A new generation of CVD grades for steel turning

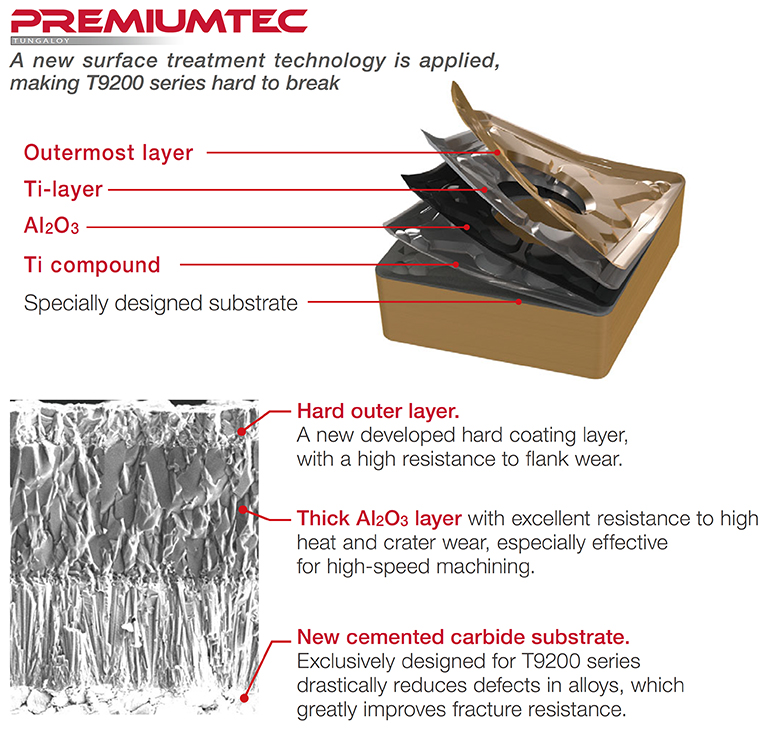

Excellent wear resistance and excellent fracture resistance to further improve your machining efficiency

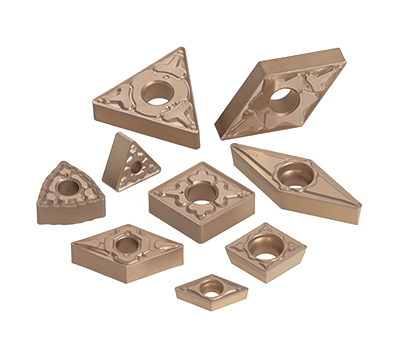

Applications & Features

Applications

Features

1. Excellent wear resistance and excellent fracture resistance

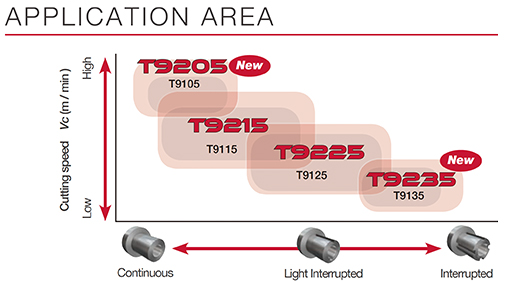

2. Application area

Grades

T9205

![]()

![]()

- P01 – P10 / K10 – K20

- High wear resistance

- Excellent performance in high-speed cutting

T9215

![]()

![]()

![]()

- P10 – P20

- Well-balanced between wear and chipping resistance

- First choice for steel

- High versatility for a wide range of applications

T9225

![]()

- P15 – P25

- First choice for roughing to medium cutting

- High fracture resistance

Practical examples

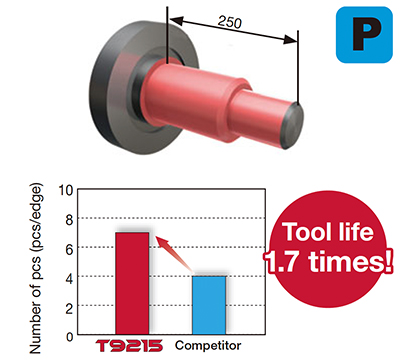

Example #1

General Engineering

| Part: | Shaft |

| Material: | SCM440 / 42CrMo4 |

| Insert: | CNMG120408-TM |

| Grade: | T9215 |

| Cutting conditions: | Vc = 250 (m/min) f = 0.3 (mm/rev) ap = 3.5 (mm) Coolant: Wet |

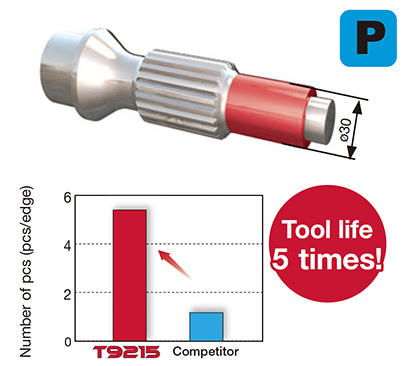

Example #2

General Engineering

| Part: | Shaft |

| Material: | SCM440 / 42CrMo4 |

| Insert: | DNMG150412-TM |

| Grade: | T9215 |

| Cutting conditions: | Vc = 140 (m/min) f = 0.38 (mm/rev) ap = 4mm x 6 pass (mm) Coolant: Wet |

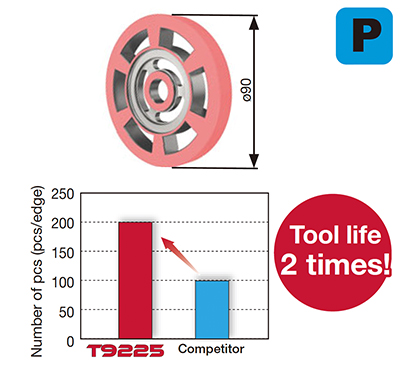

Example #3

Automotive Industry

| Part: | Rotor parts |

| Material: | S10C |

| Insert: | WNMG080412-TM |

| Grade: | T9225 |

| Cutting conditions: | Vc = 400 (m/min) f = 0.45 (mm/rev) ap = 1.5 (mm) Coolant: Wet |

Standard cutting conditions

Negative inserts

| ISO | Operation | Chipbreaker | Grades | Depth of cutDepth of cut ap (mm) | FeedFeed f (mm/rev) | Cutting speed: Vc (m/min) | ||

|---|---|---|---|---|---|---|---|---|

| Low carbon steels, alloy steels | Medium carbon steels, alloy steels | High carbon steels, alloy steels | ||||||

| Finishing | PS | T9215 | 0.3 – 1.5 | 0.1 – 0.4 | 150 – 400 | 150 – 400 | 120 – 300 | |

| T9225 | 120 – 300 | 120 – 300 | 100 – 250 | |||||

| TSF | T9205 | 0.2 – 1.5 | 0.08 – 0.4 | 180 – 400 | 180 – 400 | 150 – 350 | ||

| T9215 | 150 – 400 | 150 – 400 | 120 – 300 | |||||

| T9225 | 120 – 300 | 120 – 300 | 100 – 250 | |||||

| T9235 | 50 – 200 | 50 – 200 | 50 – 150 | |||||

| AS | T9205 | 0.2 – 1.5 | 0.08 – 0.4 | 180 – 400 | 180 – 400 | 150 – 350 | ||

| T9215 | 150 – 400 | 150 – 400 | 120 – 300 | |||||

| T9225 | 120 – 300 | 120 – 300 | 100 – 250 | |||||

| T9235 | 50 – 200 | 50 – 200 | 50 – 150 | |||||

| FW | T9205 | 0.2 – 1.5 | 0.08 – 0.4 | 180 – 400 | 180 – 400 | 150 – 350 | ||

| T9215 | 150 – 400 | 150 – 400 | 120 – 300 | |||||

| T9225 | 120 – 300 | 120 – 300 | 100 – 250 | |||||

| T9235 | 50 – 200 | 50 – 200 | 50 – 150 | |||||

| Medium cutting | PM | T9215 | 0.5 – 5.5 | 0.15 – 0.5 | 150 – 400 | 150 – 400 | 120 – 300 | |

| T9225 | 120 – 300 | 120 – 300 | 100 – 250 | |||||

| TM | T9205 | 1.0 – 5.0 | 0.2 – 0.5 | 180 – 400 | 180 – 400 | 150 – 350 | ||

| T9215 | 150 – 400 | 150 – 400 | 120 – 300 | |||||

| T9225 | 120 – 300 | 120 – 300 | 100 – 250 | |||||

| T9235 | 50 – 200 | 50 – 200 | 50 – 150 | |||||

| AM | T9205 | 1.5 – 4.5 | 0.2 – 0.6 | 180 – 400 | 180 – 400 | 150 – 350 | ||

| T9215 | 150 – 400 | 150 – 400 | 120 – 300 | |||||

| T9225 | 120 – 300 | 120 – 300 | 100 – 250 | |||||

| T9235 | 50 – 200 | 50 – 200 | 50 – 150 | |||||

| SW | T9205 | 0.5 – 2.0 | 0.3 – 0.6 | 180 – 400 | 180 – 400 | 150 – 350 | ||

| T9215 | 150 – 400 | 150 – 400 | 120 – 300 | |||||

| T9225 | 120 – 300 | 120 – 300 | 100 – 250 | |||||

| T9235 | 50 – 200 | 50 – 200 | 50 – 150 | |||||

| Medium to heavy cutting | TH | T9205 | 3.0 – 6.0 | 0.3 – 0.6 | 180 – 400 | 180 – 400 | 150 – 350 | |

| T9215 | 150 – 400 | 150 – 400 | 120 – 300 | |||||

| T9225 | 120 – 300 | 120 – 300 | 100 – 250 | |||||

| T9235 | 50 – 200 | 50 – 200 | 50 – 150 | |||||

| Stainless steel | ||||||||

| Finishing | TSF | T9215 | 0.2 – 1.5 | 0.08 – 0.4 | 100 – 250 | |||

| T9225 | ||||||||

| Medium cutting | TM | T9215 | 1.0 – 5.0 | 0.2 – 0.5 | 100 – 250 | |||

| T9225 | ||||||||

| Cast iron | ||||||||

| Finishing | TSF | T9215 | 0.2 – 1.5 | 0.08 – 0.4 | 140 – 500 | |||

| T9225 | ||||||||

| Medium cutting | TM | T9215 | 1.0 – 5.0 | 0.2 – 0.5 | 140 – 500 | |||

| T9225 | ||||||||

Positive insersts

| ISO | Operation | Chipbreaker | Grades | Depth of cutDepth of cut ap (mm) |

FeedFeed f (mm/rev) |

Cutting speed: Vc (m/min) | ||

|---|---|---|---|---|---|---|---|---|

| Low carbon steels, alloy steels | Medium carbon steels, alloy steels | High carbon steels, alloy steels | ||||||

| Finishing | PSF | T9215 | 0.1 – 0.5 | 0.05 – 0.3 | 120 – 350 | 100 – 350 | 80 – 250 | |

| T9225 | 100 – 300 | 80 – 300 | 80 – 250 | |||||

| Medium | TSF | T9215 | 0.5 – 2.5 | 0.1 – 0.25 | 120 – 350 | 100-350 | 80-250 | |

| T9225 | 100 – 300 | 80 – 300 | 80 – 250 | |||||

| TM | T9215 | 0.25 – 3.0 | 0.06 – 0.26 | 120 – 350 | 100 – 350 | 80 – 250 | ||

| T9225 | 100 – 300 | 80 – 300 | 80 – 250 | |||||

| Medium cutting | PS | T9215 | 0.5 – 2.5 | 0.08 – 0.3 | 120 – 300 | 100 – 300 | 80 – 250 | |

| T9225 | 100 – 300 | 80 – 250 | 80 – 200 | |||||

| SW | T9215 | 0.5 – 2 | 0.15 – 0.4 | 150 – 350 | 150 – 350 | 120 – 300 | ||

| T9225 | 100 – 300 | 100 – 300 | 80 – 250 | |||||

| Medium to heavy cutting | PM | T9215 | 1.0 – 3.0 | 0.15 – 0.3 | 120 – 300 | 100 – 300 | 80 – 200 | |

| T9225 | 100 – 300 | 80 – 300 | 80 – 200 | |||||

| Stainless steel | ||||||||

| Finishing | PSF | T9215 | 0.1 – 0.5 | 0.05 – 0.3 | 50 – 200 | |||

| T9225 | ||||||||

| Medium | PS | T9215 | 0.5 – 2.5 | 0.08 – 0.3 | 50 – 200 | |||

| T9225 | ||||||||

| Cast iron | ||||||||

| Finishing | PSF | T9215 | 0.1 – 0.5 | 0.05 – 0.3 | 100 – 350 | |||

| T9225 | ||||||||

| Medium | PS | T9215 | 0.5 – 2.5 | 0.08 – 0.3 | 100 – 350 | |||

| T9225 | ||||||||

For more information about this product, visit our online e-catalog or download the product report: