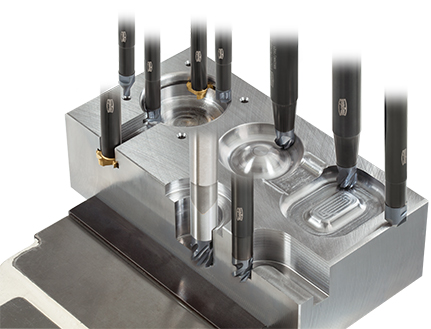

Schaftfräser mit austauschbaren Köpfen für kürzere Werkzeugwechselzeiten

Wählen Sie die beste Kopf-Schaft-Kombination für Ihre Fräsanwendung

Minimieren Sie die Rüstzeit und maximieren Sie Ihre Produktivität

Anwendungen & Eigenschaften

Anwendungen

Eigenschaften

1. Große Auswahl an Geometrien

• 45 verschiedene Geometrien sind verfügbar. Mit dem Präzisionsgewinde ist der Austausch des Fräskopfs einfach und hochgenau.

2. Drei Arten von Schaftmaterial

• Der Anwender kann die für ihn am besten geeignete Kombination je nach den Bearbeitungsparametern, der Länge und der gewünschten Anwendung auswählen.

3. Keine Einrichtungszeit

Die Stillstandszeit der Maschine wird erheblich reduziert. Vereinfachtes Einrichten, da nur der Kopf indexiert wird.

4. Hohe Genauigkeit und Wiederholbarkeit

Wiederholbarkeit und Genauigkeit werden durch den vollständigen Kontakt von Kegel und Fläche gewährleistet.

Köpfe & Sorten

Wendeschneidplatten

Quadratische Köpfe

Planfräsköpfe

Fräsköpfe zum Hochvorschub-Fräsen

Sorten

AH725

![]()

![]()

![]()

![]()

- Nano-Multilayer-Beschichtung

- Priorität auf Vermeidung von Abplatzen und Bruchsicherheit

AH715

![]()

![]()

![]()

![]()

![]()

- Nano-Multilayer-Beschichtung

- Hervorragende längere Standzeit als bestehende Sorten

GH130

![]()

![]()

![]()

- Hohe Zerspanungs- und Bruchsicherheit

- Geeignet für Stahl, rostfreien Stahl und Gusseisen

GH730

![]()

![]()

![]()

![]()

![]()

- Gutes Gleichgewicht zwischen Verschleiß- und Zerspanungsfestigkeit

- Erste Wahl für das Schlitzen von verschiedenen Materialien

Zubehör

Schaft

Gerader Hals und zylindrischer Schaft

Gerader Schaft und Hals mit Kühlmittelbohrung

Gerader Hals und Weldon Schaft

Schaft mit hoher Stabilität

Gerader Schaft und konischer Hals

Zylinderschaft und Kegelhals mit Kühlmittelbohrung

Praxis-Beispiele

Beispiel 1

| Werkstück: | Getriebe |

| Material: | SCM420 / 18CrMo4 |

| Schaft: | VSSD16L100S10-S (Steel, ø16 mm) |

| Kopf: | VEE160L12.0C60I04S10 (ø16 mm) |

| Sorte: | AH715 |

| Schnittbedingungen: | Vc = 100 (m/min) fz = 0.09 (mm/Z) ap = 10 (mm) ae = 0.1 (mm) Kühlmittel: Nass |

Beispiel 2

| Werkstück: | Welle |

| Material: | S45C / C45 |

| Schaft: | VSSD10L075S06-S (Steel, ø10 mm) |

| Kopf: | VEH100L15.0R10I04S06 (ø10 mm) |

| Sorte: | AH715 |

| Schnittbedingungen: | Vc = 100 (m/min) fz = 0.05 (mm/Z) ap = 1 (mm) ae = 6 (mm) Kühlmittel: Nass |

Beispiel 3

| Werkstück: | Zahnstange |

| Material: | SCM440 / 42CrMo4 |

| Schaft: | VSSD25L075S12-S (Steel, ø25 mm) |

| Kopf: | VEH200L30.0R05I04S12 (ø20 mm) |

| Sorte: | AH715 |

| Schnittbedingungen: | Vc = 140 (m/min) fz = 0.08 (mm/Z) ap = 24 (mm) ae = 5.5 (mm) Kühlmittel: Nass |

Standard-Schnittbedingungen

Quadratisch - Schulterfräsen

VEH, VEE: 3 Flöten, VED / VEE: 4 Flöten, VEE-A, VEE-I, VEE-R, VED-R, VEE-C

| ISO | Material des Werkstücks | Härte | Schnittgeschw. Vc (m/min) | Zahnvorschub: fz (mm/Z) | Schnitttiefe ap (mm) |

Schnittbreite ae(mm) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Werkzeug-Durchmesser: DC (mm) | ||||||||||||||

| 5 | 6 | 8 | 10 | 12 | 16 | 20 | 25 | 32 | ||||||

|

Kohlenstoffstahl S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 80 – 180 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC |

| Legierter Stahl SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 60 – 140 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC | |

| Vorgehärteter Stahl PX5, NAK80, etc. |

30 – 40 HRC | 60 – 120 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC | |

|

Rostfreier Stahl SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 40 – 100 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC |

|

Grauguss FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 80 – 200 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC |

| Kugrlgraphitguss FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 80 – 200 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC | |

|

Aluminium-Legierungen Si < 13% |

– | 200 – 700 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC |

| Aluminium-LegierungenSi ≥ 13% | – | 100 – 300 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC | |

|

Titan-Legierungen Ti-6Al-4V, etc. |

– 40 HRC | 40 – 80 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC |

| Hitzebeständige Legierungen Inconel 718, etc. |

– 40 HRC | 20 – 40 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC | |

|

Gehärteter Stahl SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 40 – 80 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC |

| Gehärteter Stahl SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 20 – 60 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC | |

VED / VEE: 6 Flöten, VED / VEE: 8, 10 Flöten, VED: 7, 9 Flöten

| ISO | Material des Werkstücks | Härte | Schnittgeschw. Vc (m/min) |

Zahnvorschub: fz (mm/Z) | Schnitttiefe ap (mm) |

Schnittbreite ae(mm) |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Werkzeug-Durchmesser: DC (mm) | |||||||||||

| 8 | 10 | 12 | 16 | 20 | 25 | ||||||

|

Titan-Legierungen Ti-6Al-4V, etc. |

– | 60 – 120 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.6 x DC | 0.02 x DC |

| Hitzebeständige Legierungen Inconel 718, etc. |

– | 30 – 60 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.6 x DC | 0.02 x DC | |

|

Gehärteter Stahl SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 80 – 160 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.6 x DC | 0.02 x DC |

| Gehärteter Stahl SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 40 – 90 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.6 x DC | 0.02 x DC | |

Quadratisch - Schlitzen

VEH, VEE: 3 Flöten, VED/VEE: 4 Flöten, VEE-A, VEE-I, VEE-R, VEE-C

| ISO | Material des Werkstücks | Härte | Schnittgeschw. Vc (m/min) | Zahnvorschub: fz (mm/Z) | Schnitttiefe ap (mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Werkzeug-Durchmesser: DC (mm) | |||||||||||||

| 5 | 6 | 8 | 10 | 12 | 16 | 20 | 25 | 32 | |||||

|

Kohlenstoffstahl S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 50 – 70 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC |

| Legierter Stahl SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 40 – 80 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC | |

| Vorgehärteter Stahl PX5, NAK80, etc. |

30 – 40 HRC | 40 – 70 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC | |

|

Rostfreier Stahl SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 30 – 60 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC |

|

Grauguss FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 50 – 120 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC |

| Kugelgraphitguss FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 50 – 120 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC | |

|

Aluminium-Legierungen Si < 13% |

– | 130 – 400 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC |

| Aluminium-Legierungen Si ≥ 13% |

– | 70 – 200 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC | |

|

Titan-Legierungen Ti-6Al-4V, etc. |

– 40 HRC | 20 – 40 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC |

| Hitzebeständige Legierungen Inconel 718, etc. |

– 40 HRC | 10 – 20 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC | |

|

Gehärteter Stahl SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 25 – 60 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC |

| Gehärteter Stahl SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 10 – 30 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC | |

VED-RS

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) | Shoulder milling | Slotting | Depth of cut ap (mm) |

Width of cut ae (mm) |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Feed per tooth: fz (mm/t) | |||||||||||

| Tool diameter: DC (mm) | |||||||||||

| 6 | 8 | 10 | 6 | 8 | 10 | ||||||

|

Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 80 – 140 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.5 x DC | 0.15 x DC |

| Alloy steel SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 60 – 120 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.5 x DC | 0.15 x DC | |

| Prehardened steel PX5, NAK80, etc. |

30 – 40 HRC | 60 – 100 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.5 x DC | 0.15 x DC | |

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 40 – 80 | 0.03 – 0.05 | 0.05 – 0.07 | 0.05 – 0.07 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.5 x DC | 0.15 x DC |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 80 – 140 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.5 x DC | 0.15 x DC |

| Ductile cast iron FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 80 – 140 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.5 x DC | 0.15 x DC | |

|

Aluminium alloys Si < 13% |

– | 200 – 500 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.5 x DC | 0.15 x DC |

| Aluminium alloys Si ≧ 13% |

– | 100 – 200 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.5 x DC | 0.15 x DC | |

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | 40 – 60 | 0.03 – 0.05 | 0.05 – 0.07 | 0.05 – 0.07 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.5 x DC | 0.15 x DC |

| Heat-resistant alloys Inconel 718, etc. |

– 40 HRC | 20 – 30 | 0.03 – 0.05 | 0.05 – 0.07 | 0.05 – 0.07 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.5 x DC | 0.15 x DC | |

|

Hardened steel SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 40 – 60 | 0.03 – 0.05 | 0.05 – 0.07 | 0.05 – 0.07 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.5 x DC | 0.15 x DC |

| Hardened steel SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 20 – 40 | 0.03 – 0.05 | 0.03 – 0.05 | 0.05 – 0.07 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.5 x DC | 0.15 x DC | |

Planfräsen

VFM

| ISO | Material des Werkstücks | Härte | Schnittgeschw. Vc (m/min) | Zahnvorschub: fz (mm/Z) | Schnitttiefe

ap (mm) |

Schnittbreite

ae(mm) |

|||

|---|---|---|---|---|---|---|---|---|---|

| Werkzeug-Durchmesser: DC (mm) | |||||||||

| 12 | 16 | 20 | 25 | ||||||

|

Kohlenstoffstahl S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 80 – 180 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC |

| Legierter Stahl SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 60 – 140 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC | |

| Vorgehärteter Stahl PX5, NAK80, etc. |

30 – 40 HRC | 60 – 120 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC | |

|

Rostfreier Stahl SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 40 – 100 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC |

|

Grauguss FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 80 – 200 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC |

| Kugelgraphitguss FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 80 – 200 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC | |

|

Aluminium-Legierungen Si < 13% |

– | 200 – 700 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC |

| Aluminium-Legierungen Si ≥ 13% |

– | 100 – 300 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC | |

|

Titan-Legierungen Ti-6Al-4V, etc. |

– 40 HRC | 40 – 80 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC |

| Hitzebeständige Legierungen Inconel 718, etc. |

– 40 HRC | 20 – 40 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC | |

|

Gehärteter Stahl SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 40 – 80 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC |

| Gehärteter Stahl SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 20 – 60 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC | |

Hochvorschub-Fräsen

VFX: 2, 4, 6 Flöten

| ISO | Material des Werkstücks | Härte | Schnittgeschw. Vc (m/min) | ø10 | ø12 | ø16 | ø20 | Schnittbreite ae (mm) |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Zahnvorschub fz (mm/Z) |

Schnitttiefe ap (mm) |

Zahnvorschub fz (mm/Z) |

Schnitttiefe ap (mm) |

Zahnvorschub fz (mm/Z) |

Schnitttiefe ap (mm) |

Zahnvorschub fz (mm/Z) |

Schnitttiefe ap (mm) |

|||||

|

Kohlenstoffstahl S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 100 – 200 | 0.3 – 0.7 | 0.5 | 0.4 – 0.8 | 0.5 | 0.5 – 0.9 | 0.75 | 0.6 – 1 | 1 | 0.6 x DC |

| Legierter Stahl SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 80 – 180 | 0.2 – 0.6 | 0.5 | 0.3 – 0.7 | 0.5 | 0.4 – 0.8 | 0.75 | 0.5 – 0.9 | 1 | 0.6 x DC | |

| Vorgehärteter Stahl PX5, NAK80, etc. |

30 – 40 HRC | 80 – 160 | 0.2 – 0.5 | 0.4 | 0.2 – 0.5 | 0.4 | 0.3 – 0.6 | 0.5 | 0.3 – 0.6 | 0.75 | 0.6 x DC | |

|

Rostfreier Stahl SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 60 – 100 | 0.2 – 0.6 | 0.4 | 0.2 – 0.6 | 0.4 | 0.3 – 0.7 | 0.5 | 0.3 – 0.7 | 0.75 | 0.6 x DC |

|

Grauguss FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 100 – 220 | 0.3 – 0.7 | 0.5 | 0.4 – 0.8 | 0.75 | 0.5 – 0.9 | 0.75 | 0.6 – 1 | 1 | 0.6 x DC |

| Kugelgraphitguss FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 100 – 220 | 0.2 – 0.6 | 0.5 | 0.3 – 0.7 | 0.75 | 0.4 – 0.8 | 0.75 | 0.5 – 0.9 | 1 | 0.6 x DC | |

|

Titan-Legierungen Ti-6Al-4V, etc. |

– 40 HRC | 40 – 80 | 0.2 – 0.5 | 0.4 | 0.2 – 0.5 | 0.4 | 0.2 – 0.6 | 0.5 | 0.2 – 0.6 | 0.5 | 0.25 x DC |

| Hitzebeständige Legierungen Inconel 718, etc. |

– 40 HRC | 20 – 40 | 0.1 – 0.3 | 0.3 | 0.1 – 0.3 | 0.3 | 0.1 – 0.3 | 0.4 | 0.1 – 0.3 | 0.4 | 0.25 x DC | |

|

Gehärteter Stahl SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 40 – 80 | 0.2 – 0.4 | 0.3 | 0.2 – 0.4 | 0.3 | 0.3 – 0.5 | 0.4 | 0.3 – 0.5 | 0.4 | 0.45 x DC |

| Gehärteter Stahl SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 20 – 60 | 0.1 – 0.2 | 0.2 | 0.1 – 0.2 | 0.2 | 0.1 – 0.3 | 0.3 | 0.1 – 0.3 | 0.3 | 0.25 x DC | |

Bitte beachten Sie, dass der Vorschub pro Schneide den maximalen Vorschub pro Schneide für jedes Produkt nicht überschreiten sollte.

Kugel - Profilieren zum Schruppen

VBB-BM / BG / SG, VBD-BG, VBE-BGA

| ISO | Material des Werkstücks | Härte | Schnittgeschw. Vc (m/min) | Zahnvorschub: fz (mm/Z) | Schnitttiefe

ap (mm) |

Taktvorschub Pf (mm) |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Werkzeug-Durchmesser: DC (mm) | |||||||||||||

| 5 | 6 | 8 | 10 | 12 | 16 | 20 | 25 | ||||||

|

Kohlenstoffstahl S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 100 – 200 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.4 x DC |

| Legierter Stahl SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 80 – 180 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.4 x DC | |

| Vorgehärteter Stahl PX5, NAK80, etc. |

30 – 40 HRC | 80 – 160 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.4 x DC | |

|

Rostfreier Stahl SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 60 – 100 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.4 x DC |

|

Grauguss FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 100 – 220 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.4 x DC |

| Kugelgraphitguss FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 100 – 220 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.4 x DC | |

|

Aluminium-Legierungen Si < 13% |

– | 200 – 700 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.4 x DC |

| Aluminium-Legierungen Si ≥ 13% |

– | 100 – 300 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.4 x DC | |

|

Titan-Legierungen Ti-6Al-4V, etc. |

– 40 HRC | 40 – 80 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.2 x DC |

| Hitzebeständige Legierungen Inconel 718, etc. |

– 40 HRC | 20 – 40 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.2 x DC | |

|

Gehärteter Stahl SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 40 – 80 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.2 x DC |

| Gehärteter Stahl SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 20 – 60 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.2 x DC | |

Kugel - Profilieren für Vorschlichten und Schlichten

VBB-BM / BG / SG, VBD-BG, VBE-BGA

| ISO | Material des Werkstücks | Härte | Schnittgeschw. Vc (m/min) |

Zahnvorschub: fz (mm/Z) | Schnitttiefe ap (mm) |

Taktvorschub Pf (mm) |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Werkzeug-Durchmesser: DC (mm) | |||||||||||||

| 5 | 6 | 8 | 10 | 12 | 16 | 20 | 25 | ||||||

|

Kohlenstoffstahl S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 120 – 250 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.1 x DC | 0.15 x DC |

| Legierter Stahl SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 100 – 220 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.1 x DC | 0.15 x DC | |

| Vorgehärteter Stahl PX5, NAK80, etc. |

30 – 40 HRC | 100 – 200 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.1 x DC | 0.15 x DC | |

|

Rostfreier Stahl SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 80 – 120 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.1 x DC | 0.15 x DC |

|

Grauguss FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 120 – 280 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.1 x DC | 0.15 x DC |

| Kugelgraphitguss FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 120 – 280 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.1 x DC | 0.15 x DC | |

|

Aluminium-Legierungen Si < 13% |

– | 300 – 1000 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.1 x DC | 0.15 x DC |

| Aluminium-Legierungen Si ≥ 13% |

– | 150 – 400 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.1 x DC | 0.15 x DC | |

|

Titan-Legierungen Ti-6Al-4V, etc. |

– 40 HRC | 50 – 100 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.08 x DC | 0.1 x DC |

| Hitzebeständige Legierungen Inconel 718, etc. |

– 40 HRC | 30 – 50 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.08 x DC | 0.1 x DC | |

|

Gehärteter Stahl SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 50 – 100 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.08 x DC | 0.1 x DC |

| Gehärteter Stahl SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 30 – 80 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.08 x DC | 0.1 x DC | |

Radius - Schulterfräsen

VRB, VRC, VRD

| ISO | Material des Werkstücks | Härte | Schnittgeschw. Vc (m/min) | Zahnvorschub: fz (mm/Z) | Schnitttiefe ap (mm) |

Schnittbreite ae(mm) |

||||

|---|---|---|---|---|---|---|---|---|---|---|

| Werkzeug-Durchmesser: DC (mm) | ||||||||||

| 8 | 10 | 12 | 16 | 20 | ||||||

|

Kohlenstoffstahl S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 80 – 180 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC |

| Legierter Stahl SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 60 – 140 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC | |

| Vorgehärteter Stahl PX5, NAK80, etc. |

30 – 40 HRC | 60 – 120 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC | |

|

Rostfreier Stahl SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 40 – 100 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC |

|

Grauguss FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 80 – 200 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC |

| Kugelgraphitguss FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 80 – 200 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC | |

|

Aluminium-Legierungen Si < 13% |

– | 200 – 700 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC |

| Aluminium-Legierungen Si ≥ 13% |

– | 100 – 300 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC | |

|

Titan-Legierungen Ti-6Al-4V, etc. |

– 40 HRC | 40 – 80 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC |

| Hitzebeständige Legierungen Inconel 718, etc. |

– 40 HRC | 20 – 40 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC | |

|

Gehärteter Stahl SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 40 – 80 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC |

| Gehärteter Stahl SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 20 – 60 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC | |

Radius - Schlitzen

VRB, VRC, VRD

| ISO | Material des Werkstücks | Härte | Schnittgeschw. Vc (m/min) | Zahnvorschub: fz (mm/Z) | Schnitttiefe ap (mm) |

||||

|---|---|---|---|---|---|---|---|---|---|

| Werkzeug-Durchmesser: DC (mm) | |||||||||

| 8 | 10 | 12 | 16 | 20 | |||||

|

Kohlenstoffstahl S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 50 – 70 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC |

| Legierter Stahl SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 40 – 80 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC | |

| Vorgehärteter Stahl PX5, NAK80, etc. |

30 – 40 HRC | 40 – 70 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC | |

|

Rostfreier Stahl SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 30 – 60 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC |

|

Grauguss FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 50 – 120 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC |

| Kugelgraphitguss FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 50 – 120 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC | |

|

Aluminium-Legierungen Si < 13% |

– | 130 – 400 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC |

| Aluminium-Legierungen Si ≥ 13% |

– | 70 – 200 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC | |

|

Titan-Legierungen Ti-6Al-4V, etc. |

– 40 HRC | 20 – 40 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC |

| Hitzebeständige Legierungen Inconel 718, etc. |

– 40 HRC | 10 – 20 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC | |

|

Gehärteter Stahl SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 25 – 60 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC |

| Gehärteter Stahl SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 10 – 30 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC | |

Faß, Bull Nose, Linse - Profilierung

VBO, VBN, VBL

| ISO | Material des Werkstücks | Härte | Schnittgeschw. Vc (m/min) | Zahnvorschub: fz (mm/Z) | Cusp-Höhe (mm) | ||

|---|---|---|---|---|---|---|---|

| Werkzeug-Durchmesser: DC (mm) | |||||||

| 10 | 12 | 16 | |||||

|

Stahl mit niedrigem Kohlenstoffgehalt S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 100 – 200 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 |

| Stahl mit hohem Kohlenstoffgehalt SCM440, SCr415, etc. 42CrMo4, 15Cr3, etc. |

– 300 HB | 80 – 180 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 | |

| Vorgehärteter Stahl PX5, NAK80, etc. |

30 – 40 HRC | 80 – 160 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 | |

|

Rostfreier Stahl SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 60 – 100 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 |

|

Grauguss FC250, FC300, etc. 250, 300, etc. |

150 – 250 HB | 100 – 220 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 |

| Kugelgraphitguss FCD400, etc. 400-15S, etc. |

150 – 250 HB | 100 – 220 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 | |

|

Aluminium-Legierungen Si < 13% |

– | 200 – 700 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 |

| Aluminium-Legierungen Si ≥13% |

– | 100 – 300 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 | |

|

Titan-Legierungen Ti-6Al-4V, etc. |

– 40 HRC | 40 – 80 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 |

| Hitzebeständige Legierungen Inconel718, etc. |

– 40 HRC | 20 – 40 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 | |

|

Gehärteter Stahl SKD61, SKT4, etc. X40CrMoV5-1, 55NiCrMoV6, etc. |

– 40 HRC | 40 – 80 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 |

| Gehärteter Stahl SKD11, SKH, etc. X153CrMoV12, HS18-0-1, etc. |

50 – 60 HRC | 20 – 60 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 | |

Anfasen und Ansenken (Fräsen, Z-Vorschub-Fasen)

VCA, VCW, VCR

| ISO | Material des Werkstücks | Härte | Schnittgeschw. Vc (m/min) |

Zahnvorschub fz (mm/Z) |

|---|---|---|---|---|

|

Kohlenstoffstahl S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 60 – 100 | 0.03 – 0.06 |

| Legierter Stahl SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 50 – 80 | 0.03 – 0.06 | |

| Vorgehärteter Stahl PX5, NAK80, etc. |

30 – 40 HRC | 40 – 70 | 0.03 – 0.06 | |

|

Rostfreier Stahl SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 30 – 50 | 0.03 – 0.06 |

|

Grauguss FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 80 – 120 | 0.03 – 0.06 |

| Kugelgraphitguss FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 80 – 120 | 0.03 – 0.06 | |

|

Aluminium-Legierungen | – | 100 – 200 | 0.04 – 0.08 |

|

Titan-Legierungen Ti-6Al-4V, etc. |

– 40 HRC | 30 – 50 | 0.025 – 0.05 |

| Hitzebeständige Legierungen Inconel 718, etc. |

– 40 HRC | 20 – 40 | 0.02 – 0.04 | |

|

Gehärteter Stahl SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 30 – 50 | 0.025 – 0.05 |

| Gehärteter Stahl SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 20 – 40 | 0.02 – 0.04 |

Anbohren

VCP, VDS

| ISO | Material des Werkstücks | Härte | Schnittgeschw. Vc (m/min) |

Vorschub f (mm/U) |

|---|---|---|---|---|

|

Kohlenstoffstahl S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 60 – 100 | 0.06 – 0.12 |

| Legierter Stahl SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 50 – 80 | 0.06 – 0.12 | |

| Vorgehärteter Stahl PX5, NAK80, etc. |

30 – 40 HRC | 40 – 70 | 0.06 – 0.12 | |

|

Rostfreier Stahl SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 30 – 50 | 0.06 – 0.12 |

|

Grauguss FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 80 – 120 | 0.06 – 0.12 |

| Kugelgraphitguss FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 80 – 120 | 0.06 – 0.12 | |

|

Aluminium-Legierungen | – | 100 – 200 | 0.08 – 0.16 |

|

Titan-Legierungen Ti-6Al-4V, etc. |

– 40 HRC | 30 – 50 | 0.05 – 0.1 |

| Hitzebeständige Legierungen Inconel 718, etc. |

– 40 HRC | 20 – 40 | 0.04 – 0.08 | |

|

Gehärteter Stahl SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 30 – 50 | 0.05 – 0.1 |

| Gehärteter Stahl SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 20 – 40 | 0.04 – 0.08 |

Zentrierbohren

VDP

| ISO | Material des Werkstücks | Härte | Schnittgeschw. Vc (m/min) | Vorschub: f (mm/U) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| VDP107 | VDP165 | VDP2 | VDP3 | VDP4 | VDP5 | VDP6 | ||||

|

Kohlenstoffstahl S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 40 – 80 | 0.02 – 0.04 | 0.025 – 0.05 | 0.025 – 0.05 | 0.04 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.06 – 0.12 |

| Legierter Stahl SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 30 – 50 | 0.02 – 0.04 | 0.025 – 0.05 | 0.025 – 0.05 | 0.04 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.06 – 0.12 | |

| Vorgehärteter Stahl PX5, NAK80, etc. |

30 – 40 HRC | 20 – 30 | 0.02 – 0.04 | 0.025 – 0.05 | 0.025 – 0.05 | 0.04 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.06 – 0.12 | |

|

Rostfreier Stahl SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 15 – 25 | 0.015 – 0.03 | 0.02 – 0.04 | 0.02 – 0.04 | 0.04 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.06 – 0.12 |

|

Grauguss FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 60 – 100 | 0.02 – 0.04 | 0.025 – 0.05 | 0.025 – 0.05 | 0.05 -0.09 | 0.07 – 0.012 | 0.07 – 0.12 | 0.12 – 0.18 |

| Kugelgraphitguss FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 60 – 100 | 0.02 – 0.04 | 0.025 – 0.05 | 0.025 – 0.05 | 0.04 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.1 – 0.15 | |

|

Titan-Legierungen Ti-6Al-4V, etc. |

– 40 HRC | 15 – 25 | 0.01 – 0.02 | 0.01 – 0.02 | 0.015 – 0.03 | 0.04 – 0.07 | 0.04 – 0.07 | 0.04 – 0.07 | 0.04 – 0.07 |

| Hitzebeständige Legierungen Inconel 718, etc. |

– 40 HRC | 10 – 20 | 0.01 – 0.02 | 0.01 – 0.02 | 0.015 – 0.03 | 0.03 – 0.06 | 0.03 – 0.06 | 0.03 – 0.06 | 0.03 – 0.06 | |

|

Gehärteter Stahl SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 15 – 25 | – | – | – | 0.04 – 0.07 | 0.04 – 0.07 | 0.04 – 0.07 | 0.04 – 0.07 |

| Gehärteter Stahl SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 10 – 20 | – | – | – | 0.03 – 0.06 | 0.03 – 0.06 | 0.03 – 0.06 | 0.03 – 0.06 | |

—0.03 – 0.060.03 – 0.060.03 – 0.060.03 – 0.06

Senkerodieren

VGC

| ISO | Material des Werkstücks | Härte | Schnittgeschw. Vc (m/min) |

Zahnvorschub fz (mm/Z) |

|---|---|---|---|---|

|

Kohlenstoffstahl S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 40 – 80 | 0.04 – 0.08 |

| Legierter Stahl SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 30 – 50 | 0.04 – 0.08 | |

| Vorgehärteter Stahl PX5, NAK80, etc. |

30 – 40 HRC | 20 – 30 | 0.04 – 0.08 | |

|

Rostfreier Stahl SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 15 – 25 | 0.04 – 0.08 |

|

Grauguss FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 60 – 100 | 0.05 – 0.09 |

| Kugelgraphitguss FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 60 – 100 | 0.04 – 0.08 | |

|

Titan-Legierungen Ti-6Al-4V, etc. |

– 40 HRC | 15 – 25 | 0.04 – 0.07 |

| Hitzebeständige Legierungen Inconel 718, etc. |

– 40 HRC | 10 – 20 | 0.03 – 0.06 | |

|

Gehärteter Stahl SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 15 – 25 | 0.04 – 0.07 |

| Gehärteter Stahl SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 10 – 20 | 0.03 – 0.06 |

Beim Bohren sollte mit einer Tiefe von 0,3 – 0,5 mm pro Schritt gebohrt werden.

Wenden Sie beim Schulterfräsen oder Schlitzen die gleichen Schnittbedingungen wie beim VEE-Kopf an.

Schlitzen

| ISO | Material des Werkstücks | Härte | VST | VTB | ||

|---|---|---|---|---|---|---|

| Schnittgeschw. Vc (m/min) |

Zahnvorschub fz (mm/Z) |

Schnittgeschw. Vc (m/min) |

Zahnvorschub fz (mm/Z) |

|||

|

Kohlenstoffstahl S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 80 – 180 | 0.05 – 0.15 | 80 – 180 | 0.08 – 0.18 |

| Legierter Stahl SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 60 – 120 | 0.04 – 0.12 | 60 – 120 | 0.05 – 0.15 | |

|

Rostfreier Stahl SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 50 – 120 | 0.04 – 0.12 | 50 – 120 | 0.05 – 0.15 |

|

Grauguss FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 100 – 200 | 0.05 – 0.15 | 100 – 200 | 0.08 – 0.18 |

| Kugelgraphitguss FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 100 – 200 | 0.04 – 0.12 | 100 – 200 | 0.05 – 0.15 | |

|

Aluminium-Legierungen Si < 13% |

– | 200 – 600 | 0.05 – 0.15 | 200 – 600 | 0.08 – 0.18 |

| Aluminium-Legierungen Si ≥ 13% |

– | 100 – 300 | 0.03 – 0.13 | 100 – 300 | 0.05 – 0.15 | |

|

Titan-Legierungen Ti-6Al-4V, etc. |

– 40 HRC | 40 – 60 | 0.04 – 0.12 | 40 – 60 | 0.05 – 0.15 |

| Hitzebeständige Legierungen Inconel 718, etc. |

– 40 HRC | 15 – 35 | 0.02 – 0.1 | 15 – 35 | 0.02 – 0.1 | |

modularer Wechsel-Kopf

HPAV06-S

| ISO | Werkstoffe des Werkstücks | Härte | Priorität | Sorte | Schnittgeschw. Vc (m/min) | Zahnvorschub fz (mm/Z) |

|

|---|---|---|---|---|---|---|---|

|

Stahl mit niedrigem Kohlenstoffgehalt S15C / C15E4, SS400 / E275A, etc. |

– 200 HB | Erste Wahl | AH3225 | 230 – 430 | 0.07 – 0.12 | |

| Kohlenstoffstahl und legierter Stahl S55C / C55, SCM440 / 42CrMo4, etc. |

– 300 HB | Erste Wahl | AH3225 | 150 – 350 | 0.07 – 0.12 | ||

| Vorgehärteter Stahl NAK80, PX5, etc. |

30 – 40 HRC | Erste Wahl | AH3225 | 100 – 230 | 0.07 – 0.12 | ||

|

Rostfreier Stahl SUS304 / X5CrNi18-9, SUS316 / X5CrNiMo17-12-3, etc. |

– | Erste Wahl | AH3135 | 150 – 220 | 0.06 – 0.1 | |

|

Grauguss FC250 / 250, FC300 / 300, etc. |

150 – 250 HB | Erste Wahl | AH120 | 200 – 330 | 0.07 – 0.12 | |

| Kugelgraphitguss FCD400, FCD600 / 600-3, etc. |

150 – 250 HB | Erste Wahl | AH120 | 150 – 240 | 0.07 – 0.12 | ||

|

Aluminium-Legierungen Si < 13% |

– | Erste Wahl | KS05F | 650 – 1000 | 0.07 – 0.12 | |

| Aluminium-Legierungen Si ≥ 13% |

– | Erste Wahl | KS05F | 100 – 230 | 0.04 – 0.12 | ||

|

Titan-Legierungen Ti-6AI-4V, etc. |

– 40 HRC | Erste Wahl | AH130 | 40 – 90 | 0.04 – 0.1 | |

| Superlegierungen Inconel718, etc. |

– 40 HRC | Erste Wahl | AH130 | 45 – 65 | 0.04 – 0.09 | ||

|

Gehärteter Stahl | SKD61 / X40CrMoV5-1, etc. |

40 – 50 HRC | Erste Wahl | AH120 | 45 – 70 | 0.04 – 0.08 |

| SKD11 / X153CrMoV12, etc. |

50 – 60 HRC | Erste Wahl | AH120 | 40 – 65 | 0.04 – 0.06 | ||

Gewindeschneiden

VMT, VTR

| ISO | Material | Zustand | Zugfestigkeit [N/mm2] | Härte HB |

Schnittgeschw. (m/min) |

Werkzeug-Ø(mm) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Vorschub (mm/Z) | ||||||||||

| AH725 | ø10 | ø12 | ø15.4, ø15.7, ø16 | ø21.7 | ||||||

|

Unlegierter Stahl und Stahlguss, Automatenstahl | < 0.25 %C | Geglüht | 420 | 125 HB | 100 – 250 | 0.08 | 0.09 | 0.12 | 0.15 |

| ≥ 0.25 %C | Geglüht | 650 | 190 HB | 80 – 210 | 0.08 | 0.09 | 0.12 | 0.15 | ||

| < 0.55 %C | Abgeschreckt und vergütet | 850 | 250 HB | 65 – 170 | ||||||

| ≥ 0.55 %C | Geglüht | 750 | 220 HB | 110 – 180 | 0.07 | 0.08 | 0.1 | 0.12 | ||

| Abgeschreckt und vergütet | 1000 | 300 HB | 95 – 160 | 0.07 | 0.08 | 0.1 | 0.12 | |||

| Niedrig legierter Stahl und Stahlguss (weniger als 5 % an Legierungselementen) |

Geglüht | 600 | 200 HB | 90 – 160 | 0.05 | 0.05 | 0.07 | 0.08 | ||

| Abgeschreckt und vergütet | 930 | 275 HB | 65 – 200 | 0.05 | 0.05 | 0.07 | 0.08 | |||

| 1000 | 300 HB | 70 – 210 | 0.05 | 0.05 | 0.07 | 0.08 | ||||

| 1200 | 350 HB | 95 – 160 | 0.05 | 0.05 | 0.07 | 0.08 | ||||

| Hochlegierter Stahl, Stahlguss und Werkzeugstahl | Geglüht | 680 | 200 HB | 130 – 170 | 0.05 | 0.05 | 0.07 | 0.08 | ||

| Abgeschreckt und vergütet | 1100 | 325 HB | 75 – 100 | 0.05 | 0.05 | 0.07 | 0.08 | |||

| Rostfreier Stahl und Stahlguss | Ferritisch/martensitisch | 680 | 200 HB | 110 – 170 | 0.05 | 0.05 | 0.07 | 0.08 | ||

| Martensitisch | 820 | 240 HB | 70 – 155 | 0.05 | 0.05 | 0.07 | 0.08 | |||

|

Rostfreier Stahl | Geglüht | 600 | 180 HB | 85 – 100 | 0.05 | 0.05 | 0.07 | 0.08 | |

|

Sphäroguss (GGG) | Ferritisch/martensitisch | 180 HB | 120 – 160 | 0.08 | 0.09 | 0.12 | 0.15 | ||

| Perlitisch | 260 HB | 75 – 160 | 0.08 | 0.09 | 0.12 | 0.15 | ||||

| Grauguss (GG) | Ferritisch | 160 HB | 70 – 150 | 0.08 | 0.09 | 0.12 | 0.15 | |||

| Perlitisch | 250 HB | 110 – 140 | 0.08 | 0.09 | 0.12 | 0.15 | ||||

| Verformbares Grauguss | Ferritisch | 130 HB | 120 – 160 | 0.08 | 0.09 | 0.12 | 0.15 | |||

| Perlitisch | 230 HB | 110 – 140 | 0.08 | 0.09 | 0.21 | 0.15 | ||||

|

Aluminium-Knetlegierung | Nicht härtbar | 60 HB | 160 – 300 | 0.08 | 0.09 | 0.12 | 0.15 | ||

| Gehärtet | 100 HB | |||||||||

| Aluminium-Guss, legiert | ≤12% Si | Nicht härtbar | 75 HB | 150 – 350 | 0.08 | 0.09 | 0.12 | 0.15 | ||

| Gehärtet | 90 HB | |||||||||

| >12% Si | Hohe Temperatur | 130 HB | 100 – 250 | 0.05 | 0.05 | 0.07 | 0.08 | |||

| Kupferlegierungen | >1% Pb | Freies Schneiden | 110 HB | |||||||

| Messing | 90 HB | |||||||||

| Elektrolitisches Kupfer | 100 HB | |||||||||

| Nicht-metallisch | Duroplaste, Faserkunststoffe | 100 – 400 | 0.11 | 0.12 | 0.15 | 0.18 | ||||

| Hartgummi | ||||||||||

|

Hochtemperatur-Legierungen | Fe-Basis | Geglüht | 200 HB | ||||||

| Gehärtet | 280 HB | |||||||||

| Ni- oder Co-Basis | Geglüht | 250 HB | 20 – 80 | 0.03 | 0.03 | 0.04 | 0.04 | |||

| Gehärtet | 350 HB | |||||||||

| Cast | 320 HB | |||||||||

| Titanium Ti-Legierungen | RM 400 | |||||||||

| Alpha+beta-Legierungen gehärtet | RM 1050 | 20 – 80 | 0.03 | 0.03 | 0.04 | 0.04 | ||||

|

Gehärteter Stahl | Gehärtet | 55 HRC | 55 – 65 | ||||||

| Gehärtet | 60 HRC | 45 – 55 | ||||||||

| Gekühltes Grauguss | Gießen | 400 HB | 90 – 105 | |||||||

| Grauguss | Gehärtet | 55 HRC | 55 – 65 | |||||||

Multi Functional

VVFH

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) | Drilling | Shoulder milling | Slotting | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Feed per revolution: f (mm/rev) | Feed per tooth: fz (mm/t) | |||||||||

| Tool diameter: DC (mm) | ||||||||||

| 6 | 8 | 10 | 6 | 8 | 10 | |||||

|

Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 80 – 180 | 0.12 – 0.18 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 |

| Alloy steel SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 60 – 140 | 0.12 – 0.18 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | |

| Prehardened steel PX5, NAK80, etc. |

30 – 40 HRC | 60 – 120 | 0.12 – 0.18 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | |

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 40 – 100 | 0.09 – 0.15 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 80 – 200 | 0.12 – 0.18 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 |

| Ductile cast iron FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 80 – 200 | 0.12 – 0.18 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | |

|

Aluminium alloys Si < 13% |

– | 200 – 700 | 0.09 – 0.15 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 |

| Aluminium alloys Si ≧ 13% |

– | 100 – 300 | 0.09 – 0.15 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | |

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | 40 – 80 | 0.02 – 0.05 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 |

| Heat-resistant alloys Inconel 718, etc. |

– 40 HRC | 20 – 40 | 0.02 – 0.05 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | |

|

Hardened steel SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 40 – 80 | 0.06 – 0.09 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 |

| Hardened steel SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 20 – 60 | 0.06 – 0.09 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.04 – 0.05 | 0.04 – 0.05 | 0.04 – 0.05 | |

Weitere Informationen zu diesem Produkt finden Sie in unserem Online-Katalog oder im Produktbericht, den Sie herunterladen können:

e-Catalog

- Haupt-Broschüre: PDF (englisch)

- Haupt-Broschüre_Apr.2025: PDF (deutsch)

Erweiterungen

- Erweiterungs-Broschüre: AH715, PDF (englisch)

- Erweiterungs-Broschüre: Lange Schneiden, hochstabile Schäfte,VFM-Planfräskopf, PDF (deutsch)

- Erweiterungs-Broschüre: VBO VBN, PDF (deutsch)

- Erweiterungs-Broschüre: Erweiterungs-Sorte und Kopf-Sortiment

- Erweiterungs-Broschüre: VER shank

- Erweiterungs-Broschüre: AH715 grade heads