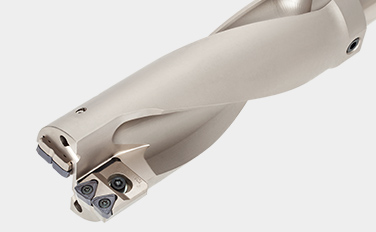

安装经济型6刀尖刀片的可转位式钻头

采用的高性能6刀尖刀片是一款非常经济的加工解决方案

应用 & 特点

应用

特点

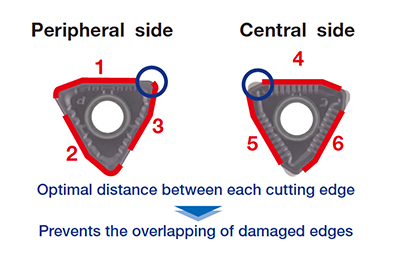

1. 带6个刀尖的双面刀片

• TungSixDrill 是世界首款采用6刀尖双面刀片的可转位式钻头,能够减少用户的刀片消耗。

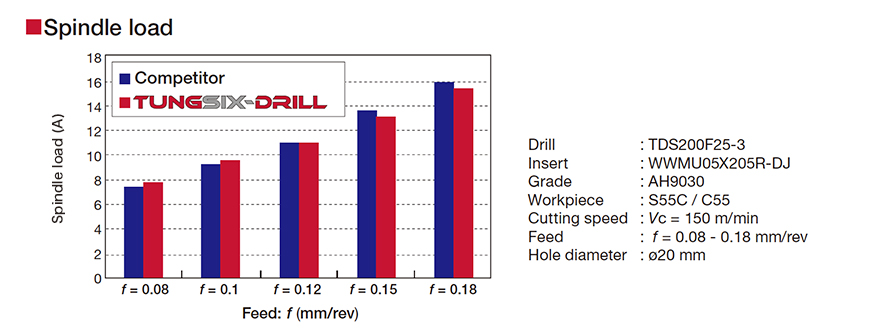

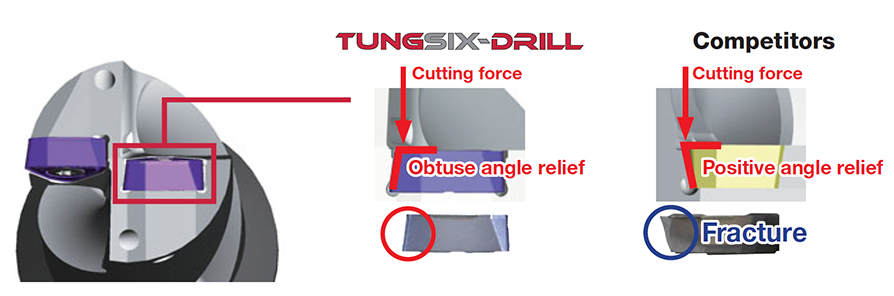

2. 低切削力双面刀片

• 切削力几乎与其它品牌单面正角刀片相同,可以实现非常高的进给速度,从而获得更高的生产效率。

3. 提高中心刃刀片刀尖强度

• 通过钝角角度强化中心刀尖,从而提高刀尖强度和可靠性。

4. TungDrillBig

带可调式刀夹的钻体覆盖孔径范围: øDc: ø55 mm – ø80 mm, L/D = 2.5

-

高刚性钻体和优化的刀片位置

平衡的切削力和稳定的加工状态实现了精确的孔加工。

-

可调节刀具直径

TungDrillBig 包含5款钻体,可以安装一系列的设置垫片,覆盖直径范围:ø55 mm – ø80 mm.

-

多种设计选项

TDX 和 TDS 型刀夹可以分别安装在相同的钻体上。

刀片 & 材质

刀片

主要材质

AH7020

![]()

![]()

- Wear-resistant grade that enables high speed machining in steel and cast iron. Improved machining efficiency with no compromise on tool life.

AH7030

![]()

![]()

![]()

![]()

![]()

- First-choice grade in all material groups. Extremely fracture resistant, the grade provides predictability in unstable drilling applications that might, otherwise, induce edge chipping.

AH3135

![]()

![]()

- P30 – P40 / M30 – M40

-

高抗崩损性

-

适用于钢和不锈钢一般条件下的加工

钻体 & 相关工具

实际案例

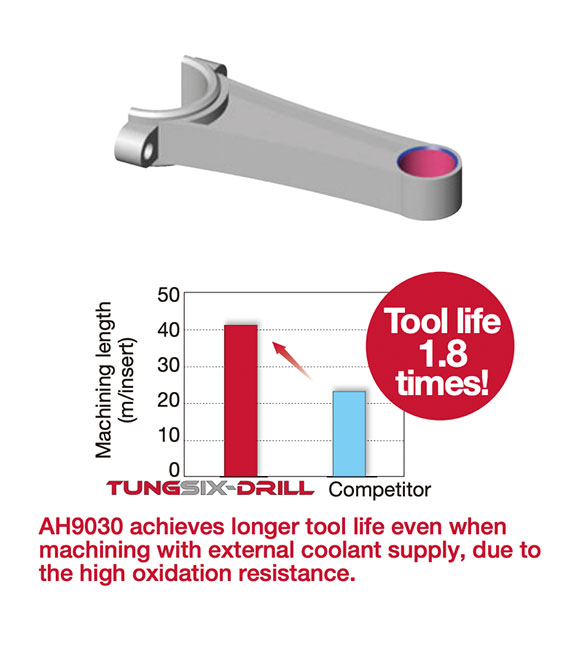

案例 #1

汽车行业

| 零件: | 连杆 |

| 材料: | S55C / C55 |

| 钻体: | TDS200F25-2, øDc = 20 mm |

| 刀片: | WWMU05X205R-DJ |

| 材质: | AH9030 |

| 加工条件: | Vc = 200 (m/min) f = 0.15 (mm/rev) Vf = 477 (mm/min) H = 30 (mm) 冷却方式: 冷却液 机床: 立式加工中心, BT40 |

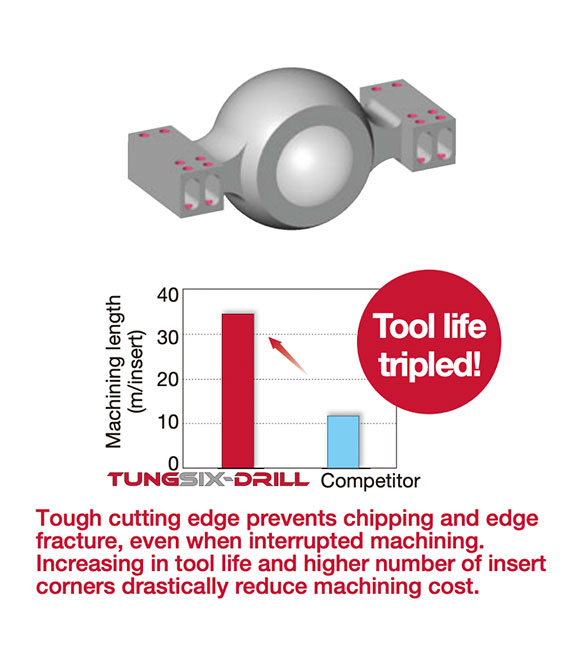

案例 #2

通用工程

| 零件: | 箱体 |

| 材料: | FCD450 / GGG45 |

| 钻体: | TDS420F40-2, øDc = 42 mm |

| 刀片: | WWMU11X512R-DJ |

| 材质: | AH9030 |

| 加工条件: | Vc = 120 (m/min) f = 0.2 (mm/rev) Vf = 180 (mm/min) H = 80 (mm) 冷却方式: 冷却液 机床: 数控车床 |

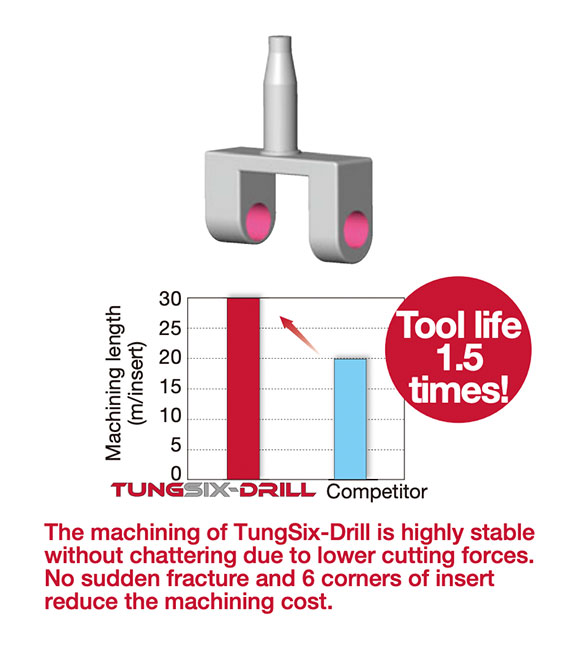

案例 #3

汽车行业

| 零件: | 转向节 |

| 材料: | SCM440 / 42CrMo4 |

| 钻体: | TDS500F40-3, øDc = 50 mm |

| 刀片: | WWMU13X512R-DJ |

| 材质: | AH9030 |

| 加工条件: | Vc = 160 (m/min) f = 0.11 (mm/rev) Vf = 112 (mm/min) H = 80, 65 (mm) 冷却方式: 冷却液 机床: 卧式加工中心, BT50 |

标准加工条件

Recommended insert

| ISO | Workpiece material | First choice | Wear resistance | Chip control |

|---|---|---|---|---|

|

Low carbon steel (C ≤ 0.3%) | DS AH7030 | DS AH7020 | DJ AH3135 |

| Carbon steel (C > 0.3%), Low alloy steel, Alloy steel |

DJ AH7030 | DJ AH7020 | DJ AH3135 | |

| Low alloy steel | DS AH7030 | DS AH7020 | DJ AH3135 | |

| Alloy steel | DJ AH7030 | DJ AH7020 | DJ AH3135 | |

|

Stainless steel | DS AH7030 | DS AH7020 | DJ AH3135 |

|

Grey cast irons | DJ AH7030 | DJ AH7020 | – |

| Ductile cast irons | DJ AH7020 | – | DJ AH7030 | |

|

Aluminium alloy | DS AH7030 | – | – |

|

Heat-resistant alloys | DS AH7020 | – | DJ AH7020 |

| Titanium alloys | DS AH7030 | DS AH7020 | DJ AH3135 | |

|

Hardened steel | DJ AH7020 | – | DJ AH7030 |

Standard cutting conditions

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) |

Series L/D |

Feed: f (mm/rev) | ||

|---|---|---|---|---|---|---|---|

| ø20 – ø27.5 | ø28 – ø38 | ø39 – ø54 | |||||

|

Low carbon steels (C < 0.3) SS400, SM490, S25C, etc. st42-1, St52-3, C25, etc. |

– 200 HB | 160 – 320 | 2D, 3D | 0.04 – 0.1 | 0.04 – 0.1 | 0.04 – 0.1 |

| 4D | 0.04 – 0.1 | 0.04 – 0.1 | 0.04 – 0.1 | ||||

| Carbon steels (C > 0.3) S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 80 – 250 | 2D, 3D | 0.06 – 0.15 | 0.06 – 0.16 | 0.08 – 0.18 | |

| 4D | 0.06 – 0.15 | 0.06 – 0.15 | 0.06 – 0.17 | ||||

| Low alloy steels SCM415, etc. |

– 200 HB | 160 – 250 | 2D, 3D | 0.06 – 0.12 | 0.06 – 0.12 | 0.06 – 0.14 | |

| 4D | 0.06 – 0.12 | 0.06 – 0.12 | 0.06 – 0.14 | ||||

| Alloy steels SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 80 – 200 | 2D, 3D | 0.06 – 0.13 | 0.06 – 0.15 | 0.08 – 0.18 | |

| 4D | 0.06 – 0.1 | 0.06 – 0.12 | 0.08 – 0.14 | ||||

|

Stainless steels (Austenitic) SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 100 – 200 | 2D, 3D | 0.04 – 0.1 | 0.04 – 0.12 | 0.04 – 0.12 |

| 4D | 0.04 – 0.1 | 0.04 – 0.12 | 0.04 – 0.12 | ||||

| Stainless steels (Martensitic and ferritic) SUS430, SUS416, etc. X6Cr17, X20Cr13, etc. |

– 200 HB | 100 – 220 | 2D, 3D | 0.04 – 0.1 | 0.04 – 0.12 | 0.04 – 0.12 | |

| 4D | 0.04 – 0.1 | 0.04 – 0.12 | 0.04 – 0.12 | ||||

| Stainless steels (Precipitation hardening) SUS630, etc. X5CrNiCuNb16-4, etc. |

– | 80 – 120 | 2D, 3D | 0.04 – 0.08 | 0.04 – 0.1 | 0.06 – 0.1 | |

| 4D | 0.04 – 0.08 | 0.04 – 0.1 | 0.06 – 0.1 | ||||

|

Grey cast irons FC250, etc., 250, etc. |

150 – 250 HB | 80 – 250 | 2D, 3D | 0.06 – 0.15 | 0.06 – 0.18 | 0.08 – 0.2 |

| 4D | 0.06 – 0.12 | 0.06 – 0.14 | 0.08 – 0.16 | ||||

| Ductile cast irons FCD700, etc., 600-3, etc. |

150 – 250 HB | 80 – 200 | 2D, 3D | 0.06 – 0.15 | 0.06 – 0.18 | 0.08 – 0.2 | |

| 4D | 0.06 – 0.12 | 0.06 – 0.14 | 0.08 – 0.16 | ||||

|

Aluminium alloy A2017, ADC12, etc. AlCu4SiMg, AlSi11Cu3, etc. |

– | 200 – 400 | 2D, 3D | 0.15 – 0.2 | 0.15 – 0.2 | 0.15 – 0.25 |

| 4D | 0.12 – 0.16 | 0.12 – 0.16 | 0.12 – 0.2 | ||||

|

Heat-resistant alloys Inconel 718, etc. |

– 40 HRC | 20 – 60 | 2D, 3D | 0.04 – 0.1 | 0.04 – 0.1 | 0.04 – 0.1 |

| 4D | 0.04 – 0.1 | 0.04 – 0.1 | 0.04 – 0.1 | ||||

| Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | 40 – 120 | 2D, 3D | 0.06 – 0.12 | 0.06 – 0.12 | 0.06 – 0.12 | |

| 4D | 0.06 – 0.1 | 0.06 – 0.1 | 0.06 – 0.1 | ||||

|

Hardened steel | – 50 HRC | 40 – 100 | 2D, 3D | 0.04 – 0.1 | 0.04 – 0.1 | 0.04 – 0.1 |

| 4D | 0.04 – 0.08 | 0.04 – 0.08 | 0.04 – 0.08 | ||||

关于该产品的更多信息,请访问我们的线上e-catalog或者下载产品样本: