BTA

Deep Hole Drilling System

High efficiency and excellent hole surface quality

Applications & Features

Applications

Features

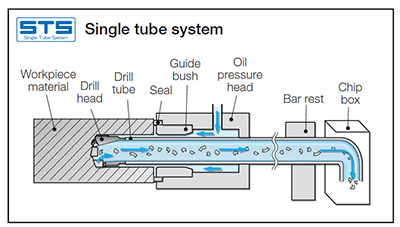

1. Single Tube System (STS)

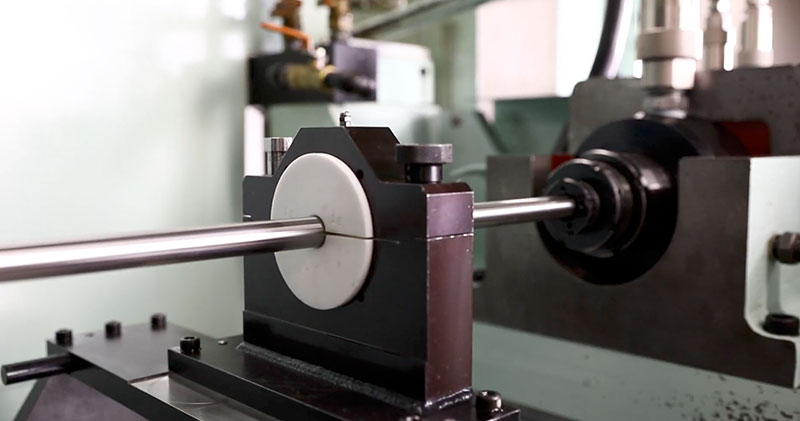

The STS is also referred to as the BTA system in the deep hole drilling process. A large volume of coolant is pumped under high pressure to the cutting area in the workpiece. Chips are then forced out through the drill tube at the back and do not touch the workpiece providing an outstanding surface finish. STS is a stable method to create holes with high accuracy by using a dedicated drilling machine and a sealing with the workpiece.

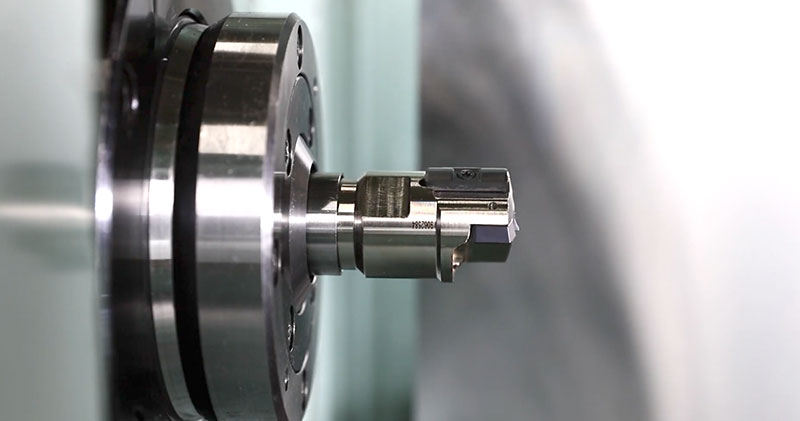

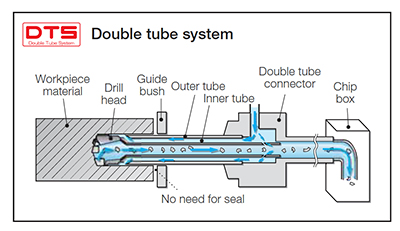

2. Double Tube System (DTS)

The DTS is characterized by its two tube construction and is therefore known as the double tube system. A sealing system and pressure head, which is required in the Single Tube System (STS), is not necessary for the DTS and it is therefore suitable for conventional general purpose machines such as lathes or machining centers. In general, because of less efficient chip evacuation than the STS, the recommended max drilling depth is 1000mm. The unique DTC-R tube connector that is capable of supplying high pressure coolant can, however, successfully achieve drilling depths of up to 2000mm.

Inserts & Grades

Inserts

FBM/FBH

- For FineBeam series

- High productivity inserts with chip breaker

N/TPMX

- For UNIDEX series

TOHT-NDJ/NDL

- For TriFine series

Main Grades

AH725

![]()

![]()

![]()

![]()

- P15 – P30 / M15 – M30 / K25 – K30 / S15 – S25

- Good balance between wear and chipping resistance

- Suitable for machining steel and stainless steel under general cutting conditions

AH8015

![]()

![]()

![]()

![]()

![]()

- M01 – M20 / S10 – S20

- Good balance between wear and fracture resistance

- First choice for machining heat-resistant alloy under general cutting conditions

BTA bodies

Practical examples

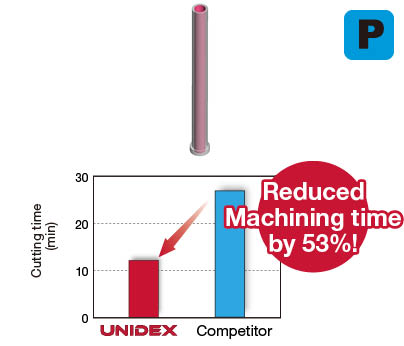

UNIDEX Example #1

General Engineering

| Part: | Main spindle |

| Material: | 15CrMo4 |

| Drill body: | KUSTS56-62.00 |

| Insert: | 1123-32RG |

| Grade: | UC1220 (DLX2) |

| Cutting conditions: | Vc = 80 (m/min) f = 0.15 (mm/rev) Vf = 62 (mm/min) øDc = 62 (mm) H = 735 (mm) Coolant: Wet (Internal) Machine: BTA machine |

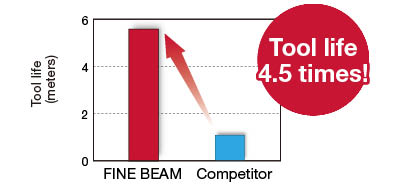

FINE BEAM Example #1

General Engineering

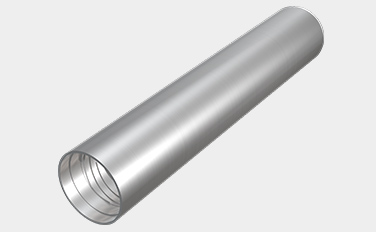

| Part: | Casing Pipe |

| Material: | Inconel 740H Alloy |

| Drill body: | FNBM-13S-63.50 |

| Insert: | FBH130408R-HF-P |

| Grade: | AH8015 |

| Cutting conditions: | Vc = 21.3 (m/min) f = 0.2 (mm/rev) Vf = 21.4 (mm/min) øDc = 63.5 (mm) H = 5690 (mm) Coolant: Wet Machine: BTA Machine |

For more information about this product, visit our online e-catalog or download the product report: