Iwaki, Japon – Janvier 2026 – Tungaloy Corporation (Président : Satoshi Kinoshita, Siège : Iwaki, Préfecture de Fukushima) annonce l’extension de sa gamme d’unités de serrage pour tours CNC dans son système d’outillage compatible PSC, la série “TungCap”, avec le lancement de 75 références destinées aux applications avec outils fixes et tournants.

Enjeux et tendances

Dans des secteurs exigeant une haute précision et une grande efficacité d’usinage – de la mécanique générale à la fabrication de pièces automobiles et de composants de moteurs d’avion – l’amélioration de la productivité et l’optimisation de l’utilisation des machines sont des priorités. La réduction des temps d’arrêt liés aux changements d’outils et de réglages reste un défi commun. De plus, lors de l’introduction de nouveaux équipements ou de systèmes à changement rapide, la compatibilité avec les lignes existantes et une mise en service fluide sont essentielles. Dans ce contexte, le marché recherche activement des solutions combinant des systèmes de serrage fiables à une grande flexibilité d’utilisation.

Aperçu du produit

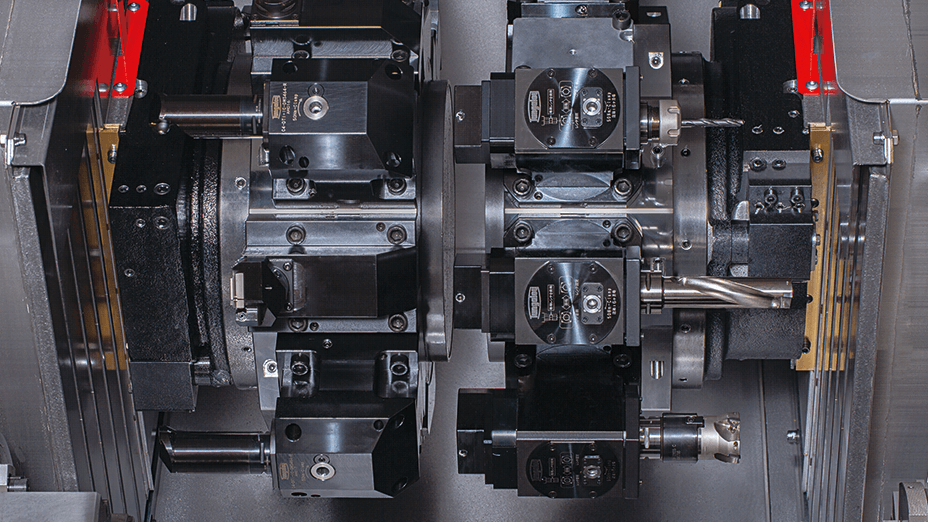

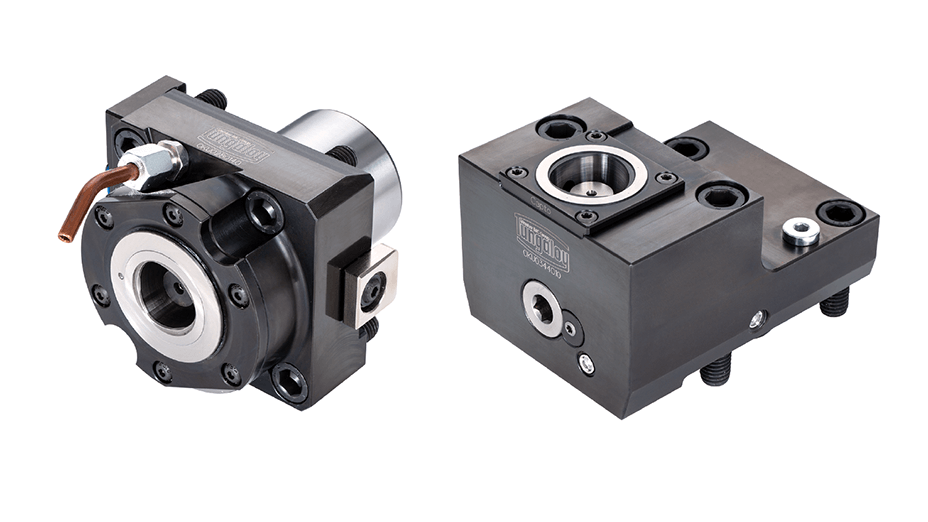

Le système d’outillage “TungCap”, compatible PSC, adopte une interface polygonale haute rigidité garantissant une précision de positionnement très élevée lors des changements d’outils. Cela élimine le besoin de coupe d’essai après remplacement de plaquette, comme c’est le cas avec les pratiques traditionnelles, réduisant ainsi considérablement les temps d’arrêt machine. De plus, un système d’arrosage interne fournit de manière fiable le liquide de refroidissement jusqu’à l’arête de coupe, permettant un usinage à haut rendement. Grâce à cette extension majeure, les porte-plaquettes et outils TungCap peuvent désormais être utilisés sur des machines équipées de tourelles traditionnelles.

Avantages et caractéristiques

Caractéristique 1 : Large compatibilité avec de nombreux types de machines

– Compatible avec les tours CNC de 31 fabricants nationaux et internationaux, permettant une installation sur une grande variété de machines.

– 559 références disponibles en version standard, offrant une grande liberté dans le choix des machines.

– Rétrofit facile sur les équipements existants, vérification de compatibilité simplifiée pour les nouvelles machines, réduisant les coûts d’intégration du système TungCap.

Caractéristique 2 : Conception adaptée aux outils fixes et tournants

– Extension de la gamme pour outils fixes et outils tournants, couvrant un large éventail d’opérations d’usinage.

– Rationalise les changements d’outils et les réglages, améliorant la productivité en atelier.

– Le mécanisme de serrage haute précision équilibre rigidité de l’outil et précision d’usinage.

Caractéristique 3 : Efficacité opérationnelle grâce à la compatibilité et à la standardisation

– La normalisation via l’interface PSC assure une compatibilité entre les outils.

– Le design standardisé simplifie la maintenance et la gestion des outils.

– Une large gamme répond avec flexibilité aux besoins variés des utilisateurs.