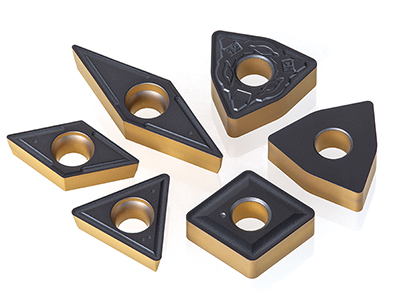

Applications & Features

Applications

Features

1. Grade feature

T505

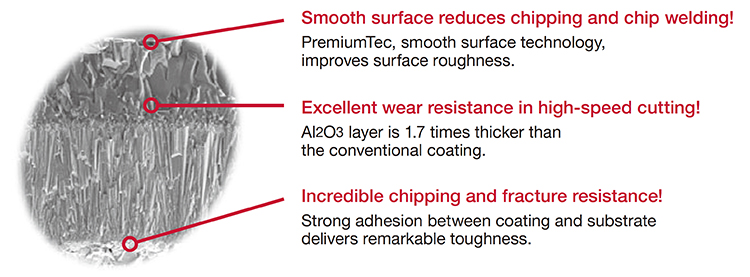

T505’s coating thickness is 1.5 times thicker than conventional grades.

The thickest coating layer of all Tungaloy’s CVD grades ever

– Thickest coating layer of all Tungaloy’s grades

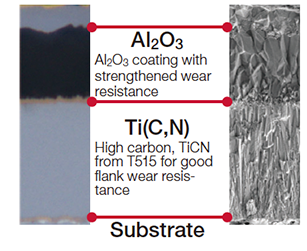

– Al2O3 coating with strengthened wear resistance

– TiCN layer with high carbon content

– New substrate with high thermal conductivity

T515

2. Application range

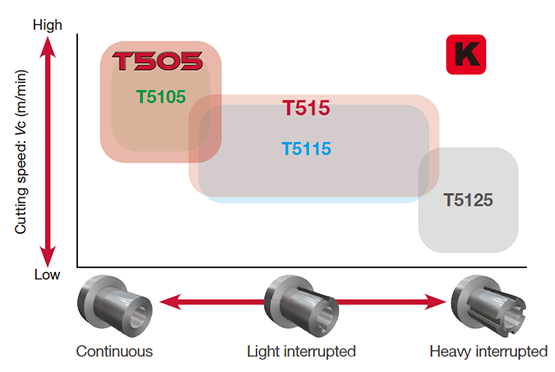

T505

– Complementary grade to T515

– High wear resistance

– The best grade for high speed machining of K05 – K20

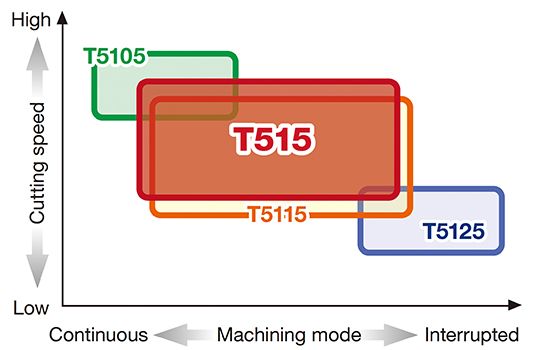

T515

Grades

T505

![]()

- K05 – K20

- An optimal CVD grade for high speed machining of cast iron

T515

![]()

- K10 – K20

- Stable machining in a wide range of applications from continuous to interrupted cutting

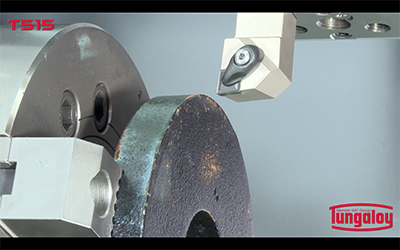

Practical examples

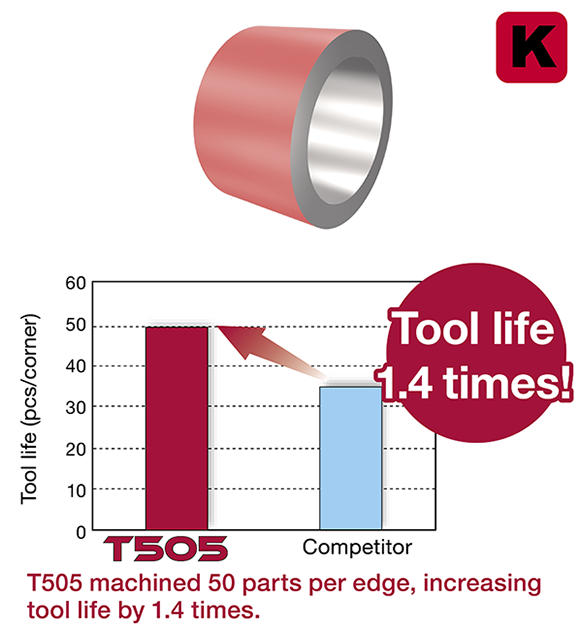

Example #1

General Industry

| Part: | Machine part |

| Material: | FCD500 |

| Insert: | CNMG120408-CM |

| Grade: | T505 |

| Cutting conditions: | Vc = 100(m/min) f = 0.5 (mm/rev) ap = 2.0 (mm) Application: External turning Coolant: Dry |

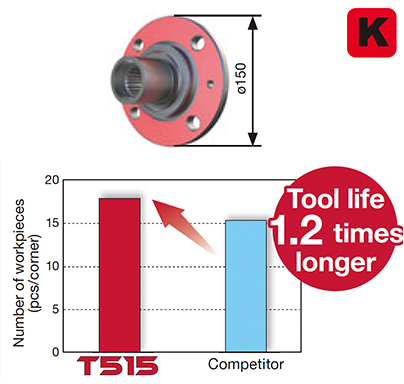

Example #2

Automotive Industry

| Part: | Hub |

| Material: | FCD400 / GGG40 |

| Insert: | CNMG120408 |

| Grade: | T515 |

| Cutting conditions: | Vc = 260 (m/min) f = 0.25 (mm/rev) ap = 3.0 (mm) Application: Face turning Coolant: Wet |

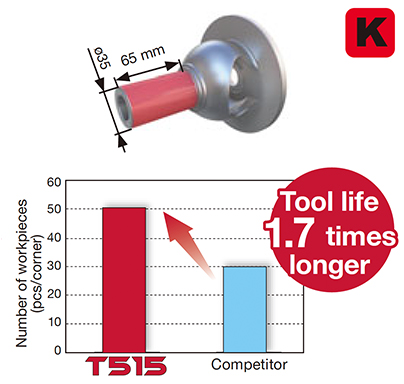

Example #3

Automotive Industry

| Part: | Differential case |

| Material: | Ductile cast iron |

| Insert: | CNMG120412 |

| Grade: | T515 |

| Cutting conditions: | Vc = 140 (m/min) f = 0.25 (mm/rev) ap = 1.0 (mm) Application: External turning Coolant: Wet |

Standard cutting conditions

Negative inserts

T505

| Chipbreaker | Grades | Corner radius RE |

Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | |

|---|---|---|---|---|---|---|

| Grey cast iron | Ductile cast iron | |||||

| CM | T505 | 0.4 | 1 – 5 | 0.1 – 0.25 | 180 – 700 | 180 – 400 |

| T505 | 0.8 | 1 – 5 | 0.15 – 0.4 | 180 – 700 | 180 – 400 | |

| T505 | 1.2 | 1 – 5 | 0.15 – 0.5 | 180 – 700 | 180 – 400 | |

| All-round | T505 | 0.4 | 1 – 6 | 0.2 – 0.3 | 180 – 700 | 180 – 400 |

| T505 | 0.8 | 1 – 6 | 0.2 – 0.5 | 180 – 700 | 180 – 400 | |

| T505 | 1.2 | 1 – 6 | 0.2 – 0.5 | 180 – 700 | 180 – 400 | |

| T505 | 1.6 | 1 – 6 | 0.3 – 0.5 | 180 – 700 | 180 – 400 | |

| Flat-top | T505 | 0.8 | 0.05 – 2 | 0.2 – 0.45 | 180 – 700 | 180 – 400 |

| T505 | 1.2 | 0.05 – 2 | 0.2 – 0.6 | 180 – 700 | 180 – 400 | |

T515

| Chipbreaker | Grades | Corner radius RE |

Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | |

|---|---|---|---|---|---|---|

| Grey cast iron | Ductile cast iron | |||||

| CM | T515 | 0.8 | 1.0 – 5.0 | 0.15 – 0.40 | 150 – 700 | 150 – 300 |

| T515 | 1.2 | 1.0 – 5.0 | 0.15 – 0.50 | 150 – 700 | 150 – 300 | |

| CH | T515 | 0.4 | 2.0 – 6.0 | 0.10 – 0.30 | 150 – 700 | 150 – 300 |

| T515 | 0.8 | 2.0 – 6.0 | 0.20 – 0.45 | 150 – 700 | 150 – 300 | |

| T515 | 1.2 | 2.0 – 6.0 | 0.20 – 0.65 | 150 – 700 | 150 – 300 | |

| All-round | T515 | 0.4 | 1.0 – 6.0 | 0.20 – 0.30 | 150 – 700 | 150 – 300 |

| T515 | 0.8 | 1.0 – 6.0 | 0.20 – 0.50 | 150 – 700 | 150 – 300 | |

| T515 | 1.2 | 1.0 – 6.0 | 0.20 – 0.50 | 150 – 700 | 150 – 300 | |

| T515 | 1.6 | 1.0 – 6.0 | 0.30 – 0.50 | 150 – 700 | 150 – 300 | |

| Fiat-top | T515 | 0.8 | 0.05 – 2.0 | 0.20 – 0.45 | 150 – 700 | 150 – 300 |

| T515 | 1.2 | 0.05 – 2.0 | 0.30 – 0.80 | 150 – 700 | 150 – 300 | |

| SW (Wiper) |

T515 | 0.8 | 0.5 – 2.0 | 0.30 – 0.60 | 150 – 700 | 150 – 300 |

| T515 | 1.2 | 0.5 – 2.0 | 0.50 – 0.80 | 150 – 700 | 150 – 300 | |

Positive insert

T505

| Chipbreaker | Grades | Corner radius RE |

Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | |

|---|---|---|---|---|---|---|

| Grey cast iron | Ductile cast iron | |||||

| CM | T505 | 0.4 | 0.05 – 2 | 0.05 – 0.2 | 180 – 700 | 180 – 400 |

| T505 | 0.8 | 0.05 – 2 | 0.05 – 0.3 | 180 – 700 | 180 – 400 | |

| T505 | 1.2 | 0.05 – 2 | 0.05 – 0.3 | 180 – 700 | 180 – 400 | |

T515

| Chipbreaker | Grades | Corner radius RE |

Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | |

|---|---|---|---|---|---|---|

| Grey cast iron | Ductile cast iron | |||||

| CM | T515 | 0.4 | 0.05 – 2.0 | 0.05 – 0.2 | 150 – 700 | 150 – 300 |

| T515 | 0.8 | 0.05 – 2.0 | 0.05 – 0.3 | 150 – 700 | 150 – 300 | |

| T515 | 1.2 | 0.05 – 2.0 | 0.05 – 0.3 | 150 – 700 | 150 – 300 | |

For more information about this product, visit our online e-catalog or download the product report: