High precision grooving and threading tool series for CNC automatic lathes

Perfect for grooving and threading bar stocks of 12 mm or smaller diameters

Applications & Features

Applications

Features

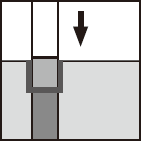

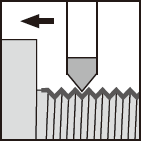

Grooving and threading tools for CNC automatic lathes with unique insert clamping system for extra tool rigidity

- V-shaped insert pocket retains the insert securely, enabling high precision machining

- Available in 8×8, 10×10, and 12×12 mm square shanks

- High-pressure through coolant directed to the rake and back faces of the cutting edge for smooth machining process and prolonged tool life

- Same inserts for right-hand and left-hand toolholders

Slim shank design eliminates interference with neighboring tools

Inserts & Grades

Inserts

VGP Inserts for Grooving / sharp edge

- CW = 0.33 – 1 mm

VGT Inserts for Threading / sharp edge

- Pitch = 0.4 – 1.5 mm

Grades

Toolholders

Grooving & Threading

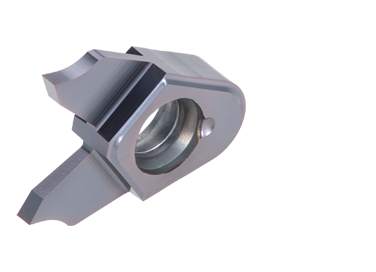

MiniV-LockGroove Toolholders

clamping system for extra tool rigidity

Grooving & Threading

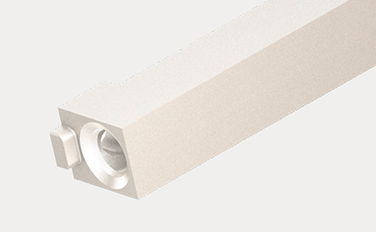

ModuMini-Turn Heads

Modular head with high pressure coolant capability

Practical examples

Example #1

| Part: | Pin |

| Material: | SUS304 / X5CrNi18-9 |

| Toolholder: | SVER1010H10 |

| Insert: | VGP10-100F-000 |

| Grade: | SH725 |

| Cutting conditions: | Vc = 60 (m/min) f = 0.02 (mm/rev) CW = 1 (mm) CDX = 0.2 (mm) Application: External grooving Coolant: Oil |

Example #2

| Part: | Sensor part |

| Material: | Tool steel |

| Toolholder: | SVER0808F08 |

| Insert: | VGP08-050F-000 |

| Grade: | SH725 |

| Cutting conditions: | Vc = 50 (m/min) f = 0.01 (mm/rev) CW = 0.5 (mm) CDX = 0.5 (mm) Application: External grooving Coolant: Oil |

Standard cutting conditions

Grooving

| ISO | Workpiece materials | Grade | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|

| Low carbon steels S15C, SS400, etc. C15E4, E275A, etc. |

SH725 | 50 – 150 | 0.005 – 0.1 | |

| Carbon steels, Alloy steels S55C, SCM440, etc. C55, 42CrMo4, etc. |

SH725 | 50 – 150 | 0.005 – 0.1 | |

| Free cutting steels SUH22, SUH23, etc. |

SH725 | 50 – 150 | 0.005 – 0.1 | |

| Stainless steels SUS304, X5CrNi18-9, etc. |

SH725 | 50 – 100 | 0.005 – 0.1 | |

| Aluminium alloys A5056, A6061, etc. |

SH725 | 150 – 200 | 0.005 – 0.1 | |

| Copper alloy C2600, C280C, etc. |

SH725 | 100 – 200 | 0.005 – 0.1 | |

| Titanium alloys Ti-6AI-4V, etc. |

SH725 | 30 – 80 | 0.005 – 0.1 | |

| Superalloys Inconel718, etc. |

SH725 | 30 – 80 | 0.005 – 0.1 |

Threading

| ISO | Workpiece materials | Grade | Cutting speed Vc (m/min) |

Pitch (mm) |

TPI |

|---|---|---|---|---|---|

| Low carbon steels S15C, SS400, etc. C15E4, E275A, etc. |

SH725 | 50 – 150 | 0.4 – 2 | 64 – 12 | |

| Carbon steels, Alloy steels S55C, SCM440, etc. C55, 42CrMo4, etc. |

SH725 | 50 – 150 | 0.4 – 2 | 64 – 12 | |

| Free cutting steels SUH22, SUH23, etc. |

SH725 | 50 – 150 | 0.4 – 2 | 64 – 12 | |

| Stainless steels SUS304, X5CrNi18-9, etc. |

SH725 | 50 – 100 | 0.4 – 2 | 64 – 12 | |

| Aluminium alloys A5056, A6061, etc. |

SH725 | 150 – 200 | 0.4 – 2 | 64 – 12 | |

| Copper alloy C2600, C280C, etc. |

SH725 | 100 – 200 | 0.4 – 2 | 64 – 12 | |

| Titanium alloys Ti-6AI-4V, etc. |

SH725 | 30 – 80 | 0.4 – 2 | 64 – 12 | |

| Superalloys Inconel718, etc. |

SH725 | 30 – 80 | 0.4 – 2 | 64 – 12 |

For more information about this product, visit our online e-catalog or download the product report: