Iwaki, Japan – January, 2026 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its TungMeister series, introducing a new sharp-corner-edge specification for square heads that enables true sharp-corner machining with enhanced precision, rigidity, and cost efficiency.

Challenges and Trends

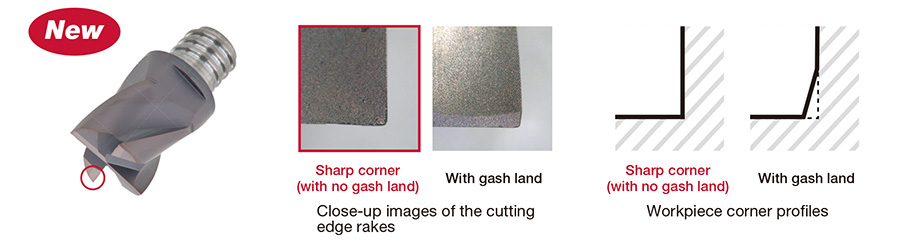

In the field of component machining, there has been a growing demand for sharp corners (pin corners) specified on drawings. Especially in the manufacturing of precision components, the dimensional accuracy of micro corner geometries is becoming increasingly critical. However, conventional TungMeister square heads feature a gash-land design, which tends to leave a slight uncut remnant at the corner, making sharp-corner machining difficult.

As a result, many users have relied on solid end mills to achieve such sharp corners. Nevertheless, this approach imposes significant burdens in terms of tool cost, setup time, and regrinding management, prompting the need for a more efficient machining method. To respond to these market needs, there is a growing requirement to expand the lineup of sharp-corner-edge specifications.

Product Overview

TungMeister is Tungaloy’s high-efficiency exchangeable-head end mill series.

With over 45 head geometries and a wide variety of shank materials, it meets a broad range of machining requirements.

The simple head replacement reduces setup time while achieving high precision and productivity.

Benefits and Features

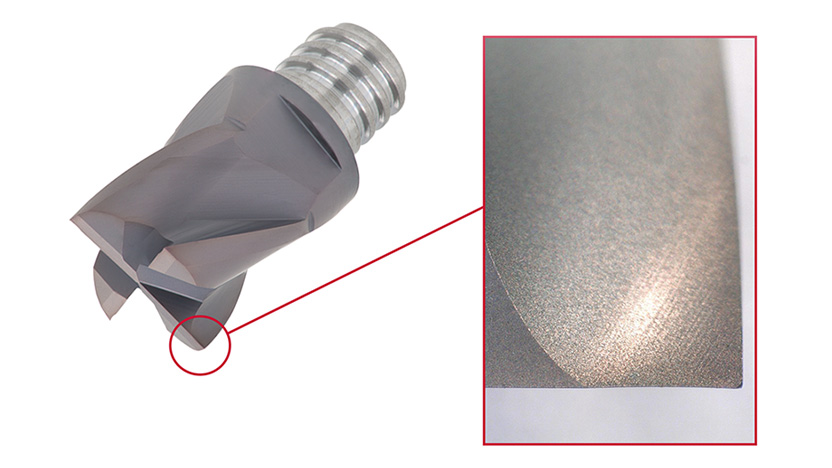

Feature 1: High-precision machining with sharp corner edge design

– The sharp corner edge design eliminates the gash land, enabling machining of shapes with specified sharp corners.

– Achieves surface quality equivalent to that of solid end mills while maintaining corner shape accuracy.

– Despite being an exchangeable-head type, it enables high-precision contour machining with sharp edge geometry.

Feature 2: Reduced setup time through exchangeable head structure

– The separable structure of the cutting head and shank allows replacement of only the head.

– The same overhang length can be maintained during head changes, reducing the need for re-setup or re-measurement.

– Significantly shortens machine downtime and contributes to improved productivity.

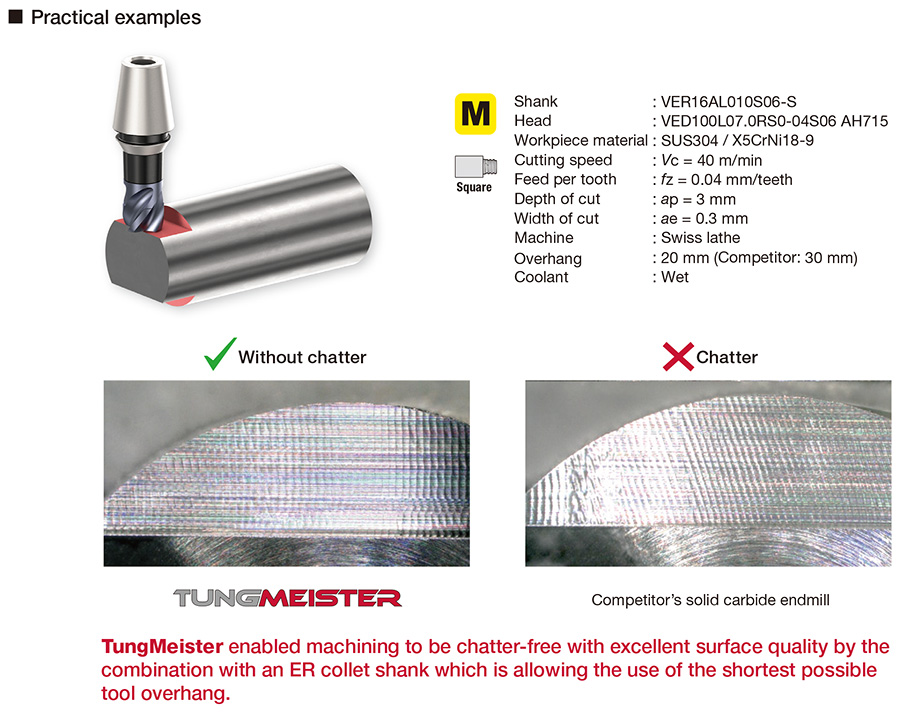

Feature 3: Stable, high-efficiency machining with a high-rigidity shank

– The use of a large-diameter shank enhances overall tool rigidity.

– When interference is not an issue, the overhang length can be freely set, allowing optimization of machining conditions.

– Suppresses vibration and maintains stable machining accuracy even under high-speed cutting conditions.