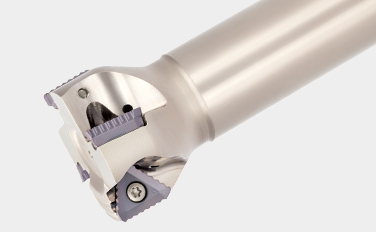

带锯齿刃的高效粗铣刀

带分屑刃的高性能铣刀提高了长悬伸粗加工中的抗振稳定性和加工效率

应用 & 特点

应用

特点

1. 抗振设计

锯齿刃产生更细小的切屑从而减少振刀的发生。

2. 简单好用的设计

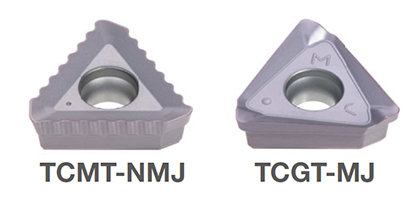

3. 2种类型的刀片可分别安装在相同的刀体上

刀片 & 材质

刀体

实际案例

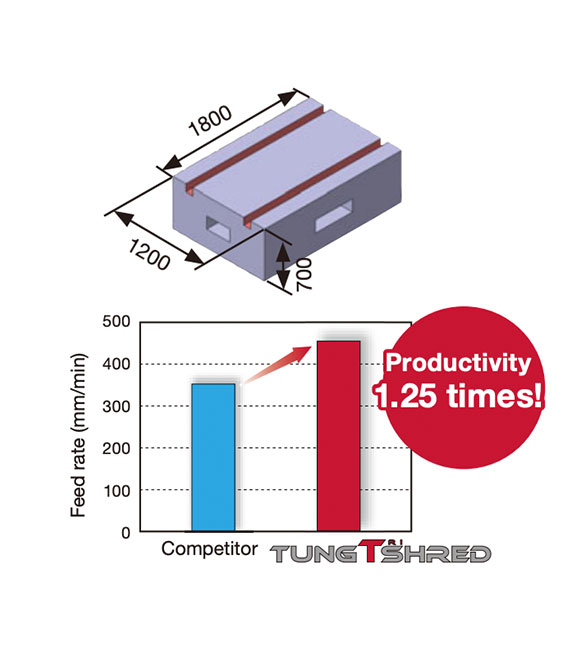

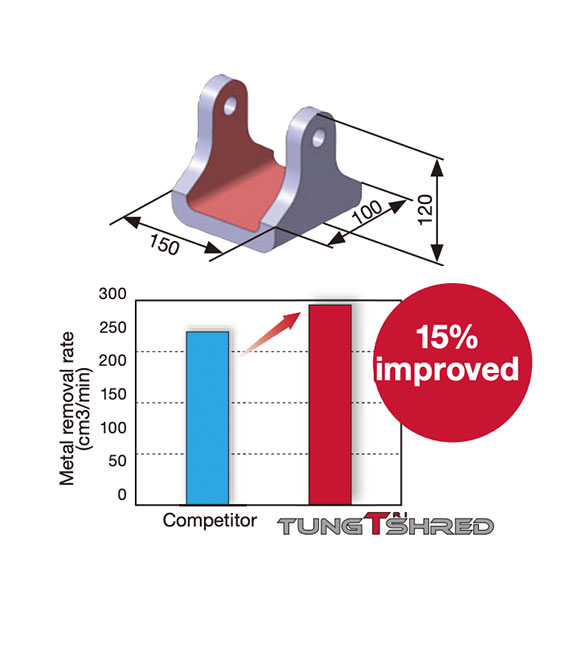

案例 #1

通用工程

| 零件: | 设备零件 |

| 材料: | SS400 |

| 刀杆: | LPTC16J063B25.4L061R03 (ø63, z = 3) |

| 刀片: | TCMT160620PDER-NMJ |

| 材质: | AH3135 |

| 加工条件: | Vc = 150 (其它品牌: Vc = 105) (m/min) fz = 0.2 (mm/t) Vf = 455 (mm/min) ap = 50 (mm) ae = 10 (mm) 应用: 方肩铣削 冷却方式: 气冷 机床: Tower M/C, BT50 |

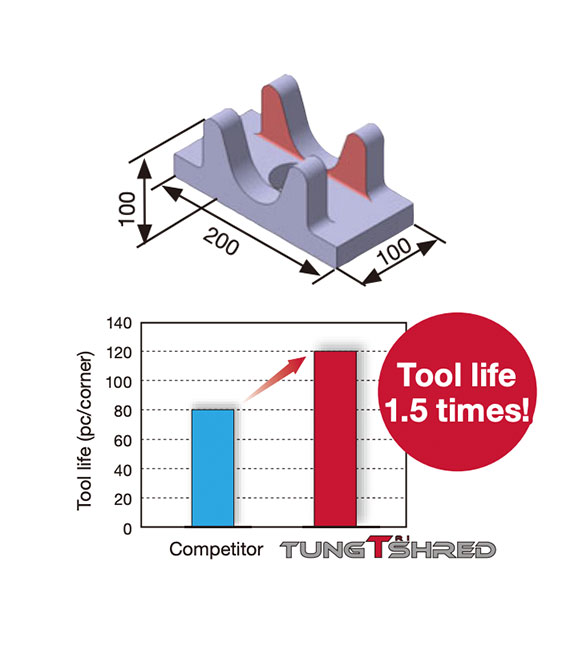

案例 #2

汽车行业

| 零件: | 支架 |

| 材料: | SCSiMn2H |

| 刀杆: | LPTC16M080B32.0L076R04 (ø80, z = 4) |

| 刀片: | TCMT160620PDER-NMJ |

| 材质: | AH3135 |

| 加工中心: | Vc = 135 (其它品牌: Vc = 126) (m/min) fz = 0.33 (其它品牌: fz = 0.3) (mm/t) Vf = 709 (mm/min) ap = 75 (mm) ae = 5 (mm) 应用: 方肩铣削 冷却方式: 气冷 机床: 立式加工中心, BT40 |

案例 #3

通用工程

| 零件: | 法兰 |

| 材料: | FC300 / GG30 |

| 刀盘: | TPTC16M050B22.0R04 (ø50, z = 4) |

| 刀片: | TCMT160620PDER-NMJ |

| 材质: | AH120 |

| 加工条件: | Vc = 150 (m/min) fz = 0.18 (mm/t) Vf = 700 (mm/min) ap = 2 (mm) ae = 10 (mm) 应用: 方肩铣削 冷却方式: 冷却液 机床: 卧式加工中心, BT40 |

标准加工条件

| ISO | Workpiece materials | Hardness | Priority | Grade | Chipbreaker | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|---|---|---|---|---|---|---|---|

| Low carbon steel S15C, S20S, etc. C15, C20, etc. |

– 300HB | First choice | AH3225 | NMJ* | 100 – 250 | 0.08 – 0.15 | |

| Fracture resistance | AH3135 | MJ | 100 – 250 | 0.08 – 0.15 | |||

| Wear resistance | T3225 | NMJ* | 100 – 300 | 0.08 – 0.15 | |||

| For finishing | AH3225 | MJ | 100 – 250 | 0.08 – 0.20 | |||

| Carbon steel and alloy steel S55C, SCM440, etc. C55, 42CrMo4, etc. |

– 300HB | First choice | AH3225 | NMJ* | 100 – 230 | 0.08 – 0.15 | |

| Fracture resistance | AH3135 | MJ | 100 – 230 | 0.08 – 0.15 | |||

| Wear resistance | T3225 | NMJ* | 100 – 280 | 0.08 – 0.15 | |||

| For finishing | AH3225 | MJ | 100 – 230 | 0.08 – 0.20 | |||

| Prehardened steel NAK80, PX5, etc. |

30 – 40 HRC | First choice | AH3225 | NMJ* | 100 – 180 | 0.08 – 0.15 | |

| Fracture resistance | AH3135 | MJ | 100 – 180 | 0.08 – 0.15 | |||

| Wear resistance | T3225 | NMJ* | 100 – 200 | 0.08 – 0.15 | |||

| For finishing | AH3225 | MJ | 100 – 180 | 0.08 – 0.20 | |||

| Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

– 250HB | First choice | AH3135 | NMJ* | 90 – 200 | 0.08 – 0.15 | |

| Wear resistance | T3225 | NMJ* | 90 – 250 | 0.08 – 0.15 | |||

| For finishing | AH3135 | MJ | 90 – 200 | 0.08 – 0.20 | |||

| Grey cast iron FC250, FC300, etc. 250, 300, etc. |

150 – 250HB | First choice | AH8015 | NMJ* | 140 – 250 | 0.08 – 0.15 | |

| Wear resistance | T1215 | NMJ* | 150 – 300 | 0.08 – 0.15 | |||

| For finishing | AH8015 | MJ | 140 – 250 | 0.08 – 0.25 | |||

| Ductile cast iron FCD400, FCD600, etc. 400-15S, 600-3, etc. |

150 – 250HB | First choice | AH8015 | NMJ* | 140 – 250 | 0.08 – 0.15 | |

| Wear resistance | T1215 | NMJ* | 150 – 300 | 0.08 – 0.15 | |||

| For finishing | AH8015 | MJ | 140 – 250 | 0.08 – 0.25 | |||

| Titanium alloys Ti-6AI-4V, etc. |

– | First choice | AH8015 | NMJ* | 20 – 60 | 0.08 – 0.15 | |

| Fracture resistance | AH3135 | NMJ* | 20 – 60 | 0.08 – 0.15 | |||

| For finishing | AH8015 | MJ | 20 – 60 | 0.08 – 0.18 | |||

| Heat-resistant alloys Inconel718, etc. |

– | First choice | AH8015 | NMJ* | 20 – 40 | 0.08 – 0.13 | |

| For finishing | AH8015 | MJ | 20 – 40 | 0.08 – 0.15 |

* When using the -NMJ chipbreaker, do not feed higher than 0.15 mm/t.