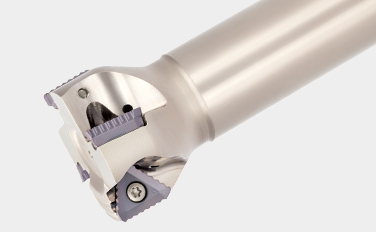

Highly productive roughing cutter with serrated edges

High performance cutter with chip splitters for improved chatter stability and efficiency in rough milling with long overhang

Applications & Features

Applications

Features

1. Anti Chatter Design

Serrated cutting edge creates smaller chips reducing chatter.

2. Intelligent and User friendly design

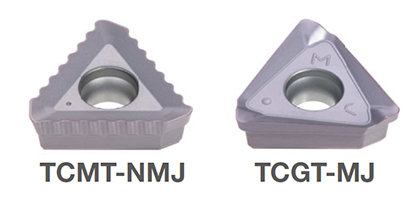

3. 2 types of inserts fit on the same cutter body

Inserts & Grades

Inserts

Main Grades

AH3135

![]()

![]()

- High fracture resistance

- Suitable for machining steel and stainless steel under general cutting conditions

T3225

![]()

![]()

- High chipping and fracture resistance

- Suitable for milling steel and stainless steel

T1215

![]()

- Good balance between wear and chipping resistance

- Suitable for milling cast iron

Cutter bodies

Practical examples

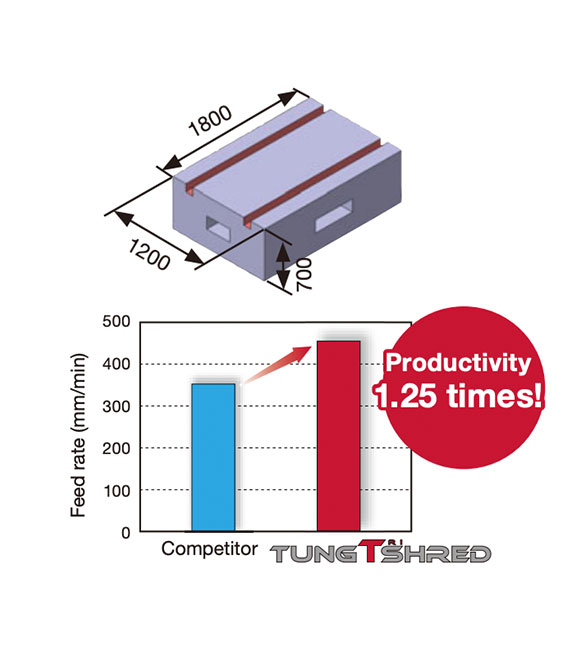

Example #1

General Engineering

| Part: | Machine parts |

| Material: | SS400 |

| Holder: | LPTC16J063B25.4L061R03 (ø63, z = 3) |

| Insert: | TCMT160620PDER-NMJ |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 150 (Competitor: Vc = 105) (m/min) fz = 0.2 (mm/t) Vf = 455 (mm/min) ap = 50 (mm) ae = 10 (mm) Application: Shoulder milling Coolant: Air Machine: Tower M/C, BT50 |

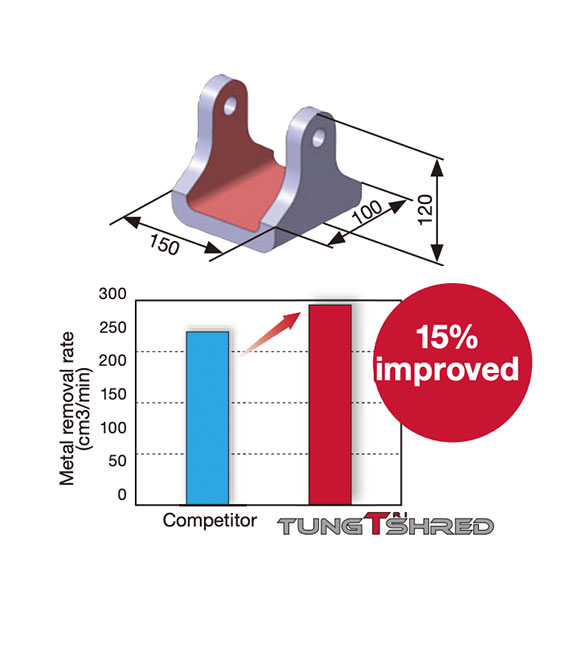

Example #2

Automotive Industry

| Part: | Bracket |

| Material: | SCSiMn2H |

| Holder: | LPTC16M080B32.0L076R04 (ø80, z = 4) |

| Insert: | TCMT160620PDER-NMJ |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 135 (Competitor: Vc = 126) (m/min) fz = 0.33 (Competitor: fz = 0.3) (mm/t) Vf = 709 (mm/min) ap = 75 (mm) ae = 5 (mm) Application: Shoulder milling Coolant: Air Machine: Vertical M/C, BT40 |

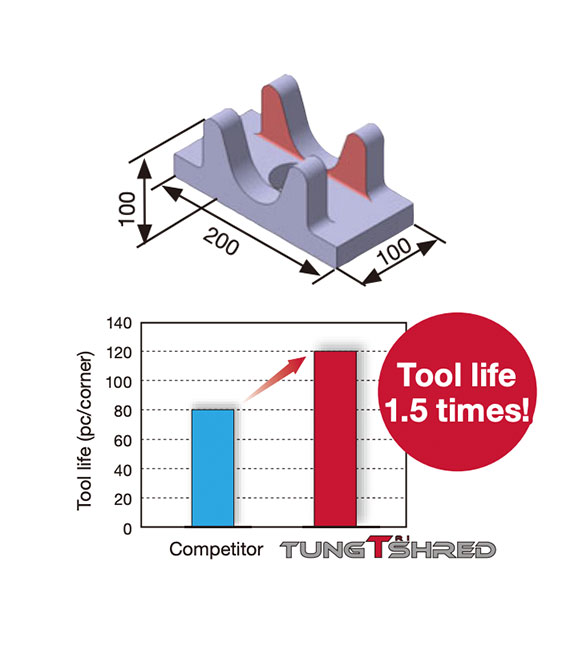

Example #3

General Engineering Industry

| Part: | Flange |

| Material: | FC300 / GG30 |

| Holder: | TPTC16M050B22.0R04 (ø50, z = 4) |

| Insert: | TCMT160620PDER-NMJ |

| Grade: | AH120 |

| Cutting conditions: | Vc = 150 (m/min) fz = 0.18 (mm/t) Vf = 700 (mm/min) ap = 2 (mm) ae = 10 (mm) Application: Shoulder milling Coolant: Wet Machine: Horizontal M/C, BT40 |

Standard cutting conditions

| ISO | Workpiece materials | Hardness | Priority | Grade | Chipbreaker | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|---|---|---|---|---|---|---|---|

| Low carbon steel S15C, S20S, etc. C15, C20, etc. |

– 300HB | First choice | AH3225 | NMJ* | 100 – 250 | 0.08 – 0.15 | |

| Fracture resistance | AH3135 | MJ | 100 – 250 | 0.08 – 0.15 | |||

| Wear resistance | T3225 | NMJ* | 100 – 300 | 0.08 – 0.15 | |||

| For finishing | AH3225 | MJ | 100 – 250 | 0.08 – 0.20 | |||

| Carbon steel and alloy steel S55C, SCM440, etc. C55, 42CrMo4, etc. |

– 300HB | First choice | AH3225 | NMJ* | 100 – 230 | 0.08 – 0.15 | |

| Fracture resistance | AH3135 | MJ | 100 – 230 | 0.08 – 0.15 | |||

| Wear resistance | T3225 | NMJ* | 100 – 280 | 0.08 – 0.15 | |||

| For finishing | AH3225 | MJ | 100 – 230 | 0.08 – 0.20 | |||

| Prehardened steel NAK80, PX5, etc. |

30 – 40 HRC | First choice | AH3225 | NMJ* | 100 – 180 | 0.08 – 0.15 | |

| Fracture resistance | AH3135 | MJ | 100 – 180 | 0.08 – 0.15 | |||

| Wear resistance | T3225 | NMJ* | 100 – 200 | 0.08 – 0.15 | |||

| For finishing | AH3225 | MJ | 100 – 180 | 0.08 – 0.20 | |||

| Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

– 250HB | First choice | AH3135 | NMJ* | 90 – 200 | 0.08 – 0.15 | |

| Wear resistance | T3225 | NMJ* | 90 – 250 | 0.08 – 0.15 | |||

| For finishing | AH3135 | MJ | 90 – 200 | 0.08 – 0.20 | |||

| Grey cast iron FC250, FC300, etc. 250, 300, etc. |

150 – 250HB | First choice | AH8015 | NMJ* | 140 – 250 | 0.08 – 0.15 | |

| Wear resistance | T1215 | NMJ* | 150 – 300 | 0.08 – 0.15 | |||

| For finishing | AH8015 | MJ | 140 – 250 | 0.08 – 0.25 | |||

| Ductile cast iron FCD400, FCD600, etc. 400-15S, 600-3, etc. |

150 – 250HB | First choice | AH8015 | NMJ* | 140 – 250 | 0.08 – 0.15 | |

| Wear resistance | T1215 | NMJ* | 150 – 300 | 0.08 – 0.15 | |||

| For finishing | AH8015 | MJ | 140 – 250 | 0.08 – 0.25 | |||

| Titanium alloys Ti-6AI-4V, etc. |

– | First choice | AH8015 | NMJ* | 20 – 60 | 0.08 – 0.15 | |

| Fracture resistance | AH3135 | NMJ* | 20 – 60 | 0.08 – 0.15 | |||

| For finishing | AH8015 | MJ | 20 – 60 | 0.08 – 0.18 | |||

| Heat-resistant alloys Inconel718, etc. |

– | First choice | AH8015 | NMJ* | 20 – 40 | 0.08 – 0.13 | |

| For finishing | AH8015 | MJ | 20 – 40 | 0.08 – 0.15 |

* When using the -NMJ chipbreaker, do not feed higher than 0.15 mm/t.

For more information about this product, visit our online e-catalog or download the product report: