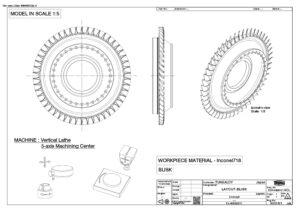

Aerospace – Blisk

Blisk is a structural component of aircraft jet engine that integrates blades and a disk. Blisk is machined by a 5-axis controlled milling machine because of the complicated machining process and high quality required.

High strength, heat resistant alloys such as Inconel and Waspaloy have excellent strength and high temperature characteristics but are difficult to machine. Tool wear is significant when machining these advanced materials, so it is necessary to utilize the latest cutting tools and techniques.

Tungaloy’s latest tool geometry and grade technology provide a stable and long life even under heavy machining conditions, providing effective solutions for difficult-to-cut materials.

Tooling concepts

- Flexible tool design for complicated machining shapes

- Minimization of machine downtime using TungCap tooling

- Prevents chattering in thin-walled and deep part area and improves processing efficiency

- Improved production efficiency in the semi-finishing process with barrel-shape tools for 5-axis machining

- Use of head changeable tools to reduce machine down time and effort of tool replacement and management

Featured process

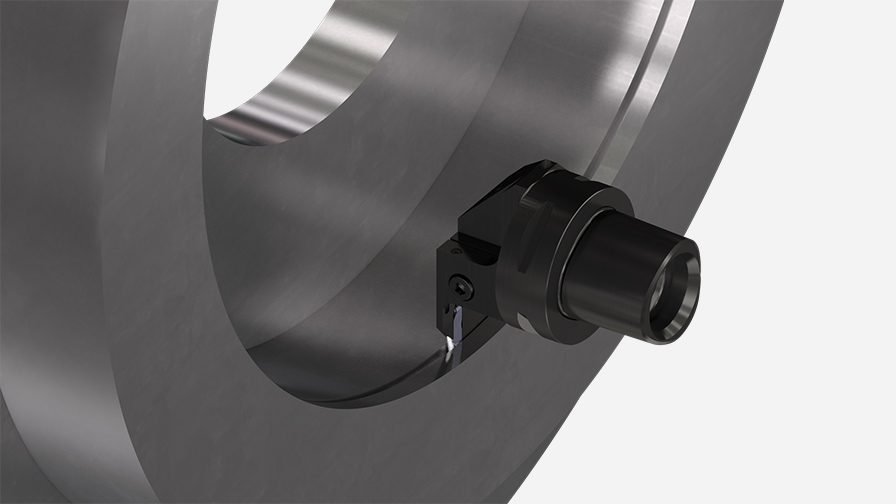

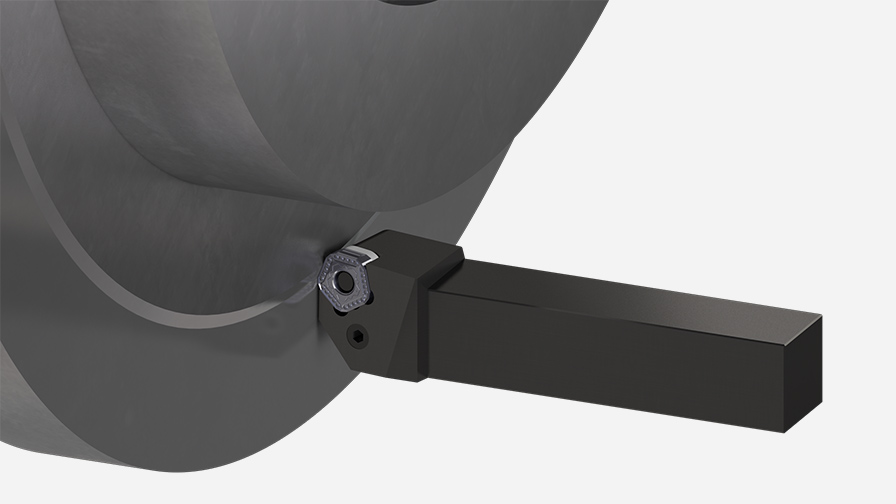

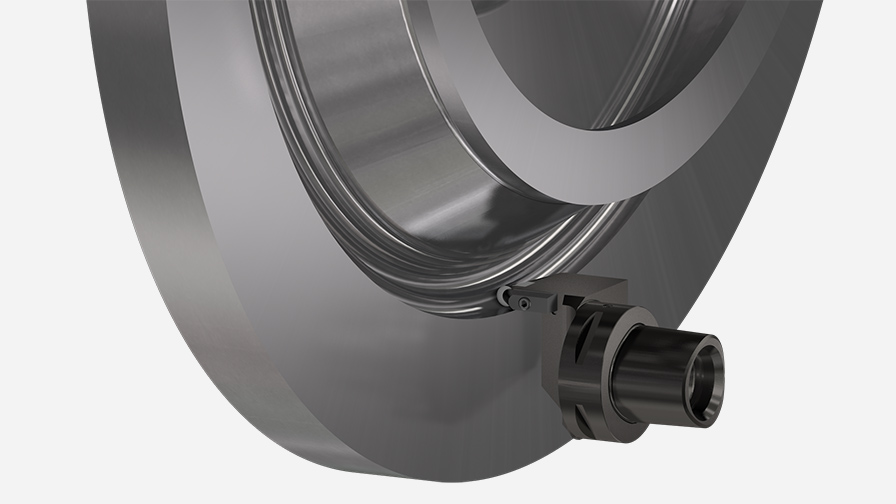

Process 1: Internal grooving

Benefits

- With chip breaker, excellent chip control even with full R insert

- By suppling coolant directly to the cutting edge, chip control issues, which tend to be a problem in grooving, are improved and insert life is extended

- TungCut’s unique arc-shaped insert seat improves clamp rigidity. Achieves high stability not only in grooving but also in turning processes

AH8005

- Prevents boundary wear which is a problem in heat-resistant alloy turning

- High wear resistance due to high hardness coating film

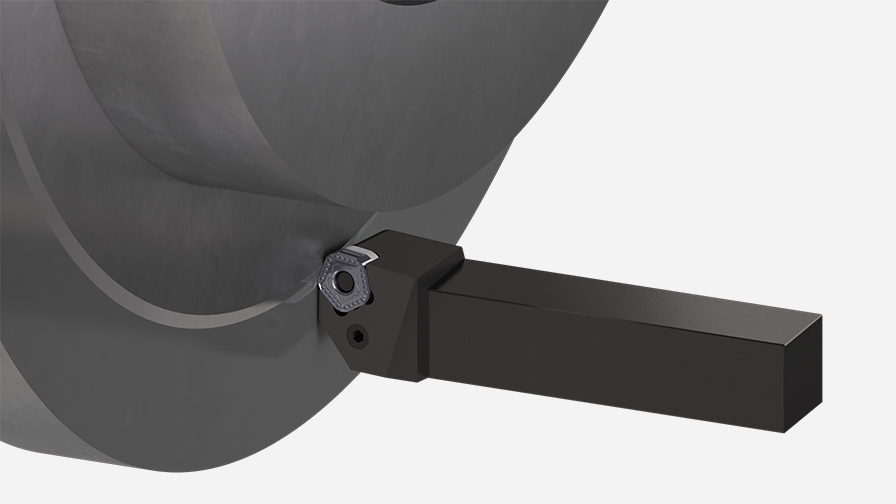

Process 2: Rough face turning

Benefits

- Achieves high feed machining by generating thin chips with small approach angle

- High clamp rigidity is achieved by the lever lock clamp and dovetail clamping mechanism

- Chips are surely controlled by the protrusions on the rake surface of the insert

- High economical double-sided 10-corner insert

- Two types of holders are available depend on machining requirements,, HD type for high D.O.C and HF type for high feed turning. The same insert can be mounted on both holders

AH8015

- Prevents boundary wear which is a problem in heat-resistant alloy turning

- Excellent balance between wear resistance and fracture resistance

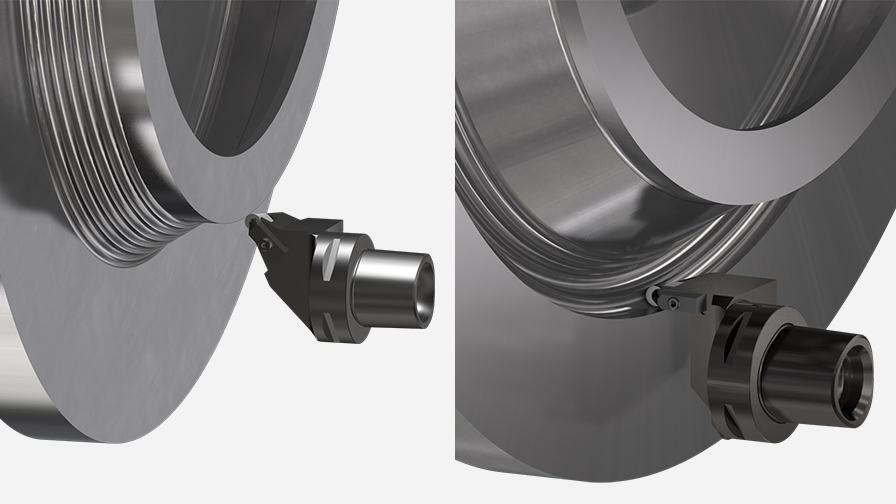

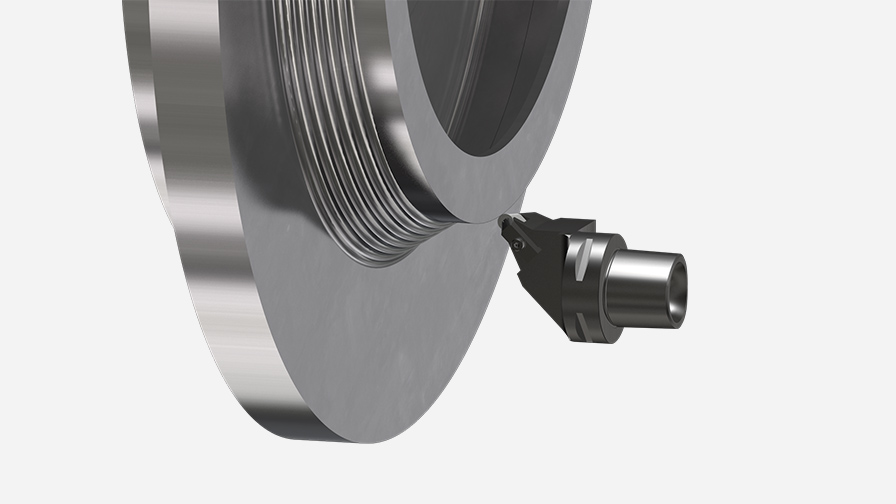

Process 3: Rough external turning / Rough face grooving

Benefits

- TS300 grade is a ceramic grade with high toughness and can be applied at a higher D.O.C. even in ceramic grade

- By reducing the number of machining paths, the effects of work hardening of materials are reduced and the tool life is extended

- TungCap tooling significantly reduces machine downtime

- TungCap, with two face contacts ensures high tool rigidity and contributes to improving the efficiency of rough machining

Rough external turning

Rough face grooving

![]()

- Sialon ceramic with excellent wear resistance and fracture resistance

- The solution for high-speed and high-efficiency machining of heat-resistant alloys

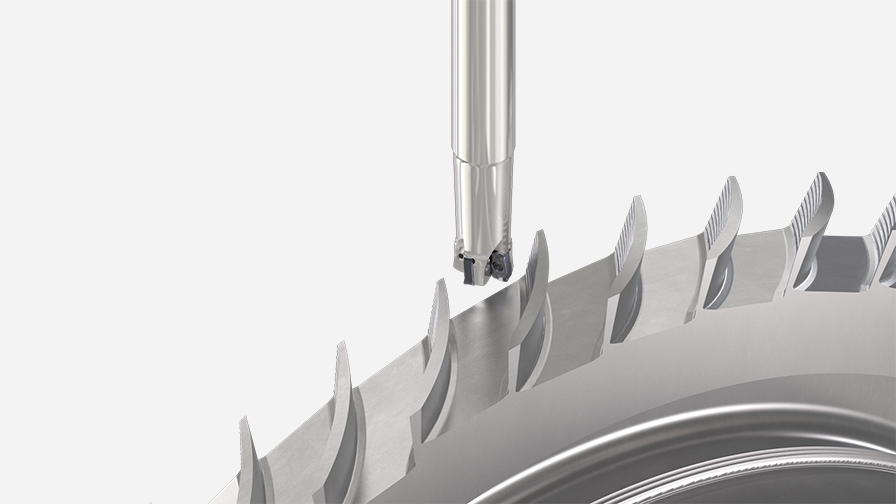

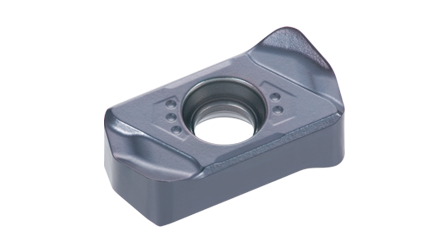

Process 4: Slot milling

Benefits

- DoFeed is a high feed cutter series with high density, and provides high-productivity machining without chattering

- The unique cutting edge geometry with deep inclination reduces work hardening effect of difficult-to-cut materials and extends tool life

- By using UER type insert with low approach angle, the chip thickness is reduced and the load on the cutting edge is reduced. Demonstrates outstanding tool life performance in high-feed machining of difficult-to-cut materials

- Economical double-sided 4-corner insert

AH8015

- Prevents boundary wear which is a problem in heat-resistant alloy turning

- Excellent balance between wear resistance and fracture resistance

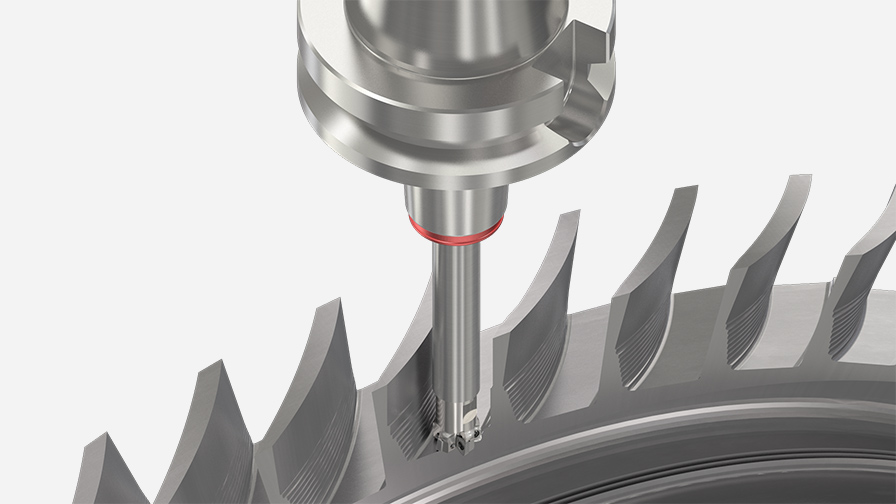

Process 5: Slot milling with long overhang

Benefits

- The direction of chip flow is reliably controlled by positive inclination cutting edge.

Outstanding stability even in pocket milling and slotting where chip biting is likely to happen - By using a high feed cutter with low approach angle that is resistant to chatter, it improves machining efficiency and stabilizes tool life even in long overhang operations

- High density cutter with small size inserts can greatly improves machining efficiency

- Small-diameter high-feed milling cutter with robust design for stability and efficiency

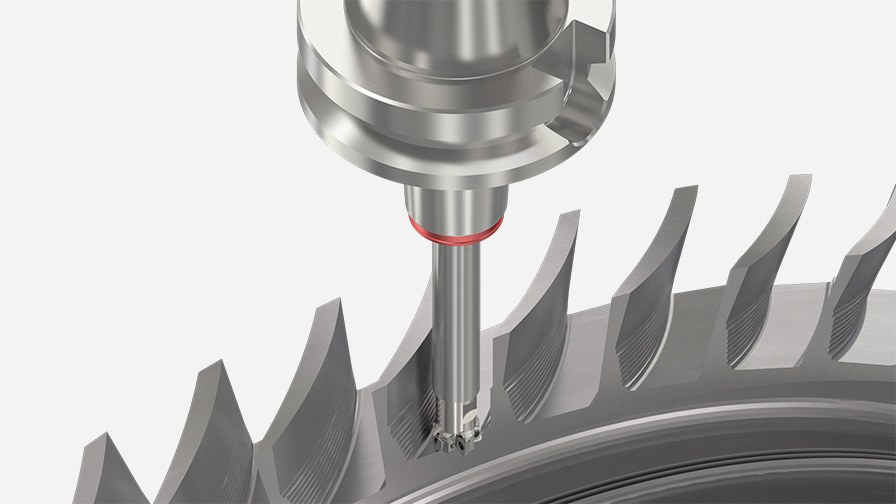

Process 6: Semi finish profiling with 5 axis machining

Benefits

- Barrel tool for 5-axis machining with “barrel” -shaped cutting edge that has an arc cutting edge with a large radius.

Compared with conventional ball end mill, the number of passes is reduced by applying large pitch and reduces machining time significantly - Since using the outer peripheral edge of the tool, the actual cutting speed on the cutting edges are increased and the tool life is improved

- Reduces the trouble of tool management by using replaceable head tools

- VBN type head has cutting edges suitable for wing of aircraft parts in semi finish operations