钢件车削加工用新一代CVD 材质

凭借优秀的耐磨性和优秀的抗崩损性进一步提高您的加工效率

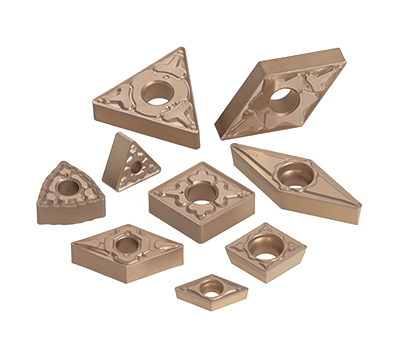

应用 & 特点

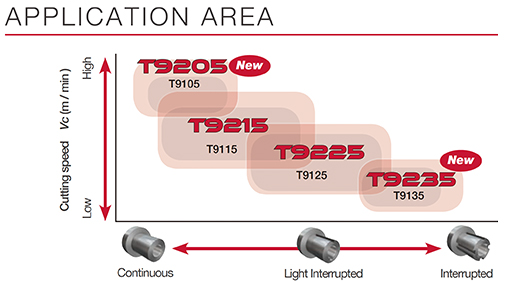

应用

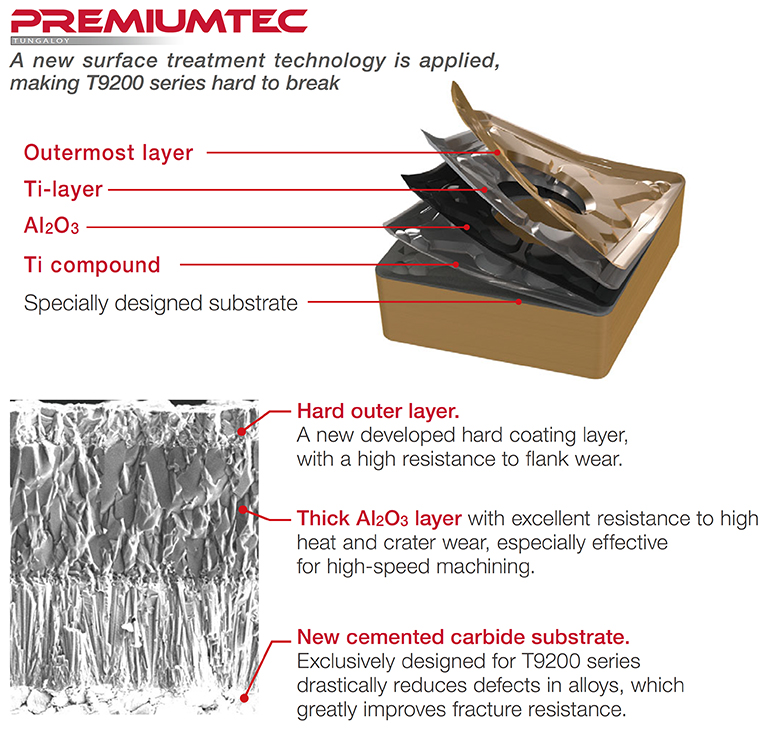

特点

1. 优秀的耐磨性和优秀的抗崩损性

2. 应用范围

材质

实际案例

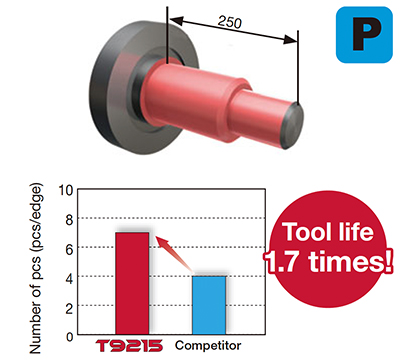

案例 #1

通用工程

| 零件: | 轴 |

| 材料: | SCM440 / 42CrMo4 |

| 刀片: | CNMG120408-TM |

| 材质: | T9215 |

| 加工条件: | Vc = 250 (m/min) f = 0.3 (mm/rev) ap = 3.5 (mm) 冷却方式: 冷却液 |

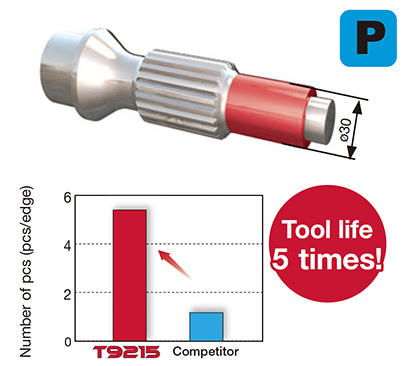

案例 #2

通用工程

| 零件: | 轴 |

| 材料: | SCM440 / 42CrMo4 |

| 刀片: | DNMG150412-TM |

| 材质: | T9215 |

| 加工条件: | Vc = 140 (m/min) f = 0.38 (mm/rev) ap = 4mm x 6 刀(mm) 冷却方式: 冷却液 |

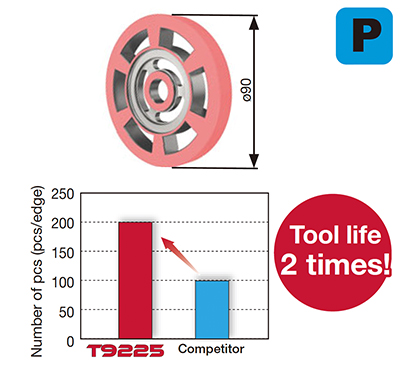

案例 #3

汽车行业

| 零件: | 转子零件 |

| 材料: | S10C |

| 刀片: | WNMG080412-TM |

| 材质: | T9225 |

| 加工条件: | Vc = 400 (m/min) f = 0.45 (mm/rev) ap = 1.5 (mm) 冷却方式: 冷却液 |

标准加工条件

负角型刀片

| ISO | 应用 | 断屑槽 | Grades | 切深 ap (mm) | 进给 f (mm/rev) | 切削速度: Vc (m/min) | ||

|---|---|---|---|---|---|---|---|---|

| 低碳钢,合金钢 | 中碳钢,合金钢 | 高碳钢,合金钢 | ||||||

| 精加工 | PS | T9215 | 0.3 – 1.5 | 0.1 – 0.4 | 150 – 400 | 150 – 400 | 120 – 300 | |

| T9225 | 120 – 300 | 120 – 300 | 100 – 250 | |||||

| TSF | T9205 | 0.2 – 1.5 | 0.08 – 0.4 | 180 – 400 | 180 – 400 | 150 – 350 | ||

| T9215 | 150 – 400 | 150 – 400 | 120 – 300 | |||||

| T9225 | 120 – 300 | 120 – 300 | 100 – 250 | |||||

| T9235 | 50 – 200 | 50 – 200 | 50 – 150 | |||||

| AS | T9205 | 0.2 – 1.5 | 0.08 – 0.4 | 180 – 400 | 180 – 400 | 150 – 350 | ||

| T9215 | 150 – 400 | 150 – 400 | 120 – 300 | |||||

| T9225 | 120 – 300 | 120 – 300 | 100 – 250 | |||||

| T9235 | 50 – 200 | 50 – 200 | 50 – 150 | |||||

| FW | T9205 | 0.2 – 1.5 | 0.08 – 0.4 | 180 – 400 | 180 – 400 | 150 – 350 | ||

| T9215 | 150 – 400 | 150 – 400 | 120 – 300 | |||||

| T9225 | 120 – 300 | 120 – 300 | 100 – 250 | |||||

| T9235 | 50 – 200 | 50 – 200 | 50 – 150 | |||||

| 半精加工 | PM | T9215 | 0.5 – 5.5 | 0.15 – 0.5 | 150 – 400 | 150 – 400 | 120 – 300 | |

| T9225 | 120 – 300 | 120 – 300 | 100 – 250 | |||||

| TM | T9205 | 1.0 – 5.0 | 0.2 – 0.5 | 180 – 400 | 180 – 400 | 150 – 350 | ||

| T9215 | 150 – 400 | 150 – 400 | 120 – 300 | |||||

| T9225 | 120 – 300 | 120 – 300 | 100 – 250 | |||||

| T9235 | 50 – 200 | 50 – 200 | 50 – 150 | |||||

| AM | T9205 | 1.5 – 4.5 | 0.2 – 0.6 | 180 – 400 | 180 – 400 | 150 – 350 | ||

| T9215 | 150 – 400 | 150 – 400 | 120 – 300 | |||||

| T9225 | 120 – 300 | 120 – 300 | 100 – 250 | |||||

| T9235 | 50 – 200 | 50 – 200 | 50 – 150 | |||||

| SW | T9205 | 0.5 – 2.0 | 0.3 – 0.6 | 180 – 400 | 180 – 400 | 150 – 350 | ||

| T9215 | 150 – 400 | 150 – 400 | 120 – 300 | |||||

| T9225 | 120 – 300 | 120 – 300 | 100 – 250 | |||||

| T9235 | 50 – 200 | 50 – 200 | 50 – 150 | |||||

| 半精加工到重载加工 | TH | T9205 | 3.0 – 6.0 | 0.3 – 0.6 | 180 – 400 | 180 – 400 | 150 – 350 | |

| T9215 | 150 – 400 | 150 – 400 | 120 – 300 | |||||

| T9225 | 120 – 300 | 120 – 300 | 100 – 250 | |||||

| T9235 | 50 – 200 | 50 – 200 | 50 – 150 | |||||

| Stainless steel | ||||||||

| 精加工 | TSF | T9215 | 0.2 – 1.5 | 0.08 – 0.4 | 100 – 250 | |||

| T9225 | ||||||||

| 半精加工 | TM | T9215 | 1.0 – 5.0 | 0.2 – 0.5 | 100 – 250 | |||

| T9225 | ||||||||

| Cast iron | ||||||||

| 精加工 | TSF | T9215 | 0.2 – 1.5 | 0.08 – 0.4 | 140 – 500 | |||

| T9225 | ||||||||

| 半精加工 | TM | T9215 | 1.0 – 5.0 | 0.2 – 0.5 | 140 – 500 | |||

| T9225 | ||||||||

正角刀片

| ISO | 应用 | 断屑槽 | Grades | 切深 ap (mm) |

进给f (mm/rev) | 切削速度: Vc (m/min) | ||

|---|---|---|---|---|---|---|---|---|

| 低碳钢,合金钢 | 中碳钢,合金钢 | 高碳钢,合金钢 | ||||||

| 精加工 | PSF | T9215 | 0.1 – 0.5 | 0.05 – 0.3 | 120 – 350 | 100 – 350 | 80 – 250 | |

| T9225 | 100 – 300 | 80 – 300 | 80 – 250 | |||||

| 半精加工 | TSF | T9215 | 0.5 – 2.5 | 0.1 – 0.25 | 120 – 350 | 100-350 | 80-250 | |

| T9225 | 100 – 300 | 80 – 300 | 80 – 250 | |||||

| TM | T9215 | 0.25 – 3.0 | 0.06 – 0.26 | 120 – 350 | 100 – 350 | 80 – 250 | ||

| T9225 | 100 – 300 | 80 – 300 | 80 – 250 | |||||

| 半精加工 | PS | T9215 | 0.5 – 2.5 | 0.08 – 0.3 | 120 – 300 | 100 – 300 | 80 – 250 | |

| T9225 | 100 – 300 | 80 – 250 | 80 – 200 | |||||

| SW | T9215 | 0.5 – 2 | 0.15 – 0.4 | 150 – 350 | 150 – 350 | 120 – 300 | ||

| T9225 | 100 – 300 | 100 – 300 | 80 – 250 | |||||

| 半精加工到重载加工 | PM | T9215 | 1.0 – 3.0 | 0.15 – 0.3 | 120 – 300 | 100 – 300 | 80 – 200 | |

| T9225 | 100 – 300 | 80 – 300 | 80 – 200 | |||||

| 重载加工 | RH | T9205 | 2 – 8 | 0.8 – 2 | 180 – 400 | 180 – 400 | 150 – 350 | |

| Stainless steel | ||||||||

| 精加工 | PSF | T9215 | 0.1 – 0.5 | 0.05 – 0.3 | 50 – 200 | |||

| T9225 | ||||||||

| 半精加工 | PS | T9215 | 0.5 – 2.5 | 0.08 – 0.3 | 50 – 200 | |||

| T9225 | ||||||||

| Cast iron | ||||||||

| 精加工 | PSF | T9215 | 0.1 – 0.5 | 0.05 – 0.3 | 100 – 350 | |||

| T9225 | ||||||||

| 半精加工 | PS | T9215 | 0.5 – 2.5 | 0.08 – 0.3 | 100 – 350 | |||

| T9225 | ||||||||