Manufacturing companies that use conventional ID boring and reaming tools on lathes often face problems with vibration, chip jamming, and short tool life. Tungaloy’s innovative head-exchangeable ReamMeister solves such issues and drastically improves productivity.

Common problems found with internal finishing operations on lathes

Vibration caused by long overhang

- To maintain stability, you have to lower your cutting conditions.

- To achieve the desired surface finish quality, you have to add extra processes, like polishing and honing.

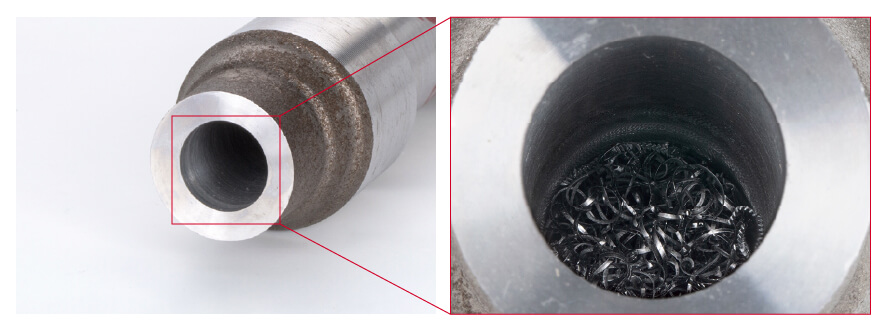

Chip jamming in blind holes

- Since tools break frequently, you have to buy new tools and replace them often.

You also…

- Suffer from short tool life because of sudden deviation in hole diameter and surface roughness.

- Frequently need to stop your machine to replace inserts.

ReamMeister can solve these problems!

Major features of ReamMeister, an innovative reamer with exchangeable head

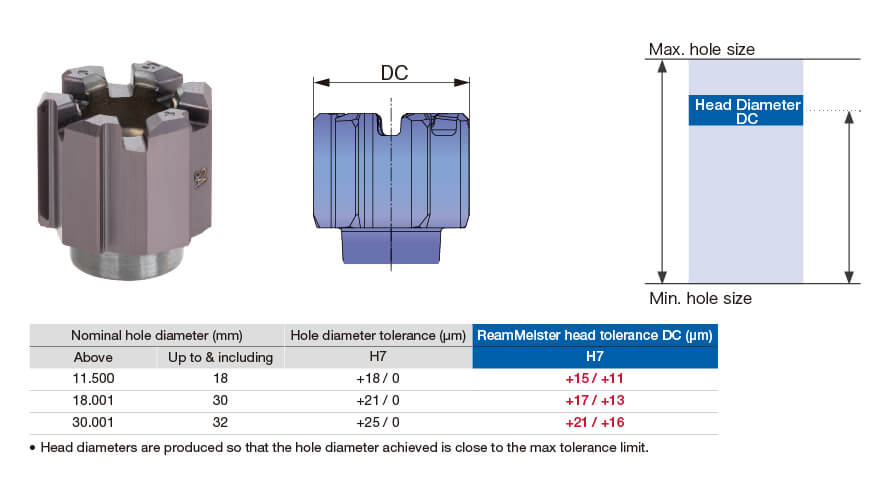

1. H7 hole finishing with high-precision head and accurate mounting

High-precision head with tolerance of 6μm

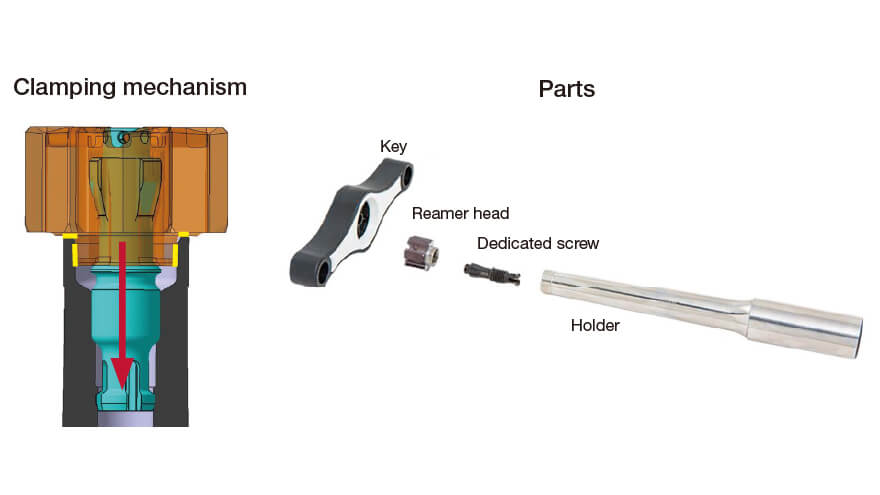

Securely clamped head with the contact on both the taper and the end face,ensuring high repeatability with minium runout

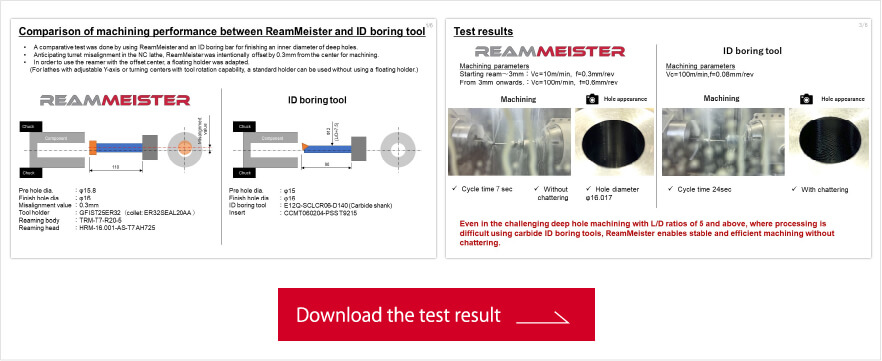

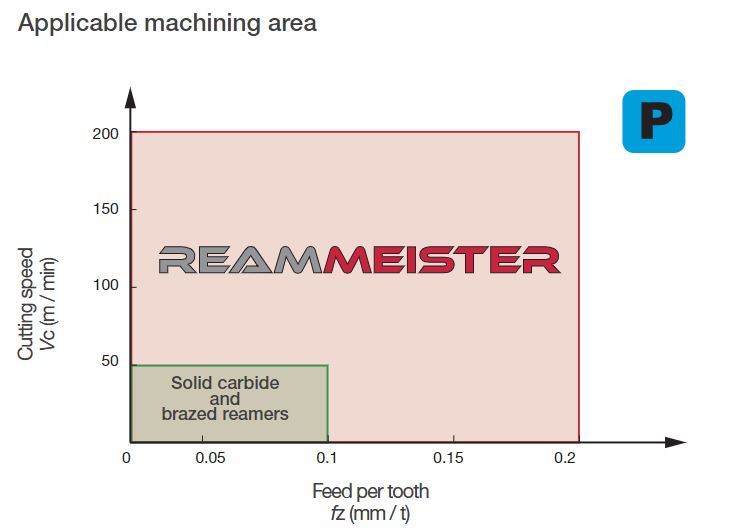

2. Higher productivity compared to conventional ID boring and reaming operations

- Increased number of cutting edges and higher feed rate

- Higher cutting speed compared to non-coated solid carbide reamers and brazed reamers because of PVD coated heads

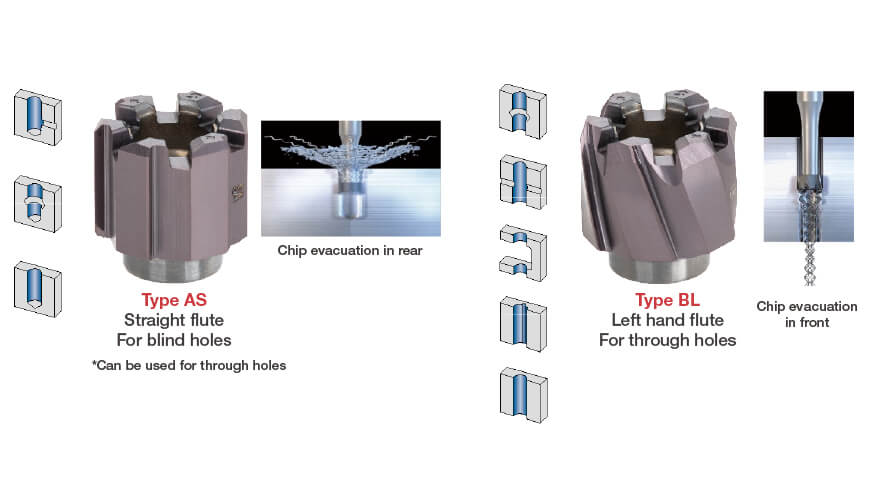

3. Prevent problems related to chip control

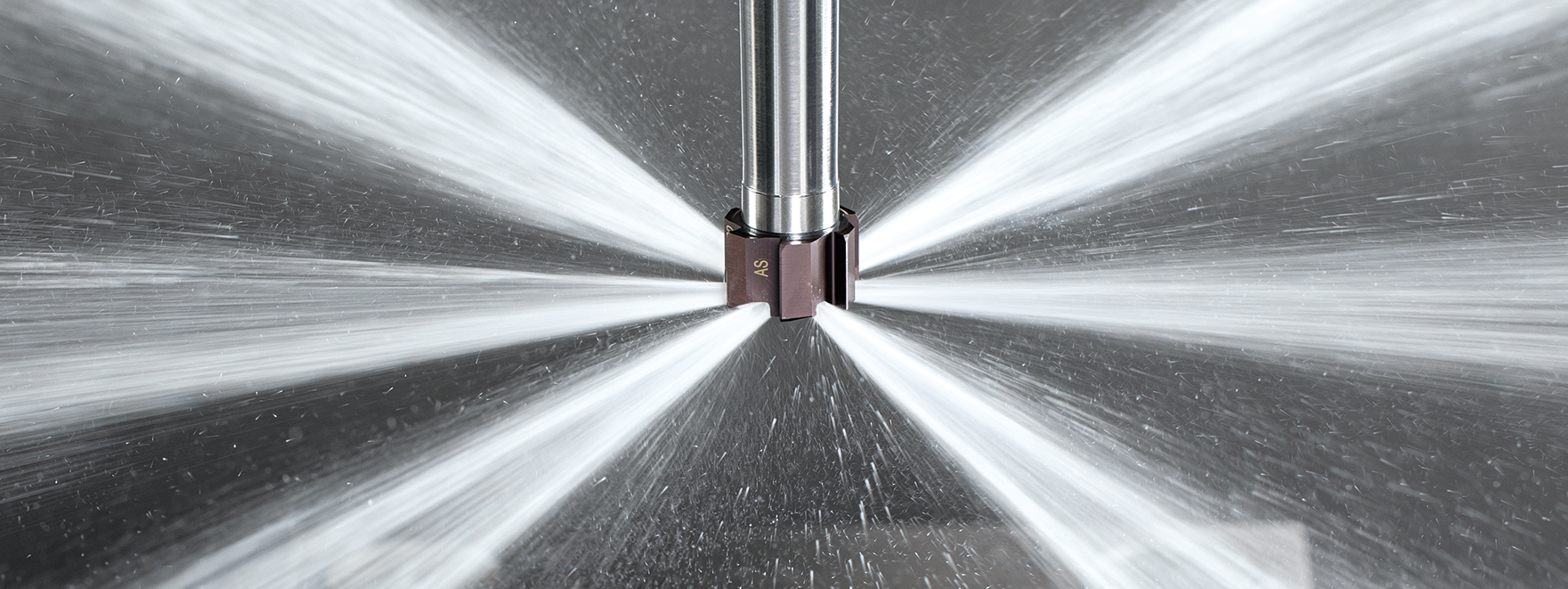

Improved chip evacuation by radially supplying coolant to the cutting edge

Different heads are available for blind holes and through holes. The through-hole head especially enhances chip evacuation and significantly reduces problems with chip entanglement.

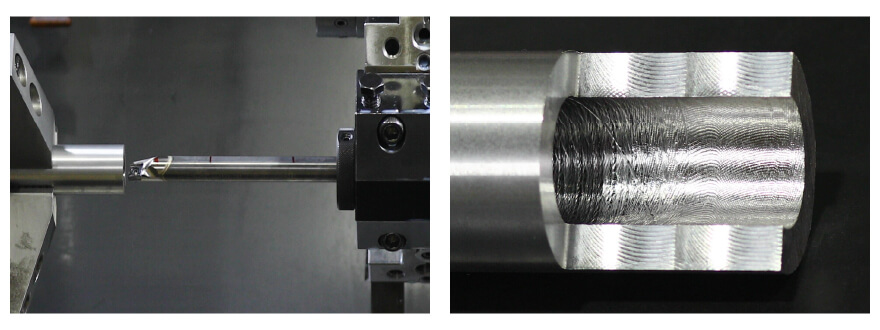

Use of floating holder with reamers on lathes

Reaming requires strict control of runout, which can be challenging on lathes without Y-axis. To improve stability during reaming operations on lathes with limited runout control, it is recommended to use a floating holder. The floating holder absorbs misalignment between the workpiece material and the tool, which enhances stability in reaming operations.

Advantages of using ReamMeister for ID boring operations

- Improved process efficiency

Significantly boost machining efficiency through increased number of cutting edges, even resulting in productivity up to 10 times higher than the conventional operations.

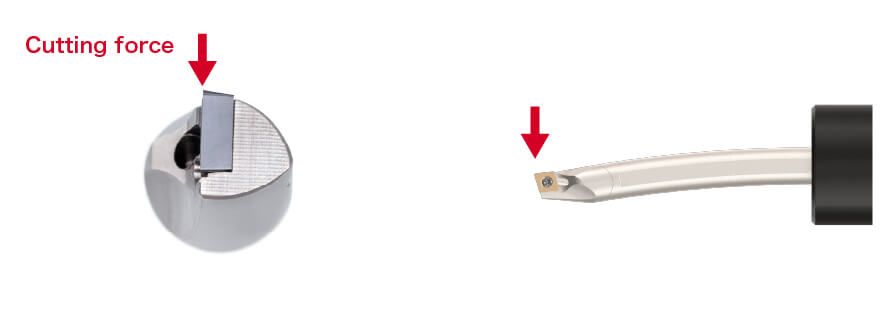

- Enhanced stability during deep hole machining (L/D ratio of 5 or higher)

Deep hole machining can be challenging during boring operations, but the margin support and the vanishing effect provided by reaming significantly improve machining stability.

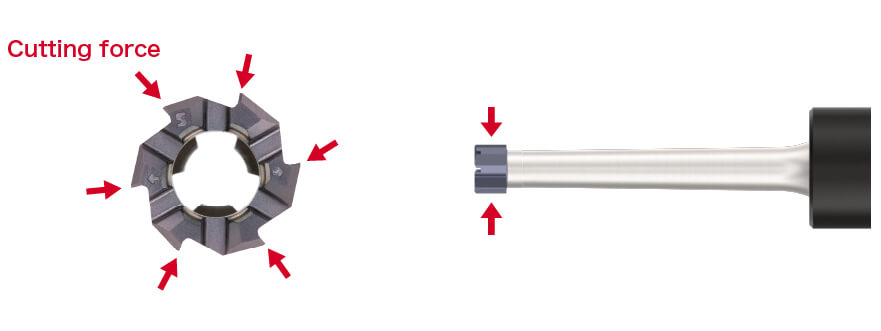

ReamMeister

Stable machining due to oppositely positioned cutting edges and margin support.

ID boring tool

Unstable machining due to tool deflection caused by cutting force.

Extended tool life reduces insert replacement and machine downtime

Reamers may have higher initial and running costs. However, in production lines where machines are often stopped to replace inserts in order to maintain accuracy or to fix issues related to diameter precision, the benefit of longer tool life may outweigh the initial investment.

Advantages of using ReamMeister

- Higher productivity

- Stable machining process by preventing the tool from bending with margin support

Disadvantages of using ReamMeister

- Higher tool cost

- Inability to machine step shapes and profile shapes

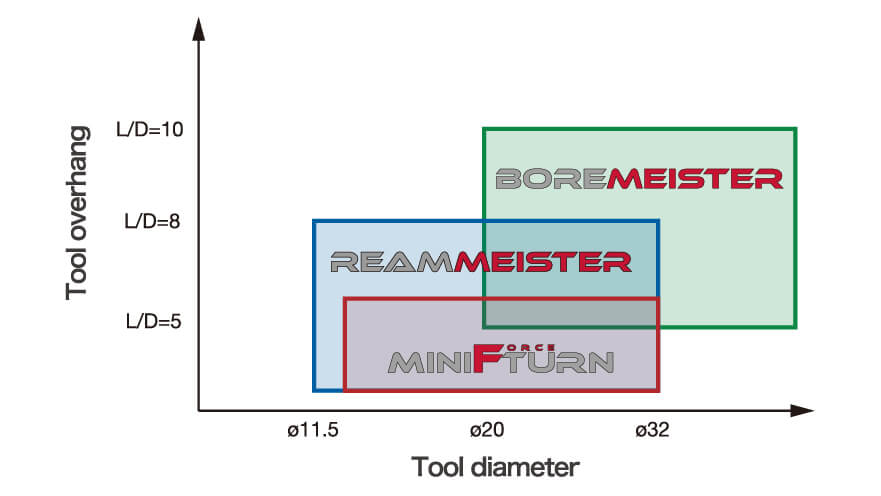

| BoreMeister Anti vibration |

ID boring tool Carbide |

ReamMeister Steel |

|

|---|---|---|---|

| Productivity | ○ | ○ | ◎ |

| Stability over L/D=5 | ○ | △ | ◎ |

| Running cost | ◎ | ◎ | △ |

| Roughness | Ra 1.6-3.2 | Ra 1.6-3.2 | Ra 0.8-1.6 |

| Profile shape | Possible | Possible | Impossible |

When efficiency and surface roughness are in high priority,ReamMeister is the best choice.

Comparison of machining performance between ReamMeister and ID boring tool

Information about the highlighted product

Hole Making

Head-exchangeable reamer

ReamMeister

High precision and efficiency in reaming operations with an innovative head-clamping method