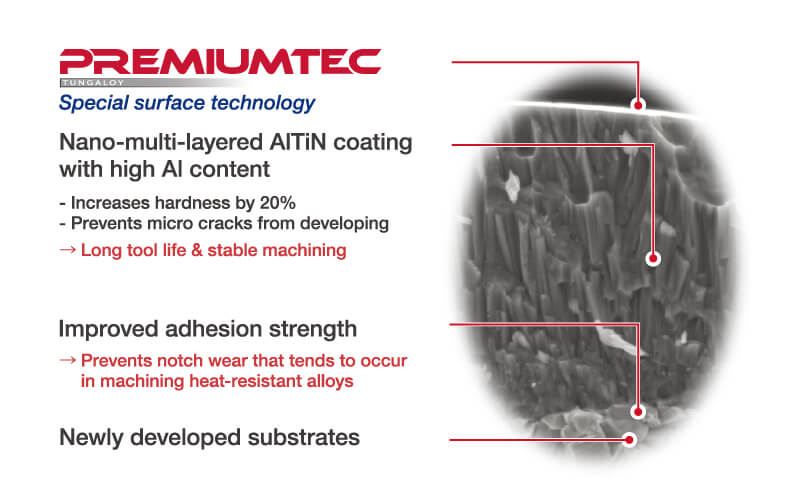

耐热合金加工用 PVD 材质

采用高铝含量的AlTiN 纳米复合涂层,在耐热合金车削加工中实现了出色的可靠性

应用&特点

应用

特点

1. AH8000 系列

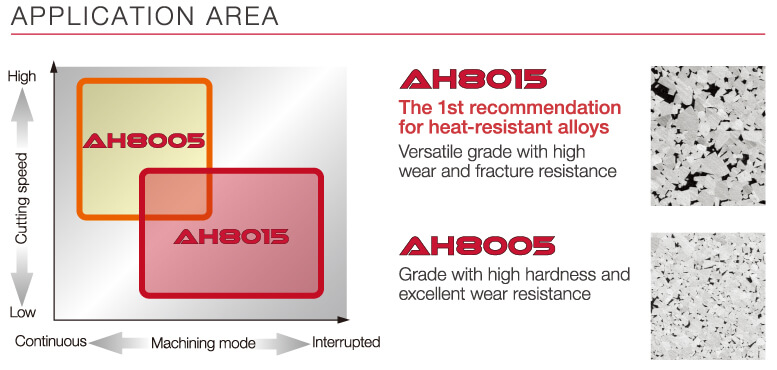

2. 应用范围

主要材质

实际案例

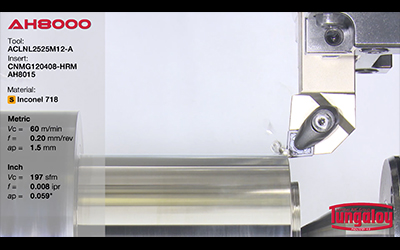

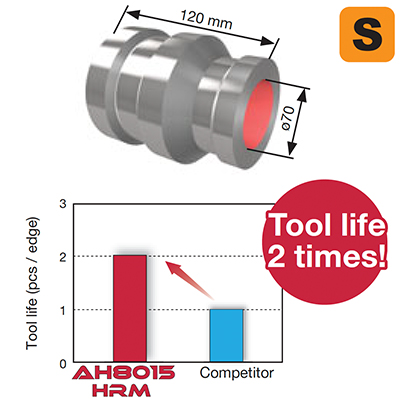

案例 #1

航空航天

| 零件: | 飞机零件 |

| 材料: | Inconel 718 |

| 刀片: | CNMG120408-HRM |

| 材质: | AH8015 |

| 加工条件: | Vc = 40 (m/min) f = 0.22 (mm/rev) ap = 2.0 (mm) 冷却方式: 冷却液 |

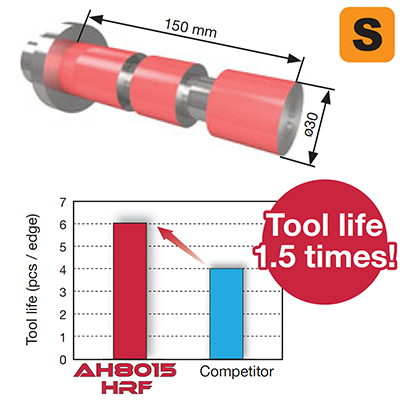

案例 #2

航空航天

| 零件: | 飞机零件 |

| 材料: | Inconel 909 |

| 刀片: | CNMG120412-HRF |

| 材质: | AH8015 |

| 加工条件: | Vc = 55 (m/min) f = 0.30 (mm/rev) ap = 0.5 (mm) 冷却方式: 冷却液 |

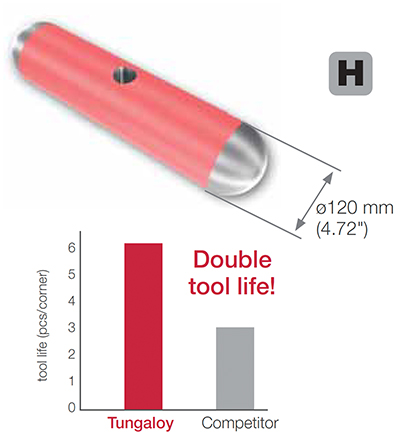

案例 #3

通用工程

| 零件: | 拨动销 |

| 材料: | Tool steel (49 HRC) |

| 刀片: | CNMG190616-HRM |

| 材质: | AH8005 |

| 加工条件: | Vc = 66 (m/min) f = 0.6 (mm/rev) ap = 1.25 (mm) 应用: 车外圆 冷却方式: 干式 机床: 数控车床 |

标准加工条件

For negative inserts chipbreaker

| ISO | Chipbreaker | Corner radius RE |

Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | |

|---|---|---|---|---|---|---|

| AH8005 | AH8015 | |||||

|

HRF | 0.4 | 0.2 – 1.5 | 0.05 – 0.23 | 40 – 100 | 20 – 80 |

| 0.8 | 0.2 – 1.5 | 0.05 – 0.25 | 40 – 100 | 20 – 80 | ||

| 1.2 | 0.2 – 1.5 | 0.07 – 0.27 | 40 – 100 | 20 – 80 | ||

| HRM | 0.4 | 0.5 – 4 | 0.05 – 0.3 | 40 – 100 | 20 – 80 | |

| 0.8 | 0.5 – 4 | 0.07 – 0.33 | 40 – 100 | 20 – 80 | ||

| 1.2 | 0.5 – 4 | 0.10 – 0.35 | 40 – 100 | 20 – 80 | ||

| 1.6 | 0.5 – 4 | 0.15 – 0.4 | 40 – 100 | 20 – 80 | ||

| SDM | 0.4 | 1 – 4 | 0.2 – 0.3 | 40 – 100 | 20 – 80 | |

| 0.8 | 1 – 4 | 0.2 – 0.5 | 40 – 100 | 20 – 80 | ||

| 1.2 | 1 – 4 | 0.2 – 0.5 | 40 – 100 | 20 – 80 | ||

| 28 | 0.4 | 0.5 – 3 | 0.08 – 0.2 | 40 – 100 | 20 – 80 | |

| 0.8 | 0.5 – 3 | 0.1 – 0.3 | 40 – 100 | 20 – 80 | ||

| 1.2 | 0.5 – 3 | 0.1 – 0.3 | 40 – 100 | 20 – 80 | ||

For positive inserts chipbreaker

| ISO | Chipbreaker | Size | Corner radius RE |

Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | |

|---|---|---|---|---|---|---|---|

| AH8005 | AH8015 | ||||||

|

PSF | – | 0.4 | 0.05 – 0.5 | 0.02 – 0.2 | 40 – 100 | 20 – 80 |

| – | 0.8 | 0.05 – 0.5 | 0.02 – 0.3 | 40 – 100 | 20 – 80 | ||

| PSS | – | 0.4 | 0.3 – 2 | 0.02 – 0.2 | 40 – 100 | 20 – 80 | |

| – | 0.8 | 0.3 – 2 | 0.03 – 0.3 | 40 – 100 | 20 – 80 | ||

| – | 1.2 | 0.3 – 2 | 0.05 – 0.3 | 40 – 100 | 20 – 80 | ||

| PS | – | 0.4 | 0.5 – 2.5 | 0.02 – 0.2 | 40 – 100 | 20 – 80 | |

| – | 0.8 | 0.5 – 2.5 | 0.03 – 0.3 | 40 – 100 | 20 – 80 | ||

| – | 1.2 | 0.5 – 2.5 | 0.05 – 0.3 | 40 – 100 | 20 – 80 | ||

| PM | – | 0.4 | 1 – 3 | 0.15 – 0.3 | 40 – 100 | 20 – 80 | |

| – | 0.8 | 1 – 3 | 0.15 – 0.3 | 40 – 100 | 20 – 80 | ||

| – | 1.2 | 1 – 3 | 0.15 – 0.3 | 40 – 100 | 20 – 80 | ||

| RS | RCMT06… | – | 0.5 – 2 | 0.2 – 0.6 | 40 – 100 | 20 – 80 | |

| RCMT08… | – | 0.5 – 2 | 0.2 – 0.6 | 40 – 100 | 20 – 80 | ||

| RCMT10… | – | 1 – 2.5 | 0.2 – 0.6 | 40 – 100 | 20 – 80 | ||

| RCMT12… | – | 1 – 2.5 | 0.2 – 0.6 | 40 – 100 | 20 – 80 | ||

| RCMT16… | – | 1.5 – 3 | 0.5 – 1 | 40 – 100 | 20 – 80 | ||

| RCMT20… | – | 1.5 – 3 | 0.5 – 1 | 40 – 100 | 20 – 80 | ||

| RCMT25… | – | 1.5 – 5 | 0.5 – 1 | 40 – 100 | 20 – 80 | ||

| JS | – | < 0.1 | 0.5 – 3 | 0.02 – 0.05 | – | 20 – 80 | |

| – | < 0.2 | 0.5 – 3 | 0.02 – 0.1 | – | 20 – 80 | ||

| – | < 0.4 | 0.5 – 3 | 0.05 – 0.2 | – | 20 – 80 | ||

关于该产品的更多信息,请访问我们的线上e-catalog或者下载产品样本: