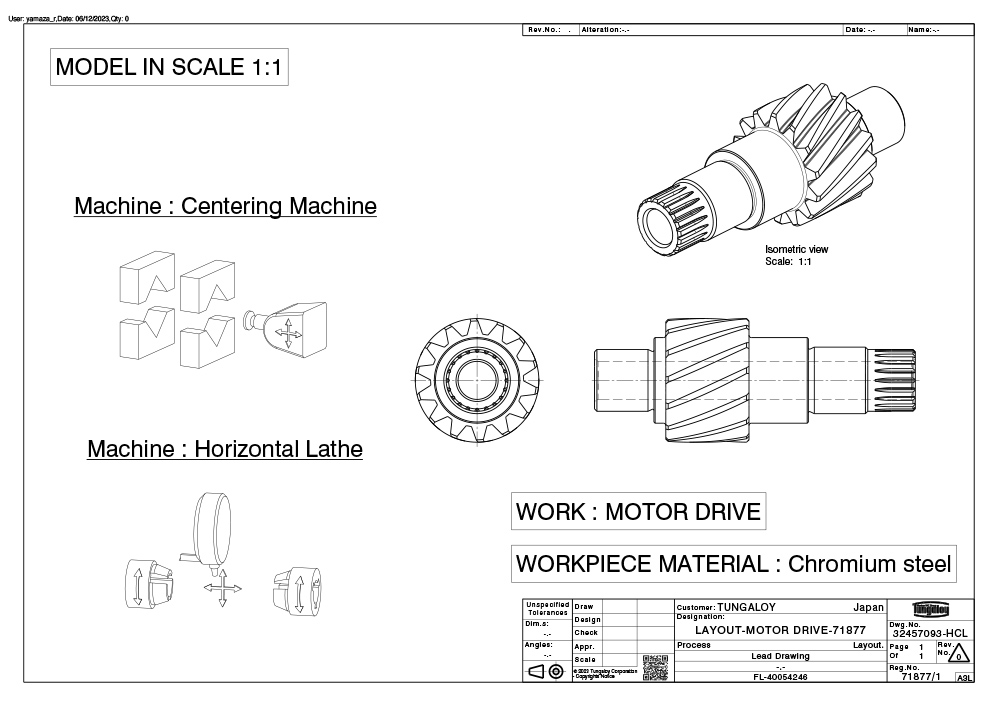

Automotive – Motorantrieb

In den letzten Jahren hat sich der Wandel hin zur Elektrifizierung in der Automobilindustrie beschleunigt, und Motorantriebe spielen eine immer wichtigere Rolle als Energiequelle für Elektrofahrzeuge.

Motorantriebe sind wesentliche Komponenten für eine effiziente und zuverlässige Kraftübertragung, und die Verbesserung ihrer Leistung ist eine zentrale Anforderung.

Um diese präzisen Bearbeitungsanforderungen zu erfüllen, bietet Tungaloy innovative Schneidwerkzeuglösungen an. Durch das Gleichgewicht zwischen hoher Bearbeitungsgenauigkeit und Produktivität helfen wir unseren Kunden, ihre Fertigungsprozesse zu optimieren und die Entwicklung wettbewerbsfähiger Produkte zu unterstützen.

Werkzeugkonzepte

- Reduzierung der Bearbeitungszeit und der Anzahl der verwendeten Werkzeuge durch Prozessintegration.

- Deutliche Verkürzung der Stillstandszeit beim Werkzeugwechsel durch den Einsatz des TungCap-Systems.

- Hocheffiziente Bearbeitung durch Schlichtfräsen mit hohem Vorschub und AddMultiTurn-Technologie.

- Verbesserung der Bearbeitungseffizienz und Senkung der Produktionskosten durch Hartdrehen in Nachhärtungsprozessen, wodurch das Schleifen überflüssig wird.

Besonderer Prozess

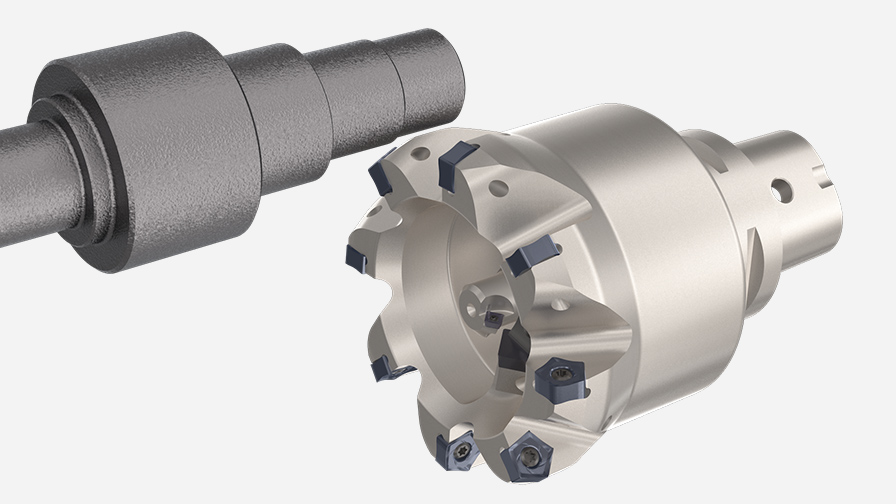

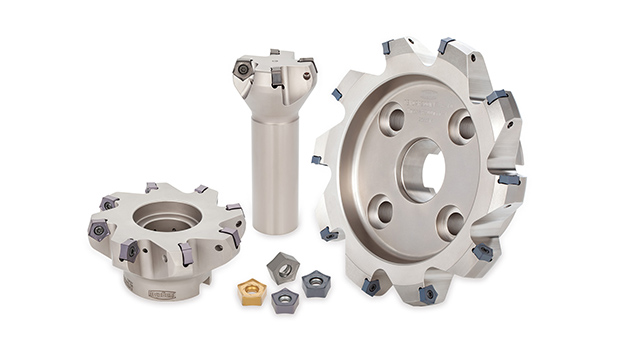

Prozess 1: Kombiniertes Planfräsen und Anfasen

Nutzen

- Reduzierung der Bearbeitungszeit und der Anzahl der verwendeten Werkzeuge durch Prozessintegration

- Bearbeitung von schwach eingespannten Schmiedeteilen

- Fräser mit einem Schnittwinkel von 70°:

- Idealer Winkel für das Gleichgewicht zwischen Haupt- und Rückkräften

- Sorgt für Stabilität und zuverlässige Kontrolle, insbesondere bei instabilen Spannkräften auf Schmiedewerkstoffen.

- Das TungCap-Werkzeug reduziert die Maschinenstillstandszeiten erheblich.

- Die Sorte AH3225 erreicht eine außerordentlich lange Standzeit durch ein ausgewogenes Verhältnis von Verschleißfestigkeit und Bruchfestigkeit auf hohem Niveau.

- Scharfe Schneide und großer Spanwinkel reduzieren den Schnittwiderstand.

- Wirtschaftlich mit 10 Schneiden

- Anfasfräser mit wirtschaftlichen, einseitigen 4-Eck-Wendeschneidplatten.

- Hohe Qualität der Bearbeitungsoberfläche durch Unterdrückung von Grat und Rattern mit scharfen Schneidkanten.

- Verwendung der Sorte AH725, die für ihre hohe Verschleißfestigkeit bekannt ist

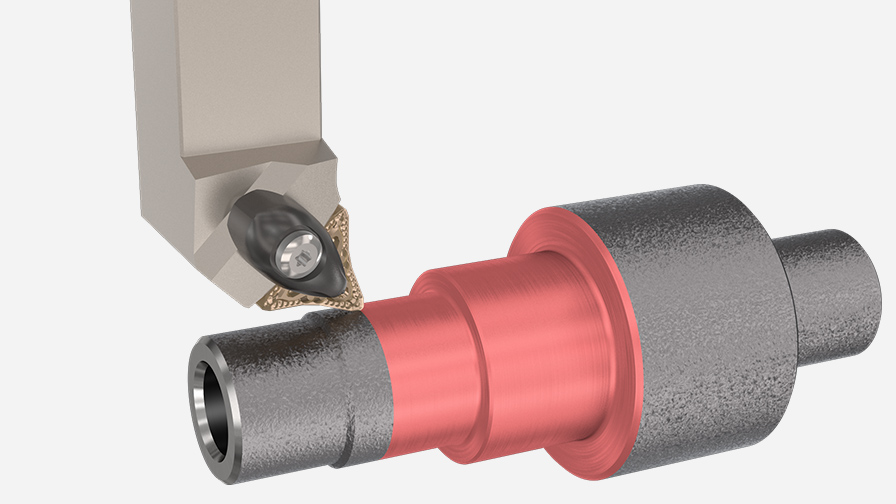

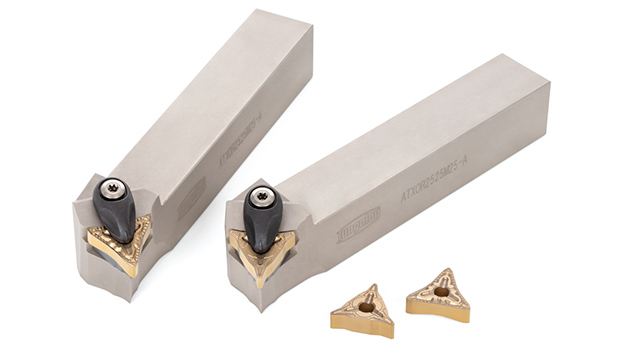

Prozess 2: Außendrehen Schruppen

Nutzen

- Die Kantengeometrie mit hohem Vorschub und Hinterdrehen ermöglicht eine hocheffiziente Bearbeitung, die herkömmliche ISO-Werkzeuge bei Drehbearbeitungen um etwa 200 % übertrifft.

- Das Hinterdrehen reduziert effektiv das Auftreten von ringförmigem Grat, einem häufigen Problem bei der Bearbeitung von Stufenwellen.

- Das Y-PRISM-Klemmsystem für Wendeschneidplatten, das für seine Einzigartigkeit und Robustheit bekannt ist, gewährleistet eine hervorragende Klemmsteifigkeit. Diese Eigenschaft ermöglicht eine stabile multidirektionale Bearbeitung und erleichtert eine hocheffiziente Bearbeitung.

6C-TOMG-TM

- Wirtschaftlich mit einer doppelseitigen 6-Ecken-Spezifikation.

- Ein 80°-Eckwinkeltyp, der für mittlere bis Schruppbearbeitungen geeignet ist

- Die Sorte T9215 gewährleistet eine außergewöhnliche Verschleiß- und Bruchfestigkeit bei der Stahldrehbearbeitung und bietet eine hervorragende Leistung.

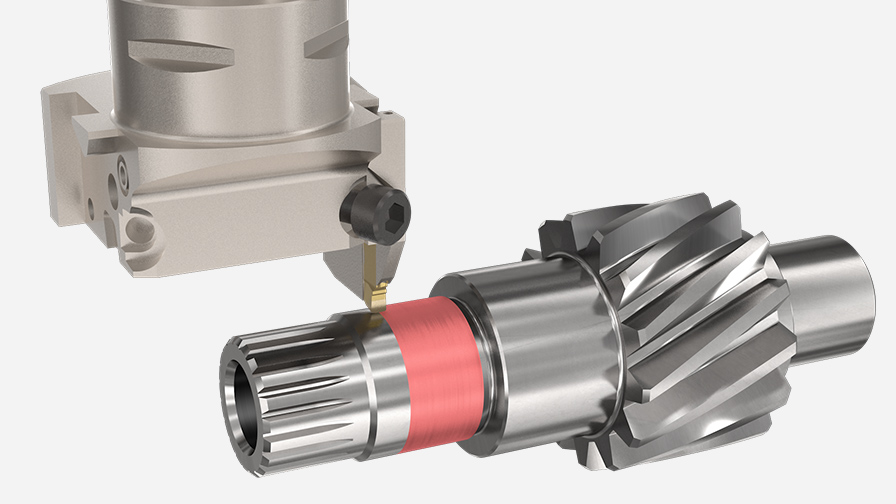

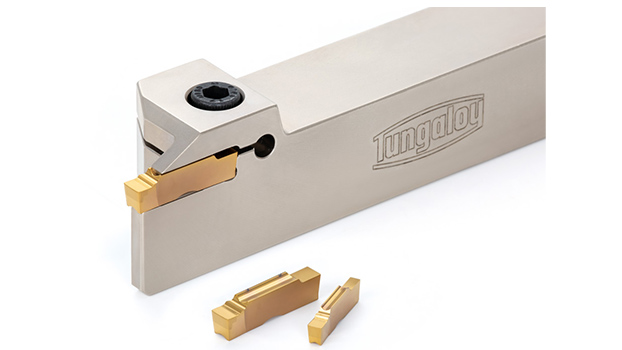

Prozess 3: Außendrehen Schlichten (Hartdrehen)

Nutzen

- Auch für Prozesse, die zwei Schritte erfordern, um Interferenzen zu vermeiden, ist eine Prozessintegration durch die Verwendung eines Halters für das Stechen möglich.

- Mit einem Wiper, der eine große Bogenform an der vorderen Schneidkante aufweist, wird auch bei der Bearbeitung durch Außendrehen mit hohem Vorschub eine hervorragende Oberflächengüte erzielt.

- Das TungCap-Werkzeug reduziert die Maschinenstillstandszeiten erheblich.

- Durch den Einsatz des TungTurn-Jet-Halters kann das Kühlmittel aus zwei Richtungen zugeführt werden: sowohl von der Span- als auch von der Freifläche der Schneide. Dadurch wird der Kühleffekt an der Schneide verstärkt, was zu einer längeren Standzeit des Werkzeugs führt.

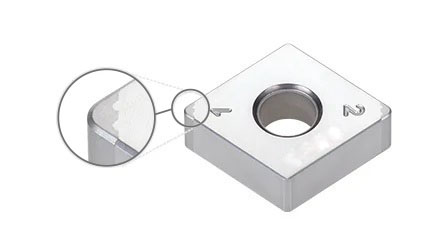

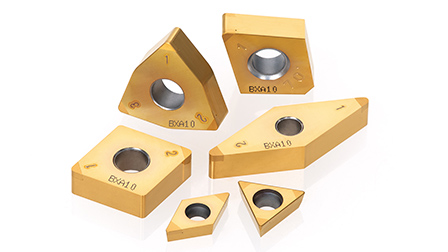

CBN Wendeschneidplatte

- Multifunktionales System für die unterschiedlichsten Anforderungen beim Einstechen.

- Durch die „WavyJoint“-Form, die eine größere Lötoberfläche ermöglicht, wird auch bei der Bearbeitung mit hohem Vorschub eine Erweichung des Lotes durch die Schnittwärme vermieden.

![]()

- Die beschichtete CBN-Sorte „BXA10“ für das Drehen von gehärtetem Stahl ist die erste Wahl für die kontinuierliche bis leicht unterbrochene Bearbeitung.

- Kraterverschleißfestes CBN-Substrat für Prozesssicherheit.

- Einzigartige mehrschichtige PVD-Beschichtungstechnologie erhöht die Verschleißfestigkeit und Kantenzähigkeit der Sorte für maximale Standzeiten.