High productivity profile milling cutter

Barrel-shaped inserts for profile milling with productivity boost

Applications & Features

Applications

Features

1. Large R cutting edge and multi-fl ute design for unparalleled productivity

Large R for small cusp height

Close pitch design

DCX = 20 mm, PRFRAD = 30 mm

DCX = 20 mm, R = 10 mm

Ball endmill

2. Two kinds of barrel-shaped cutting edge profi les (PRFRAD)

1st choice

ZNHU1003R30…

2-corner double sided insert

High productive geometry that provides a large stepover distance for reduced cusp height

ZNHU1003R30…

2-corner double sided insert

Profiling geometry with an increased tilt angle for enhanced application versatility

3. Excellent clamping reliability with dove-tail back support

AddForceBarrel reduces the number of passes by 40% compared to ball endmill with 10 mm radius without compromising the surface quality (cusp height).

Inserts & Grades

Inserts

Main Grades

Cutter bodies

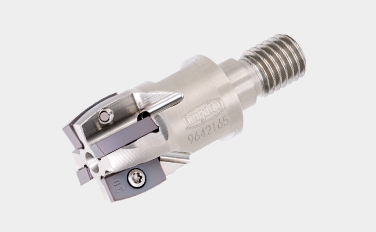

Modular Type

HFZN10-M (ø16 – ø40 mm)

Profiling endmill, modular type (TungFlex), for 2-corner double sided inserts

Practical examples

Example #1

| Part: | Test piece |

| Material: | S55C / C55 |

| Cutter: | HFZN10M020M10R04 (DCX = 20 mm, CICT = 4) |

| Insert: | ZNHU1003R20-MM |

| Grade: | AH9130 |

| Cutting conditions: | Vc = 500 (m/min) fz = 0.1 (mm/t) p= 0.8 (mm) ae = 0.3 (mm) Application: Profiling Coolant: Dry Machine: Vertical M/C, BT40 |

Example #2

| Part: | Test piece |

| Material: | SUS304 / X5CrNi18-9 |

| Cutter: | HFZN10M020M10R04 (DCX = 20 mm, CICT = 4) |

| Insert: | ZNHU1003R30-MM |

| Grade: | AH9130 |

| Cutting conditions: | Vc = 350 (m/min) fz = 0.12 (mm/t) p = 1 (mm) ae = 0.2 (mm) Application: Profiling Coolant: Wet Machine: Vertical M/C, BT40 |

Standard cutting conditions

| ISO | Workpiece materials | Hardness | Cutting speed Vc (m/min) | Feed per tooth fz (mm/t) | Width of cut ae (mm) |

|---|---|---|---|---|---|

|

Low carbon steel S15C, SS400, etc. C15, C20, etc. |

– 200HB | 100 – 600 | 0.05 – 0.3 | < 0.4 |

| Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300HB | 100 – 600 | 0.05 – 0.3 | < 0.3 | |

| Prehardened steel NAK80, PX5, etc. |

30 – 40HRC | 100 – 600 | 0.05 – 0.3 | < 0.3 | |

|

Austenitic stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200HB | 100 – 500 | 0.05 – 0.3 | < 0.3 |

| Precipitation hardening stainless steel SUS630, etc. X5CrNiCuNb16-4, etc. |

– 45HRC | 100 – 300 | 0.05 – 0.25 | < 0.2 | |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc. |

150 – 250HB | 100 – 600 | 0.05 – 0.3 | < 0.3 |

| Ductile cast iron FCD400, etc. 400-15, 600-3, etc. |

150 – 250HB | 100 – 600 | 0.05 – 0.3 | < 0.3 | |

|

Titanium alloys Ti-6AI-4V, etc. |

– 45HRC | 40 – 120 | 0.05 – 0.2 | < 0.2 |

| Superalloys Inconel718, etc. |

– 45HRC | 20 – 80 | 0.05 – 0.2 | < 0.2 | |

|

Hardened steel SKD61, etc. X40CrMoV5-1, etc. |

40 – 55HRC | 50 – 300 | 0.05 – 0.2 | < 0.2 |

For more information about this product, visit our online e-catalog or download the product report: