Think Green chez Tungaloy : construire un avenir durable dans l’industrie manufacturière

Partout dans le monde, les industriels font face à une pression croissante pour réduire leur impact environnemental. De l’automobile à l’aéronautique, nos clients se fixent des objectifs climatiques ambitieux et attendent de leurs partenaires qu’ils s’engagent dans la même voie. Dans l’industrie des outils de coupe, où la précision rencontre la performance, nous partageons la responsabilité de faire en sorte que l’innovation aille de pair avec la durabilité.

Chez Tungaloy, cette responsabilité va bien au-delà des mots. À travers notre initiative Think Green, nous investissons dans des énergies plus propres, des processus plus intelligents et des solutions plus respectueuses de l’environnement, contribuant à la fois au succès de nos clients et au bien-être de notre planète.

Un engagement environnemental certifié

Notre engagement en faveur du développement durable s’appuie sur des systèmes de management reconnus à l’échelle internationale. Tungaloy a obtenu la certification ISO 14001 (management environnemental) en 1997, devenant ainsi le premier fabricant de l’industrie japonaise des outils en carbure cémenté à y parvenir. Cette année marque le 29ᵉ anniversaire de cette certification. En août 2024, notre siège d’Iwaki a également obtenu la certification ISO 50001 (management de l’énergie), portant à quatre le nombre de normes internationales couvertes : qualité, environnement, santé et sécurité au travail, et énergie.

Ces certifications démontrent que la durabilité n’est pas une ambition abstraite, mais une composante essentielle de la gestion de nos opérations, de manière structurée, transparente et avec des améliorations mesurables.

Les énergies renouvelables en action

L’une de nos plus grandes fiertés est notre site de production de Nagoya, qui fonctionne exclusivement à partir d’électricité issue de sources renouvelables depuis 2022. Nagoya est l’un des principaux pôles de production de Tungaloy, et sa transformation en site alimenté à 100 % par des énergies renouvelables illustre parfaitement la coexistence entre fabrication de classe mondiale et responsabilité environnementale.

En complément, notre siège d’Iwaki est équipé depuis 2015 d’un système de production d’énergie solaire, générant environ 160 MWh d’électricité par an et réduisant les émissions de CO₂ d’environ 75 tonnes par an.

Sur l’ensemble de nos sites, nous continuons à augmenter la part d’énergies renouvelables, progressant de manière constante vers notre objectif de neutralité carbone à l’horizon 2050.

Des actions concrètes pour réduire les émissions de CO₂

Au-delà de l’approvisionnement en électricité, nous mettons en œuvre des actions concrètes pour réduire nos émissions de CO₂ :

- En 2023, le siège d’Iwaki est passé du kérosène au gaz de ville comme source d’énergie, entraînant une réduction de 27 % des émissions de CO₂ liées aux combustibles en 2024, avec des améliorations continues en 2025.

- Sur le site de Nirasaki, la transition de l’hydrogène gris vers de l’hydrogène vert produit localement a permis de réduire les émissions d’environ 300 tonnes de CO₂ par an.

- Globalement, par rapport à 2023, les émissions totales de Tungaloy ont diminué d’environ 10 % en 2024 et cette tendance à la baisse s’est maintenue tout au long de 2025.

Nous visons une réduction de 46 % des émissions de CO₂ d’ici 2030 (par rapport aux niveaux de 2013), en soutien à notre objectif de neutralité carbone à long terme.

Un leadership environnemental reconnu

En 2024 et 2025, nos activités environnementales de longue date ont été récompensées par le Grand Prix Environnement décerné par la Japan Cutting & Wear-Resistant Tool Association. Cette reconnaissance par nos pairs souligne l’impact de nos actions et encourage l’ensemble de l’industrie à relever encore davantage le niveau d’exigence.

Un développement produit responsable

Tous les nouveaux produits développés par Tungaloy sont évalués selon la norme de la Japan Cutting & Wear-resistant Tool Association pour les produits éco-responsables (ECP), un système de certification officiel visant à promouvoir une fabrication respectueuse de l’environnement dans l’industrie japonaise des outils de coupe.

Le système de certification des produits respectueux de l’environnement constitue une référence pour le secteur depuis 2007 et continue d’être utilisé par la Japan Cutting & Wear-resistant Tool Association depuis sa création en 2015.

Dans ce cadre, chaque produit est évalué sur une échelle de 100 points, répartis entre le concept de développement du produit (60 points) et les activités environnementales de l’entreprise (40 points).

- 80 points ou plus : ☆☆☆

- 79 à 60 points : ☆☆

- 59 à 40 points : ☆

- Moins de 40 points : non certifié

Cette évaluation prend en compte des critères tels que la durée de vie du produit, la réduction des substances dangereuses, l’efficacité énergétique, l’optimisation des ressources, ainsi que les pratiques environnementales à l’échelle de l’entreprise, comme les achats responsables et les initiatives de recyclage.

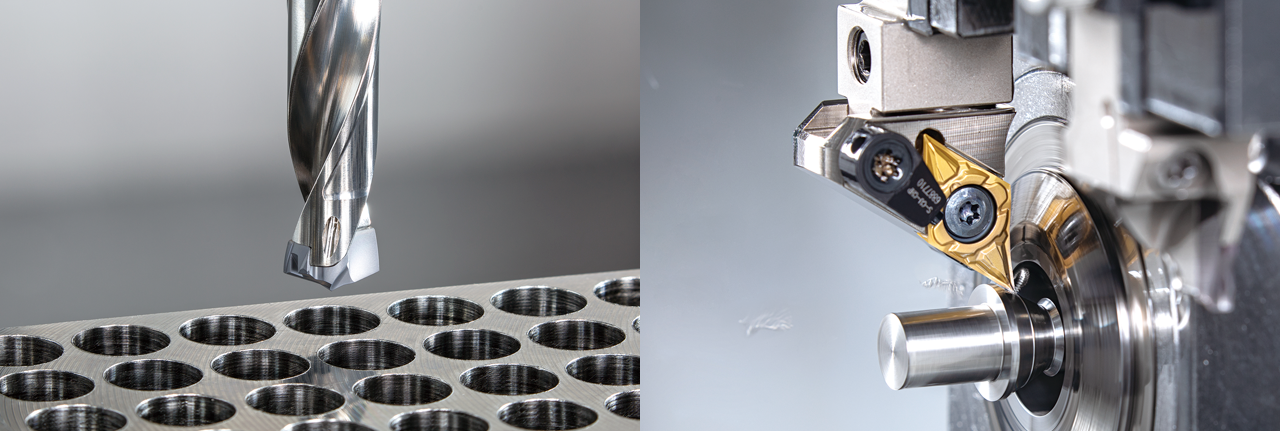

Plusieurs gammes de produits Tungaloy, notamment nos systèmes de perçage à tête interchangeable (DrillMeister et DrillForceMeister), notre nuance PVD SH7025 dédiée à l’usinage de précision des petites pièces, ainsi que d’autres solutions d’outillage avancées, ont obtenu des certifications deux et trois étoiles dans ce cadre.

Nos équipes R&D travaillent en permanence selon ces standards, afin que chaque innovation Tungaloy contribue à une industrie plus durable et plus respectueuse de l’environnement.

Une utilisation plus intelligente des ressources

Tungaloy réduit en permanence son empreinte environnementale grâce à l’innovation en matière d’emballage et à la gestion des déchets :

- Depuis 2004, nous maintenons un taux de mise en décharge inférieur à 1 % (zéro émission).

- Calage des fraises : remplacement de la mousse plastique par du carton (–580 kg de plastique par an).

- Emballage des têtes brasées pour BTA : passage à du carton recyclable (–1,2 tonne de plastique par an).

Nous favorisons également une économie circulaire en collectant et recyclant les outils en carbure cémenté usagés au Japon, afin de récupérer des matières premières précieuses telles que le tungstène pour leur réutilisation dans de nouveaux produits.

Une culture de la durabilité

En poursuivant ce parcours, Tungaloy s’appuie sur ses réalisations actuelles tout en explorant de nouvelles initiatives : adoption des énergies renouvelables et de l’hydrogène vert, extension de la production d’énergie solaire, renforcement des programmes de recyclage et promotion d’une approche numérique globale visant à réduire l’utilisation du papier.

Chacune de ces actions rapproche Tungaloy de sa vision d’un avenir durable pour notre industrie et pour la société.

Think Green chez Tungaloy ne se résume pas à des actions ponctuelles ou à de simples obligations réglementaires.

Il s’agit de construire une culture de responsabilité, d’innovation et de progrès, au service de nos clients, de nos collaborateurs et de notre planète.