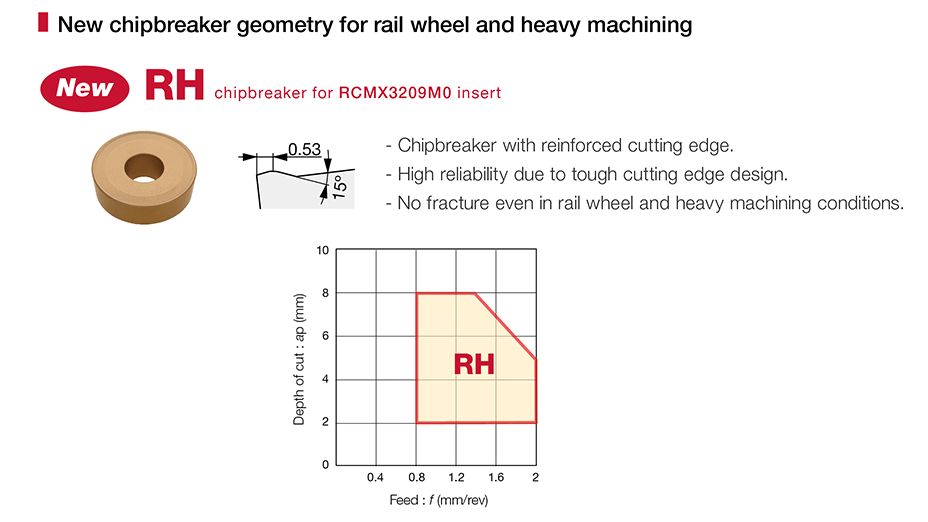

2025年10月, 泰珂洛宣布扩充T9200系列,现新增RCMX3209M0刀片,旨在提升铁路车轮和重型切削应用中的性能。

挑战与趋势

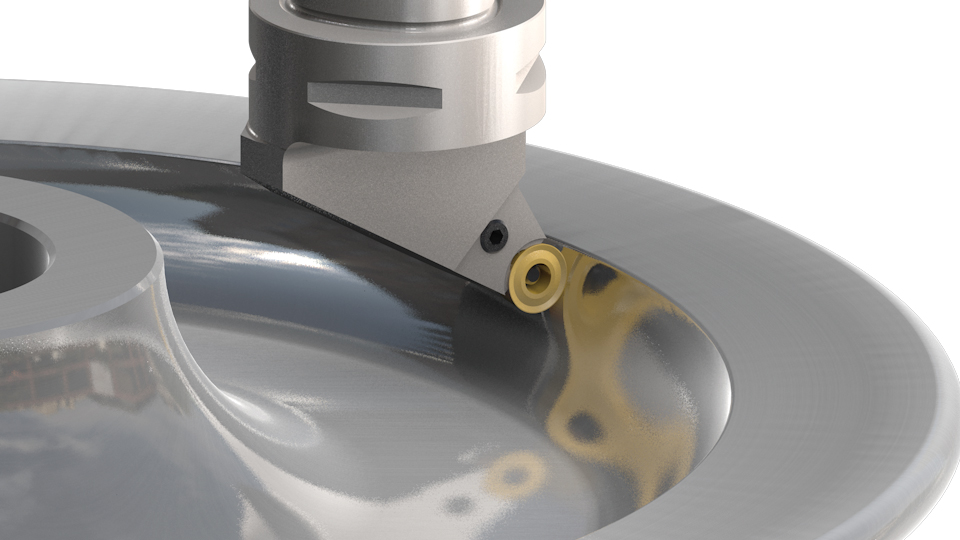

在诸如铁路车轮加工和通用重型切削等机加工应用中,高切削性能与稳定性至关重要。然而,适用于这些苛刻操作的RCMX3209M0形状刀片,此前并未纳入我们T9200系列的标准产品阵容。其结果是,在严苛的切削条件下,刀片频繁出现崩刃或破损,在某些情况下甚至导致刀杆损坏——这在生产效率和成本方面带来了挑战。为回应这些用户关切,市场强烈要求扩展刀片形状范围,以更好地应对这些“挑战与市场状况”。

产品概述

T9200系列是一款专为钢件车削应用而设计的下一代CVD涂层材质。它兼具卓越的耐磨性和高韧性,确保了稳定且长效的刀具寿命。该材质能够耐受高速切削,是在大批量生产环境中实现高效加工的理想解决方案。