Iwaki, Japan – December, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its TungForce-Rec series with new PCD inserts for small-diameter cutters (DC ≤ 40 mm), delivering superior precision and productivity in aluminum machining on compact machining centers.

Challenges and Trends

In industries such as automotive and semiconductor manufacturing, the demand for high-precision and high-efficiency machining of aluminum components is increasing more than ever. However, in machining environments that use BT30 machining centers, the spindle speed is limited to a maximum of 10,000 rpm, making it difficult to further increase cutting speed. Therefore, improving productivity requires increasing the number of cutting edges to allow for higher feed rates, which in turn demands innovative tool designs.

Previously, TungRec11 was available as a cutter capable of mounting PCD inserts in end mill types of 40 mm diameter or smaller. However, since the number of cutting edges was equivalent to that of competing products of the same diameter, it was challenging to propose a higher-efficiency machining solution.

Product Overview

TungForce-Rec is a high-precision, high-efficiency 90° shoulder milling cutter developed by Tungaloy. Its unique V-shaped insert seat and high-rigidity body design ensure stable cutting performance even in small diameters. It delivers excellent machining accuracy and productivity across a wide range of applications, including shoulder milling and slotting.

Benefits and Features

Feature 1: Multi-flute design for high-efficiency machining

– Adopts a higher flute count compared to competitors for the same tool diameter, increasing the amount of material removed per revolution and achieving high-efficiency machining.

– The increased number of flutes allows for stable cutting even at higher feed rates.

– Delivers high productivity and reduced machining time even in small-diameter ranges (DC ≤ 40 mm).

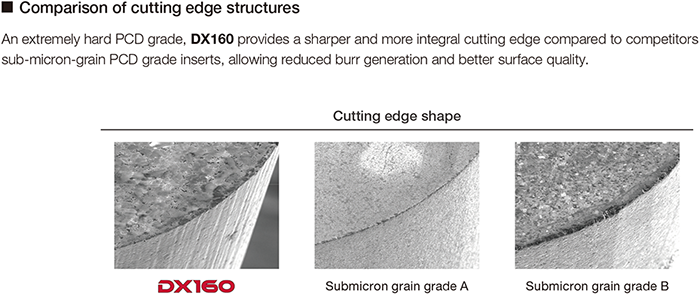

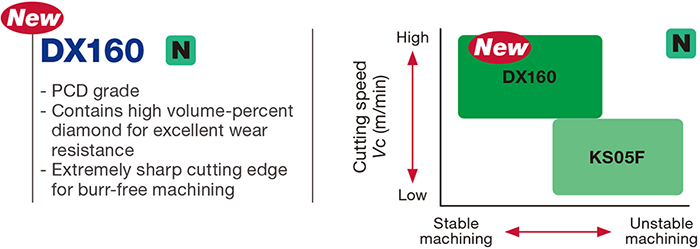

Feature 2: PCD grade DX160 combining high wear resistance and excellent sharpness

– Employs high-content PCD grade DX160, offering improved wear resistance compared to competitors’ ultra-fine-grain PCD grades.

– Sharp cutting edge design enables smooth cutting and low-resistance machining.

– Suppresses burr formation during cutting, reducing the workload in subsequent processes.

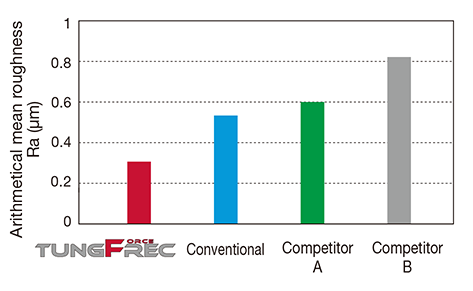

Feature 3: Achieving superior surface finish quality

– Low cutting resistance per edge ensures a stable cutting condition.

– Minimizes tool vibration, reducing surface roughness.

– Provides excellent surface quality in high-precision finishing of aluminum and non-ferrous metals.

Cutting Performance

Comparison of surface quality

| Cutter | EPAV12M025C25.0R04 (DC = 25 mm, CICT = 4) |

| Insert | AVGW120404PDFR-D DX160 |

| Workpiece material | ADC12 |

| Cutting speed | Vc = 1,000 m/min |

| Feed per tooth | fz = 0.1 mm/t |

| Depth of cut | ap = 1 mm |

| Cutting width | ae = 20 mm |

| Coolant | Wet (Internal) |

DX160 provides superior surface finishing quality.

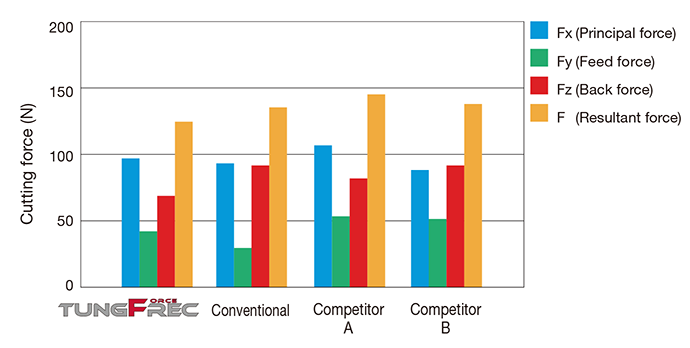

Cutting force comparison

| Cutter | EPAV12M025C25.0R04 (DC = 25 mm, CICT = 1) |

| Insert | AVGW120404PDFR-D DX160 |

| Workpiece material | ADC12 |

| Cutting speed | Vc = 1,000 m/min |

| Feed per tooth | fz = 0.1 mm/t |

| Depth of cut | ap = 2 mm |

| Cutting width | ae = 2.5 mm |

| Coolant | Wet (Internal) |

DX160 inserts generates light cutting action, compared with the predecessor grades as well as competitors, making it ideal for chatter-prone long reach applications.