用于可靠螺纹加工的经济型高性能丝锥

适用于多种材料的高质量高速钢丝锥

应用和特征

应用

特点

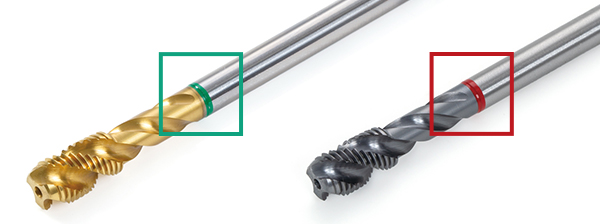

1.柄上的色环有助于轻松识别丝锥的推荐工件材料。

- M– 多种材料应用

- W– 机加工性能良好的钢材 Rm<750N/mm2

- S– 不锈钢

- H– 淬硬钢和高温/超级合金 Rm>750N/mm2

- G– 灰铸铁

- N– 低合金钢 Rm<600N/mm2

- A– 铝和铝合金

- F– 伸长率至少为 8%~10% 的任何材料

- Y– 镍合金

丝锥 & 材质

丝锥

年级

GB070

![]()

![]()

![]()

![]()

- 当加工条件要求涂层具有不同的硬度和韧性时,TiCN 将取代 TiN。TiCN 在加工非常难加工的钢材或切割断续孔时具有优势。TiCN 涂层的硬度约为 3,000 HV,但耐温性能仅达到约 400°。这意味着 TiCN 需要良好的冷却,以延长使用寿命。

DB070

![]()

- DLC(类金刚石碳)涂层具有很高的耐磨性,对有色金属的附着力很弱,非常适合切割铝和铝合金。

AB070

![]()

![]()

![]()

![]()

- 这是一种特殊涂层,适用于加工磨损性材料,例如:灰铸铁、含硅铝合金、纤维增强

塑料等,或在高温(即冷却不足)或高速(≥ 600 米/分钟)条件下进行加工。TiAIN 的硬度约为 3,000 HV,耐温最高可达约 800°。

实际案例

轻按指定代码键

| 孔类型 | 丝锥颜色代码 | W | M | M | M | M | M | M | S | H | N | H | G | F | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 工具材料 | HSS | HSS-E | HSS-E | HSS-E | HSS-E | HSS-E | HSS-E | HSS-E | HSS-E | HSS-E | HSS-E | HSS-E | HSS-E | |||||||||||||||||||

| 表面处理/涂层 | – | – | TI | ST | – | TI | ST | ST | – | ST | ST | NI | TI | |||||||||||||||||||

| 槽向与螺旋角 | – | – | – | – | R40° | R40° | R40° | – | – | R40° | R40° | – | – | |||||||||||||||||||

| 铅含量符合 DIN 2197 标准 | 1\2\3 | B | B | B | C | C | C | B | B | C | C | C | C | |||||||||||||||||||

| 孔类型 | 1-2-3-4-5 | 4-5 | 4-5 | 4-5 | 1-2-3 | 1-2-3 | 1-2-3 | 4-5 | 4-5 | 1-2-3 | 1-2-3 | 1-2-3-4-5 | 1-2-3-4-5 | |||||||||||||||||||

| 材料 编号 |

材料 | 条件 | 拉伸强度 [N/mm²] |

硬度 HB | 切屑 | 冷却液 | 米/分钟 | 米/分钟 | 米/分钟 | 米/分钟 | 米/分钟 | 米/分钟 | 米/分钟 | 米/分钟 | 米/分钟 | 米/分钟 | 米/分钟 | 米/分钟 | 米/分钟 | |||||||||||||

| 1 | 非合金钢和铸钢、易切削钢 | <0.25% C | 韧 | 420 | 125 | 延长 | T | ● | 10-25 | ●● | 15-45 | ● | 8-25 | ●● | 20-25 | ●● | 15-45 | ● | 8-25 | ●● | 20-25 | ●● | 8-25 | ● | 20-25 | ●● | 20-60 | |||||

| 2 | ≥0.25% C | 韧 | 650 | 190 | 中型 | T | ● | 10-20 | ●● | 12-40 | ● | 10-35 | ●● | 15-20 | ●● | 12-40 | ● | 10-35 | ●● | 15-20 | ●● | 10-35 | ●● | 15-20 | ●● | 20-60 | ||||||

| 3 | <0.55% C | 淬火和回火 | 850 | 250 | 长 | T | ● | 12-18 | ●● | 15-25 | ● | 6-12 | ●● | 12-18 | ●● | 15-25 | ● | 6-12 | ●● | 12-18 | ●● | 12-18 | ●● | 17-55 | ||||||||

| 4 | ≥0.55% C | 韧 | 750 | 220 | 长 | T | ● | 12-18 | ●● | 15-40 | ● | 6-20 | ●● | 12-18 | ●● | 15-40 | ● | 6-20 | ●● | 12-18 | ●● | 12-18 | ●● | 17-55 | ||||||||

| 7 | 低合金钢和铸钢 (合金元素含量低于 5%) |

淬火和回火 | 930 | 275 | 长 | X | ● | 10-15 | ●● | 5-25 | ● | 4-10 | ●● | 10-15 | ●● | 5-25 | ● | 4-10 | ●● | 10-15 | ●● | 10-15 | ●● | |||||||||

| 8 | 1000 | 300 | 长 | X | ● | 6-10 | ●● | 5-25 | ● | 4-10 | ●● | 6-10 | ●● | 5-25 | ● | 4-10 | ●● | 6-10 | ●● | 6-10 | ●● | |||||||||||

| 9 | 1200 | 350 | 长 | A | ● | 3-5 | ●● | 5-20 | ● | 3-5 | ●● | 3-5 | ●● | 5-20 | ● | 3-5 | ●● | 3-5 | ●● | 3-5 | ●● | |||||||||||

| 10 | 高合金钢、铸钢和工具钢 | 韧 | 680 | 200 | 长 | X | ● | 10-15 | ●● | 20-30 | ● | 7-12 | ●● | 10-15 | ●● | 20-30 | ● | 7-12 | ●● | 10-15 | ●● | 10-15 | ●● | 10-30 | ||||||||

| 11 | 淬火和回火 | 1100 | 325 | 长 | X | ● | 7-13 | ●● | 12-25 | ● | 5-10 | ●● | 7-13 | ●● | 12-25 | ● | 5-10 | ●● | 7-13 | ●● | 7-13 | ●● | ||||||||||

| 12 | 不锈钢和铸钢 | 铁素体/马氏体 | 680 | 200 | 中型 | A | ● | 5-9 | ●● | 8-18 | ● | 1-5 | ● | 5-9 | ●● | 2-10 | ● | 1-5 | ●● | 2-10 | ● | 5-9 | ●● | 7-15 | ||||||||

| 13 | 马氏体 | 820 | 240 | 长 | A | ● | 4-6 | ●● | 8-15 | ● | 1-5 | ● | 4-6 | ●● | 2-10 | ● | 1-5 | ● | 2-10 | ● | 4-6 | ●● | ||||||||||

| 14 | 不锈钢和铸钢 | 奥氏体,双相 | 600 | 180 | 长 | A | ● | 5-9 | ●● | 8-15 | ● | 1-4 | ● | 5-9 | ●● | 2-10 | ● | 1-4 | ● | 2-10 | ● | 5-9 | ●● | |||||||||

| 15 | 灰铸铁(GG) | 铁素体/珠光体 | 180 | 短号 | X | ● | 10-15 | ●● | 15-45 | ●● | 13-20 | ● | 10-15 | ●● | 15-45 | ●● | 13-20 | ● | 10-15 | ●● | 10-30 | ● | ||||||||||

| 16 | 珠光体/马氏体 | 260 | 短号 | X | ● | 8-12 | ●● | 10-40 | ●● | 21-31 | ● | 8-12 | ●● | 10-40 | ●● | 21-31 | ● | 8-12 | ●● | 10-30 | ● | |||||||||||

| 17 | 球墨铸铁(GGG) | 铁素体 | 160 | 短 | X | ● | 8-12 | ●● | 10-25 | ●● | 21-31 | ● | 8-12 | ● | 10-25 | ● | 21-31 | ● | 8-12 | ●● | 10-40 | ● | ||||||||||

| 18 | 珠光体 | 250 | 短号 | X | ● | 8-12 | ●● | 10-20 | ●● | 21-31 | ● | 8-12 | ●● | 10-20 | ●● | 21-31 | ● | 8-12 | ●● | 10-35 | ● | |||||||||||

| 19 | 可锻铸铁 | 铁素体 | 130 | 短 | X | ● | 10-15 | ● | 15-45 | ●● | 13-20 | ● | 10-15 | ●● | 15-45 | ●● | 13-20 | ● | 10-15 | ●● | 10-45 | ● | ||||||||||

| 20 | 珠光体 | 230 | 短 | X | ● | 10-15 | ● | 10-40 | ●● | 13-20 | ● | 10-15 | ●● | 10-40 | ●● | 13-20 | ● | 10-15 | ●● | 10-40 | ● | |||||||||||

| 21 | 锻铝合金 | 不硬化 | 60 | 中型 | T | ● | 25-35 | ● | 50-70 | ● | 12-25 | ●● | 25-35 | ● | 30-60 | ● | 12-25 | ●● | 12-25 | ●● | 25-35 | ●● | ||||||||||

| 22 | 硬化 | 100 | 中型 | T | ● | 25-35 | ● | 50-70 | ● | 12-25 | ●● | 25-35 | ● | 30-60 | ● | 12-25 | ●● | 12-25 | ●● | 25-35 | ●● | |||||||||||

| 23 | 铝铸件合金 | ≤12% Si | 不硬化 | 75 | 短 | T | ● | 10-15 | ● | 10-40 | ● | 10-25 | ●● | 10-15 | ● | 15-40 | ● | 10-25 | ●● | 10-25 | ●● | 10-15 | ●● | |||||||||

| 24 | 硬化 | 90 | 短 | T | ● | 10-15 | ● | 10-40 | ● | 10-25 | ●● | 10-15 | ● | 15-40 | ● | 10-25 | ●● | 10-25 | ●● | 10-15 | ●● | |||||||||||

| 25 | >12% 硅 | 高温 | 130 | 短 | T | ● | 10-15 | ● | 10-30 | ● | 10-20 | ●● | 10-15 | ● | 15-30 | ● | 10-20 | ●● | 10-20 | ●● | 10-15 | ●● | ||||||||||

| 26 | 铜合金 | >1% 铅 | 自由切割 | 110 | 中号/短号 | T | ● | 25-35 | ● | 50-70 | ● | 20-40 | ●● | 25-35 | ● | 30-65 | ● | 20-40 | ●● | 20-40 | ●● | 25-35 | ●● | 17-40 | ||||||||

| 27 | 黄铜 | 90 | 长 | T | ● | 15-20 | ● | 5-60 | ● | 13-30 | ●● | 15-20 | ● | 20-45 | ● | 13-30 | ●● | 13-30 | ●● | 15-20 | ●● | 20-60 | ||||||||||

| 28 | 电解铜 | 100 | 长 | T | ● | 15-20 | ● | 5-25 | ● | 10-17 | ●● | 15-20 | ● | 15-30 | ● | 10-17 | ●● | 10-17 | ●● | 15-20 | ●● | 20-60 | ||||||||||

| 29 | 非金属 | 杜罗塑料、纤维塑料 | 70 岸 D | 短 | Z | ● | 6-10 | ● | 5-25 | ● | 6-13 | ●● | 6-10 | ● | 10-20 | ● | 6-13 | ●● | 6-13 | ●● | 6-10 | ●● | ||||||||||

| 31 | 高温合金 | 铁基 | 韧 | 200 | 长 | A | ● | 2-4 | ●● | 4-8 | ● | 2-4 | ● | 3-7 | ●● | 2-4 | 2-4 | ● | ||||||||||||||

| 32 | 硬化 | 280 | 长 | A | ● | 2-4 | ●● | 4-8 | ● | 2-4 | 3-7 | ●● | 2-4 | 2-4 | ● | |||||||||||||||||

| 33 | 镍或钴基 | 韧 | 250 | 长 | A | ● | 2-4 | ●● | 4-8 | ● | 2-4 | 3-7 | ●● | 2-4 | 2-4 | ● | ||||||||||||||||

| 34 | 硬化 | 350 | 长 | A | ● | 2-4 | ●● | 4-8 | ● | 2-4 | 3-7 | ●● | 2-4 | 2-4 | ● | |||||||||||||||||

| 35 | 铸造 | 320 | 长 | A | ● | 2-4 | ●● | 4-8 | ● | 2-4 | 3-7 | ●● | 2-4 | 2-4 | ● | |||||||||||||||||

| 36 | 钛合金 | 纯粹 | 400 | 190 | 中号/短号 | A | ● | 6-10 | ●● | 6-10 | ●● | 6-10 | 6-10 | ● | ||||||||||||||||||

| 37 | α+β合金,淬硬 | 1050 | 310 | 中号/短号 | A | ● | 6-10 | ● | 6-10 | ●● | 6-10 | 6-10 | ● | |||||||||||||||||||

| A – 切削油 T – 油 X – 油或乳液 Z – 干油或乳液 |

推荐 ●●适合 |

|||||||||||||||||||||||||||||||

| 孔类型 | 丝锥颜色代码 | W | M | M | M | M | M | M | S | H | N | H | G | F | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 工件材料 | HSS | HSS-E | HSS-E | HSS-E | HSS-E | HSS-E | HSS-E | HSS-E | HSS-E | HSS-E | HSS-E | HSS-E | HSS-E | |||||||||||||||||||

| 表面处理/涂层 | – | – | TI | ST | – | TI | ST | ST | – | ST | ST | NI | TI | |||||||||||||||||||

| 槽向与螺旋角 | – | – | – | – | R40° | R40° | R40° | – | – | R40° | R40° | – | – | |||||||||||||||||||

| 铅含量符合 DIN 2197 标准 | 1\2\3 | B | B | B | C | C | C | B | B | C | C | C | C | |||||||||||||||||||

| 孔类型 | 1-2-3-4-5 | 4-5 | 4-5 | 4-5 | 1-2-3 | 1-2-3 | 1-2-3 | 4-5 | 4-5 | 1-2-3 | 1-2-3 | 1-2-3-4-5 | 1-2-3-4-5 | |||||||||||||||||||

| 材料 编号 |

材料 | 条件 | 拉伸强度 [ksi] |

硬度 HB | 切屑 | 冷却液 | SFM | SFM | SFM | SFM | SFM | SFM | SFM | SFM | SFM | SFM | SFM | SFM | SFM | |||||||||||||

| 1 | 非合金钢和铸钢、易切削钢 | <0.25% C | 韧 | 61 | 125 | 延长 | T | ● | 35-80 | ●● | 15-150 | ● | 25-80 | ●● | 65-80 | ●● | 50-150 | ● | 25-80 | ●● | 65-80 | ●● | 25-80 | ● | 65-80 | ●● | 65-195 | |||||

| 2 | ≥0.25% C | 韧 | 94 | 190 | 中型 | T | ● | 35-65 | ●● | 40-130 | ● | 35-115 | ●● | 60-65 | ●● | 40-130 | ● | 35-115 | ●● | 50-65 | ●● | 35-115 | ●● | 50-65 | ●● | 65-195 | ||||||

| 3 | <0.55% C | 淬火和回火 | 123 | 250 | 长 | T | ● | 40-60 | ●● | 50-80 | ● | 20-40 | ●● | 40-60 | ●● | 50-80 | ● | 20-40 | ●● | 40-60 | ●● | 40-60 | ●● | 55-180 | ||||||||

| 4 | ≥0.55% C | 韧 | 109 | 220 | 长 | T | ● | 40-60 | ●● | 50-130 | ● | 20-65 | ●● | 40-60 | ●● | 50-130 | ● | 15-35 | ●● | 40-60 | ●● | 40-60 | ●● | 55-180 | ||||||||

| 7 | 低合金钢和铸钢 (合金元素含量低于 5%) |

淬火和回火 | 135 | 275 | 长 | X | ● | 35-50 | ●● | 15-80 | ● | 15-35 | ●● | 35-50 | ●● | 15-80 | ● | 15-35 | ●● | 35-50 | ●● | 35-50 | ●● | |||||||||

| 8 | 145 | 300 | 长 | X | ● | 20-35 | ●● | 15-80 | ● | 15-35 | ●● | 20-35 | ●● | 15-80 | ● | 15-35 | ●● | 20-35 | ●● | 20-35 | ●● | |||||||||||

| 9 | 174 | 350 | 长 | A | ● | 10-15 | ●● | 15-65 | ● | 10-15 | ●● | 10-15 | ●● | 15-65 | ● | 10-15 | ●● | 10-15 | ●● | 10-15 | ●● | |||||||||||

| 10 | 高合金钢、铸钢和工具钢 | 韧 | 99 | 200 | 长 | X | ● | 35-50 | ●● | 65-100 | ● | 25-40 | ●● | 35-50 | ●● | 65-100 | ● | 25-40 | ●● | 35-50 | ●● | 35-50 | ●● | 35-100 | ||||||||

| 11 | 淬火和回火 | 160 | 325 | 长 | X | ● | 25-45 | ●● | 40-80 | ● | 15-35 | ●● | 25-45 | ●● | 40-80 | ● | 15-35 | ●● | 25-45 | ●● | 25-45 | ●● | ||||||||||

| 12 | 不锈钢和铸钢 | 铁素体/马氏体 | 99 | 200 | 中型 | A | ● | 15-30 | ●● | 25-60 | ● | 5-15 | ● | 15-30 | ●● | 5-35 | ● | 5-16 | ●● | 5-35 | ● | 15-30 | ●● | 25-50 | ||||||||

| 13 | 马氏体 | 119 | 240 | 长 | A | ● | 15-20 | ●● | 25-50 | ● | 5-15 | ● | 15-20 | ●● | 5-35 | ● | 5-16 | ● | 5-35 | ● | 15-20 | ●● | ||||||||||

| 14 | 不锈钢和铸钢 | 奥氏体,双相 | 87 | 180 | 长 | A | ● | 15-30 | ●● | 25-50 | ● | 5-15 | ● | 15-30 | ●● | 5-35 | ● | 5-15 | ● | 5-35 | ● | 15-30 | ●● | |||||||||

| 15 | 灰铸铁(GG) | 铁素体/珠光体 | 180 | 短号 | X | ● | 35-50 | ●● | 50-150 | ●● | 45-65 | ● | 35-50 | ●● | 50-150 | ●● | 45-65 | ● | 35-50 | ●● | 35-100 | ● | ||||||||||

| 16 | 珠光体/马氏体 | 260 | 短号 | X | ● | 25-40 | ●● | 35-130 | ●● | 70-100 | ● | 25-40 | ●● | 35-130 | ●● | 70-100 | ● | 25-40 | ●● | 35-100 | ● | |||||||||||

| 17 | 球墨铸铁(GGG) | 铁素体 | 160 | 短 | X | ● | 25-40 | ●● | 35-80 | ●● | 70-100 | ● | 25-40 | ● | 35-80 | ● | 70-100 | ● | 25-40 | ●● | 35-130 | ● | ||||||||||

| 18 | 珠光体 | 250 | 短号 | X | ● | 25-40 | ●● | 35-65 | ●● | 70-100 | ● | 25-40 | ●● | 35-65 | ●● | 70-100 | ● | 25-40 | ●● | 35-100 | ● | |||||||||||

| 19 | 可锻铸铁 | 铁素体 | 130 | 短 | X | ● | 35-50 | ● | 50-150 | ●● | 45-65 | ● | 35-50 | ●● | 50-150 | ●● | 45-65 | ● | 35-50 | ●● | 35-150 | ● | ||||||||||

| 20 | 珠光体 | 230 | 短 | X | ● | 35-50 | ● | 35-130 | ●● | 45-65 | ● | 35-50 | ●● | 35-130 | ●● | 45-65 | ● | 35-50 | ●● | 35-130 | ● | |||||||||||

| 21 | 锻铝合金 | 不硬化 | 60 | 中型 | T | ● | 80-115 | ● | 165-230 | ● | 40-80 | ●● | 80-115 | ● | 100-195 | ● | 40-80 | ●● | 40-80 | ●● | 80-115 | ●● | ||||||||||

| 22 | 硬化 | 100 | 中型 | T | ● | 80-115 | ● | 165-230 | ● | 40-80 | ●● | 80-115 | ● | 100-195 | ● | 40-80 | ●● | 40-80 | ●● | 80-115 | ●● | |||||||||||

| 23 | 铝铸件合金 | ≤12% Si | 不硬化 | 75 | 短 | T | ● | 35-50 | ● | 35-130 | ● | 35-80 | ●● | 35-50 | ● | 50-130 | ● | 35-80 | ●● | 35-80 | ●● | 35-50 | ●● | |||||||||

| 24 | 硬化 | 90 | 短 | T | ● | 35-50 | ● | 35-100 | ● | 35-80 | ●● | 35-50 | ● | 50-130 | ● | 35-80 | ●● | 35-80 | ●● | 35-50 | ●● | |||||||||||

| 25 | >12% 硅 | 高温 | 130 | 短 | T | ● | 35-50 | ● | 35-100 | ● | 35-65 | ●● | 35-50 | ● | 50-100 | ● | 35-65 | ●● | 35-65 | ●● | 35-50 | ●● | ||||||||||

| 26 | 铜合金 | >1% 铅 | 自由切割 | 110 | 中号/短号 | T | ● | 80-115 | ● | 165-230 | ● | 65-130 | ●● | 80-115 | ● | 100-215 | ● | 65-130 | ●● | 65-130 | ●● | 80-115 | ●● | 55-130 | ||||||||

| 27 | 黄铜 | 90 | 长 | T | ● | 50-65 | ● | 15-195 | ● | 45-100 | ●● | 50-65 | ● | 65-150 | ● | 45-100 | ●● | 45-100 | ●● | 50-65 | ●● | 65-195 | ||||||||||

| 28 | 电解铜 | 100 | 长 | T | ● | 50-65 | ● | 15-80 | ● | 35-55 | ●● | 50-65 | ● | 50-100 | ● | 35-55 | ●● | 35-55 | ●● | 50-65 | ●● | 65-195 | ||||||||||

| 29 | 非金属 | 杜罗塑料、纤维塑料 | 70 岸 D | 短 | Z | ● | 20-35 | ● | 15-80 | ● | 25-45 | ●● | 20-35 | ● | 35-65 | ● | 20-45 | ●● | 20-45 | ●● | 20-35 | ●● | ||||||||||

| 31 | 高温合金 | 铁基 | 韧 | 200 | 长 | A | ● | 5-15 | ●● | 15-25 | ● | 5-15 | ● | 10-25 | ●● | 5-15 | 5-15 | ● | ||||||||||||||

| 32 | 硬化 | 280 | 长 | A | ● | 5-15 | ●● | 15-25 | ● | 5-15 | 10-25 | ●● | 5-15 | 5-15 | ● | |||||||||||||||||

| 33 | 镍或钴基 | 韧 | 250 | 长 | A | ● | 5-15 | ●● | 15-25 | ● | 5-15 | 10-25 | ●● | 5-15 | 5-15 | ● | ||||||||||||||||

| 34 | 硬化 | 350 | 长 | A | ● | 5-15 | ●● | 15-25 | ● | 5-15 | 10-25 | ●● | 5-15 | 5-15 | ● | |||||||||||||||||

| 35 | 铸造 | 320 | 长 | A | ● | 5-15 | ●● | 15-25 | ● | 5-15 | 10-25 | ●● | 5-15 | 5-15 | ● | |||||||||||||||||

| 36 | 钛合金 | 纯粹 | 58 | 190 | 中号/短号 | A | ● | 20-35 | ●● | 20-35 | ●● | 20-35 | 20-35 | ● | ||||||||||||||||||

| 37 | α+β合金,淬硬 | 152 | 310 | 中号/短号 | A | ● | 20-35 | ● | 20-35 | ●● | 20-35 | 20-35 | ● | |||||||||||||||||||

| A – 切削油 T – 油 X – 油或乳液 Z – 干油或乳液 |

推荐 ●●适合 |

|||||||||||||||||||||||||||||||

How can I help you?

Hi, I'm Gabby, Tungaloy's AI assistant. I'm here to help you find the best tap for your threading application.

How can I assist you today?

How can I assist you today?