High-feed cutter for a wide range of applications

DoFeed offers outstanding productivity due to its close-pitch insert orientation and light cutting geometry

The rich lineup is suitable for a wide variety of milling applications

Applications & Features

Applications

Features

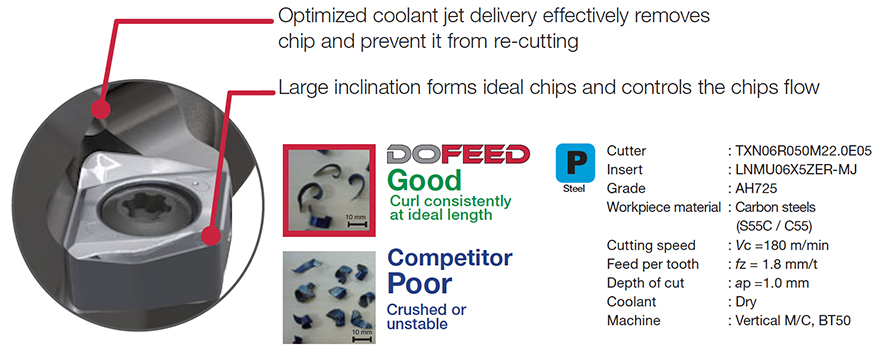

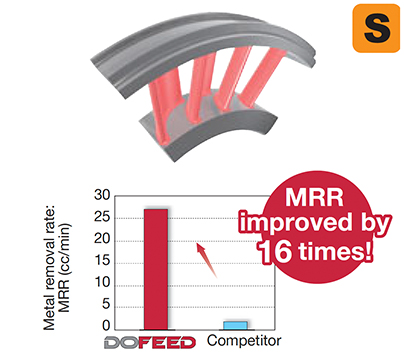

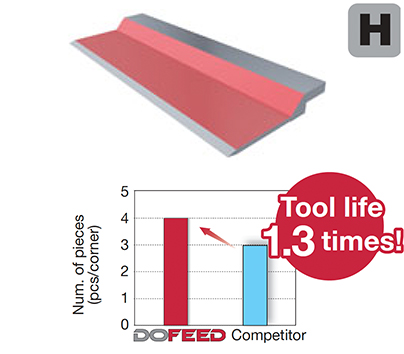

1. Outstanding productivity

– Excellent chip evacuation prevents chip packing.

– Innovative geometry allows for extremely light cutting for negative inserts.

– Close pitch cutters for high productivity.

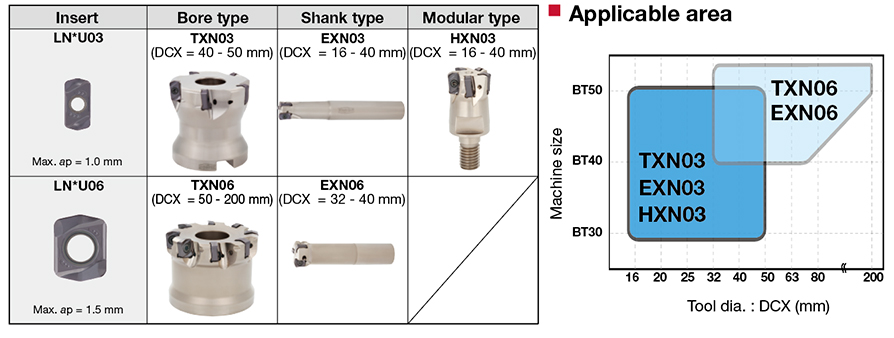

2. Rich lineup of cutter bodies from ø16 to ø200 mm

Inserts & Grades

Inserts

Main Grades

AH130

![]()

![]()

- High chipping and fracture resistance

- Designed for machining austenitic stainless steel under general cutting conditions

AH3225

![]()

![]()

- Good balance between wear and fracture resistance

- Suitable for steel and stainless steel

AH725

![]()

![]()

![]()

![]()

- Good balance between wear and chipping resistance

- Suitable for machining steel and stainless steel under general cutting conditions

AH8015

![]()

![]()

![]()

![]()

![]()

- Good balance between wear and fracture resistance

- First choice for machining heat-resistant alloy under general cutting conditions

Cutter bodies

Practical examples

Example #1

Die and mold Industry

| Part: | Mold |

| Material: | S45C / C45 (20 – 35 HRC) |

| Cutter: | TXN06R063M22.0E04 (ø63, z = 4) |

| Insert: | LNMU06X5ZER-MJ |

| Grade: | AH3225 |

| Cutting conditions: | Vc = 197 (m/min) fz = 1.5 (mm/t) ap = 0.75 (mm) ae = 45 (mm) Application: Contouring Coolant: Dry Machine: Vertical M/C, BT50 |

Example #2

Aerospace Industry

| Part: | Turbine blade |

| Material: | Heat resistant cast steel |

| Cutter: | EXN03R030M32.0-05 (ø30, z = 5) |

| Insert: | LNMU0303ZER-ML |

| Grade: | AH725 |

| Cutting conditions: | Vc = 70 (m/min) fz = 0.5 (mm/t) ap = 0.5 (mm) ae = 30 (mm) Application: Shoulder milling Coolant: Wet Machine: Vertical M/C, BT50 |

Example #3

Die and Mold Industry

| Part: | Press-cutter blade |

| Material: | SCM440/42CrMo4(44HRC) |

| Cutter: | TXN06R063M22.0E06 (ø63, z = 6) |

| Insert: | LNGU06X5ZER-MH |

| Grade: | AH8015 |

| Cutting conditions: | Vc = 118 (m/min) fz = 0.8 (mm/t) ap = 0.8 (mm) ae = 38 (mm) Application: Face milling Coolant: Dry (air) Machine: Vertical M/C |

Standard cutting conditions

TXN03 / EXN03 / HXN03

| ISO | Workpiece material | Hardness | Priority | Grade | Chip-breaker | Cutting speed |

Feed per tooth: fz (mm/t) | Tool dia.: DCX (mm), Number of revolutions: n (min-1), Feed speed: Vf (mm/min), Max. depth of cut: ap = 1.0 mm | ||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tool dia.: DCX (mm) | Plunging | ø16, CICT = 2 | ø18, CICT = 2 | ø20 | ø22 | ø25 | ø28 | ø30 | ø32 | ø35 | ø40 | ø50 | ||||||||||||||||||||||||||||

| Vc (m/min) |

ø16 ~ ø22 | ø25 ~ ø50 | n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | ||||||||||||||||

| CICT = 3 | CICT = 4 | CICT = 3 | CICT = 4 | CICT = 4 | CICT= 5 | CICT = 4 | CICT = 5 | CICT = 4 | CICT = 5 | CICT = 5 | CICT = 6 | CICT = 5 | CICT = 6 | CICT = 5 | CICT = 6 | CICT = 5 | CICT = 8 | |||||||||||||||||||||||

| Carbon steels (S45C / C45, S55C / C55, etc.) |

– 300HB | First choice | AH3225 | MJ | 100 – 300 | 0.5 -1.2 | 0.5 – 1.5 | 0.1 | 3,980 | 6,370 | 3,540 | 5,660 | 3,180 | 7,630 | 10,180 | 2,890 | 6,940 | 9,250 | 2,550 | 8,160 | 10,180 | 2,270 | 7,280 | 9,100 | 2,120 | 8,480 | 10,600 | 1,990 | 9,950 | 11,940 | 1,820 | 9,100 | 10,920 | 1,590 | 7,950 | 9,540 | 1,270 | 6,350 | 10,160 | |

| Vc = 200 m/min, fz = 0.8 mm/t | Vc = 200 m/min, fz = 1.0 mm/t | |||||||||||||||||||||||||||||||||||||||

| Alloy steels (SCM440 / 42CrMo4, etc.) |

– 300HB | First choice | AH3225 | MJ | 100 – 300 | 0.5 -1.2 | 0.5 – 1.5 | 0.1 | 3,980 | 6,370 | 3,540 | 5,660 | 3,180 | 7,630 | 10,180 | 2,890 | 6,940 | 9,250 | 2,550 | 8,160 | 10,180 | 2,270 | 7,280 | 9,100 | 2,120 | 8,480 | 10,600 | 1,990 | 9,950 | 11,940 | 1,820 | 9,100 | 10,920 | 1,590 | 7,950 | 9,540 | 1,270 | 6,350 | 10,160 | |

| Vc = 200 m/min, fz = 0.8 mm/t | Vc = 200 m/min, fz = 1.0 mm/t | |||||||||||||||||||||||||||||||||||||||

| Prehardened steels (NAK80, PX5, etc.) | 30 – 40HRC | First choice | AH3225 | MJ | 100 – 200 | 0.5 – 1.0 | 0.5 – 1.0 | 0.1 | 2,980 | 4,170 | 2,650 | 3,710 | 2,390 | 5,020 | 6,690 | 2,170 | 4,560 | 6,080 | 1,910 | 5,350 | 6,690 | 1,710 | 4,790 | 5,990 | 1,590 | 4,450 | 5,570 | 1,490 | 5,220 | 6,260 | 1,360 | 4,760 | 5,710 | 1,190 | 4,170 | 5,000 | 950 | 3,330 | 5,320 | |

| Vc = 150 m/min, fz = 0.7 mm/t | Vc = 150 m/min, fz = 0.7 mm/t | |||||||||||||||||||||||||||||||||||||||

| 30 – 40HRC | for wear resistance | AH8015 | MJ | 100 – 200 | 0.5 – 1.0 | 0.5 – 1.0 | 0.1 | 2,980 | 4,170 | 2,650 | 3,710 | 2,390 | 5,020 | 6,690 | 2,170 | 4,560 | 6,080 | 1,910 | 5,350 | 6,690 | 1,710 | 4,790 | 5,990 | 1,590 | 4,450 | 5,570 | 1,490 | 5,220 | 6,260 | 1,360 | 4,760 | 5,710 | 1,190 | 4,170 | 5,000 | 950 | 3,330 | 5,320 | ||

| Vc = 150 m/min, fz = 0.7 mm/t | Vc = 150 m/min, fz = 0.7 mm/t | |||||||||||||||||||||||||||||||||||||||

| Austenitic stainless steels (SUS304 / X5CrNi18-9, etc.) | – 200HB | First choice | AH130 | MS | 80 – 150 | 0.3 – 0.8 | 0.3 – 0.8 | 0.1 | 2,390 | 2,390 | 2,120 | 2,120 | 1,910 | 2,860 | 3,820 | 3,180 | 4,770 | 6,360 | 1,530 | 3,060 | 3,820 | 1,360 | 2,720 | 3,400 | 1,270 | 2,540 | 3,180 | 1,190 | 2,980 | 3,570 | 1,090 | 2,720 | 3,270 | 960 | 2,400 | 2,880 | 760 | 1,900 | 2,280 | |

| Vc = 120 m/min, fz = 0.5 mm/t | Vc = 120 m/min, fz = 0.5 mm/t | |||||||||||||||||||||||||||||||||||||||

| Precipitation hardening stainless steels (SUS630 / X5CrNiCuNb16-4) | 28HRC -28HRC – (H1150) |

First choice | AH130 | MS | 80 – 150 | 0.2 – 0.5 | 0.2 – 0.5 | 0.1 | 2,390 | 1,430 | 2,120 | 1,270 | 1,910 | 1,720 | 2,290 | 1,740 | 1,570 | 2,090 | 1,530 | 1,840 | 2,300 | 1,370 | 1,640 | 2,060 | 1,270 | 1,520 | 1,910 | 1,190 | 1,790 | 2,140 | 1,090 | 1,640 | 1,960 | 960 | 1,440 | 1,730 | 760 | 1,140 | 1,820 | |

| for wear resistance | AH3225 | MS | Vc = 120 m/min, fz = 0.3 mm/t | Vc = 120 m/min, fz = 0.3 mm/t | ||||||||||||||||||||||||||||||||||||

| 40HRC -40HRC – (H900) |

First choice | AH3035 | ML | 80 – 120 | 0.1 – 0.3 | 0.1 – 0.3 | 0.1 | 1,990 | 800 | 1,770 | 710 | 1,590 | 950 | 1,270 | 1,450 | 870 | 1,160 | 1,270 | 1,020 | 1,270 | 1,140 | 910 | 1,140 | 1,060 | 850 | 1,060 | 1,000 | 1,000 | 1,200 | 910 | 910 | 1,090 | 800 | 800 | 960 | 640 | 640 | 1,020 | ||

| for impact resistance | AH3035 | MJ | Vc = 100 m/min, fz = 0.2 mm/t | Vc = 100 m/min, fz = 0.2 mm/t | ||||||||||||||||||||||||||||||||||||

| Gray cast irons (FC250 / GG25 / 250, etc.) |

150 – 250HB | First choice | AH725 | MJ | 100 – 300 | 0.5 – 1.2 | 0.5 – 1.5 | 0.1 | 3,980 | 6,370 | 3,540 | 5,660 | 3,180 | 7,630 | 10,180 | 2,890 | 6,940 | 9,250 | 2,550 | 8,160 | 10,180 | 2,270 | 7,280 | 9,100 | 2,120 | 8,480 | 10,600 | 1,990 | 9,950 | 11,940 | 1,820 | 9,100 | 10,920 | 1,590 | 7,950 | 9,540 | 1,270 | 6,350 | 10,160 | |

| Vc = 200 m/min, fz = 0.8 mm/t | Vc = 200 m/min, fz = 1.0 mm/t | |||||||||||||||||||||||||||||||||||||||

| Ductile cast irons (FCD400, etc.) |

150 – 250HB | First choice | AH725 | MJ | 80 – 200 | 0.5 – 1.2 | 0.5 – 1.5 | 0.1 | 2,980 | 4,770 | 2,650 | 4,240 | 2,390 | 5,740 | 7,650 | 2,170 | 5,210 | 6,940 | 1,910 | 6,110 | 7,640 | 1,710 | 5,460 | 6,820 | 1,590 | 6,360 | 7,950 | 1,490 | 7,450 | 8,940 | 1,360 | 6,800 | 8,160 | 1,190 | 5,950 | 7,140 | 950 | 4,750 | 5,700 | |

| Vc = 150 m/min, fz = 0.8 mm/t | Vc = 150 m/min, fz = 1.0 mm/t | |||||||||||||||||||||||||||||||||||||||

| Titanium alloy (Ti-6Al-4V, etc.) |

– 40HRC | First choice | AH130 | ML | 30 – 60 | 0.3 – 0.7 | 0.3 – 0.7 | 0.08 | 800 | 640 | 710 | 570 | 640 | 770 | 1,020 | 580 | 700 | 930 | 510 | 820 | 1,020 | 450 | 730 | 910 | 420 | 840 | 1,050 | 400 | 1,000 | 1,200 | 360 | 900 | 1,080 | 320 | 800 | 960 | 250 | 630 | 1,000 | |

| for impact resistance | AH130 | MJ | Vc = 40 m/min, fz = 0.4 mm/t | Vc = 40 m/min, fz = 0.5 mm/t | ||||||||||||||||||||||||||||||||||||

| Heat-resistance alloy (Inconel, Hasteroy, etc.) |

– 40HRC | First choice | AH8015 | ML | 20 – 50 | 0.1 – 0.3 | 0.1 – 0.3 | 0.05 | 600 | 240 | 530 | 210 | 480 | 290 | 380 | 430 | 260 | 340 | 380 | 230 | 290 | 340 | 200 | 260 | 320 | 260 | 320 | 300 | 300 | 360 | 270 | 270 | 320 | 240 | 240 | 290 | 190 | 190 | 300 | |

| for impact resistance | AH725 | ML | Vc = 30 m/min, fz = 0.2 mm/t | Vc = 30 m/min, fz = 0.2 mm/t | ||||||||||||||||||||||||||||||||||||

| Hot mold steel (SKD61 / X40CrMoV5-1, etc.) |

40 – 55HRC | First choice | AH8015 | MH | 80 – 150 | 0.1 – 0.5 | 0.1 – 0.5 | 0.05 | 2,390 | 1,430 | 2,120 | 1,270 | 1,910 | 1,720 | 2,290 | 1,740 | 1,570 | 2,090 | 1,530 | 1,840 | 2,300 | 1,360 | 1,630 | 2,040 | 1,270 | 1,520 | 1,910 | 1,190 | 1,790 | 2,140 | 1,090 | 1,640 | 1,960 | 950 | 1,430 | 1,710 | 760 | 1,140 | 1,820 | |

| Low resistance | AH8015 | MJ | 0.1 – 0.3 | 0.1 – 0.3 | Vc = 120 m/min, fz = 0.3 mm/t | Vc = 120 m/min, fz = 0.3 mm/t | ||||||||||||||||||||||||||||||||||

| Hot mold steel of D.T.C materials (DAC**, DH**, DIEVER, etc) |

40 – 55HRC | First choice | AH8015 | MJ | 50-100 | 0.1 – 0.3 | 0.1 – 0.3 | 0.05 | 1,590 | 640 | 1,420 | 570 | 1,270 | 760 | 1,020 | 1,160 | 700 | 930 | 1,020 | 820 | 1,020 | 910 | 730 | 910 | 850 | 680 | 850 | 800 | 800 | 960 | 730 | 730 | 880 | 640 | 640 | 770 | 510 | 510 | 820 | |

| for impact resistance | AH8015 | MH | 0.1 – 0.5 | 0.1 – 0.5 | Vc = 80 m/min, fz = 0.2mm/t | Vc = 80 m/min, fz = 0.2mm/t | ||||||||||||||||||||||||||||||||||

| Cold mold steels (SKD11 / X153CrMoV12, etc.) |

55 – 60HRC | First choice | AH8005 | MH | 50 – 70 | 0.05 – 0.2 | 0.03 – 0.1 | 0.03 | 1,190 | 290 | 1,060 | 250 | 950 | 340 | 450 | 870 | 310 | 420 | 760 | 300 | 380 | 680 | 270 | 340 | 640 | 260 | 320 | 600 | 300 | 360 | 550 | 230 | 340 | 480 | 240 | 280 | 380 | 200 | 300 | |

| Vc = 60 m/min, fz = 0.12 mm/t | Vc = 60 m/min, fz = 0.1 mm/t | |||||||||||||||||||||||||||||||||||||||

| 55 – 60HRC | for impact resistance | AH8015 | MH | 50 – 70 | 0.03 – 0.1 | 0.05 – 0.2 | 0.03 | 1,190 | 150 | 1,060 | 130 | 950 | 170 | 230 | 870 | 160 | 210 | 760 | 150 | 190 | 680 | 140 | 170 | 640 | 130 | 160 | 600 | 150 | 180 | 550 | 120 | 170 | 480 | 120 | 140 | 380 | 100 | 150 | ||

| Vc = 60 m/min, fz = 0.06 mm/t | Vc = 60 m/min, fz = 0.06 mm/t | |||||||||||||||||||||||||||||||||||||||

- When chips stay in the cutting zone during slotting or pocketing, use air blast to remove chips from the work area.

- Tool overhang length must be as short as possible to avoid chatter. When the tool overhang length is long, decrease the number of revolutions and feed.

- The above table shows the conditions for standard shank type cutters. When using long shank type cutters, the number of teeth may be different. In this case, the cutting conditions should be changed by referring to the brochure (PDF).

- Cutting conditions are generally limited by the rigidity and power of the machine and the rigidity of the workpiece. When setting the conditions, start from half of the values of the standard cutting conditions and then increase the value gradually while making sure the machine is running normally.

TXN06 / EXN06

| ISO | Workpiece material | Hardness | Priority | Grade | Chip-breaker | Cutting speed |

Feed per tooth: fz (mm/t) |

Tool dia.: DCX (mm), Number of revolutions: n (min-1), Feed speed: Vf (mm/min), Max. depth of cut: ap = 1.5 mm, Number of teeth: CICT | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Vc (m/min) |

Tool dia.: DCX (mm) | Plunging | ø32, CICT = 2 | ø35, CICT = 2 | ø40, CICT = 3 | ø50 | ø63 | ø80 | ø100, CICT = 6 | ø125, CICT = 8 | ø160, CICT = 10 | ø200, CICT = 12 | |||||||||||||||||||

| n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | ||||||||||||

| ø32 ~ ø200 | CICT = 4 | CICT = 5 | CICT = 4 | CICT = 6 | CICT = 5 | CICT = 8 | |||||||||||||||||||||||||

| Carbon steels (S45C / C45, S55C / C55, etc.) |

– 300HB | First choice | AH3225 | MJ | 100 – 300 | 0.5 – 1.5 | 0.15 | 1,990 | 3,980 | 1,820 | 3,640 | 1,590 | 4,770 | 1,270 | 5,080 | 6,350 | 1,010 | 4,040 | 6,060 | 800 | 4,000 | 6,400 | 640 | 3,820 | 510 | 4,080 | 400 | 3,980 | 320 | 3,820 | |

| Vc = 200 m/min, fz = 1.0 mm/t | Vc = 200 m/min, fz = 1.0 mm/t | ||||||||||||||||||||||||||||||

| Alloy steels (SCM440 / 42CrMo4, etc.) |

– 300HB | First choice | AH3225 | MJ | 100 – 200 | 0.5 – 1.5 | 0.15 | 1,990 | 3,980 | 1,820 | 3,640 | 1,590 | 4,770 | 1,270 | 5,080 | 6,350 | 1,010 | 4,040 | 6,060 | 800 | 4,000 | 6,400 | 640 | 3,820 | 510 | 4,080 | 400 | 3,980 | 320 | 3,820 | |

| Vc = 200 m/min, fz = 1.0 mm/t | Vc = 200 m/min, fz = 1.0 mm/t | ||||||||||||||||||||||||||||||

| Prehardened steels (NAK80, PX5, etc.) | 30 – 40HRC | First choice | AH3225 | MJ | 100 – 200 | 0.5 – 1.2 | 0.15 | 1,490 | 2,380 | 1,360 | 2,180 | 1,190 | 2,860 | 950 | 3,040 | 3,800 | 760 | 2,430 | 3,650 | 600 | 2,400 | 3,840 | 480 | 2,290 | 380 | 2,450 | 300 | 2,390 | 240 | 2,290 | |

| Vc = 150 m/min, fz = 0.8 mm/t | Vc = 150 m/min, fz = 0.8 mm/t | ||||||||||||||||||||||||||||||

| 30 – 40HRC | for wear resistance | AH8015 | MJ | 100 – 200 | 0.5 – 1.5 | 0.15 | 1,490 | 2,980 | 1,360 | 2,720 | 1,190 | 3,570 | 950 | 3,800 | 4,750 | 760 | 3,040 | 4,560 | 600 | 3,000 | 4,800 | 480 | 2,880 | 380 | 3,040 | 300 | 3,000 | 240 | 2,880 | ||

| Vc = 150 m/min, fz = 1.0 mm/t | Vc = 150 m/min, fz = 1.0 mm/t | ||||||||||||||||||||||||||||||

| Stainless steels (SUS304 / X5CrNi18-9, etc.) |

– 200HB | First choice | AH130 | ML | 80 – 150 | 0.3 – 0.8 | 0.1 | 1,190 | 1,430 | 1,090 | 1,310 | 950 | 1,710 | 760 | 1,820 | 2,280 | 610 | 1,470 | 2,200 | 480 | 1,440 | 2,300 | 380 | 1,380 | 310 | 1,470 | 240 | 1,430 | 190 | 1,380 | |

| Vc = 120 m/min, fz = 0.6 mm/t | Vc = 120 m/min, fz = 0.6 mm/t | ||||||||||||||||||||||||||||||

| Precipitation hardening stainless steels (SUS630 / X5CrNiCuNb16-4) | 28HRC – (H1150) | First choice | AH130 | MS | 80 – 150 | 0.2 – 0.5 | 0.1 | 1,190 | 710 | 1,090 | 650 | 960 | 860 | 760 | 910 | 1,140 | 610 | 730 | 1,100 | 480 | 720 | 1,150 | 380 | 680 | 310 | 740 | 240 | 720 | 190 | 680 | |

| for wear resistance | AH3225 | MS | Vc = 120 m/min, fz = 0.3 mm/t | Vc = 120 m/min, fz = 0.3 mm/t | |||||||||||||||||||||||||||

| 40HRC -40HRC – (H900) |

First choice | AH3035 | ML | 80 – 120 | 0.1 – 0.3 | 0.1 | 1,000 | 400 | 910 | 360 | 800 | 480 | 640 | 510 | 640 | 510 | 410 | 610 | 400 | 400 | 640 | 320 | 380 | 260 | 420 | 200 | 400 | 160 | 380 | ||

| for impact resistance | AH3035 | MJ | Vc = 100 m/min, fz = 0.2 mm/t | Vc = 100 m/min, fz = 0.2 mm/t | |||||||||||||||||||||||||||

| Gray cast irons (FC250 / GG25 / 250, etc.) |

150 – 250HB | First choice | AH120 | MJ | 100 – 300 | 0.5 – 1.5 | 0.15 | 1,990 | 3,980 | 1,820 | 3,640 | 1,590 | 4,770 | 1,270 | 5,080 | 6,350 | 1,010 | 4,040 | 6,060 | 800 | 4,000 | 6,400 | 640 | 3,820 | 510 | 4,080 | 400 | 3,980 | 320 | 3,820 | |

| Vc = 200 m/min, fz = 1.0 mm/t | Vc = 200 m/min, fz = 1.0 mm/t | ||||||||||||||||||||||||||||||

| 150 – 250HB | First choice | AH120 | MJ | 80 – 200 | 0.5 – 1.5 | 0.15 | 1,490 | 2,980 | 1,360 | 2,720 | 1,190 | 3,570 | 950 | 3,800 | 4,750 | 760 | 3,040 | 4,560 | 600 | 3,000 | 4,800 | 480 | 2,870 | 380 | 3,060 | 300 | 2,990 | 240 | 2,870 | ||

| Vc = 150 m/min, fz = 1.0 mm/t | Vc = 150 m/min, fz = 1.0 mm/t | ||||||||||||||||||||||||||||||

| Titanium alloy (Ti-6Al-4V, etc.) |

– 40HRC | First choice | AH130 | ML | 30 – 60 | 0.3 – 0.7 | 0.08 | 400 | 400 | 360 | 360 | 320 | 480 | 250 | 500 | 630 | 200 | 400 | 600 | 160 | 400 | 640 | 130 | 380 | 100 | 410 | 80 | 400 | 60 | 380 | |

| for impact resistance | AH130 | MJ | Vc = 40 m/min, fz = 0.5 mm/t | Vc = 40 m/min, fz = 0.5 mm/t | |||||||||||||||||||||||||||

| Heat-resistance alloy (Inconel, Hasteroy, etc.) |

– 40HRC | First choice | AH8015 | ML | 20 – 50 | 0.1 – 0.3 | 0.05 | 300 | 120 | 270 | 110 | 240 | 140 | 190 | 150 | 190 | 150 | 120 | 180 | 120 | 120 | 190 | 100 | 120 | 80 | 120 | 60 | 120 | 50 | 120 | |

| for impact resistance | AH725 | ML | Vc = 30 m/min, fz = 0.2 mm/t | Vc = 30 m/min, fz = 0.2 mm/t | |||||||||||||||||||||||||||

| Hot mold steel (SKD61 / X40CrMoV5-1, etc.) |

40 – 55HRC | First choice | AH8015 | MH | 80 – 150 | 0.1 – 0.5 | 0.05 | 1,190 | 710 | 1,090 | 650 | 950 | 850 | 760 | 910 | 1,140 | 610 | 730 | 1,100 | 480 | 720 | 1,150 | 380 | 680 | 310 | 740 | 240 | 720 | 190 | 680 | |

| Low resistance | AH8015 | MJ | 0.1 – 0.3 | Vc = 120 m/min, fz = 0.3mm/t | Vc = 120 m/min, fz = 0.3mm/t | ||||||||||||||||||||||||||

| Hot mold steel of D.T.C materials (DAC**, DH**, DIEVER, etc) |

40 – 55HRC | First choice | AH8015 | MJ | 50-100 | 0.1 – 0.3 | 0.05 | 800 | 320 | 730 | 290 | 640 | 380 | 510 | 410 | 510 | 400 | 320 | 480 | 320 | 320 | 510 | 250 | 300 | 200 | 320 | 160 | 320 | 130 | 310 | |

| for impact resistance | AH8015 | MH | 0.1 – 0.5 | Vc = 80 m/min, fz = 0.2mm/t | Vc = 80 m/min, fz = 0.2mm/t | ||||||||||||||||||||||||||

| Cold mold steels (SKD11 / X153CrMoV12, etc.) |

55 – 60HRC | First choice | AH8005 | MH | 50 – 70 | 0.05 – 0.3 | 0.03 | 600 | 120 | 550 | 110 | 480 | 140 | 380 | 150 | 190 | 300 | 120 | 180 | 240 | 120 | 190 | 190 | 110 | 150 | 120 | 120 | 120 | 100 | 120 | |

| Vc = 60 m/min, fz = 0.1 mm/t | Vc = 60 m/min, fz = 0.1 mm/t | ||||||||||||||||||||||||||||||

| 55 – 60HRC | for impact resistance | AH8015 | MH | 50 – 70 | 0.05 – 0.3 | 0.03 | 600 | 60 | 550 | 55 | 480 | 70 | 380 | 75 | 95 | 300 | 60 | 90 | 240 | 60 | 95 | 190 | 55 | 150 | 60 | 120 | 60 | 100 | 60 | ||

| Vc = 60 m/min, fz = 0.05 mm/t | Vc = 60 m/min, fz = 0.05 mm/t | ||||||||||||||||||||||||||||||

- When chips stay in the cutting zone during slotting or pocketing, use air blast to remove chips from the work area.

- Tool overhang length must be as short as possible to avoid chatter. When the tool overhang length is long, decrease the number of revolutions and feed.

- The above table shows the conditions for standard shank type cutters. When using long shank type cutters, the number of teeth may be different. In this case, the cutting conditions should be changed by referring to the brochure (PDF).

- Cutting conditions are generally limited by the rigidity and power of the machine and the rigidity of the workpiece. When setting the conditions, start from half of the values of the standard cutting conditions and then increase the value gradually while making sure the machine is running normally.

For more information about this product, visit our online e-catalog or download the product report: