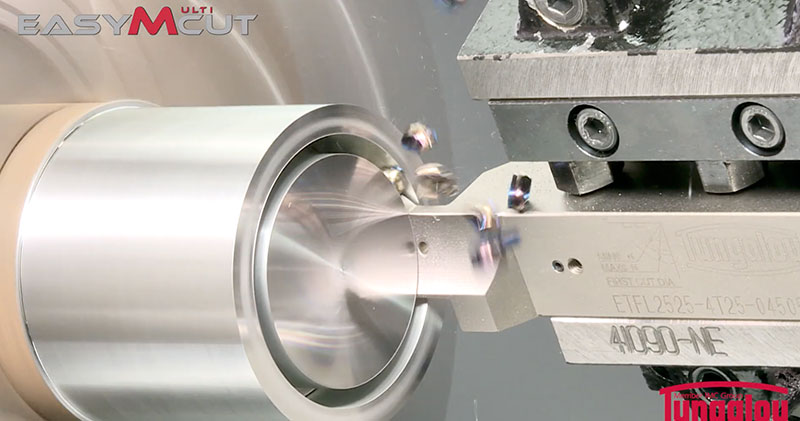

The most efficient multi-functional tool for face grooving, and turning operations

Unique self-clamping system increases tool rigidity, resulting in excellent performance with high machining conditions

Applications & Features

Applications

Features

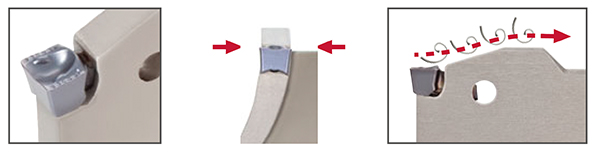

1. Unique insert clamping

• Easy indexing with highly reliable insert fixation.

• High stability against side force.

• Smooth chip flow in the groove due to the simple structure.

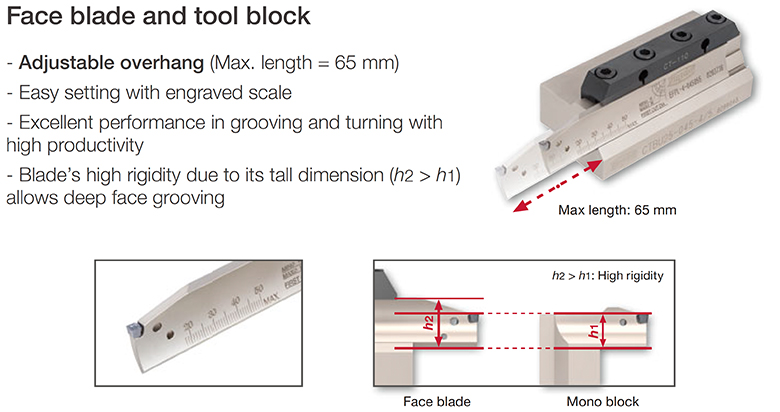

2. Face blade and tool block

• Adjustable overhang (Max. length = 65 mm)

• Easy setting with engraved scale.

• Excellent performance in grooving and turning with high productivity.

• Blade’s high rigidity due to its tall dimension (h2 > h1) allows deep face grooving.

3. CHP type toolholders for high-pressure coolant

• The coolant is directed to the cutting edge, resulting in improved chip control and long tool life.

Inserts & Grades

Inserts

ETX Single-ended inserts for face grooving and turning (Cutting width 4, 5, 6 mm)

- Optimized protrusion smoothly controls chips in grooving and turning

EGM Single-ended inserts for grooving and parting (Cutting width 4 mm)

- Deep dimple makes chips narrower than the groove width for easy evacuation

- Straight cutting edge makes the bottom of the machined groove flat

Grades

AH725

![]()

![]()

![]()

![]()

- P15 – P30 / M15 – M30 / K25 – K30 / S15 – S25

- Good balance between wear and chipping resistance

- Suitable for machining steel and stainless steel under general cutting conditions

Toolholders

Grooving & Parting

EasyMulti-Cut Toolholders for Face Grooving

Unique self-clamping system increases tool rigidity

Other

EasyMulti-Cut Tool Blocks for Face Grooving

Unique self-clamping system increases tool rigidity

Practical examples

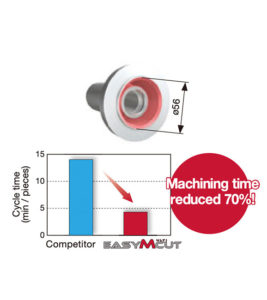

Example #1

General Engineering

| Part: | Puncher part |

| Material: | SCM435 / 34CrMo4 |

| Toolholder: | CTBU25-055-6-CHP + EFPR-6-045055 |

| Insert: | ETX6-040 |

| Grade: | AH725 |

| Cutting conditions: | Vc = 65 (m/min) f = 0.07 (mm/rev) W = 6 (mm) ar = 53 (mm) Application: Face grooving Coolant: Wet |

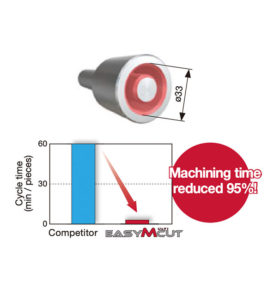

Example #2

General Engineering

| Part: | Endcap |

| Material: | S45C / C45 |

| Toolholder: | CTBU25-030-4-CHP + EFPR-4-030035 |

| Insert: | ETX4-040 |

| Grade: | AH725 |

| Cutting conditions: | Vc = 100 (m/min) f = 0.1 (mm/rev) W = 4 (mm) ar = 50 (mm) Application: Face grooving Coolant: Wet |

Standard cutting conditions

| ISO | Workpiece materials | Hardness | Grades | Chip-breaker | Cutting speed Vc (m/min) |

|---|---|---|---|---|---|

| Low carbon steel (C15, C20, etc.) |

– 300HB | AH725 | ETX | 80 – 180 | |

| – 300HB | AH725 | EGM | 80 – 180 | ||

| Carbon steel, Alloy steel (C55, 42CrMoS4, etc.) |

– 300HB | AH725 | ETX | 80 – 180 | |

| – 300HB | AH725 | EGM | 80 – 180 | ||

| Prehardened steel (NAK80, PX5, etc.) |

– 300HB | AH725 | ETX | 80 – 180 | |

| – 300HB | AH725 | EGM | 80 – 180 | ||

| Stainless steel (X5CrNi18-9, X5CrNiMo17-12-2, etc) |

– | AH725 | ETX | 50 – 120 | |

| – | AH725 | EGM | 50 – 120 |

For more information about this product, visit our online e-catalog or download the product report: