用于大直径钻孔加工的可换钻尖式钻头

钻头采用特殊锁紧理念和两个有效切削刃的钻尖实现了优异的孔质量和较高的生产效率

应用& 特点

应用

特点

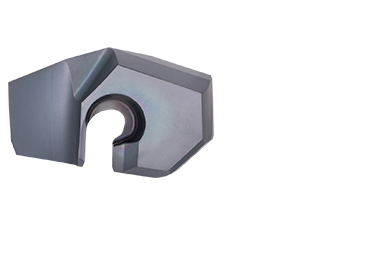

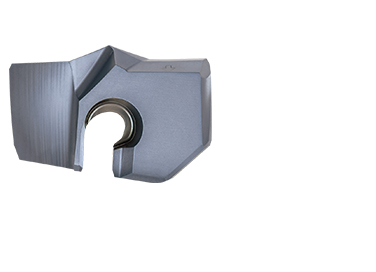

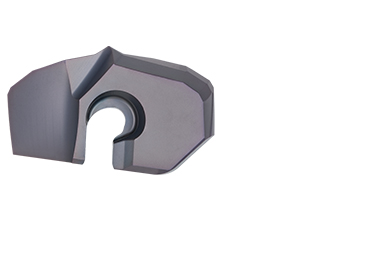

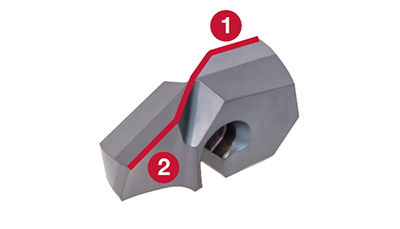

1. 两个有效切削刃

• 带两个有效切削刃的钻尖实现较高的生产效率和可靠性。

2.特殊锁紧系统

• 无需将钻体从刀柄或主轴拆除就能更换钻尖,避免了重新对刀的麻烦。

• 对称形状的钻尖不仅保证了重型加工中的稳定性,而且还防止了钻尖安装错误。

• 钻体对钻尖拥有宽支撑面实现了牢固的刀片锁紧。

刀片 & 材质

刀片

材质

钻体

实际案例

案例 #1

通用工程

| 零件: | 阀门 |

| 材料: | SUS304 / X5CrNi18-9 |

| 钻体: | TIS300F40-5 |

| 钻尖: | SMP300 |

| 材质: | AH725 |

| 加工条件: | Vc = 60 (m/min) f = 0.25 (mm/rev) Vf = 160 (mm/min) H = 120 (mm) 机床: 卧式加工中心 |

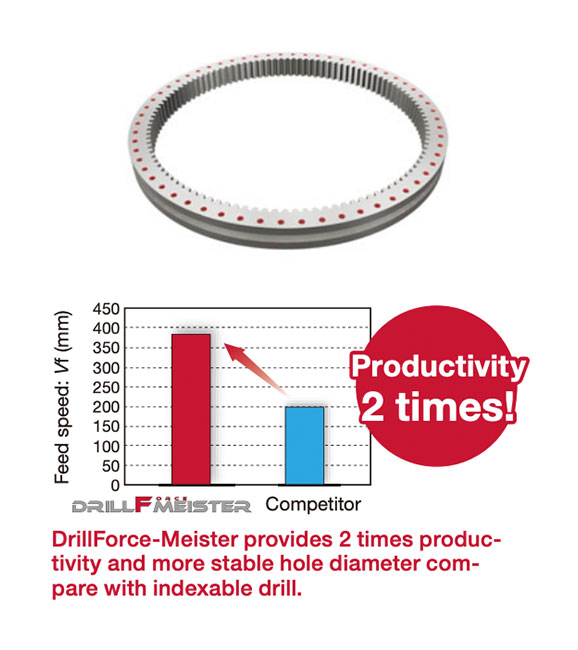

案例 #2

重工业

| 零件: | 回转支承 |

| 材料: | SCM440 / 42CrMo4 |

| 钻体: | TIS330F40-5 |

| 钻尖: | SMP331 |

| 材质: | AH725 |

| 加工条件: | Vc = 100 (m/min) f = 0.4 (mm/rev) Vf = 380 (mm/min) H = 150 (mm) 机床: 立式加工中心 |

标准加工条件

SMP General purpose

| ISO |

Workpiece materials |

Cutting speed |

Feed: f (mm/rev) |

||

|---|---|---|---|---|---|

| Vc (m/min) | ø20 – 29.9 | ø30 – 35.9 | ø36 – 41 | ||

|

Low carbon steel S15C, S20C, etc. C15E4, etc. |

80 – 140 | 0.2 – 0.5 | 0.2 – 0.5 | 0.2 – 0.55 |

| Carbon steel and alloy steel S55C, SCM440, etc. C55, 42CrMo4, etc. |

80 – 130 | 0.2 – 0.5 | 0.2 – 0.5 | 0.2 – 0.55 | |

| Prehardened steel NAK80, PX5, etc. |

50 – 100 | 0.2 – 0.5 | 0.2 – 0.5 | 0.2 – 0.55 | |

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

40 – 80 | 0.15 – 0.3 | 0.2 – 0.3 | 0.2 – 0.35 |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc. |

80 – 180 | 0.25 – 0.55 | 0.25 – 0.55 | 0.3 – 0.6 |

| Ductile cast iron FCD400, FCD600, etc. 400-15, 600-3, etc. |

80 – 140 | 0.25 – 0.55 | 0.25 – 0.55 | 0.3 – 0.6 | |

|

Non ferrous materials | 100 – 200 | 0.4 – 0.6 | 0.4 – 0.6 | 0.5 – 0.7 |

|

Heat-resistant alloys Inconel718, etc. |

20 – 50 | 0.1 – 0.2 | 0.1 – 0.2 | 0.1 – 0.25 |

| Titanium alloys Ti-6AI-4V, etc. |

20 – 50 | 0.1 – 0.2 | 0.1 – 0.2 | 0.1 – 0.25 | |

|

Hard materials | 20 – 60 | 0.1 – 0.2 | 0.1 – 0.2 | 0.1 – 0.25 |

SMF Flat geometry head

| ISO |

Workpiece materials |

Cutting speed |

Feed: f (mm/rev) |

||

|---|---|---|---|---|---|

| Vc (m/min) | ø20 – 29.9 | ø30 – 35.9 | ø36 – 41 | ||

|

Low carbon steel S15C, S20C, etc. C15E4, etc. |

80 – 140 | 0.2 – 0.5 | 0.2 – 0.5 | 0.2 – 0.55 |

| Carbon steel and alloy steel S55C, SCM440, etc. C55, 42CrMo4, etc. |

80 – 130 | 0.2 – 0.5 | 0.2 – 0.5 | 0.2 – 0.55 | |

| Prehardened steel NAK80, PX5, etc. |

50 – 100 | 0.2 – 0.5 | 0.2 – 0.5 | 0.2 – 0.55 | |

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

40 – 70 | 0.15 – 0.25 | 0.2 – 0.3 | 0.2 – 0.35 |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc. |

80 – 180 | 0.25 – 0.55 | 0.25 – 0.55 | 0.3 – 0.6 |

| Ductile cast iron FCD400, FCD600, etc. 400-15, 600-3, etc. |

80 – 140 | 0.25 – 0.55 | 0.25 – 0.55 | 0.3 – 0.6 | |

|

Non ferrous materials | 100 – 200 | 0.4 – 0.6 | 0.4 – 0.6 | 0.5 – 0.7 |

|

Heat-resistant alloys Inconel718, etc. |

20 – 50 | 0.1 – 0.2 | 0.1 – 0.2 | 0.1 – 0.25 |

| Titanium alloys Ti-6AI-4V, etc. |

20 – 50 | 0.1 – 0.2 | 0.1 – 0.2 | 0.1 – 0.25 | |

|

Hard materials | 20 – 60 | 0.1 – 0.2 | 0.1 – 0.2 | 0.1 – 0.25 |

SMC High precision drilling

| ISO | Workpiece materials |

Cutting speed |

Feed: f (mm/rev) |

|---|---|---|---|

| Vc (m/min) | ø26 – 33 | ||

|

Low carbon steel S15C, S20C, etc. C15E4, etc. |

80 – 140 | 0.2 – 0.5 |

| Carbon steel and alloy steel S55C, SCM440, etc. C55, 42CrMo4, etc. |

80 – 130 | 0.2 – 0.5 | |

| Prehardened steel NAK80, PX5, etc. |

50 – 100 | 0.2 – 0.5 | |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc. |

80 – 180 | 0.25 – 0.55 |

| Ductile cast iron FCD400, FCD600, etc. 400-15, 600-3, etc. |

80 – 140 | 0.25 – 0.55 | |

|

Non ferrous materials | 100 – 200 | 0.4 – 0.6 |

|

Hard materials | 20 – 60 | 0.1 – 0.2 |

关于该产品的更多信息,请访问我们的线上e-catalog或者下载产品样本: