宽槽和仿形宽槽加工特殊系统

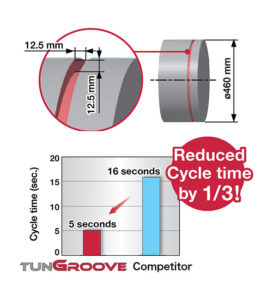

TungHeavyGroove 能够有效减少宽槽和复杂形状成型加工的时间

应用 & 特点

应用

特点

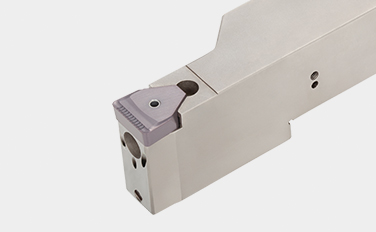

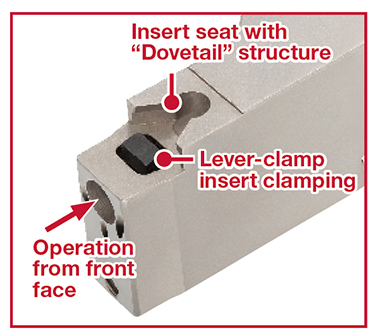

1. 从前端面轻松锁紧刀片

从刀杆前端面可以完成刀片转位,缩短刀片更换时间和停机时间。

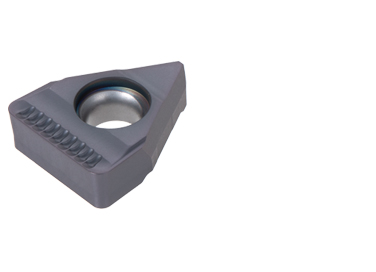

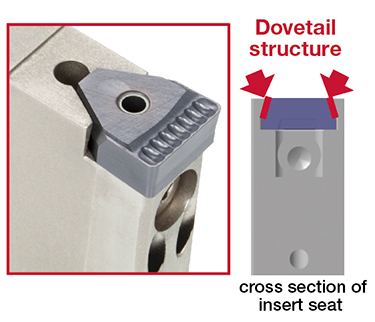

2. 高刚性杠杆式锁紧实现稳定的槽加工

燕尾槽结构防止宽槽加工时刀片发生移动。

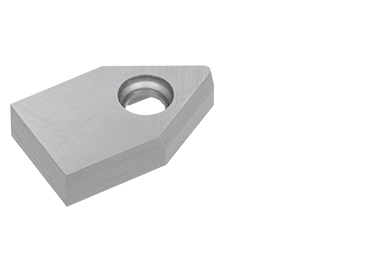

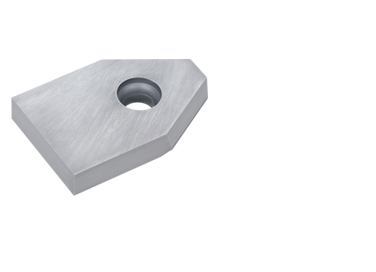

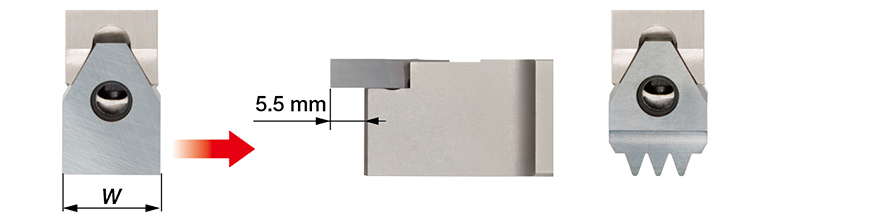

3. 仿形槽加工刀片和刀具

- 刀片宽度(W) 10 – 25 mm.

- 刀片长度可以使仿形部分深达5.5 mm。

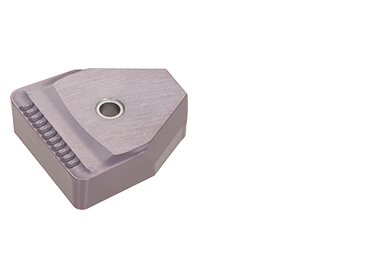

刀片 & 材质

刀片

材质

AH8015

![]()

![]()

![]()

![]()

![]()

- P10 – P20 / M10 – M20 / K10 – K25 / S10 – S20 / H10 – H20

- Good balance between wear and fracture resistance

- First choice for machining heat-resistant alloy under general cutting conditions

- First choice for threading

T9215

![]()

![]()

![]()

- P10 – P20 / M10 – M20 / K10 – K20

- Well-balanced between wear and chipping resistance

- First choice for steel

- High versatility for a wide range of applications

刀杆

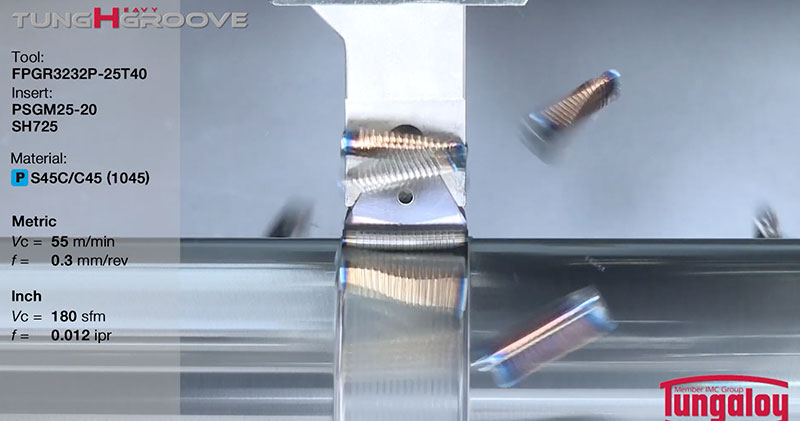

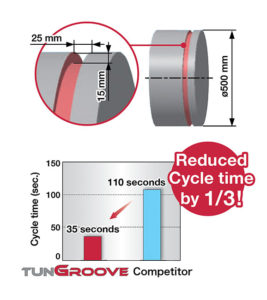

实际案例

案例 #1

重工业

| 零件: | 设备零件 |

| 材料: | SCM415 |

| 刀杆: | FPGR3232P-10T36 |

| 刀片: | PSGM10-08 (W = 10 mm) |

| 材质: | AH725 |

| 加工条件: | Vc = 110 (m/min) f = 0.3 (mm/rev) 加工1个槽的走刀次数= 2 应用: 槽加工 冷却方式: 冷却液 |

案例 #2

重工业

| 零件: | 发电机零件 |

| 材料: | 铸钢 |

| 刀杆: | FPGR3232P-10T36 |

| 刀片: | PSGM10-08 (W = 10 mm) |

| 材质: | AH725 |

| 加工条件: | Vc = 65 (m/min) f = 0.37 (mm/rev) 加工1个槽的走刀次数 = 3 应用: 槽加工 冷却方式: 冷却液 |

标准加工条件

Wide grooving

| ISO | Workpiece materials | Hardness(HB) | Grade | Cutting speed Vc (m/min) |

|---|---|---|---|---|

|

Alloy Steels SCM440, 42CrM04, etc. |

< 300 | AH725 | 50 – 180 |

| Alloy Steels SCM440, 42CrM04, etc. |

< 300 | UX30 | 50 – 120 |

Forming

| ISO | Workpiece materials | Hardness(HB) | Grade | Cutting speed Vc (m/min) |

|---|---|---|---|---|

|

Steels S45C, C45, etc. |

< 200 | UX30 | 50 – 150 |

| Alloy steels SCM440, 42CrMo4, etc. |

< 300 | UX30 | 50 – 120 | |

|

Stainless steels SUS303, X10CrNiS18-9, etc. |

< 200 | UX30 | 50 – 120 |

|

Grey cast irons FC250, 250, etc. |

– | TH10 | 50 – 150 |

| Ductile cast irons FCD450, 450-10S, etc. |

– | TH10 | 50 – 120 | |

|

Aluminium alloy Si < 12%, etc. |

– | TH10 | 100 – 500 |

Wide grooving (HGM insert)

| ISO | Workpiece materials | Hardness | Priority | Grade | Cutting speed Vc (m/min) |

|---|---|---|---|---|---|

|

Steel S45C, SCM435, etc. C45, 34CrMo4, etc. |

< 300 | First Choice | AH8015 | 80 – 180 |

| < 300 | Wear resistance | T9215 | 100 – 350 | ||

|

Stainless steel SUS303, SUS304, etc. X10CrNiS18-9, X5CrNi18-9, etc. |

< 200 | First Choice | AH8015 | 50 – 130 |

| < 200 | Wear resistance | T9215 | 100 – 250 | ||

|

Grey cast iron FC250, 250, etc. |

– | First Choice | AH8015 | 50 – 180 |

| – | Wear resistance | T9215 | 140 – 300 | ||

| Ductile cast iron FCD450, etc. 450-10S, etc. |

– | First Choice | AH8015 | 50 – 180 | |

| – | Wear resistance | T9215 | 140 – 300 | ||

|

Superalloys Inconel718, etc. |

< HRC 40 | First Choice | AH8015 | 20 – 80 |

| Titanium alloys Ti-6AL-4V, etc. |

< HRC 40 | First Choice | AH8015 | 20 – 80 |

关于该产品的更多信息,请访问我们的线上e-catalog或者下载产品样本: