Cost effective: Identical cutting performance, only smaller

ISO-EcoTurn Small size inserts, for an economical advantage

Applications & Features

Applications

Features

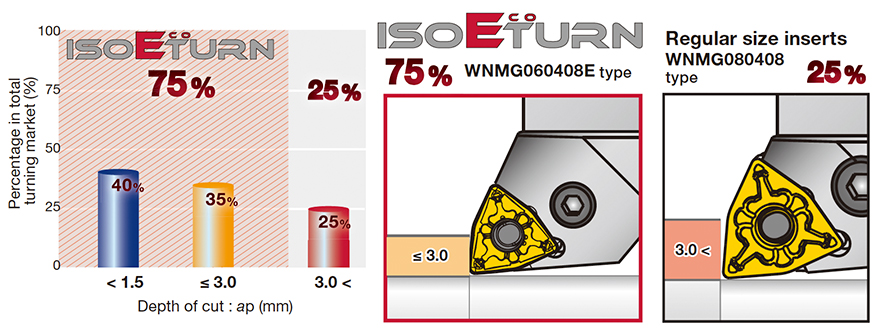

1. Over 75%* of the turning market only uses a depth of cut at or less than 3 mm

* Based on Tungaloy market research.

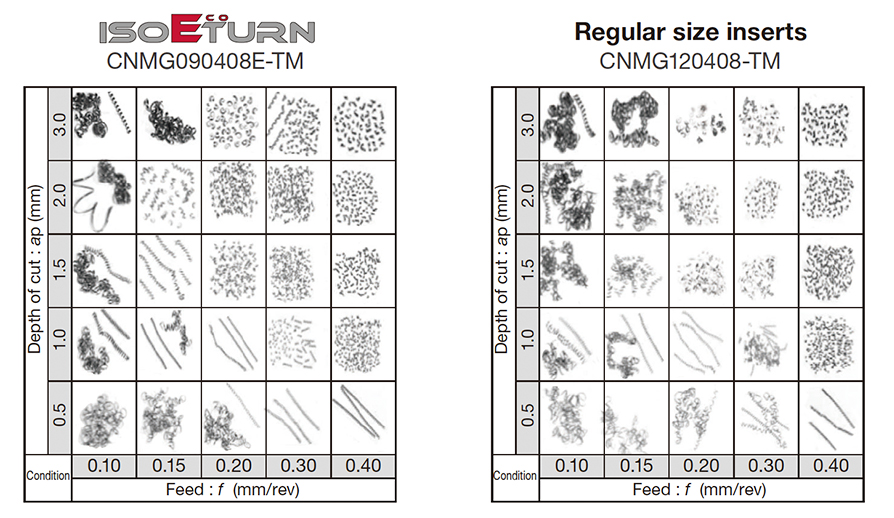

2. Chip control

ISO-EcoTurn inserts incorporate an identical chipbreaker geometry as regular size inserts providing the same chip removal at a depth of cut up to 3 mm.

Workpiece: S45C / C45

Cutting speed: Vc = 200 m/min

Coolant: Wet

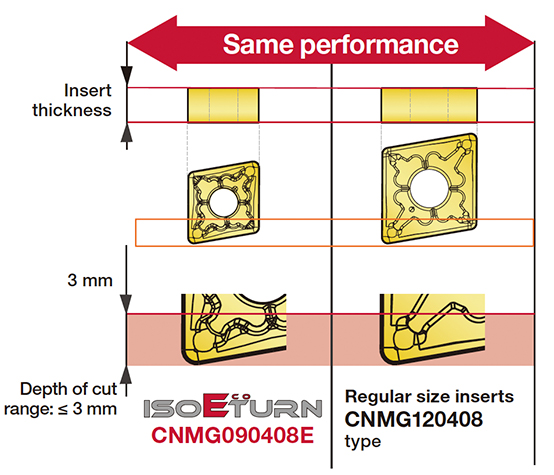

3. Uncompromising insert performance

Comparison of ISO-EcoTurn and regular size inserts

ISO-EcoTurn inserts feature the identical thickness and chipbreaker geometry as Tungaloy’s regular size inserts.

These properties provide cutting performance equal to that of the regular size inserts, including chip control at a depth of cut up to 3 mm.

Inserts & Grades

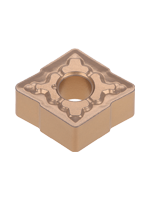

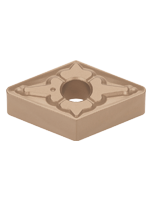

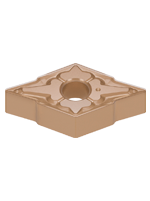

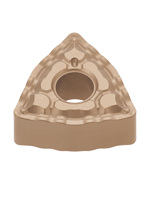

Inserts

Main Grades

T9215

![]()

![]()

![]()

- P10 – P20

- Well-balanced between wear and chipping resistance

- First choice for steel

- High versatility for a wide range of applications

T6130

![]()

- P15 – P30 / M15 – M30

- High wear resistance in cutting at medium to high speed

- First choice for stainless steel

T515

![]()

- K10 – K20

- Stable machining in a wide range of applications from continuous to interrupted cutting

Toolholders

Practical examples

Example #1

General Engineering

| Part: | Machine part |

| Material: | SCM415 |

| Toolholder: | AWLNR2525M0604-A |

| Insert: | WNMG060408E-TM |

| Grade: | T9215 |

| Cutting conditions: | Vc = 240 (m/min) f = 0.1 – 0.25 (mm/rev) ap = 1 (mm) Application: External face turning Coolant: Wet |

Example #2

Automotive Industry

| Part: | Shaft |

| Material: | S45C / C45 |

| Toolholder: | ADJNR2525M1104-A |

| Insert: | DNMG110408E-TSF |

| Grade: | T9215 |

| Cutting conditions: | Vc = 260 (m/min) f = 0.2 (mm/rev) ap = 1 (mm) Application: External turning Coolant: Wet |

Standard cutting conditions

CN/DN/TN/VN/WN

| ISO | Application | Chipbreaker | Grades | Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | ||

|---|---|---|---|---|---|---|---|---|

| Low carbon steels Alloy steels |

Medium carbon steelsAlloy steels | High carbon steels Alloy steels |

||||||

| Precision finishing | TF | T9215 | 0.1 – 0.5 | 0.03 – 0.15 | 150 – 400 | 150 – 400 | 120 – 300 | |

| T9225 | 0.1 – 0.5 | 0.03 – 0.15 | 120 – 300 | 120 – 300 | 100 – 250 | |||

| Finishing | TSF | NS9530 | 0.2 – 1.5 | 0.08 – 0.4 | 150 – 250 | 80 – 220 | 80 – 180 | |

| GT9530 | 0.2 – 1.5 | 0.08 – 0.4 | 150 – 300 | 80 – 250 | 80 – 200 | |||

| AT9530 | 0.2 – 1.5 | 0.08 – 0.4 | 150 – 300 | 80 – 250 | 80 – 200 | |||

| T9215 | 0.2 – 1.5 | 0.08 – 0.4 | 150 – 400 | 150 – 400 | 120 – 300 | |||

| T9225 | 0.2 – 1.5 | 0.08 – 0.4 | 120 – 300 | 120 – 300 | 100 – 250 | |||

| ZF | T9215 | 0.2 – 1.5 | 0.07 – 0.2 | 150 – 400 | 150 – 400 | 120 – 300 | ||

| T9225 | 0.2 – 1.5 | 0.07 – 0.2 | 120 – 300 | 120 – 300 | 100 – 250 | |||

| Finishing (Wiper) | FW | T9205 | 0.2 – 1.5 | 0.08 – 0.4 | 180 – 400 | 180 – 400 | 150 – 350 | |

| T9215 | 0.2 – 1.5 | 0.08 – 0.4 | 150 – 400 | 150 – 400 | 120 – 300 | |||

| T9225 | 0.2 – 1.5 | 0.08 – 0.4 | 120 – 300 | 120 – 300 | 100 – 250 | |||

| NS9530 | 0.5 – 1.5 | 0.2 – 0.4 | 150 – 250 | 80 – 220 | 80 – 180 | |||

| GT9530 | 0.5 – 1.5 | 0.2 – 0.4 | 150 – 300 | 80 – 250 | 80 – 200 | |||

| Finishing to medium cutting | ZM | T9215 | 0.7 – 2 | 0.15 – 0.4 | 150 – 400 | 150 – 400 | 120 – 300 | |

| T9225 | 0.7 – 2 | 0.15 – 0.4 | 120 – 300 | 120 – 300 | 100 – 250 | |||

| Finishing to medium cutting (Wiper) | SW | T9205 | 0.5 – 2 | 0.3 – 0.6 | 180 – 400 | 180 – 400 | 150 – 350 | |

| T9215 | 0.5 – 2 | 0.3 – 0.6 | 150 – 400 | 150 – 400 | 120 – 300 | |||

| T9225 | 0.5 – 2 | 0.3 – 0.6 | 120 – 300 | 120 – 300 | 100 – 250 | |||

| Finishing to medium cutting | NM | T9225 | 0.5 – 2 | 0.15 – 0.4 | 120 – 300 | 120 – 300 | 100 – 250 | |

| Medium cutting | TM | T9215 | 1 – 3 | 0.2 – 0.5 | 150 – 400 | 150 – 400 | 120 – 300 | |

| T9225 | 1 – 3 | 0.2 – 0.5 | 120 – 300 | 120 – 300 | 100 – 250 | |||

| Austenitic stainless steel | Ferritic / martensite stainless steel | Precipitation hardened stainless steel | ||||||

| Finishing | SS | AH630 | 0.5 – 3 | 0.08 – 0.2 | 90 – 190 | 110 – 210 | 60 – 90 | |

| AH645 | 0.5 – 3 | 0.08 – 0.2 | 70 – 150 | 90 – 170 | – | |||

| Medium cutting | SM | T6120 | 1 – 3 | 0.2 – 0.5 | 140 – 240 | 160 – 280 | 80 – 150 | |

| T6130 | 1 – 3 | 0.2 – 0.5 | 100 – 200 | 120 – 240 | 70 – 110 | |||

| AH630 | 1 – 3 | 0.2 – 0.5 | 90 – 190 | 110 – 210 | 60 – 90 | |||

| Grey cast irons | Ductile cast irons | |||||||

| Finishing to medium cutting (Wiper) | SW | T5115 | 0.5 – 2 | 0.3 – 0.6 | 140 – 400 | 140 – 370 | ||

| Medium cutting | TM | T515 | 1 – 3 | 0.2 – 0.5 | 150 – 700 | 140 – 370 | ||

| Titanium alloys | Ni-base alloys | |||||||

| Medium cutting | TM | AH8015 | 1 – 3 | 0.2 – 0.5 | 20 – 150 | 20 – 100 | ||

GN/FN

| ISO | Operation | Chipbreaker | Grade | Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | ||

|---|---|---|---|---|---|---|---|---|

| Low carbon steel, alloy steel | Medium carbon steel, alloy steel | High carbon steel, alloy steel | ||||||

| Finishing | TSF | T9215 | 0.2 – 1.5 | 0.08 – 0.4 | 150 – 400 | 150 – 400 | 120 – 300 | |

| T9225 | 0.2 – 1.5 | 0.08 – 0.4 | 120 – 300 | 120 – 300 | 100 – 250 | |||

| Medium cutting | TM | T9215 | 1 – 3 | 0.2 – 0.5 | 150 – 400 | 150 – 400 | 120 – 300 | |

| T9225 | 1 – 3 | 0.2 – 0.5 | 120 – 300 | 120 – 300 | 100 – 250 | |||

| ISO | Operation | Chipbreaker | Grade | Depth of cut ap (mm) |

Feed f (mm/rev) |

Stainless steel | ||

| Finishing | TSF | T9215 | 0.2 – 1.5 | 0.08 – 0.4 | 100 – 250 | |||

| T9225 | 0.2 – 1.5 | 0.08 – 0.4 | 100 – 250 | |||||

| AH8015 | 0.2 – 1.5 | 0.08 – 0.4 | 90 – 190 | |||||

| Medium cutting | TM | T9215 | 1 – 3 | 0.2 – 0.5 | 100 – 250 | |||

| T9225 | 1 – 3 | 0.2 – 0.5 | 100 – 250 | |||||

| AH8015 | 1 – 3 | 0.2 – 0.5 | 90 – 190 | |||||

| ISO | Operation | Chipbreaker | Grade | Depth of cut ap (mm) |

Feed f (mm/rev) |

Cast iron | ||

| Finishing | TSF | T9215 | 0.2 – 1.5 | 0.08 – 0.4 | 140 – 500 | |||

| T9225 | 0.2 – 1.5 | 0.08 – 0.4 | 140 – 500 | |||||

| Medium cutting | TM | T9215 | 1 – 3 | 0.2 – 0.5 | 140 – 500 | |||

| T9225 | 1 – 3 | 0.2 – 0.5 | 140 – 500 | |||||

| ISO | Operation | Chipbreaker | Grade | Depth of cut ap (mm) |

Feed f (mm/rev) |

Heat-resistant alloys | ||

| Finishing | TSF | AH8015 | 0.2 – 1.5 | 0.08 – 0.4 | 20 – 80 | |||

| Medium cutting | TM | AH8015 | 1 – 3 | 0.2 – 0.5 | 20 – 80 | |||

For more information about this product, visit our online e-catalog or download the product report: