carbide drill for excellent stability

Ideal combination of drill geometry and carbide composition for exceptional performance on a wide range of drilling applications

การใช้งาน & คุณสมบัติ

การใช้งาน

Features for DSW

1. New coated grade with highly improved wear resistance

• New coated carbide grade with a high level of versatility. Perfect grade for stable and long tool life on a wide range of materials.

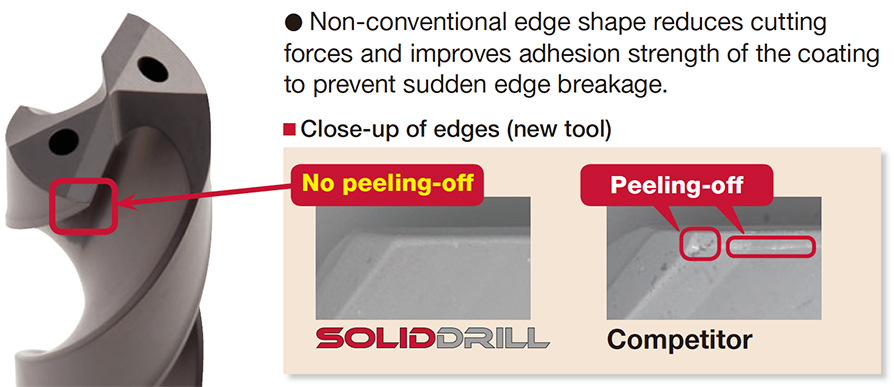

2. Innovative cutting edge offers reliable drilling

• Non-conventional edge shape reduces cutting forces and improves adhesion strength of the coating to prevent sudden edge breakage.

3. World-wide standard shank style – Standardized with DIN6535-Form HA

• Only 6 shank size diameters available – ø6, ø8, ø10, ø12, ø14, ø16 mm. This reduces the number of collets required.

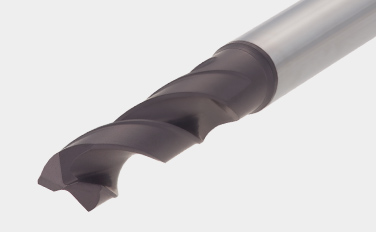

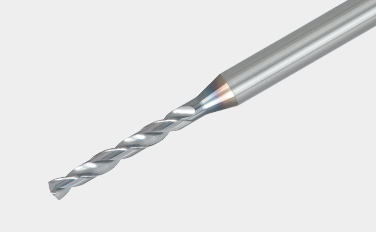

Features for DSM

1. Variety of dimensions and L/D

• Allows deep hole drilling up to 5 to 15 times the drill diameter.

• Available as standard items from ø0.1 to ø3.0 mm in 0.01 mm increments. Shank diameters are all unified to ø3 mm.

2. Center drills for machining guide hole

• DSM-CP140 type has a 140° point angle which can effectively prevent the cutting edge from chipping.

• DSM-CP90 type, which has a 90° point angle, can be also used for chamfering of the hole mouth.

ด้ามสว่าน & เกรด

ด้ามสว่าน

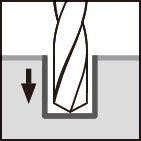

DSW-DI (ø3 – ø12 มม.)

- ชนิดมีรูน้ำหล่อเย็น

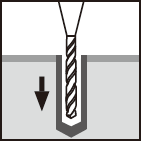

DSW-DE (ø3 – ø12 มม.)

- ชนิดไม่มีรูน้ำหล่อเย็น

DSW-CI (ø3 – ø10 mm)

- Cylindrical shank, with coolant holes

DSM (ø0.1 – ø3 มม.)

- ขนาดเล็ก ดอกสว่านคาร์ไบด์เนื้อตัน, L/D (ULDR) = 5 – 15

DSM-CP (ø3 มม.)

- ดอกสว่านสำหรับการเจาะรู

เกรดหลัก

AH725

![]()

![]()

![]()

![]()

- P15 – P30 / M15 – M30 / K25 – K30 / S15 – S25

- Good balance between wear and chipping resistance

- Suitable for machining steel and stainless steel under general cutting conditions

YH170

![]()

![]()

- P20 – P35 / M20 – M35

- High resistance to wear and fracture

- Designed for drilling carbon steel and stainless steel

YH180

![]()

![]()

- High wear resistance

- Designed for drilling carbon steel and stainless steel

ตัวอย่างการใช้งาน

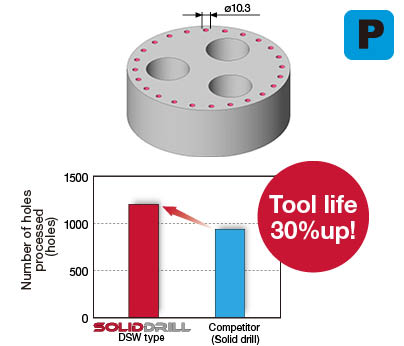

ตัวอย่างที่ #1

General Engineering

| ชิ้นงาน: | Machine parts |

| วัสดุ: | C55 (ISO) |

| ด้ามสว่าน: | DSW103-040-12DE3 |

| เส้นผ่านศูนย์กลางของรู: | øDc = 10.3 (mm) |

| เกรด: | AH725 |

| เงื่อนไขการตัดเฉือน: | Vc = 50 (m/min) f = 0.3 (mm/rev) H = 24 (mm) Coolant: Wet (External) Machine: Horizontal MC |

เงื่อนไขการตัดเฉือนมาตรฐาน

DSW-DE (External supply)

| ISO | Workpiece material | Brinell hardness (HB) |

Cutting speedVc (m/min) | Feed: f (mm/rev) | ||||

|---|---|---|---|---|---|---|---|---|

| ø3 – ø6 | ø6 – ø10 | ø10 – ø16 | ø3 – ø6 | ø6 – ø10 | ø10 – ø12 | |||

|

Low carbon steels (C < 0.3) SS400, SM490, S25C, etc. C15E4, E275A, E355D, etc. |

– 180 | 40 – 100 | 60 – 120 | 60 – 130 | 0.15 – 0.3 | 0.15 – 0.35 | 0.2 – 0.5 |

| Carbon steels (C > 0.3) S45C, S55C, , etc. C45, C55, etc. |

180 – 300 | 40 – 90 | 50 – 120 | 60 – 130 | 0.15 – 0.3 | 0.15 – 0.35 | 0.2 – 0.4 | |

| High alloy steels SCM440, etc. 42CrMo4, etc. |

250 – 350 | 40 – 80 | 50 – 100 | 50 – 100 | 0.1 – 0.2 | 0.15 – 0.3 | 0.15 – 0.35 | |

|

Stainless steels SUS304, etc. X5CrNi18-9, etc. |

– 200 | 20 – 40 | 30 – 50 | 30 – 60 | 0.05 – 0.2 | 0.1 – 0.25 | 0.1 – 0.3 |

|

Grey cast irons FC300, etc. 250, etc. |

– 200 | 40 – 90 | 50 – 95 | 50 – 100 | 0.15 – 0.3 | 0.2 – 0.4 | 0.2 – 0.5 |

| Ductile cast irons FCD450, etc. 450-10S, etc. |

– 300 | 30 – 80 | 40 – 90 | 45 – 90 | 0.1 – 0.3 | 0.2 – 0.4 | 0.2 – 0.4 | |

|

Aluminium alloys ADC12, etc. AlSi11Cu3, etc. |

– | 40 – 90 | 50 – 100 | 50 – 100 | 0.15 – 0.3 | 0.2 – 0.4 | 0.2 – 0.5 |

|

Titanium alloys Ti-6Al-4V, etc. |

– | 20 – 40 | 20 – 40 | 20 – 40 | 0.1 – 0.2 | 0.15 – 0.25 | 0.15 – 0.4 |

| Heat-resistant alloys, Inconel Inconel 718, etc. |

250 – | 10 – 30 | 10 – 30 | 10 – 30 | 0.03 – 0.07 | 0.05 – 0.1 | 0.07 – 0.12 | |

|

High hardened steels SKD11, etc. X153CrMoV12, etc. |

– 40HRC | 20 – 40 | 20 – 40 | 20 – 40 | 0.05 – 0.15 | 0.05 – 0.15 | 0.05 – 0.2 |

- The cutting parameters shown in the table are merely a starting guideline for general machining. Values should be varied depending on the power or rigidity of the machine to be used. Optimum conditions should be selected depending on the actual chip control or damage on edges.

- When using the smaller diameter tools in each range, set the feed “f” to the lower recommended values.

- The coolant supply is critical for the provision of stable machining conditions and enhanced tool life. A large coolant volume should be supplied, especially when drilling difficult-to-cut materials.

- When drilling stainless steel with low machinability such as austenitic stainless steel with a depth deeper than L/D = 3, a pecking cycle or internal coolant supply is recommended.

DSW-DI (Internal supply)

| ISO | Workpiece material | Brinell hardness (HB) |

Cutting speedVc (m/min) | Feed: f (mm/rev) | ||||

|---|---|---|---|---|---|---|---|---|

| ø3 – ø6 | ø6 – ø10 | ø10 – ø16 | ø3 – ø6 | ø6 – ø10 | ø10 – ø12 | |||

|

Low carbon steels (C < 0.3) SS400, SM490, S25C, etc. C15E4, E275A, E355D, etc. |

– 180 | 70 – 140 | 80 – 160 | 90 – 190 | 0.15 – 0.3 | 0.15 – 0.35 | 0.2 – 0.5 |

| Carbon steels (C > 0.3) S45C, S55C, , etc. C45, C55, etc. |

180 – 300 | 50 – 130 | 70 – 160 | 80 – 170 | 0.15 – 0.3 | 0.15 – 0.35 | 0.2 – 0.4 | |

| High alloy steels SCM440, etc. 42CrMo4, etc. |

250 – 350 | 40 – 100 | 60 – 140 | 60 – 160 | 0.1 – 0.2 | 0.15 – 0.3 | 0.15 – 0.35 | |

|

Stainless steels SUS304, etc. X5CrNi18-9, etc. |

– 200 | 25 – 75 | 50 – 100 | 50 – 120 | 0.05 – 0.2 | 0.1 – 0.25 | 0.1 – 0.3 |

|

Grey cast irons FC300, etc. 250, etc. |

– 200 | 80 – 140 | 100 – 160 | 100 – 180 | 0.15 – 0.3 | 0.2 – 0.4 | 0.2 – 0.45 |

| Ductile cast irons FCD450, etc. 450-10S, etc. |

– 300 | 70 – 140 | 80 – 150 | 80 – 170 | 0.1 – 0.3 | 0.2 – 0.4 | 0.2 – 0.45 | |

|

Aluminium alloys ADC12, etc. AlSi11Cu3, etc. |

– | 60 – 200 | 60 – 200 | 60 – 200 | 0.15 – 0.3 | 0.2 – 0.4 | 0.2 – 0.5 |

|

Titanium alloys Ti-6Al-4V, etc. |

– | 20 – 60 | 30 – 80 | 30 – 80 | 0.1 – 0.2 | 0.1 – 0.25 | 0.15 – 0.4 |

| Heat-resistant alloys, Inconel Inconel 718, etc. |

250 – | 10 – 30 | 10 – 40 | 10 – 40 | 0.03 – 0.07 | 0.05 – 0.1 | 0.07 – 0.15 | |

|

High hardened steels SKD11, etc. X153CrMoV12, etc. |

– 40HRC | 20 – 50 | 30 – 60 | 30 – 60 | 0.05 – 0.15 | 0.05 – 0.15 | 0.05 – 0.2 |

- The cutting parameters shown in the table are merely a starting guideline for general machining. Values should be varied depending on the power or rigidity of the machine to be used. Optimum conditions should be selected depending on the actual chip control or damage on edges.

- When using the smaller diameter tools in each range, set the feed “f” to the lower recommended values.

- Oil holes that become blocked may cause drill breakages. A fi lter to prevent the circulation of chips must be used on the coolant supply system.

DSW-CI (16xD, 20xD)

| ISO | Workpiece material | Cutting speed Vc (m/min) |

Feed: f (mm/rev) | ||

|---|---|---|---|---|---|

| Tool diameter: DC (mm) | |||||

| ø3 – ø5 | ø5.1 – ø8 | ø8.1 – ø10 | |||

|

Low carbon steels (C < 0.3) SS400, SM490, S25C, etc. C15E4, E275A, E355D, etc. |

70 – 90 | 0.1 – 0.18 | 0.1 – 0.2 | 0.1 – 0.25 |

| High carbon steels (C > 0.3) S45C, S55C, etc. C45, C55, etc. |

70 – 90 | 0.1 – 0.18 | 0.1 – 0.2 | 0.1 – 0.25 | |

| Low alloy steels SCM415, etc. 18CrMo4, etc. |

70 – 90 | 0.1 – 0.18 | 0.1 – 0.2 | 0.1 – 0.25 | |

| Alloy steels SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

75 – 85 | 0.08 – 0.14 | 0.08 – 0.18 | 0.12 – 0.2 | |

|

Stainless steels SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

55 – 65 | 0.04 – 0.12 | 0.08 – 0.16 | 0.1 – 0.18 |

|

Grey cast irons FC250, etc. GG25, etc. |

80 – 100 | 0.14 – 0.24 | 0.16 – 0.26 | 0.18 – 0.3 |

| Ductile cast irons FCD700, etc. GGG70, etc. |

80 – 100 | 0.14 – 0.24 | 0.16 – 0.26 | 0.18 – 0.3 | |

|

Titanium alloys Ti-6Al-4V, etc. |

35 – 45 | 0.06 – 0.12 | 0.08 – 0.16 | 0.1 – 0.18 |

| Nickel-based alloys | 30 – 40 | 0.06 – 0.12 | 0.08 – 0.16 | 0.1 – 0.18 | |

DSW-CI (30xD)

| ISO | Workpiece material | Cutting speed Vc (m/min) |

Feed: f (mm/rev) | ||

|---|---|---|---|---|---|

| Tool diameter: DC (mm) | |||||

| ø3 – ø5 | ø5.1 – ø8 | ø8.1 – ø10 | |||

|

Low carbon steels (C < 0.3) SS400, SM490, S25C, etc. C15E4, E275A, E355D, etc. |

70 – 90 | 0.08 – 0.11 | 0.12 – 0.17 | 0.1 – 0.22 |

| High carbon steels (C > 0.3) S45C, S55C, etc. C45, C55, etc. |

70 – 90 | 0.08 – 0.11 | 0.12 – 0.17 | 0.1 – 0.22 | |

| Low alloy steels SCM415, etc. 18CrMo4, etc. |

70 – 90 | 0.08 – 0.11 | 0.12 – 0.17 | 0.1 – 0.22 | |

| Alloy steels SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

75 – 85 | 0.06 – 0.09 | 0.08 – 0.14 | 0.1 – 0.18 | |

|

Stainless steels SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

55 – 65 | 0.04 – 0.1 | 0.08 – 0.14 | 0.1 – 0.16 |

|

Grey cast irons FC250, etc. GG25, etc. |

80 – 100 | 0.14 – 0.22 | 0.16 – 0.26 | 0.18 – 0.25 |

| Ductile cast irons FCD700, etc. GGG70, etc. |

80 – 100 | 0.14 – 0.22 | 0.16 – 0.24 | 0.18 – 0.25 | |

|

Titanium alloys Ti-6Al-4V, etc. |

35 – 45 | 0.06 – 0.1 | 0.08 – 0.12 | 0.1 – 0.13 |

| Nickel-based alloys | 30 – 40 | 0.06 – 0.1 | 0.08 – 0.12 | 0.08 – 0.13 | |

DSM

| ISO | Workpiece material | Hardness | Cutting speedVc (m/min) | Feed: f (mm/rev) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ø0.1 – ø0.3 | ø0.31 – ø0.5 | ø0.51 – ø3 | ø0.1 – ø0.3 | ø0.31 – ø0.5 | ø0.51 – ø1 | ø1.01 – ø2 | ø2.01 – ø3 | |||

|

Carbon steels, Alloy steels |

– 300HB | 5 – 20 | 15 – 30 | 25 – 60 | 0.001 – 0.004 | 0.002 – 0.01 | 0.005 – 0.05 | 0.03 – 0.09 | 0.05 – 0.1 |

|

Stainless steels | – 200HB | 2 – 12 | 6 – 18 | 10 – 20 | 0.0005 – 0.004 | 0.002 – 0.008 | 0.005 – 0.03 | 0.01 – 0.04 | 0.02 – 0.05 |

|

Grey cast irons | 150 – 250HB | 5 – 15 | 10 – 25 | 20 – 50 | 0.0005 – 0.004 | 0.002 – 0.012 | 0.005 – 0.03 | 0.01 – 0.06 | 0.03 – 0.12 |

| Ductile cast irons | 150 – 250HB | 5 – 15 | 10 – 25 | 20 – 50 | 0.001 – 0.003 | 0.002 – 0.01 | 0.005 – 0.02 | 0.01 – 0.05 | 0.03 – 0.1 | |

|

Aluminium alloys | – | 10 – 20 | 10 – 30 | 20 – 50 | 0.001 – 0.01 | 0.005 – 0.03 | 0.01 – 0.05 | 0.04 – 0.15 | 0.06 – 0.2 |

| Copper / Brass | – | 10 – 20 | 10 – 30 | 20 – 50 | 0.001 – 0.01 | 0.005 – 0.03 | 0.01 – 0.05 | 0.04 – 0.15 | 0.06 – 0.2 | |

|

Heat-resistant alloys | – 40HRC | 2 – 6 | 5 – 10 | 8 – 20 | 0.0005 – 0.003 | 0.002 – 0.004 | 0.002 – 0.004 | 0.002 – 0.004 | ※ |

|

High hardened steels | – 50HRC | 4 – 8 | 6 – 10 | 6 – 16 | 0.0005 – 0.002 | 0.001 – 0.005 | 0.005 – 0.02 | 0.01 – 0.03 | 0.02 – 0.06 |

※ Not recommended

- When the drilling depth is deeper than L/D = 5, use drill pecking every 10 to 50% of the drill diameter.

- The above cutting conditions are applied to when a water soluble cutting fluid is used. For drilling a hole smaller than ø0. 3 mm, use of a starting drill is recommended.

- When setting the drill, the drill runout should be within 0.002 mm on the taper. (Especially for the drill diameter smaller than ø0.5 mm)

DSM-CP

| ISO | Workpiece material | Hardness | Cutting speedVc (m/min) | Feed: f (mm/rev) | |

|---|---|---|---|---|---|

| DSM-CP90 | DSM-CP140 | ||||

|

Carbon, Mild and Alloy steels | – 300HB | 30 – 80 | 0.01 – 0.06 | 0.03 – 0.08 |

|

Stainless steels | – 200HB | 15 – 40 | 0.01 – 0.03 | 0.02 – 0.06 |

|

Grey and ductile cast irons | 150 – 250HB | 30 – 80 | 0.02 – 0.06 | 0.05 – 0.1 |

|

Aluminium alloys | – | 60 – 120 | 0.02 – 0.1 | 0.05 – 0.15 |

|

High hardened steels | – 45HRC | 10 – 40 | ※ | 0.01 – 0.05 |

※ Not recommended

- Use DSM-CP140 for drilling hard materials and stainless steel that have work-hardening characteristic.

- The above cutting conditions are designed when using water-soluble cutting fluid, in which case, set the cutting speed to the lower side of the range.

ไปที่ e-catalog ออนไลน์ของเรา หรือดาวน์โหลดรายงานสินค้าเพื่อดูข้อมูลเพิ่มเติมเกี่ยวกับผลิตภัณฑ์นี้: