Különböző menetmaró szerszámok

Kiválóan alkalmas hőálló ötvözetek vagy edzett acélok menetmegmunkálásához

Alkalmazhatóság nagyméretű menetmegmunkáláshoz is, alacsony vágóerővel

Alkalmazhatóság és jellemzők

Alkalmazhatóság

Jellemzők

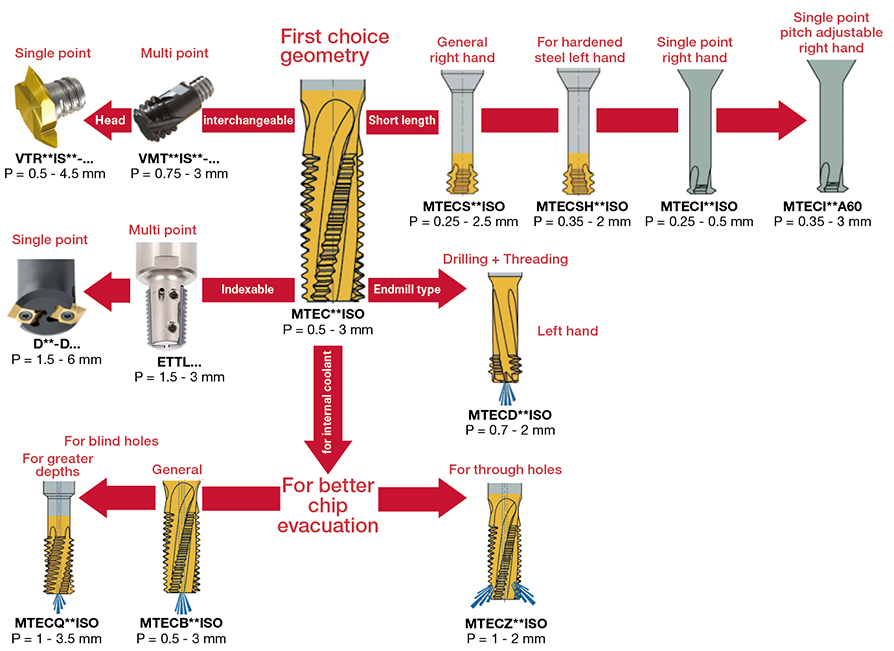

Szerszámválasztási útmutató belső ISO metrikus menethez

Lapkák, fejek, tömör keményfém Szármarók és Minőségek

Lapkák, fejek, tömör keményfém szármarók

Tömör keményfém szármarók

SolidThread

- Menetemelkedés 0,25 mm – 3,5 mm, szerszámátmérő 0,72 mm

- Kis átmérőjű menetek megmunkálása, mint például M1x0,25 és 0-80UNF

Fejek

TungMeister Menetmegmunkálási fejek (VMT / VTR)

- Menetemelkedés 0,5 mm – 4,5 mm, szerszám átmérő 10 mm

- Cserélhető fejű menetmaró szerszámok, melyek rövidebb állásidővel dolgoznak a tömör menetvágó szerszámokhoz képest

Lapkák

Menetmaró váltólapkák

- Menetemelkedés 1,5 mm – 6,0 mm, szerszám átmérő 17 mm

- Többféle lapkával, különböző menetmegmunkálási átmérőkhöz és menetemelkedésekhez

Minőségek

AH725

![]()

![]()

![]()

![]()

- Kiegyensúlyozott kopás- és törésállóság

- Alkalmas acél és rozsdamentes acél megmunkálására általános megmunkálási paraméterekkel

GH330

![]()

![]()

![]()

- Nagy kopás- és törésállóság

- Alkalmas folyamatos és közepesen megszakított felületekhez

Marók

Szármaró típus

Váltólapkás menetmegmunkálás (ø17- ø80 mm)

Hengeres típusú marók visszasüllyesztéshez

Gyakorlati példák

Javasolt paraméterek

ETTL/ETLN

| ISO | Munkadarab alapanyag | Minőségek | Vágósebesség Vc(m/min) |

Fogankénti előtolás fz(mm/z) |

|---|---|---|---|---|

| Alacsony széntartalmú acél | AH725 | 100 – 200 | 0.1 – 0.3 | |

| Magas széntartalmú acél | AH725 | 70 – 150 | 0.1 – 0.3 | |

| Magas széntartalmú acélok | AH725 | 70 – 170 | 0.1 – 0.3 | |

| Öntött acél | AH725 | 70 – 170 | 0.1 – 0.3 | |

| Rozsdamentes acél | AH725 | 90 – 140 | 0.1 – 0.3 | |

| Öntöttvas | AH725 | 60 – 130 | 0.05 – 0.3 | |

| Alumínium ötvözetek | AH725 | 80 – 400 | 0.1 – 0.4 | |

| Hőálló ötvözetek | AH725 | 10 – 30 | 0.02 – 0.1 | |

| Titán ötvözet | AH725 | 20 – 90 | 0.02 – 0.1 |

- Emelkedő marás ajánlott.

Egylapkás menetmarók

| ISO | Munkadarab alapanyag | Minőségek | Vágósebesség Vc(m/min) |

Fogankénti előtolás fz(mm/z) |

|---|---|---|---|---|

| Közepesen lágy acélok / edzetlen acélok < 200HB | GH330 | 150 – 200 | 0.3 – 0.4 | |

| Szénacélok / ötvözött acélok < 300HB | GH330 | 150 – 200 | 0.17 – 0.26 | |

| Szerszámacélok < 50HRC | GH330 | 30 – 50 | 0.14 – 0.2 | |

| Rozsdamentes acélok < 300HB | GH330 | 150 – 200 | 0.05 – 0.12 |

- Emelkedő marás ajánlott.

- Zsákfurat menetmarásakor használjon jobbos marót, jobbos forgatással. Lentről felfelé forgácsoljon, hogy elkerülje a forgács újravágását.

- A furat csúcsról történő menetmaráskor balos marót használjon, balra forgatva.

SolidThread / TungMeister

| ISO | Munkadarab alapanyag | Kondíció | Szakítószilárdság erő [N/mm2] |

Keménység HB | Vágósebesség Vc(m/min) |

Szerszám átmérő | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fogankénti előtolás fz(mm/z) | ||||||||||||||||||

| AH725 | ø2 | ø3 | ø4 | ø6 | ø8 | ø10 | ø12 | ø14 | ø16 | ø20 | ø25 | ø30 | ||||||

| |

Ötvözetlen acél és öntött acél, könnyen forgácsolható acél | < 0,25 %C | Lágyított | 420 | 125 | 100 – 250 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 |

| ≥ 0.25 %C | Lágyított | 650 | 190 | 80 – 210 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | ||

| < 0,55 %C | Hőkezelt és edzett | 850 | 250 | 65 – 170 | ||||||||||||||

| ≥ 0.55 %C | Lágyított | 750 | 220 | 110 – 180 | 0.02 | 0.03 | 0.03 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.12 | 0.15 | 0.18 | ||

| Hőkezelt és edzett | 1000 | 300 | 95 – 160 | 0.02 | 0.03 | 0.03 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.12 | 0.15 | 0.18 | |||

| Alacsonyan ötvözött acél és öntött acél Alacsonyan ötvözött acél és öntött acél (kevesebb, mint 5% ötvözőelem) |

Lágyított | 600 | 200 | 90 – 160 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | ||

| Hőkezelt és edzett | 930 | 275 | 65 – 200 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | |||

| 1000 | 300 | 70 – 210 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | ||||

| 1200 | 350 | 95 – 160 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | ||||

| Magasan ötvözött acél, öntött acél és szerszámacél | Lágyított | 680 | 200 | 130 – 170 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | ||

| Hőkezelt és edzett | 1100 | 325 | 75 – 100 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | |||

| Rozsdamentes acél és öntött acél | Ferrites/martenzites | 680 | 200 | 110 – 170 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | ||

| Martenzites | 820 | 240 | 70 – 155 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | |||

| |

Rozsdamentes acél | Lágyított | 600 | 180 | 85 – 100 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | |

| |

Gömbgrafitos öntöttvas (GGG) | Ferrites/martenzites | 180 | 120 – 160 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | ||

| Perlites | 260 | 75 – 160 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | ||||

| Szürkeöntvény (GG) | Ferrites | 160 | 70 – 150 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | |||

| Perlites | 250 | 110 – 140 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | ||||

| Formázható öntöttvas | Ferrites | 130 | 120 – 160 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | |||

| Perlites | 230 | 110 – 140 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.21 | 0.15 | 0.18 | 0.21 | ||||

| |

Alumínium kovácsolt ötvözet | Nem keményíthető | 60 | 160 – 300 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | ||

| Keményített | 100 | |||||||||||||||||

| Alumínium-öntvény, alumínium-öntvény, ötvözött |

=<12% Si | Nem keményíthető | 75 | 150 – 350 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | ||

| Keményített | 90 | |||||||||||||||||

| >12% Si | Magas hőmérséklet | 130 | 100 – 250 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.10 | 0.12 | |||

| Rézötvözetek | >1% Pb | Szabad forgácsolás | 110 | |||||||||||||||

| Sárgaréz | 90 | |||||||||||||||||

| Elektrolitikus réz | 100 | |||||||||||||||||

| Nem fémes | Duroplastok, szálas műanyagok | 100 – 400 | 0.05 | 0.06 | 0.07 | 0.09 | 0.1 | 0.11 | 0.12 | 0.13 | 0.15 | 0.18 | 0.22 | 0.25 | ||||

| Kemény gumi | ||||||||||||||||||

| |

Magas hőmérséklet. ötvözetek | Fe-alapú | Lágyított | 200 | ||||||||||||||

| Keményített | 280 | |||||||||||||||||

| Ni vagy Co alapú | Lágyított | 250 | 20 – 80 | 0.02 | 0.02 | 0.02 | 0.03 | 0.03 | 0.03 | 0.03 | 0.04 | 0.04 | 0.04 | 0.05 | 0.05 | |||

| Keményített | 350 | |||||||||||||||||

| Öntött | 320 | |||||||||||||||||

| Titán Ti ötvözetek | RM 400 | |||||||||||||||||

| Alfa+béta ötvözetek kikeményedése | RM 1050 | 20 – 80 | 0.02 | 0.02 | 0.02 | 0.03 | 0.03 | 0.03 | 0.03 | 0.04 | 0.04 | 0.04 | 0.05 | 0.05 | ||||

| |

Edzett acél | Edzett | 55 HRC | 55 – 65 | ||||||||||||||

| Edzett | 60 HRC | 45 – 55 | ||||||||||||||||

| Hűtött öntöttvas | Öntött | 400 | 90 – 105 | |||||||||||||||

| Öntöttvas | Edzett | 55 HRC | 55 – 65 | |||||||||||||||

- Hosszú él esetén csökkentse az ellőtoláś sebességét 40%-ra.

MTECS – Kis átmérő, rövid típus

| ISO | Munkadarab anyaga | FogásmélységFogásmélység Vc(m/min) |

Szerszám átmérője | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fogankénti előtolás fz(mm/z) | |||||||||||||||

| ø1.5 | ø2 | ø3 | ø4 | ø5 | ø6 | ø7 | ø8 | ø9 | ø10 | ø12 | ø14 | ø15 | |||

| Alacsony és közepes Alacsony és közepes szénacélok |

60 – 120 | 0.05 | 0.05 | 0.07 | 0.09 | 0.11 | 0.13 | 0.14 | 0.15 | 0.16 | 0.16 | 0.17 | 0.18 | 0.18 | |

| Magas szénatomszámMagas szénatomszám acélok |

60 – 90 | 0.04 | 0.05 | 0.06 | 0.08 | 0.09 | 0.1 | 0.12 | 0.13 | 0.14 | 0.14 | 0.16 | 0.17 | 0.18 | |

| ötvözött acélok, ötvözött acélok, kezelt acélok |

50 – 80 | 0.04 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.07 | 0.08 | 0.09 | 0.1 | 0.12 | 0.13 | 0.14 | |

| Öntött acélok | 70 – 90 | 0.04 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.07 | 0.08 | 0.09 | 0.1 | 0.12 | 0.13 | 0.14 | |

| Rozsdamentes acélok | 60 – 90 | 0.03 | 0.03 | 0.04 | 0.05 | 0.06 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.11 | 0.12 | 0.13 | |

| Öntöttvas | 40 – 80 | 0.05 | 0.05 | 0.07 | 0.09 | 0.11 | 0.13 | 0.14 | 0.15 | 0.16 | 0.16 | 0.17 | 0.18 | 0.18 | |

| Alumínium | 80 – 150 | 0.05 | 0.05 | 0.07 | 0.09 | 0.11 | 0.13 | 0.14 | 0.15 | 0.16 | 0.16 | 0.17 | 0.18 | 0.18 | |

| Műanyagok, duroműanyagok, hőre lágyuló műanyagok | 50 – 200 | 0.1 | 0.11 | 0.12 | 0.14 | 0.16 | 0.18 | 0.19 | 0.19 | 0.19 | 0.19 | 0.19 | 0.2 | 0.2 | |

| Nikkel ötvözetek,Nikkel ötvözetek, titánötvözetek |

20 – 40 | 0.03 | 0.03 | 0.04 | 0.04 | 0.05 | 0.06 | 0.06 | 0.06 | 0.07 | 0.07 | 0.07 | 0.08 | 0.08 | |

Ha további információt szeretne kapni erről a termékről, látogasson el online e-katalógusunkba, vagy töltse le a termékriportot: