Schulterfräser mit kosteneffizienten Wendeschneidplatten und hervorragender Stabilität gegen Rattern

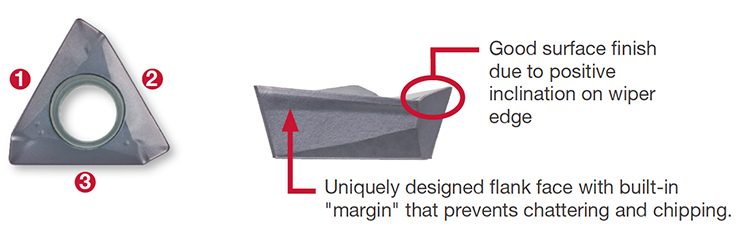

Wirtschaftliche 3-Schneiden-Wendeplatte reduziert mit großem Spanwinkel an der Schneidkante die Schnittkraft und sorgt für eine hervorragende Spanbildung

Optimierte Freifläche an der Wendeschneidplatte und differentielle Teilung am Fräser verhindern Rattern bei der Bearbeitung

Anwendungen & Eigenschaften

Anwendungen

Eigenschaften

1. Wendeschneidplatten mit 3 Schneiden

2. Deutlich reduzierte Schnittkraft

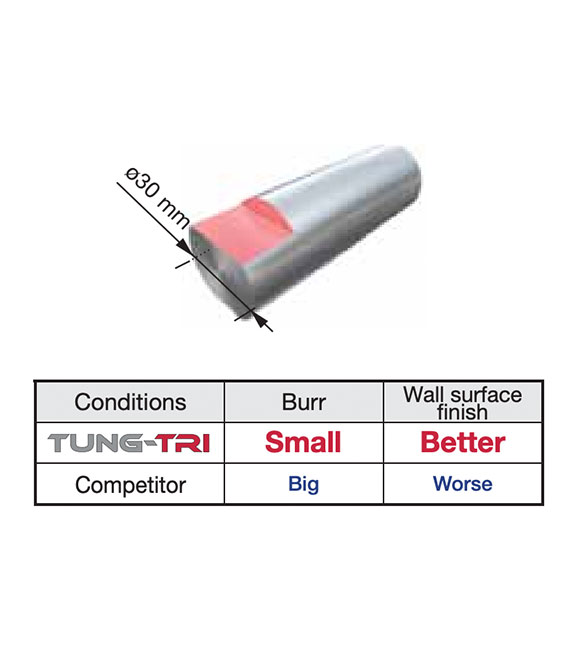

3. Ausgezeichnete Wandgenauigkeit

– Hohe Wandgenauigkeit durch schraubenförmige Schneidkante

Inserts & Grades

Wendeschneidplatten

TO*T

- Maximale Schnitttiefe

- – TO*T04: 3.5 mm

- – TO*T06: 6 mm

- – TO*T10: 10 mm

– TO*T15: 15 mm - Wirtschaftliche Wendeschneidplatten mit 3 Schneiden und geringen Schneidkräften

Haupt-Sorten

AH3135

![]()

![]()

- Hohe Bruchsicherheit

- Geeignet für die Bearbeitung von Stahl und rostfreiem Stahl unter allgemeinen Schnittbedingungen

AH3225

![]()

![]()

- Gutes Gleichgewicht zwischen Verschleiß- und Bruchfestigkeit

- Geeignet für Stahl und rostfreien Stahl

AH8015

![]()

![]()

![]()

![]()

![]()

- Gutes Gleichgewicht zwischen Verschleiß- und Bruchfestigkeit

- Erste Wahl für die Bearbeitung hitzebeständiger Legierungen unter allgemeinen Schnittbedingungen

Fräs-Körper

Praxis-Beispiele

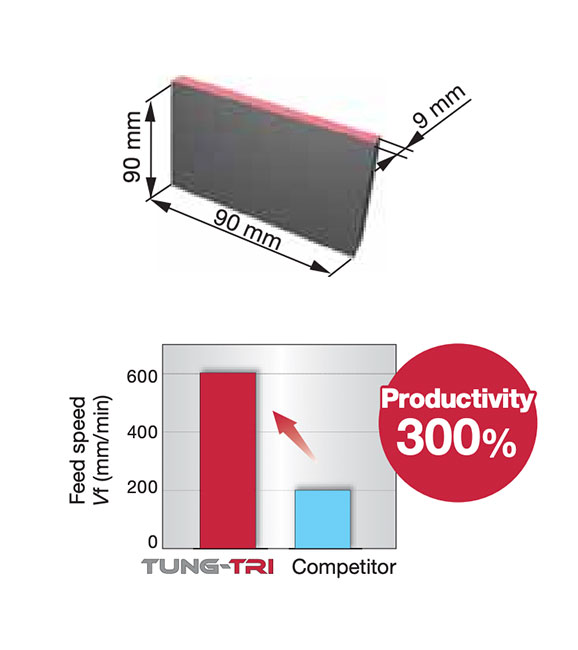

Beispiel 1

Allgemeiner Maschinenbau

| Werkstück: | Platte |

| Material: | SUS304 / X5CrNi18-9 |

| Fräser: | EPA06R020M20.0-03N (ø20 mm, z = 3) |

| Wendeschneidplatte: | TOMT060304PDER-MJ |

| Sorte: | AH3135 |

| Schnittbedingungen: | Vc = 125 (m/min) fz = 0.083 (mm/Z) Vf = 600 (mm/min) ap = 1.5 (mm) ae = 9 (mm) Anwendung: Planfräsen Kühlmittel: Trocken Maschine: BT40 |

Beispiel 2

Allgemeiner Maschinenbau

| Werkstück: | Maschinenteil |

| Material: | S45C / C45 |

| Fräser: | EPA10R032M32.0-03N (ø32 mm, z = 3) |

| Wendeschneidplatte: | TOMT100404PDER-MJ |

| Sorte: | AH3135 |

| Schnittbedingungen: | Vc = 150 (m/min) fz = 0.19 (mm/Z) Vf = 836 (mm/min) ap = 1 (mm) ae = 5 (mm) Anwendung: Schulterfräsen Kühlmittel: Nass (externe Zufuhr) Maschine: Turn-Mill center |

Beispiel 3

Allgemeiner Maschinenbau

| Werkstück: | Grundplatte |

| Material: | S50C / C50 |

| Fräser: | EPA10R032M32.0-03N (ø32 mm, z = 3) |

| Wendeschneidplatte: | TOMT100404PDER-MJ |

| Sorte: | AH3135 |

| Schnittbedingungen: | Vc = 130 (m/min) fz = 0.1 (mm/Z) Vf = 390 (mm/min) ap = 1.5 (mm) ae = 25 (mm) Anwendung: Schulterfräsen Kühlmittel: Externe Luft Maschine: Vertical M/C |

Standard-Schnittbedingungen

EPA04

| ISO | Werkstoffe des Werkstücks | Härte | Sorte | Schnittgeschw. Vc (m/min) |

Zahnvorschub fz (mm/Z) |

|

|---|---|---|---|---|---|---|

|

Stahl mit niedrigem Kohlenstoffgehalt SS400, S15C, usw. E275A, C15E4, usw. |

– 200 HB | AH3225 | 100 – 250 | 0.05 – 0.12 | |

| Kohlenstoffstahl und legierter Stahl S55C, SCM440, usw. C55, 42CrMo4, usw. |

– 300 HB | AH3225 | 100 – 230 | 0.05 – 0.12 | ||

| Vorgehärteter Stahl NAK80, PX5, usw. |

30 – 40 HRC | AH3225 | 100 – 180 | 0.05 – 0.1 | ||

|

Rostfreier Stahl SUS304, usw. X5CrNi18-9, usw. |

– | AH3225 | 90 – 200 | 0.05 – 0.1 | |

|

Grauguss FC250, etc. 250, usw., GG25, usw. |

150 – 250 HB | AH120 | 100 – 300 | 0.05 – 0.12 | |

| Kugelgraphitguss FCD450, etc. 450-10S, etc., GGG45, etc. |

150 – 250 HB | AH120 | 100 – 200 | 0.05 – 0.12 | ||

|

Titan-Legierungen Ti-6AI-4V, usw. |

– | AH3225 | 20 – 60 | 0.04 – 0.07 | |

| Hitzebeständige Legierungen Inconel 718, usw. |

– | AH8015 | 20 – 40 | 0.04 – 0.07 | ||

|

Gehärteter Stahl | SKD61, etc. X40CrMoV5-1, etc. |

40 – 50 HRC | AH8015 | 50 – 150 | 0.04 – 0.07 |

| SKD11, etc. X153CrMoV12, etc. |

50 – 60 HRC | AH8015 | 40 – 70 | 0.04 – 0.07 | ||

- Entfernen Sie übermäßige Spanansammlungen mit einem Luftstrahl.

- Bei einer Bearbeitung mit variabler Schnitttiefe (z. B. Gusshaut) oder bei der Bearbeitung von Werkstoffen mit unterbrochener Oberfläche sollte der Vorschub pro Zahn (fz) auf den niedrigeren empfohlenen Wert aus der obigen Tabelle eingestellt werden.

- Die Schnittbedingungen können je nach Maschinenleistung, Werkstücksteifigkeit und Spindelleistung eingeschränkt sein. Wenn die Schnittbreite, -tiefe oder -auskraglänge groß ist, stellen Sie Vc und fz auf die niedrigeren empfohlenen Werte ein und überprüfen Sie die Maschinenleistung und Vibrationen.

T/E/HPA06, T/E/HPA10, T/EPA15

| ISO | Werkstoffe des Werkstücks | Härte | Priorität | Spanbrecher | Sorte | T/E/HPA06 | T/E/HPA10 | T/EPA15 | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Schnittgeschw. Vc (m/min) |

Zahnvorschub fz (mm/Z) |

Schnittgeschw. Vc (m/min) |

Zahnvorschub fz (mm/Z) |

Schnittgeschw. Vc (m/min) |

Zahnvorschub fz (mm/Z) |

|||||||

| MJ/AJ | NMJ | |||||||||||

|

Stahl mit niedrigem Kohlenstoffgehalt SS400, S15C, usw. E275A, C15E4, etc. |

– 200 HB | Erste Wahl | MJ/NMJ | AH3225 | 100 – 220 | 0.05 – 0.15 | 100 – 250 | 0.08 – 0.2 | 100 – 300 | 0.06 – 0.22 | 0.06 – 0.15 |

| Verschleißfestigkeit | MJ/NMJ | T3225 | 100 – 250 | 0.08 – 0.1 | 100 – 300 | 0.08 – 0.12 | 100 – 300 | 0.08 – 0.15 | 0.08 – 0.15 | |||

| Kohlenstoffstahl und legierter Stahl S55C, SCM440, usw. C55, 42CrMo4, usw. |

– 300 HB | Erste Wahl | MJ/NMJ | AH3225 | 100 – 170 | 0.05 – 0.12 | 100 – 250 | 0.06 – 0.22 | 100 – 250 | 0.06 – 0.22 | 0.06 – 0.15 | |

| Verschleißfestigkeit | MJ/NMJ | T3225 | 100 – 250 | 0.05 – 0.1 | 100 – 300 | 0.05 – 0.12 | 100 – 300 | 0.05 – 0.15 | 0.05 – 0.15 | |||

| Vorvergüteter Stahl und Werkzeugstahl NAK80, PX5, SKD61, usw. X40CrMoV5-1, usw. |

30 – 40 HRC | Erste Wahl | MJ/NMJ | AH3225 | 100 – 120 | 0.05 – 0.12 | 100 – 200 | 0.06 – 0.22 | 100 – 200 | 0.06 – 0.22 | 0.06 – 0.15 | |

| Verschleißfestigkeit | MJ/NMJ | T3225 | 100 – 250 | 0.05 – 0.1 | 100 – 300 | 0.05 – 0.12 | 100 – 300 | 0.05 – 0.15 | 0.05 – 0.15 | |||

|

Rostfreier Stahl SUS304, usw. X5CrNi18-9, usw. |

– | Erste Wahl | MJ/NMJ | AH3135 | 80 – 150 | 0.05 – 0.15 | 80 – 200 | 0.08 – 0.2 | 90 – 200 | 0.08 – 0.2 | 0.08 – 0.15 |

| Verschleißfestigkeit | MJ/NMJ | T3225 | 90 – 200 | 0.05 – 0.1 | 90 – 250 | 0.05 – 0.12 | 90 – 250 | 0.05 – 0.15 | 0.05 – 0.15 | |||

|

Grauguss FC250, etc. 250, usw. GG25, usw. |

150 – 250 HB | Erste Wahl | MJ/NMJ | AH120 | 100 – 200 | 0.05 – 0.15 | 100 – 250 | 0.05 – 0.15 | 140 – 250 | 0.08 – 0.25 | 0.08 – 0.15 |

| Verschleißfestigkeit | MJ | T1215 | 150 – 250 | 0.05 – 0.12 | 150 – 300 | 0.08 – 0.2 | 200 – 300 | 0.08 – 0.18 | – | |||

| Kugelgraphitguss FCD450, etc. 450-10S, etc. GGG45, etc. |

150 – 250 HB | Erste Wahl | MJ/NMJ | AH120 | 80 – 150 | 0.05 – 0.15 | 80 – 200 | 0.08 – 0.2 | 110 – 200 | 0.08 – 0.25 | 0.08 – 0.15 | |

| Verschleißfestigkeit | MJ | T1215 | 100 – 200 | 0.05 – 0.12 | 130 – 250 | 0.05 – 0.15 | 150 – 250 | 0.08 – 0.18 | – | |||

|

Aluminium Si < 13% |

– | Erste Wahl | AJ | KS05F | 300 – 900 | 0.08 – 0.22 | 300 – 1000 | 0.08 – 0.22 | 300 – 1000 | 0.08 – 0.22 | – |

| Aluminium Si ≥ 13% |

– | Erste Wahl | AJ | KS05F | 100 – 200 | 0.08 – 0.22 | 100 – 200 | 0.08 – 0.22 | 100 – 200 | 0.08 – 0.22 | – | |

|

Titan-Legierungen Ti-6Al-4V, etc. |

– | Erste Wahl | MJ/NMJ | AH3135 | 20 – 50 | 0.05 – 0.1 | 20 – 60 | 0.05 – 0.1 | 20 – 60 | 0.08 – 0.15 | 0.08 – 0.15 |

| Hitzebeständige Legierungen Inconel 718, usw. |

– | Erste Wahl | MJ/NMJ | AH120 | 20 – 35 | 0.03 – 0.08 | 20 – 40 | 0.05 – 0.13 | 20 – 40 | 0.07 – 0.15 | 0.07 – 0.15 | |

- Wenn Sie den NMJ-Spanbrecher verwenden, stellen Sie bitte den Vorschub auf weniger als 0,15 mm/t ein.

- Entfernen Sie übermäßige Spanansammlungen mit einem Luftstrahl.

- Bei einer Bearbeitung mit schwankender Schnitttiefe (z.B. Gusshaut) oder bei der Bearbeitung von Werkstoffen mit unterbrochener Oberfläche sollte der Vorschub pro Zahn (fz) auf den niedrigeren empfohlenen Wert aus der obigen Tabelle eingestellt werden.

- Die Schnittbedingungen können je nach Maschinenleistung, Werkstücksteifigkeit und Spindelleistung eingeschränkt sein. Wenn die Schnittbreite, -tiefe oder -auskraglänge groß ist, stellen Sie Vc und fz auf die niedrigeren empfohlenen Werte ein und überprüfen Sie die Maschinenleistung und Vibrationen.

TLA (Typ Schruppen)

| ISO | Werkstoffe des Werkstücks | Härte | Priorität | Spanbrecher | Sorte | TLA10 | TLA15 | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Schnittgeschw. Vc (m/min) |

Zahnvorschub fz (mm/Z) |

Schnittgeschw. Vc (m/min) |

Zahnvorschub fz (mm/Z) |

|||||||

| MJ/AJ | NMJ | |||||||||

|

Stahl mit niedrigem Kohlenstoffgehalt SS400, S15C, usw. E275A, C15E4, usw. |

– 200 HB | Erste Wahl | MJ/NMJ | AH3225 | 100 – 250 | 0.08 – 0.2 | 100 – 300 | 0.06 – 0.22 | 0.06 – 0.15 |

| Verschleißfestigkeit | MJ/NMJ | T3225 | 100 – 300 | 0.08 – 0.12 | 100 – 300 | 0.08 – 0.15 | 0.08 – 0.15 | |||

| Kohlenstoffstahl und legierter Stahl S55C, SCM440, usw. C55, 42CrMo4, usw. |

– 300 HB | Erste Wahl | MJ/NMJ | AH3225 | 100 – 250 | 0.06 – 0.22 | 100 – 250 | 0.06 – 0.22 | 0.06 – 0.15 | |

| Verschleißfestigkeit | MJ/NMJ | T3225 | 100 – 300 | 0.05 – 0.12 | 100 – 300 | 0.05 – 0.15 | 0.05 – 0.15 | |||

| Vorvergüteter Stahl und Werkzeugstahl NAK80, PX5, SKD61, usw. X40CrMoV5-1, usw. |

30 – 40 HRC | Erste Wahl | MJ/NMJ | AH3225 | 100 – 200 | 0.06 – 0.22 | 100 – 200 | 0.06 – 0.22 | 0.06 – 0.15 | |

| Verschleißfestigkeit | MJ/NMJ | T3225 | 100 – 300 | 0.05 – 0.12 | 100 – 300 | 0.05 – 0.15 | 0.05 – 0.15 | |||

|

Rostfreier Stahl SUS304, usw. X5CrNi18-9, usw. |

– | Erste Wahl | MJ/NMJ | AH3135 | 80 – 200 | 0.08 – 0.2 | 90 – 200 | 0.08 – 0.2 | 0.08 – 0.15 |

| Verschleißfestigkeit | MJ/NMJ | T3225 | 90 – 250 | 0.05 – 0.12 | 90 – 250 | 0.05 – 0.15 | 0.05 – 0.15 | |||

|

Grauguss FC250, etc. 250, usw. GG25, usw. |

150 – 250 HB | Erste Wahl | MJ/NMJ | AH120 | 100 – 250 | 0.05 – 0.15 | 140 – 250 | 0.08 – 0.25 | 0.08 – 0.15 |

| Verschleißfestigkeit | MJ | T1215 | 150 – 300 | 0.08 – 0.2 | 200 – 300 | 0.08 – 0.18 | – | |||

| Kugelgraphitguss FCD450, etc. 450-10S, etc. GGG45, etc. |

150 – 250 HB | Erste Wahl | MJ/NMJ | AH120 | 80 – 200 | 0.08 – 0.2 | 110 – 200 | 0.08 – 0.25 | 0.08 – 0.15 | |

| Verschleißfestigkeit | MJ | T1215 | 130 – 250 | 0.05 – 0.15 | 150 – 250 | 0.08 – 0.18 | – | |||

|

Aluminium Si < 13% |

40 – 50 HRC | Erste Wahl | AJ | KS05F | 300 – 1000 | 0.08 – 0.22 | 300 – 1000 | 0.08 – 0.22 | – |

| Aluminium Si ≥ 13% |

50 – 60 HRC | Erste Wahl | AJ | KS05F | 100 – 200 | 0.08 – 0.22 | 100 – 200 | 0.08 – 0.22 | – | |

|

Titan-Legierungen Ti-6Al-4V, usw. |

– | Erste Wahl | MJ/NMJ | AH3135 | 20 – 60 | 0.05 – 0.1 | 20 – 60 | 0.08 – 0.15 | 0.08 – 0.15 |

| Hitzebeständige Legierungen Inconel 718, usw. |

– | Erste Wahl | MJ/NMJ | AH120 | 20 – 40 | 0.05 – 0.13 | 20 – 40 | 0.07 – 0.15 | 0.07 – 0.15 | |

- Bei Verwendung des NMJ-Spanbrechers sollte der Vorschub nicht mehr als 0,15 mm/t betragen.

Weitere Informationen zu diesem Produkt finden Sie in unserem Online-Katalog oder im Produktbericht, den Sie herunterladen können: