冷却液驱动高速紧凑型主轴

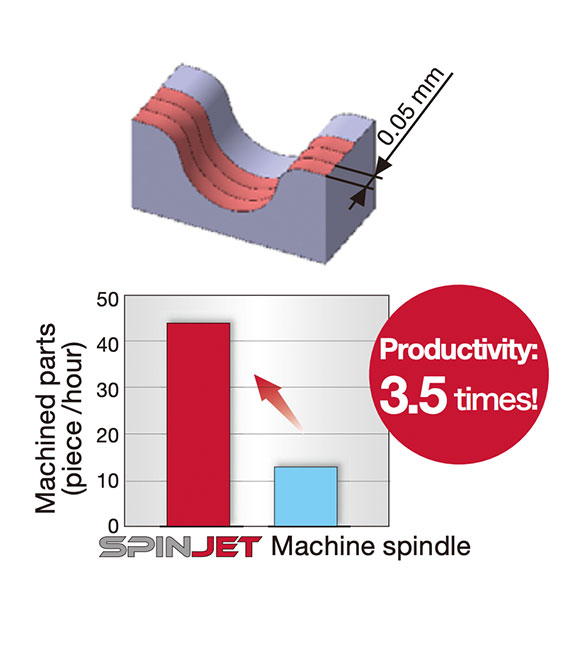

因为主轴在冷却液压力的驱动下高速旋转使生产效率提高了4倍

特点

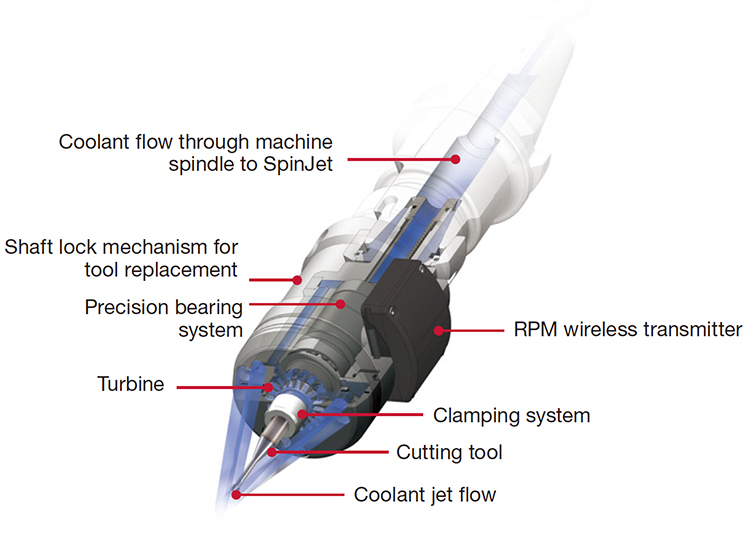

1. 在主轴转速受到限制的机床上使用小直径刀具时,冷却液驱动的高转速主轴能够获得高生产效率

• SpinJet利用机床现有的冷却液供给,利用高压泵作为能量来源高速驱动涡轮旋转。

• 强大的冷却液射流能够延长刀具寿命并实现加工稳定性。

2. 节能

• 仅利用冷却液压力让刀具旋转,SpinJet在工作时机床主轴保持不转。

注意:当SpinJet主轴安装在机床上时,机床主轴应该保持静止。

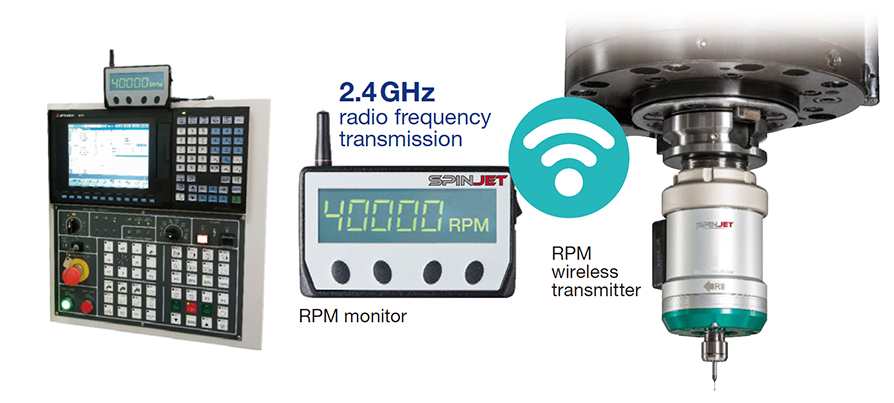

3. 无线转速监控系统

• 转呗了一款线上速度显示系统, 在加工时监控实际的刀具转速。

刀柄 & 附件

实际案例

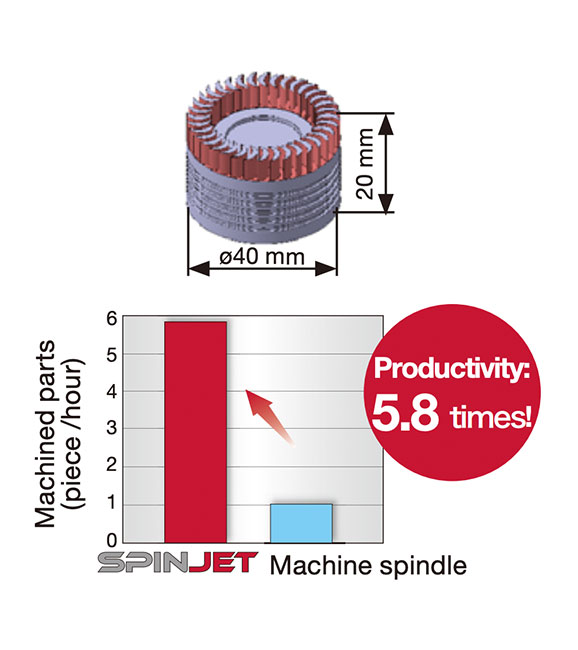

案例 #1

通用工程

| 零件: | 机床零件 |

| 材料: | SUS303 / X10CrNiS18-9 (25HRC) |

| 刀柄: | TJSGJETST20 |

| 立铣刀: | TEB010A2-015/12C4M45 (ø1.0, z = 2) |

| 材质: | AH750 |

| 加工条件: | Vc = 120 (m/min) n = 45,600 (RPM) fz = 0.016 (mm/t) ap = 0.01 (mm) ae = 1 (mm) 应用: 切槽 冷却方式: 冷却液 机床: 立式加工中心, BT30 |

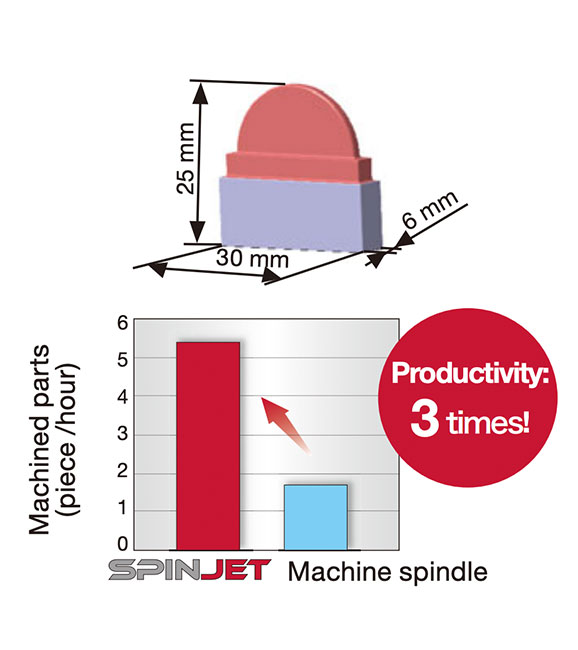

案例 #2

模具行业

| 零件: | 电极 |

| 材料: | C1100 |

| 刀柄: | TJSGJETST20 |

| 立铣刀: | TEB010A2-015/12C4M45 (ø1.0, z = 2) |

| 材质: | AH750 |

| 加工条件: | Vc = 95 (m/min) n = 40,000 (RPM) fz = 0.025 (mm/t) ap = 0.04 (mm) ae = 0.04 (mm) 应用: 仿形加工 冷却方式: 冷却液 机床: 立式加工中心, BT30 |

案例 #3

医疗行业

| 零件: | 医疗器械 |

| 材料: | 钛合金 |

| 刀柄: | TJSGJETER32 |

| 立铣刀: | TEB010A2-015/12C4M45 (ø1.0, z = 2) |

| 材质: | AH750 |

| 加工条件: | Vc = 80 (m/min) n = 35,000 (RPM) fz = 0.03 (mm/t) ap = 0.03 (mm) ae = 0.05 (mm) 应用: 仿形加工 冷却方式: 冷却液 机床: 立式加工中心, BT30 |

标准加工条件

TJS M00

| ISO | 工件材料 | 刀具 | 应用 | 刀具直径 DC (mm) |

冷却液压力 (MPa) |

主轴转速 n (min-1) |

切削宽度 ae (mm) |

切削深度 ap (mm) |

每齿进给量 fz (mm/t) |

|---|---|---|---|---|---|---|---|---|---|

|

合金钢 35 HRC |

钻头 | 钻削 | 0.5 | 1.5 | 18,000 | – | – | 0.007 |

| 2 | 23,000 | – | – | 0.01 | |||||

| 3 | 31,000 | – | – | 0.01 | |||||

| 4 | 40,000 | – | – | 0.01 | |||||

| 1 | 1.5 | 18,000 | – | – | 0.01 | ||||

| 2 | 23,000 | – | – | 0.01 | |||||

| 3 | 31,000 | – | – | 0.01 | |||||

| 4 | 40,000 | – | – | 0.01 | |||||

| 2 | 1.5 | 18,000 | – | – | 0.01 | ||||

| 2 | 23,000 | – | – | 0.01 | |||||

| 3 | 31,000 | – | – | 0.01 | |||||

| 4 | 40,000 | – | – | 0.01 | |||||

| 球型立铣刀 | 仿形 | 1 | 1.5 | 18,000 | – | 0.05 | 0.003 | ||

| 2 | 23,000 | – | 0.05 | 0.003 | |||||

| 3 | 31,000 | – | 0.05 | 0.003 | |||||

| 4 | 40,000 | – | 0.05 | 0.003 | |||||

| 2 | 1.5 | 18,000 | – | 0.08 | 0.004 | ||||

| 2 | 23,000 | – | 0.08 | 0.004 | |||||

| 3 | 31,000 | – | 0.08 | 0.004 | |||||

| 4 | 40,000 | – | 0.08 | 0.004 | |||||

| 3 | 1.5 | 18,000 | – | 0.1 | 0.006 | ||||

| 2 | 23,000 | – | 0.1 | 0.006 | |||||

| 3 | 31,000 | – | 0.1 | 0.006 | |||||

| 4 | 40,000 | – | 0.1 | 0.006 | |||||

| 立铣刀 | 切槽 | 1 | 1.5 | 18,000 | 1 | 0.1 | 0.006 | ||

| 2 | 23,000 | 1 | 0.1 | 0.006 | |||||

| 3 | 31,000 | 1 | 0.1 | 0.006 | |||||

| 4 | 40,000 | 1 | 0.15 | 0.006 | |||||

| 2 | 1.5 | 18,000 | 2 | 0.12 | 0.01 | ||||

| 2 | 23,000 | 2 | 0.12 | 0.01 | |||||

| 3 | 31,000 | 2 | 0.14 | 0.01 | |||||

| 4 | 40,000 | 2 | 0.14 | 0.01 | |||||

| 3 | 1.5 | 18,000 | 3 | 0.12 | 0.01 | ||||

| 2 | 23,000 | 3 | 0.12 | 0.01 | |||||

| 3 | 31,000 | 3 | 0.12 | 0.01 | |||||

| 4 | 40,000 | 3 | 0.15 | 0.01 | |||||

| 方肩铣 | 2 | 1.5 | 18,000 | 0.5 | 0.5 | 0.002 | |||

| 2 | 23,000 | 0.5 | 0.5 | 0.014 | |||||

| 3 | 31,000 | 0.5 | 0.5 | 0.017 | |||||

| 4 | 40,000 | 0.5 | 0.5 | 0.018 | |||||

|

不锈钢 180 – 250 HB |

钻体 | 钻削 | 0.5 | 1.5 | 18,000 | – | – | 0.015 |

| 2 | 23,000 | – | – | 0.015 | |||||

| 3 | 31,000 | – | – | 0.015 | |||||

| 4 | 40,000 | – | – | 0.015 | |||||

| 1 | 1.5 | 18,000 | – | – | 0.015 | ||||

| 2 | 23,000 | – | – | 0.015 | |||||

| 3 | 31,000 | – | – | 0.015 | |||||

| 4 | 40,000 | – | – | 0.015 | |||||

| 2 | 1.5 | 18,000 | – | – | 0.015 | ||||

| 2 | 23,000 | – | – | 0.015 | |||||

| 3 | 31,000 | – | – | 0.015 | |||||

| 4 | 40,000 | – | – | 0.015 | |||||

| 立铣刀 | 切槽 | 1 | 1.5 | 18,000 | 1 | 0.1 | 0.015 | ||

| 2 | 23,000 | 1 | 0.1 | 0.015 | |||||

| 3 | 31,000 | 1 | 0.15 | 0.015 | |||||

| 4 | 40,000 | 1 | 0.15 | 0.015 | |||||

| 2 | 1.5 | 18,000 | 2 | 0.15 | 0.015 | ||||

| 2 | 23,000 | 2 | 0.15 | 0.015 | |||||

| 3 | 31,000 | 2 | 0.15 | 0.015 | |||||

| 4 | 40,000 | 2 | 0.2 | 0.015 | |||||

| 方肩铣 | 2 | 1.5 | 18,000 | 0.35 | 0.15 | 0.02 | |||

| 2 | 23,000 | 0.35 | 0.15 | 0.02 | |||||

| 3 | 31,000 | 0.4 | 0.15 | 0.02 | |||||

| 4 | 40,000 | 0.5 | 0.18 | 0.025 | |||||

|

铝合金 80 – 160 HB |

钻头 | 钻削 | 0.5 | 1.5 | 18,000 | – | – | 0.01 |

| 2 | 23,000 | – | – | 0.01 | |||||

| 3 | 31,000 | – | – | 0.01 | |||||

| 4 | 40,000 | – | – | 0.01 | |||||

| 1 | 1.5 | 18,000 | – | – | 0.01 | ||||

| 2 | 23,000 | – | – | 0.01 | |||||

| 3 | 31,000 | – | – | 0.01 | |||||

| 4 | 40,000 | – | – | 0.01 | |||||

| 2 | 1.5 | 18,000 | – | – | 0.015 | ||||

| 2 | 23,000 | – | – | 0.015 | |||||

| 3 | 31,000 | – | – | 0.017 | |||||

| 4 | 40,000 | – | – | 0.018 | |||||

| 球型立铣刀 | 仿型铣 | 1 | 1.5 | 18,000 | – | 0.05 | 0.003 | ||

| 2 | 23,000 | – | 0.05 | 0.003 | |||||

| 3 | 31,000 | – | 0.05 | 0.003 | |||||

| 4 | 40,000 | – | 0.13 | 0.003 | |||||

| 2 | 1.5 | 18,000 | – | 0.08 | 0.004 | ||||

| 2 | 23,000 | – | 0.08 | 0.004 | |||||

| 3 | 31,000 | – | 0.08 | 0.004 | |||||

| 4 | 40,000 | – | 0.15 | 0.004 | |||||

| 3 | 1.5 | 18,000 | – | 0.08 | 0.006 | ||||

| 2 | 23,000 | – | 0.09 | 0.006 | |||||

| 3 | 31,000 | – | 0.09 | 0.006 | |||||

| 4 | 40,000 | – | 0.15 | 0.006 | |||||

| 立铣刀 | 切槽 | 1 | 1.5 | 18,000 | 1 | 0.1 | 0.025 | ||

| 2 | 23,000 | 1 | 0.1 | 0.025 | |||||

| 3 | 31,000 | 1 | 0.15 | 0.025 | |||||

| 4 | 40,000 | 1 | 0.15 | 0.025 | |||||

| 2 | 1.5 | 18,000 | 2 | 0.2 | 0.025 | ||||

| 2 | 23,000 | 2 | 0.2 | 0.025 | |||||

| 3 | 31,000 | 2 | 0.2 | 0.025 | |||||

| 4 | 40,000 | 2 | 0.2 | 0.025 | |||||

| 仿形 | 2 | 1.5 | 18,000 | 0.5 | 0.25 | 0.02 | |||

| 2 | 23,000 | 0.5 | 0.25 | 0.02 | |||||

| 3 | 31,000 | 0.5 | 0.5 | 0.02 | |||||

| 4 | 40,000 | 0.5 | 0.5 | 0.025 |

TJS M90

| ISO | Workpiece material | Tool | Application | Tool diameter DC (mm) |

Coolant pressure (MPa) |

Spindle speed n (min-1) |

Width of cut ae (mm) |

Depth of cut ap (mm) |

Feed per tooth fz (mm/t) |

|---|---|---|---|---|---|---|---|---|---|

|

Pre-hardened steel 35 HRC |

Drill | Drilling | 0.5 | 2 | 35,000 | – | – | 0.01 |

| 3 | 44,000 | – | – | 0.01 | |||||

| 4 | 53,000 | – | – | 0.01 | |||||

| 1 | 2 | 35,000 | – | – | 0.01 | ||||

| 3 | 44,000 | – | – | 0.01 | |||||

| 4 | 53,000 | – | – | 0.01 | |||||

| 2 | 2 | 35,000 | – | – | 0.01 | ||||

| 3 | 44,000 | – | – | 0.01 | |||||

| 4 | 53,000 | – | – | 0.01 | |||||

| Ball type endmill |

Profiling | 1 | 2 | 35,000 | – | 0.05 | 0.003 | ||

| 3 | 44,000 | – | 0.05 | 0.003 | |||||

| 4 | 53,000 | – | 0.05 | 0.003 | |||||

| 2 | 2 | 35,000 | – | 0.08 | 0.004 | ||||

| 3 | 44,000 | – | 0.08 | 0.004 | |||||

| 4 | 53,000 | – | 0.08 | 0.004 | |||||

| 3 | 2 | 35,000 | – | 0.1 | 0.006 | ||||

| 3 | 44,000 | – | 0.1 | 0.006 | |||||

| 4 | 53,000 | – | 0.1 | 0.006 | |||||

| Endmill | Slotting | 0.5 | 2 | 35,000 | 0.5 | 0.05 | 0.006 | ||

| 3 | 44,000 | 0.5 | 0.05 | 0.006 | |||||

| 4 | 53,000 | 0.5 | 0.05 | 0.006 | |||||

| 1 | 2 | 35,000 | 1 | 0.1 | 0.006 | ||||

| 3 | 44,000 | 1 | 0.1 | 0.006 | |||||

| 4 | 53,000 | 1 | 0.15 | 0.006 | |||||

| 2 | 2 | 35,000 | 2 | 0.12 | 0.01 | ||||

| 3 | 44,000 | 2 | 0.14 | 0.01 | |||||

| 4 | 53,000 | 2 | 0.14 | 0.01 | |||||

| 3 | 2 | 35,000 | 3 | 0.12 | 0.01 | ||||

| 3 | 44,000 | 3 | 0.12 | 0.01 | |||||

| 4 | 53,000 | 3 | 0.15 | 0.01 | |||||

| Shouldering | 2 | 2 | 35,000 | 0.5 | 0.5 | 0.001 | |||

| 3 | 44,000 | 0.5 | 0.5 | 0.017 | |||||

| 4 | 53,000 | 0.5 | 0.5 | 0.018 | |||||

|

Stainless steel SUS316 35 HRC |

Drill | Drilling | 0.5 | 2 | 35,000 | – | – | 0.015 |

| 3 | 44,000 | – | – | 0.015 | |||||

| 4 | 53,000 | – | – | 0.015 | |||||

| 1 | 2 | 35,000 | – | – | 0.015 | ||||

| 3 | 44,000 | – | – | 0.015 | |||||

| 4 | 53,000 | – | – | 0.015 | |||||

| 2 | 2 | 35,000 | – | – | 0.015 | ||||

| 3 | 44,000 | – | – | 0.015 | |||||

| 4 | 53,000 | – | – | 0.015 | |||||

| Endmill | Slotting | 1 | 2 | 35,000 | 1 | 0.1 | 0.015 | ||

| 3 | 44,000 | 1 | 0.15 | 0.015 | |||||

| 4 | 53,000 | 1 | 0.15 | 0.015 | |||||

| 2 | 2 | 35,000 | 2 | 0.15 | 0.015 | ||||

| 3 | 44,000 | 2 | 0.15 | 0.015 | |||||

| 4 | 53,000 | 2 | 0.2 | 0.015 | |||||

| Shouldering | 2 | 2 | 35,000 | 0.35 | 0.15 | 0.02 | |||

| 3 | 44,000 | 0.4 | 0.15 | 0.02 | |||||

| 4 | 53,000 | 0.5 | 0.18 | 0.025 | |||||

|

Aluminium alloy ADC12 28 HRC |

Drill | Drilling | 0.5 | 2 | 35,000 | – | – | 0.01 |

| 3 | 44,000 | – | – | 0.01 | |||||

| 4 | 53,000 | – | – | 0.01 | |||||

| 1 | 2 | 35,000 | – | – | 0.01 | ||||

| 3 | 44,000 | – | – | 0.01 | |||||

| 4 | 53,000 | – | – | 0.01 | |||||

| 2 | 2 | 35,000 | – | – | 0.015 | ||||

| 3 | 44,000 | – | – | 0.017 | |||||

| 4 | 53,000 | – | – | 0.018 | |||||

| Ball type endmill |

Profiling | 1 | 2 | 35,000 | – | 0.05 | 0.003 | ||

| 3 | 44,000 | – | 0.05 | 0.003 | |||||

| 4 | 53,000 | – | 0.13 | 0.003 | |||||

| 2 | 2 | 35,000 | – | 0.08 | 0.004 | ||||

| 3 | 44,000 | – | 0.08 | 0.004 | |||||

| 4 | 53,000 | – | 0.15 | 0.004 | |||||

| 3 | 2 | 35,000 | – | 0.08 | 0.006 | ||||

| 3 | 44,000 | – | 0.09 | 0.006 | |||||

| 4 | 53,000 | – | 0.15 | 0.006 | |||||

| Endmill | Slotting | 0.5 | 2 | 35,000 | 0.5 | 0.1 | 0.02 | ||

| 3 | 44,000 | 0.5 | 0.12 | 0.02 | |||||

| 4 | 53,000 | 0.5 | 0.15 | 0.02 | |||||

| 1 | 2 | 35,000 | 1 | 0.1 | 0.025 | ||||

| 3 | 44,000 | 1 | 0.15 | 0.025 | |||||

| 4 | 53,000 | 1 | 0.15 | 0.025 | |||||

| 2 | 2 | 35,000 | 2 | 0.2 | 0.025 | ||||

| 3 | 44,000 | 2 | 0.2 | 0.025 | |||||

| 4 | 53,000 | 2 | 0.2 | 0.025 | |||||

| Shouldering | 2 | 2 | 35,000 | 0.5 | 0.25 | 0.02 | |||

| 3 | 44,000 | 0.5 | 0.5 | 0.02 | |||||

| 4 | 53,000 | 0.5 | 0.5 | 0.025 | |||||

|

Tool steel SKD61 58 HRC |

Ball type endmill |

Profiling | 1 | 2 | 35,000 | – | 0.05 | 0.005 |

| 3 | 44,000 | – | 0.05 | 0.005 | |||||

| 4 | 53,000 | – | 0.05 | 0.005 | |||||

| 2 | 2 | 35,000 | – | 0.07 | 0.006 | ||||

| 3 | 44,000 | – | 0.08 | 0.006 | |||||

| 4 | 53,000 | – | 0.08 | 0.006 | |||||

| 3 | 2 | 35,000 | – | 0.08 | 0.006 | ||||

| 3 | 44,000 | – | 0.1 | 0.006 | |||||

| 4 | 53,000 | – | 0.1 | 0.006 |

关于该产品的更多信息,请访问我们的线上e-catalog或者下载产品样本:

Video

关于SpinJet请联系泰珂洛

如果您需要泰珂洛提供支持,请通过以下联系方式联系我们