Applications & Fonctionnalités

Applications

Fonctionnalités

Conçu pour la résistance de l’outil et une évacuation optimale des copeaux

1. Corps d’outil en aciers alliés spéciaux, conçu pour réduire le broutage

- Assure une qualité de finition de surface supérieure par rapport aux outils de tournage ID conventionnels

- Amélioration de la durée de vie, de l’efficacité et de l’économie de l’outil

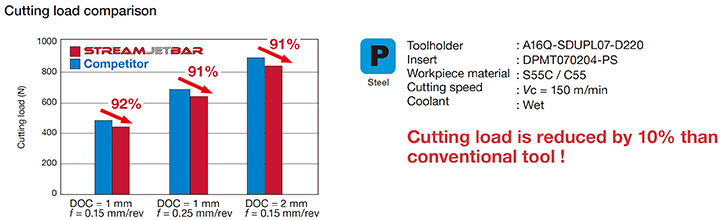

2. La conception optimale du support assure une faible charge de coupe et des performances élevées dans les plus petits diamètres d’alésage

3. Facile à utiliser

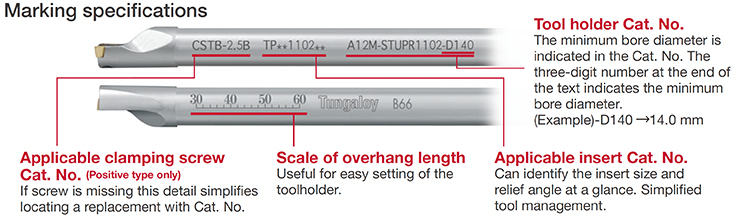

Spécifications de marquage

Plaquettes & Nuances

Plaquettes

Nuances principales

T9215

![]()

![]()

![]()

- P10 – P20

- Bel équilibre entre résistance à l’usure et à l’écaillage

- Premier choix pour les aciers

- Grande polyvalence pour une large gamme d’applications

T6130

![]()

- P15 – P30 / M15 – M30

- Haute résistance à l’usure lors de la coupe à vitesse moyenne à élevée

- Premier choix pour les aciers inoxydables

AH8015

![]()

![]()

![]()

![]()

![]()

- M01 – M20 / S10 – S20

- Bel équilibre entre résistance à l’usure et à la rupture

- Premier choix pour l’usinage d’alliages résistants à la chaleur dans des conditions de coupe générales

Porte-outils

Tournage interne

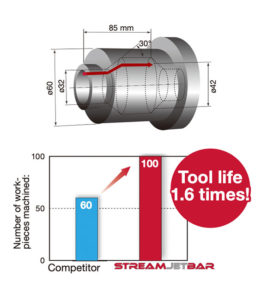

Porte-outils StreamJetBar

Porte-outil interne très rigide avec une excellente évacuation des copeaux

Exemples pratiques

Exemple #1

Ingénierie générale

| Partie: | Parties machine |

| Matériau: | S35C (C35) |

| Porte-outil: | E20S-SDUCR11-D270 |

| Plaquette: | DCMT11T304-PS |

| Nuance: | T9215 |

| Conditions de coupe: | Vc = 70 – 160 (m/min) f = 0.12 – 0.2 (mm/rev) ap = 1.0 (mm) Liquide de refroidissement : avec |

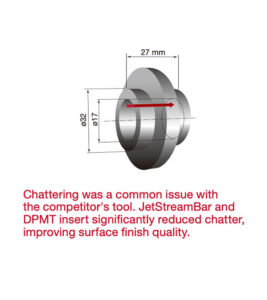

Exemple #2

Industrie automobile

| Partie: | Parties automobile |

| Matériau: | S45C (C45) |

| Porte-outil: | A12M-SDUPL07-D180-P |

| Plaquette: | DPMT070204-PS |

| Nuance: | T9215 |

| Conditions de coupe: | Vc = 130 (m/min) f = 0.1 (mm/rev) ap = 1.5 (mm) Liquide de refroidissement : avec |

Conditions de coupe standards

| ISO | Operation | Work condition | Chip-breaker | Grade | Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | ||

|---|---|---|---|---|---|---|---|---|---|

| Low carbon steels, Alloy steels |

Medium carbon steels, Alloy steels |

High carbon steels, Alloy steels |

|||||||

| Precision finishing |

Continuous | 01 | NS9530 | 0.05 – 0.5 | 0.03 – 0.15 | 150 – 250 | 80 – 220 | 80 – 180 | |

| Light interrupted | 01 | NS9530 | 0.05 – 0.5 | 0.03 – 0.15 | 150 – 250 | 80 – 220 | 80 – 180 | ||

| Finishing | Continuous | PSS | NS9530 | 0.1 – 0.5 | 0.05 – 0.3 | 150 – 250 | 80 – 220 | 80 – 180 | |

| Light interrupted | PSS | NS9530 | 0.1 – 0.5 | 0.05 – 0.3 | 150 – 250 | 80 – 220 | 80 – 180 | ||

| Heavy interrupted | PSS | NS9530 | 0.1 – 0.5 | 0.05 – 0.3 | 150 – 250 | 80 – 220 | 80 – 180 | ||

| Finishing to light cutting |

Continuous | PS | NS9530 | 0.3 – 2.0 | 0.08 – 0.3 | 150 – 250 | 80 – 220 | 80 – 180 | |

| Light interrupted | PS | NS9530 | 0.3 – 2.0 | 0.08 – 0.3 | 150 – 250 | 80 – 220 | 80 – 180 | ||

| Heavy interrupted | PS | NS9530 | 0.3 – 2.0 | 0.08 – 0.3 | 150 – 250 | 80 – 220 | 80 – 180 | ||

| Finishing to Medium cutting |

Continuous to Heavy interrupted |

PS | T9215 | 0.5 – 2.5 | 0.08 – 0.3 | 120 – 300 | 100 – 300 | 80 – 250 | |

| PS | T9125 | 0.5 – 2.5 | 0.08 – 0.3 | 120 – 250 | 80 – 180 | 80 – 120 | |||

| Medium cutting | Continuous to Heavy interrupted |

PM | T9215 | 1.0 – 3.0 | 0.15 – 0.3 | 120 – 300 | 100 – 300 | 80 – 250 | |

| PM | T9125 | 1.0 – 3.0 | 0.15 – 0.3 | 120 – 250 | 80 – 180 | 80 – 120 | |||

Low carbon steels, Alloy steels: S10C, SCM415, SS400, SCr420H, etc. C10, 18CrMo4, E275A, 20Cr4, etc. Medium carbon steels, Alloy steels: S45C, SCM440, etc. C45, 42CrMo4, etc. Hi carbon steels, Alloy steels: SNCM439, etc. 41CrNiMo2, etc.

| ISO | Operation | Work condition | Chip-breaker | Grade | Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) |

|---|---|---|---|---|---|---|---|

| Precision finishing | Continuous | Whh | GH330 | 0.05 – 2.0 | 0.03 – 0.2 | 100 – 150 | |

| Finishing | Continuous | PSF | AH725 | 0.1 – 0.5 | 0.05 – 0.3 | 50 – 150 | |

| Light interrupted | PSF | AH725 | 0.1 – 0.5 | 0.05 – 0.3 | 50 – 150 | ||

| Heavy interrupted | PSF | AH725 | 0.1 – 0.5 | 0.05 – 0.3 | 50 – 120 | ||

| Finishing to light cutting |

Continuous | PSS | AH630 | 0.3 – 2.0 | 0.08 – 0.3 | 90 – 190 | |

| Light interrupted | PSS | AH630 | 0.3 – 2.0 | 0.08 – 0.3 | 90 – 190 | ||

| Heavy interrupted | PSS | AH630 | 0.3 – 2.0 | 0.08 – 0.3 | 90 – 190 | ||

| Finishing to medium cutting |

Continuous | PS | T6130 | 0.5 – 2.5 | 0.08 – 0.3 | 100 – 200 | |

| Light interrupted | PS | AH630 | 0.5 – 2.5 | 0.08 – 0.3 | 90 – 190 | ||

| Heavy interrupted | PS | AH630 | 0.5 – 2.5 | 0.08 – 0.3 | 90 – 190 | ||

| Medium cutting | Continuous | PM | T6130 | 1.0 – 3.0* | 0.15 – 0.3 | 90 – 190 | |

| Light interrupted | PM | AH630 | 1.0 – 3.0* | 0.15 – 0.3 | 90 – 190 | ||

| Heavy interrupted | PM | AH630 | 1.0 – 3.0* | 0.15 – 0.3 | 90 – 190 |

* For CCMT0602 and DCMT0702 type inserts, a p = 0.5 – 2.5

Stainless steels: SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc.

| ISO | Operation | Work condition | Chip-breaker | Grade | Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | |

|---|---|---|---|---|---|---|---|---|

| Grey cast irons | Ductile cast irons | |||||||

| Finishing | Continuous | CM | T515 | 0.05 – 2.0 | 0.05 – 0.3 | 150 – 700 | 150 – 300 | |

| Heavy interrupted | CM | T515 | 0.05 – 2.0 | 0.05 – 0.3 | 100 – 200 | 100 – 200 | ||

| Medium cutting | Light interrupted | CM | T515 | 0.05 – 2.0 | 0.05 – 0.3 | 100 – 300 | 100 – 250 | |

Grey cast irons: FC250, etc. 250, etc.

Ductile cast irons: FCD450, etc. 450-10S, etc.

| ISO | Operation | Work condition | Chip-breaker | Grade | Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | |

|---|---|---|---|---|---|---|---|---|

| Titanium alloys | Ni-base alloys | |||||||

| Finishing | Continuous | PSS | AH8015 | 0.3 – 2.0 | 0.02 – 0.3 | 20 – 150 | 20 – 100 | |

| Light interrupted | PSS | AH8015 | 0.3 – 2.0 | 0.02 – 0.3 | 20 – 150 | 20 – 100 | ||

| Finishing to medium cutting |

Continuous | PS | AH8015 | 0.5 – 2.5 | 0.02 – 0.3 | 20 – 150 | 20 – 100 | |

| Light interrupted | PS | AH8015 | 0.5 – 2.5 | 0.02 – 0.3 | 20 – 150 | 20 – 100 | ||

Ni-base alloys: INCONEL718 etc.

Titanium alloys: Ti – 6Al – 4V etc.

RETOUR