Non-Ferrous Application Series

Complete turning solutions for non-ferrous materials

The ultimate tools for high speed machining of non-ferrous alloys.

Chip nesting is a thing of the past.

Applications & Features

Applications

Features

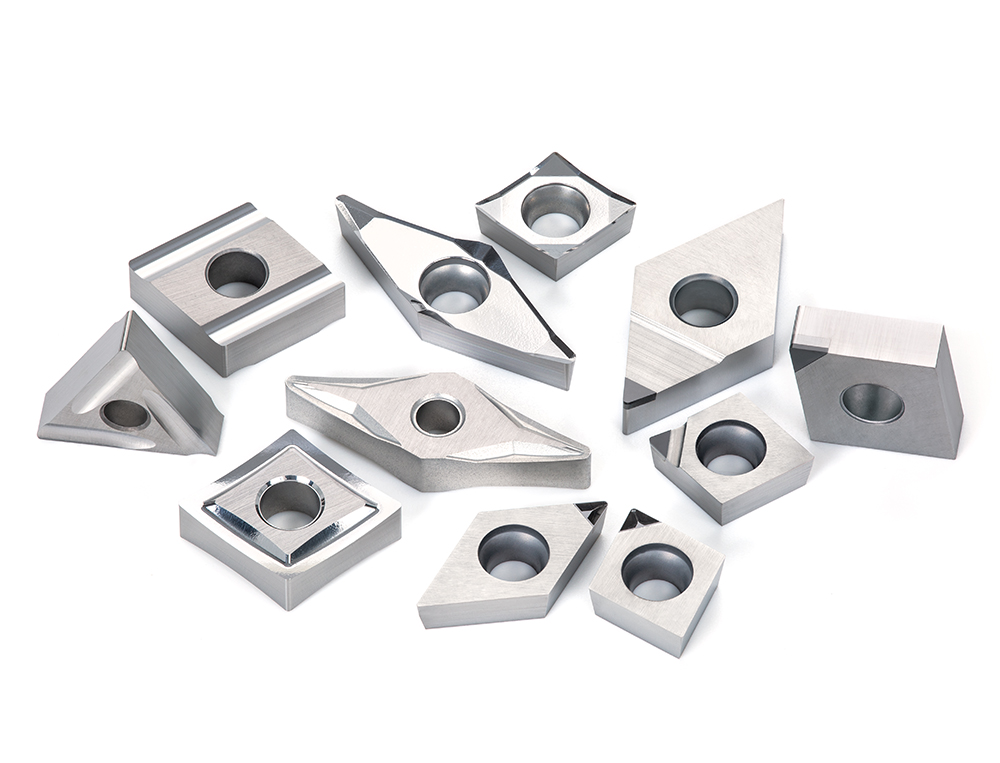

Ultra-fine grained PCD-tipped inserts

Definitive insert series for high speed machining of aluminum alloys

- Ultra-fine grained PCD grade for edge sharpness

- An extremely wear-resistant grade, featuring strongly-bonded diamond grains that prevents the grains from breaking off during machining

- Thanks to ultra-fine diamond grains, DX110 provides superior surface finish

- Chipbreaker series with rake angle of 10°

1. Grade selection guide

2. PCD grades and applications

PCD inserts with 3D chipbreaker

No more chip nesting in aluminum alloy machining

Unique 3D chipbreaker

- Versatile geometry allows excellent chip control

- One insert handles from rough to finish operations

- Optimal rake angle design effectively directs chips to the redirector

Fine-grained cemented carbide inserts with chipbreaker for non-ferrous alloy

No more chip nesting in aluminum alloy and copper alloy machining

For positive insert

First-choice geometry for non-ferrous applications

AL

- Provides excellent chip control and resistance to wear and built-up edge

- Low cutting forces generated by a large rake angle and sharp cutting edge

- 3D geometry with lapped rake face

- Superb chip control enabled by large inclination angle of the cutting edge

- Available on 26 total inserts, including CCGT, DCGT, RCGT, TCGT, and VCGT inserts

For negative insert

Press-in chipbreaker ideal for medium to finish operations

28

- Versatile geometry with a large inclination angle of the cutting edge. Ideal for medium to finish operations

- Provides superior surface finish and chip control

Linear chipbreaker

P

Provides process security across a wide range of applications

Grades

DX110

![]()

- Excellent sharpness for high surface quality

- Suitable for finishing non-ferrous metal and nonmetal

KS05F

![]()

- N15

- Uncoated cemented carbide

DX200

![]()

- 100% diamond grade

- DX200 has a sharp cutting edge that provides excellent surface finish.

Practical examples

Example #1

Automotive Industry

| Part: | Con-rods |

| Material: | Copper-based sintered alloy |

| Insert: | 1QP-CCMT09T304, 1QP-CCMT32.51 |

| Grade: | DX110 |

| Cutting conditions: | Vc = 300 (m/min) f = 0.05 (mm/rev) ap = 0.1 (mm) Coolant: Wet |

Example #2

| Part: | Transmission parts |

| Material: | A2011 / AlCu6BiPb |

| Insert: | 1QP-VCGT160404-NS |

| Grade: | DX110 |

| Cutting conditions: | Vc = 1,400 (m/min) f = 0.08 (mm/rev) ap = 0.1 (mm) Coolant: Wet |

Example #3

| Part: | Pipe |

| Material: | A5052S / AlMg2.5 |

| Insert: | 1QP-DCGT11T304-NS |

| Grade: | DX110 |

| Cutting conditions: | Vc = 400 (m/min) f = 0.1 (mm/rev) ap = 1 (mm) Coolant: Wet |

Standard cutting conditions

| ISO | Workpiece materials | Chipbreaker | Grade | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

Depth of cut ap (mm) |

|---|---|---|---|---|---|---|

|

Aluminum alloys (Si ≤ 12%) |

NS | DX110, DX160 | 300 – 2500 | 0.03 – 0.3 | 0.1 – 2 |

| Without | DX110, DX120, DX140, DX160 |

300 – 2500 | 0.05 – 0.2 | 0.05 – 2 | ||

| AL | KS05F | 100 – 1200 | 0.1 – 0.5 | 0.05 -5 | ||

| 28 | KS05F | 100 – 1200 | 0.1 – 0.5 | 0.5 – 3 | ||

| P | TH10 | 100 – 1000 | 0.2 – 0.5 | 0.5 – 4 | ||

| JP | KS05F | 100 – 1200 | 0.02 – 0.1 | 0.05 – 2.5 | ||

| JS | KS05F | 100 – 1200 | 0.02 – 0.2 | 0.5 – 3 | ||

| Aluminum alloys (Si ≥ 12%) |

NS | DX110, DX160 | 300 – 800 | 0.03 – 0.2 | 0.1 – 2 | |

| Without | DX110, DX120, DX140, DX160 |

300 – 800 | 0.05 – 0.2 | 0.05 – 2 | ||

| Without | DX120 | 400 – 800 | 0.05 – 0.2 | 0.05 – 2 | ||

| Without | DX140 | 400 – 800 | 0.05 – 0.2 | 0.05 – 2 | ||

| Without | DX160 | 400 – 800 | 0.05 – 0.2 | 0.05 – 2 | ||

| AL | KS05F | 100 – 300 | 0.1 – 0.5 | 0.5 – 5 | ||

| 28 | KS05F | 100 – 300 | 0.1 – 0.5 | 0.5 – 3 | ||

| P | TH10 | 100 – 300 | 0.2 – 0.5 | 0.5 – 4 | ||

| JP | KS05F | 100 – 1200 | 0.02 – 0.1 | 0.05 – 2.5 | ||

| JS | KS05F | 100 – 300 | 0.02 – 0.2 | 0.5 – 3 | ||

| Copper and copper alloys | NS | DX110, DX160 | 300 – 1500 | 0.03 – 0.3 | 0.1 – 2 | |

| Without | DX110, DX120, DX140, DX160 |

300 – 1500 | 0.05 – 0.2 | 0.05 – 2 | ||

| AL | KS05F | 100 – 300 | 0.1 – 0.5 | 0.5 – 5 | ||

| 28 | KS05F | 100 – 300 | 0.1 – 0.5 | 0.5 – 3 | ||

| P | TH10 | 100 – 300 | 0.2 – 0.5 | 0.5 – 4 | ||

| JP | KS05F | 100 – 300 | 0.02 – 0.1 | 0.05 – 2.5 | ||

| JS | KS05F | 100 – 300 | 0.02 – 0.2 | 0.5 – 3 | ||

| Magnesium alloys | Without | DX110, DX120, DX140, DX160 |

400 – 1200 | 0.05 – 0.2 | 0.05 – 1 | |

| FRP | Without | DX160, DX200 | 500 – 1000 | 0.05 – 0.3 | 0.1 – 1 | |

| CFRP | Without | DX160, DX200 | 100 – 700 | 0.05 – 0.3 | 0.1 – 1 | |

| Carbon | Without | DX160, DX200 | 300 – 500 | 0.05 – 0.3 | 0.1 – 1 | |

| Green ceramics | Without | DX160, DX200 | 100 – 200 | 0.02 – 0.1 | 0.1 – 1 | |

| Tungsten carbide (HRA80 – 95) | Without | DX160, DX200 | 5 – 30 | 0.02 – 0.1 | 0.02 – 0.2 | |

| Sputtering targets for semiconductor | Without | DX200 | 10 – 100 | 0.02 – 0.1 | 0.02 – 0.2 |

For more information about this product, visit our online e-catalog or download the product report: