高效可转位式枪钻

DeepTri-Drill,便于操作, 可转位式枪钻系列, 拥有出色性能, 实现高效稳定的深孔钻孔加工

应用&特点

应用

特点

1. 选择范围宽用于各种深孔加工

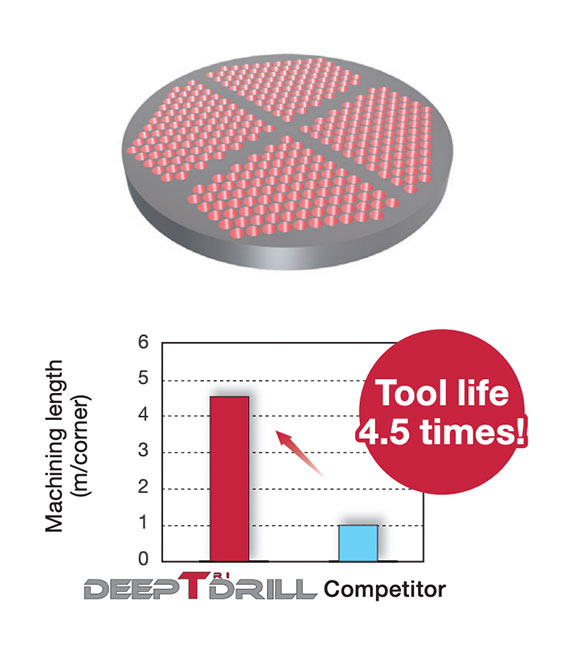

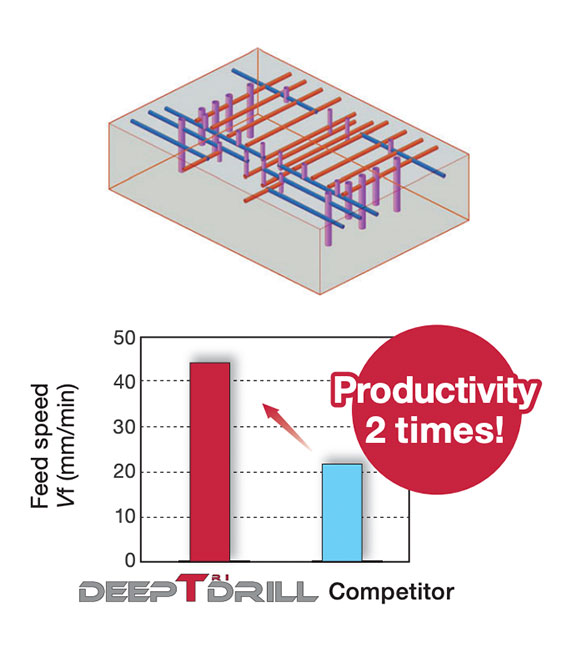

2. 效率高

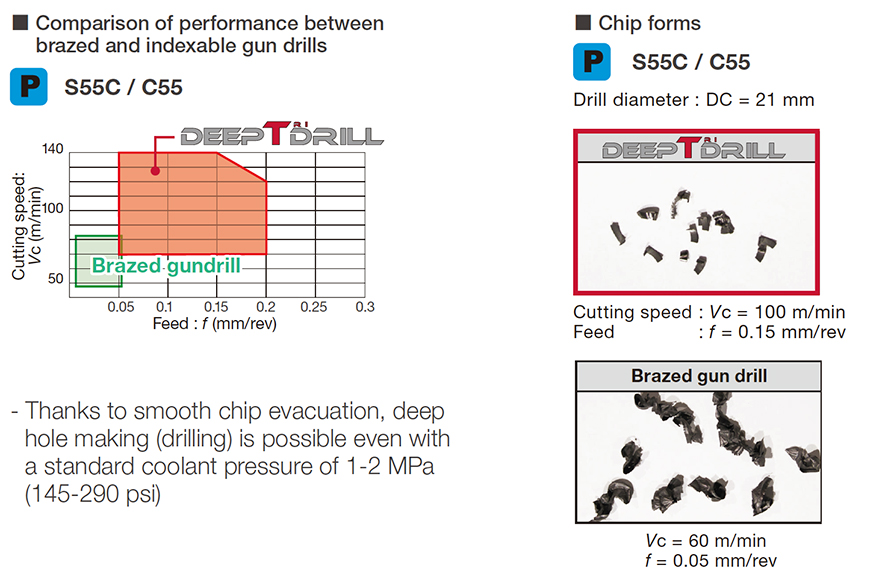

• 刃口上特殊的断屑槽和分屑刃能够在任何进给速度下改善切屑控制,特别是在高进给速度条件下效果明显

• 凭借顺畅的排屑,即使在标准冷却液压力1-2 MPa (145-290 psi)条件下也能够进行深孔加工(钻孔)

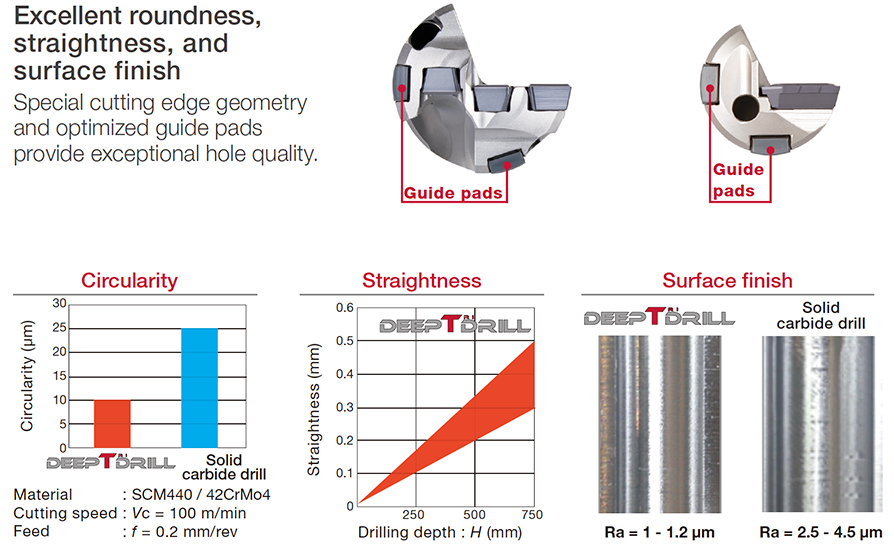

3. 优异的圆度,直线度和表面精度

• 特殊的刃口几何形状和优化分布的导向条实现了优异的孔质量。

刀片&材质

刀片

主要材质

钻杆

实际案例

案例 #1

热交换器行业

| 零件: | 管板 |

| 材料: | SUS304 / X5CrNi18-9 |

| 钻头: | MCTR20.00XM32-10 |

| 刀片: | TOHT090305R-NDL |

| 材质: | AH725 |

| 加工条件: | Vc = 80 (m/min) f = 0.04 (mm/rev) Vf = 53 (mm/min) H = 200 (mm) 冷却方式: 冷却液 机床: 卧式加工中心 |

案例 #2

模具行业

| 零件: | 塑料模具 |

| 材料: | SKD61 / X40CrMoV5-1 (45 HRC) |

| 钻头: | TRLGCH18.00X1500-36A |

| 刀片: | TOHT080305R-NDJ |

| 材质: | AH725 |

| 加工条件: | Vc = 62 (m/min) f = 0.04 (mm/rev) Vf = 44 (mm/min) H = 700 (mm) 冷却方式: 冷却液 机床: 卧式加工中心 |

案例 #3

汽车行业

| 零件: | 轴 |

| 材料: | SCM420H |

| 钻头: | MCTR12.00XM20-20 |

| 刀片: | LOGT060204R-NDJ |

| 材质: | AH725 |

| 加工条件: | Vc = 150 (m/min) f = 0.13 (mm/rev) Vf = 517 (mm/min) øDc = 12 (mm) H = 233 (mm) 冷却方式: 冷却液 机床: 立式加工中心 |

标准加工条件

Drill diameter: DC = ø7.94 – ø9.99 mm

| ISO | Workpiece material | Chip-breaker | Grade | Cutting speed Vc (m/min) |

Feedf (mm/rev) |

|---|---|---|---|---|---|

| Low carbon steel (C < 0.3) SS400, SM490, S25C, etc. E275A, C25, etc |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | |

| Carbon steel (C > 0.3) S45C, S55C, etc. C45, C55, etc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.14 | |

| Low alloy steel (C < 0.3) SCM415, 18CrMo4, etc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | |

| Alloy steel (C > 0.3) SCM440, SCr420, 42CrMo4, 20Cr4, etc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.14 | |

| Stainless steel (Austenitic) SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

NDJ | AH9130 | 60 – 80 | 0.05 – 0.08 | |

| Stainless steel (Martensitic, Ferritic) SUS430, SUS416, etc. X6Cr17, X12CrS13, etc. |

NDJ | AH9130 | 60 – 80 | 0.05 – 0.08 | |

| Stainless steel (Precipitation hardening) SUS630, X5CrNiCuNb16-4, etc. |

NDJ | AH9130 | 60 – 80 | 0.05 – 0.08 | |

| Grey cast iron FC250, GG25, 250, etc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.2 | |

| Ductile cast iron FCD700, 700-2, etc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.2 | |

| Aluminium alloys | NDJ | AH9130 | 60 – 100 | 0.05 – 0.18 | |

| Heat-resistant alloys Inconel 718, etc. |

NDJ | AH9130 | 20 – 50 | 0.04 – 0.06 | |

| Titanium alloys Ti-6Al-4V, etc. |

NDJ | AH9130 | 30 – 60 | 0.04 – 0.1 | |

| Hardened steel ≥ 40HRC |

NDJ | AH9130 | 20 – 50 | 0.04 – 0.06 |

*Coolant recommendations for drilling stainless steel:

– Oil coolant is first priority

– Water soluble coolant requires at least 20% oil concentration

Drill diameter: DC = ø10 – ø28 mm

| ISO | Workpiece material | Priority | Chip-breaker | Grade | Cutting speed Vc (m/min) |

Feed:f (mm/rev) | |||

|---|---|---|---|---|---|---|---|---|---|

| ø10 – ø11.8 | ø11.81 – ø13.99 | ø14 – ø18 | ø18.01 – ø28 | ||||||

| Low carbon steel (C < 0.3) SS400, SM490, S25C, etc. E275A, C25, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.1 | 0.03 – 0.1 | |

| First choice | NDJ | AH9130 | 80 – 140 | 0.05 – 0.08 | 0.05 – 0.1 | 0.06 – 0.12 | 0.08 – 0.16 | ||

| Carbon steel (C > 0.3) S45C, S55C, etc. C45, C55, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.1 | 0.03 – 0.12 | |

| First choice | NDJ | AH9130 | 80 – 140 | 0.05 – 0.14 | 0.05 – 0.16 | 0.07 – 0.18 | 0.08 – 0.2 | ||

| Low alloy steel (C < 0.3) SCM415, 18CrMo4, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.12 | 0.08 – 0.1 | |

| First choice | NDJ | AH9130 | 80 – 140 | 0.05 – 0.08 | 0.05 – 0.1 | 0.06 – 0.12 | 0.08 – 0.16 | ||

| Alloy steel (C > 0.3) SCM440, SCr420, 42CrMo4, 20Cr4, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.1 | 0.03 – 0.12 | |

| First choice | NDJ | AH9130 | 80 – 120 | 0.05 – 0.14 | 0.05 – 0.16 | 0.07 – 0.18 | 0.08 – 0.2 | ||

| Stainless steel (Austenitic) SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.06 | 0.03 – 0.06 | |

| First choice | NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.05 – 0.12 | ||

| Stainless steel (Martensitic, Ferritic) SUS430, SUS416, etc. X6Cr17, X12CrS13, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.06 | 0.03 – 0.06 | |

| First choice | NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.05 – 0.12 | ||

| Stainless steel (Precipitation hardening) SUS630, X5CrNiCuNb16-4, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.06 | 0.03 – 0.06 | |

| First choice | NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.05 – 0.12 | ||

| Grey cast iron FC250, GG25, 250, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.15 | 0.05 – 0.18 | |

| First choice | NDJ | AH9130 | 80 – 140 | 0.05 – 0.2 | 0.05 – 0.25 | 0.05 – 0.25 | 0.05 – 0.3 | ||

| Ductile cast iron FCD700, 700-2, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.15 | 0.05 – 0.18 | |

| First choice | NDJ | AH9130 | 80 – 140 | 0.05 – 0.2 | 0.05 – 0.25 | 0.05 – 0.25 | 0.05 – 0.3 | ||

| Aluminium alloys | Lower feed | NDL | AH725 | 80 – 160 | – | – | 0.03 – 0.15 | 0.03 – 0.15 | |

| First choice | NDJ | AH9130 | 100 – 200 | 0.05 – 0.18 | 0.05 – 0.2 | 0.08 – 0.22 | 0.1 – 0.25 | ||

| Heat-resistant alloys Inconel 718, etc. |

Lower feed | NDL | AH725 | 20 – 50 | – | – | 0.03 – 0.06 | 0.03 – 0.08 | |

| First choice | NDJ | AH9130 | 20 – 50 | 0.04 – 0.06 | 0.04 – 0.08 | 0.04 – 0.08 | 0.04 – 0.1 | ||

| Titanium alloys Ti-6Al-4V, etc. |

Lower feed | NDL | AH725 | 30 – 60 | – | – | 0.03 – 0.1 | 0.03 – 0.12 | |

| First choice | NDJ | AH9130 | 30 – 60 | 0.04 – 0.1 | 0.05 – 0.13 | 0.05 – 0.13 | 0.05 – 0.15 | ||

| Hardened steel ≥ 40HRC |

Lower feed | NDL | AH725 | 40 – 100 | – | – | 0.03 – 0.08 | 0.03 – 0.08 | |

| First choice | NDJ | AH9130 | 50 – 100 | 0.04 – 0.06 | 0.04 – 0.08 | 0.04 – 0.08 | 0.04 – 0.1 | ||

The use of NDL chipbreakers is recommended for cross hole drilling with low feed conditions.

*Coolant recommendations for drilling stainless steel:

– Oil coolant is first priority

– Water soluble coolant requires at least 20% oil concentration

Drill diameter: DC = ø28.01 – ø40 mm

| ISO | Workpiece material | Priority | For central | For intermediate | For peripheral | Cutting speed Vc (m/min) |

Feedf (mm/rev) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Chip-breaker | Grade | Chip-breaker | Grade | Chip-breaker | Grade | ø28.01 – ø40 | ||||

| Low carbon steel (C < 0.3) SS400, SM490, S25C, etc. E275A, C25, etc. |

Lower feed | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.25 | ||

| Carbon steel (C > 0.3) S45C, S55C, etc. C45, C55, etc. |

Lower feed | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.12 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.3 | ||

| Low alloy steel (C < 0.3) SCM415, 18CrMo4, etc. |

Lower feed | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.25 | ||

| Alloy steel (C > 0.3) SCM440, SCr420, 42CrMo4, 20Cr4, etc. |

Lower feed | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.12 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 80 – 120 | 0.1 – 0.3 | ||

| Stainless steel (Austenitic) SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

Lower feed | G | AH8015 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| First choice | G | AH8015 | G | AH8015 | G | AH8015 | 60 – 100 | 0.1 – 0.15 | ||

| Stainless steel (Martensitic, Ferritic) SUS430, SUS416, etc. X6Cr17, X12CrS13, etc. |

Lower feed | G | AH8015 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| First choice | G | AH8015 | G | AH8015 | G | AH8015 | 60 – 100 | 0.1 – 0.15 | ||

| Stainless steel (Precipitation hardening) SUS630, X5CrNiCuNb16-4, etc. |

Lower feed | G | AH8015 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| First choice | G | AH8015 | G | AH8015 | G | AH8015 | 60 – 100 | 0.1 – 0.15 | ||

| Grey cast iron FC250, GG25, 250, etc. |

Lower feed | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.14 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.35 | ||

| Ductile cast iron FCD700, 700-2, etc. |

Lower feed | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.14 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.35 | ||

| Aluminium alloys | Lower feed | G | AH725 | DL | AH725 | G | AH725 | 80 – 160 | 0.03 – 0.2 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 100 – 200 | 0.1 – 0.3 | ||

| Heat-resistant alloys Inconel 718, etc. |

Lower feed | G | AH8015 | DL | AH725 | G | AH725 | 20 – 50 | 0.03 – 0.08 | |

| First choice | G | AH8015 | G | AH8015 | G | AH8015 | 20 – 50 | 0.06 – 0.13 | ||

| Titanium alloys Ti-6Al-4V, etc. |

Lower feed | G | AH725 | DL | AH725 | G | AH725 | 30 – 60 | 0.03 – 0.1 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 30 – 60 | 0.1 – 0.18 | ||

| Hardened steel ≥ 40HRC |

Lower feed | G | AH8015 | DL | AH725 | G | AH725 | 40 – 100 | 0.03 – 0.1 | |

| First choice | G | AH8015 | G | AH8015 | G | AH8015 | 50 – 100 | 0.06 – 0.13 | ||

The use of NDL chipbreakers is recommended for cross hole drilling with low feed conditions.

*Coolant recommendations for drilling stainless steel:

– Oil coolant is first priority

– Water soluble coolant requires at least 20% oil concentration

关于该产品的更多信息,请访问我们的线上e-catalog或者下载产品样本:

e-Catalog

导向条