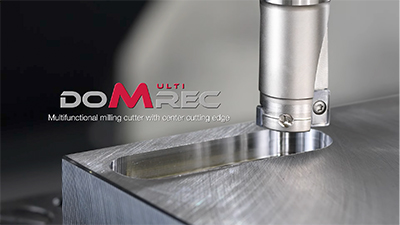

带有中心刃的多功能铣刀

带有中心切削能力的多功能铣刀实现超常的加工通用性

应用 & 特点

应用

特点

1. 多功能

– 带中心切削能力,单支铣刀可以完成各种应用,实现工艺和刀具集成,以实现最大生产效率。燕尾槽锁紧方式能够确保较高的加工安全性。

DoMultiRec的应用功能

| 刀片尺寸 | APMX (mm) | 刀具直径DC (mm) |

|---|---|---|

| 08 | 7 | ø16 |

| ø17 | ||

| 10 | 9 | ø20 |

| ø21 | ||

| 12 | 11 | ø25 |

| ø26 |

2. 带有中心刃方肩铣刀最大的单刃成本效益

– 单个刀片既可以用于中心刃也可以用于外周刃位置,并且可以在每个位置使用两个刀尖-总共4个刀尖实现了最高的刀片经济性。

3. 平孔底

– 易于使孔底尽可能平坦。也适用于锪孔。

12 尺寸

| 刀杆 | : EVLX12M025C25.0R02 (ø25 mm, z = 2) |

| 刀片 | : LXMU120408PER-MM AH3225 |

| 切削速度 | : Vc = 150 m/min |

| 每齿进给 | : fz = 0.07 mm/t |

| 孔深 | : 5 mm |

| 悬伸长度 | : 45 mm |

| 冷却方式 | : 干切 |

优化的底刃设计使孔底平整。

刀片 & 材质

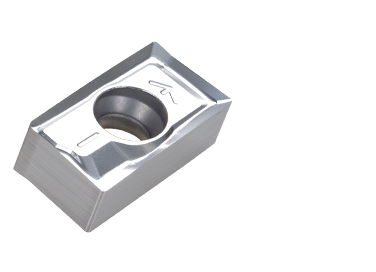

刀片

主要材质

刀体

实际案例

案例 #1

| 零件: | 设备零件 |

| 材料: | 铸造不锈钢 |

| 刀杆: | EVLX12M026C25.0R02 (ø26 mm, z = 2) |

| 刀片: | LXMU120408PER-MM |

| 材质: | AH3225 |

| 加工条件: | Vc = 60 (m/min) fz = 0.07 (mm/t) Vf = 102.8 (mm) ap = 5 (mm) ae =26 (mm) 应用: 锪孔,铣槽 冷却方式: 外冷 悬伸长度: 40 (mm) 机床: 立式加工中心, BT40 |

案例 #2

| 零件: | 设备零件 |

| 材料: | SCM420/18CrMo4 |

| 刀杆: | EVLX12M026C25.0R02 (ø26 mm, z = 2) |

| 刀片: | LXMU120408PER-MM |

| 材质: | AH3225 |

| 加工条件: | Vc = 118 (m/min) fz = 0.31 (mm/t) Vf = 900 (mm) ap = 2 (mm) ae = 5 (mm) 应用: 方肩铣削 冷却方式: 压缩空气 悬伸长度: 100 (mm) 机床: 立式加工中心, BT50 |

标准加工条件

| ISO | Workpiece materials | Hardness | Chip-breakers | Grades | Cutting speed Vc (m/min) | Drilling (ZEFP = 1)(1) |

Shouldering / Helical interpolation(1),(2) |

|||

|---|---|---|---|---|---|---|---|---|---|---|

| Feed per revolution f (mm/rev) |

Feed per tooth fz (mm/t) |

|||||||||

| 06 | 08 | 10 / 12 / 16 / 19 | ||||||||

|

|

Low carbon steel S15C, SS400, etc. C15E4, E275A, etc. |

– 200 HB | MM | AH3225 | 100 – 300 | 0.03 – 0.08 | 0.05 – 0.2 | 0.05 – 0.25 | 0.05 – 0.3 | |

| Carbon steel and alloy steel S55C, SCM440, etc. C55, 42CrMo4, etc. |

– 300 HB | MM | AH3225 | 100 – 250 | 0.03 – 0.08 | 0.05 – 0.2 | 0.05 – 0.25 | 0.05 – 0.3 | ||

| Prehardened steel NAK80, PX5, etc. |

30 – 40 HRC | MM | AH3225 | 80 – 180 | 0.03 – 0.06 | 0.05 – 0.15 | 0.05 – 0.2 | 0.05 – 0.25 | ||

|

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

– | MM | AH3225 | 80 – 180 | 0.03 – 0.08 | 0.05 – 0.15 | 0.05 – 0.2 | 0.05 – 0.22 | |

|

|

Grey cast iron FC250, FC300, etc. 250, 300, etc. |

150 – 250 HB | MM | AH120 | 100 – 300 | 0.03 – 0.1 | 0.05 – 0.2 | 0.05 – 0.25 | 0.05 – 0.3 | |

| Ductile cast iron FCD400, FCD600, etc. 400-15S, 600-3, etc. |

150 – 250 HB | MM | AH120 | 100 – 250 | 0.03 – 0.08 | 0.05 – 0.15 | 0.05 – 0.2 | 0.05 – 0.25 | ||

|

|

Aluminium alloy Si < 13% |

– | AM | DS2005 KS05F |

400 – 800 | 0.03 – 0.08 | 0.05 – 0.2 | 0.05 – 0.25 | 0.05 – 0.3 | |

| Aluminium alloy Si ≥ 13% |

– | AM | DS2005 KS05F |

100 – 200 | 0.03 – 0.08 | 0.05 – 0.2 | 0.05 – 0.25 | 0.05 – 0.3 | ||

|

|

Titanium alloys Ti-6AI-4V, etc. |

– | MM | AH3225 | 20 – 60 | 0.03 – 0.06 | 0.04 – 0.1 | 0.04 – 0.15 | 0.04 – 0.15 | |

| Superalloys Inconel 718, etc. |

– | MM | AH8015 | 20 – 40 | 0.03 – 0.06 | 0.04 – 0.1 | 0.04 – 0.15 | 0.04 – 0.15 | ||

|

|

Hardened steel | SKD61, etc. X40CrMoV5-1, etc. |

40 – 50 HRC | MM | AH8015 | 50 – 150 | 0.03 – 0.05 | 0.04 – 0.1 | 0.04 – 0.15 | 0.04 – 0.15 |

| SKD11, etc. X153CrMoV12, etc. |

50 – 60 HRC | MM | AH8015 | 40 – 70 | 0.03 – 0.05 | 0.04 – 0.1 | 0.04 – 0.15 | 0.04 – 0.15 | ||

- (1)In the following cases, feed as if the cutter has a single effective cutting edge (ZEFP = 1):

- Hole making

- Helical interpolating for holes with a hole diameter (øD) ≤ 1.25x the tool diameter (DC)

- The axial D.O.C. exceeds APMX2

- (2)The tool is prone to vibration when the tool overhang exceeds 3.5xD and cause poor part quality. Make sure to use the axial cutting depth (ap) that do not exceed the value indicated in the APMX2 column. Also reduce the cutting speed and feed rate to 50% of the recommended speed.