Wechselkopf-Tieflochbohrer mit außergewöhnlicher Effizienz

DeepTri-Drill, die einfach zu handhabende, Wechselkopf-Bohrer Serie, bietet hervorragende Leistung, außergewöhnliche Effizienz und Stabilität beim Tieflochbohren

Anwendungen & Eigenschaften

Anwendungen

Eigenschaften

1. Große Auswahl an Optionen für verschiedene Tiefbohranwendungen

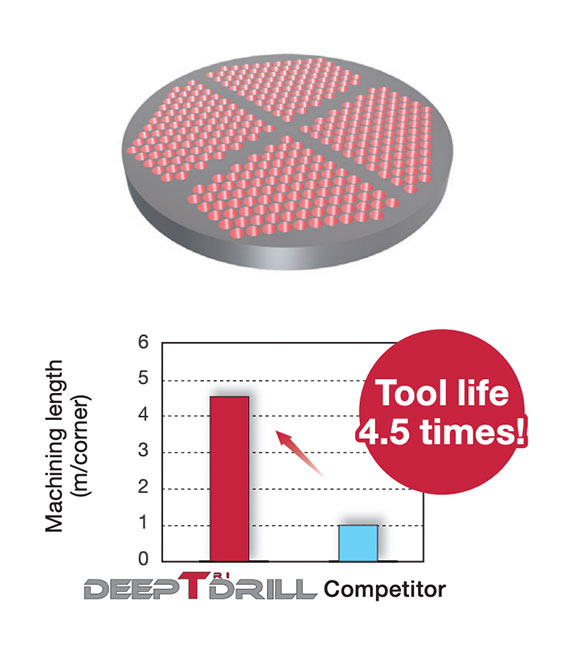

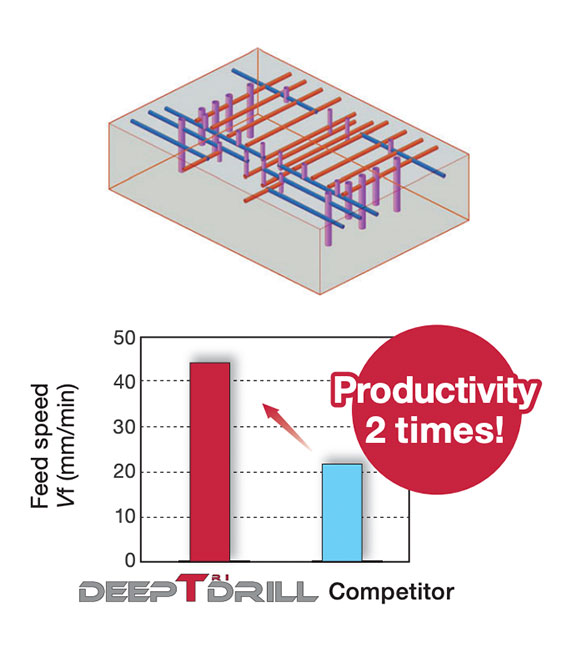

2. Höchste Effizienz

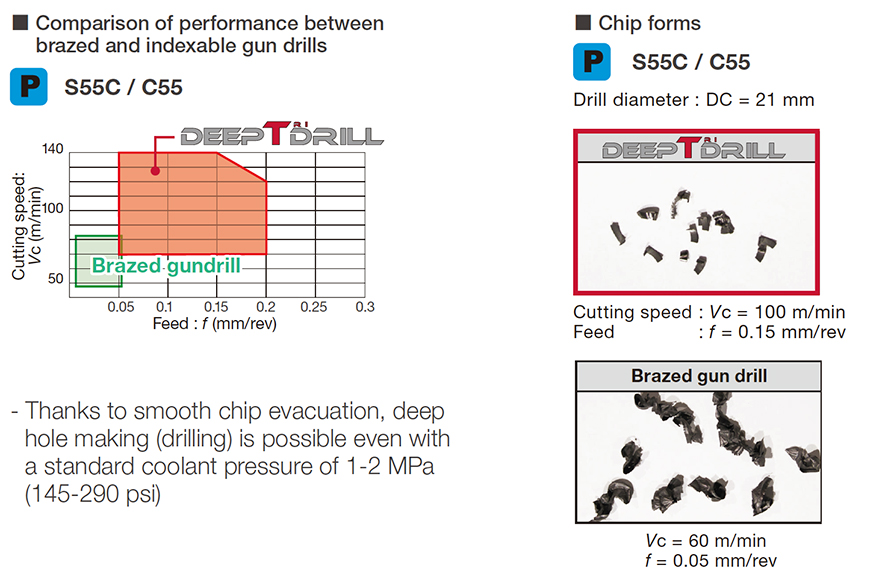

- Einzigartiger Spanbrecher und Spänesplitter an der Schneide ermöglichen eine beeindruckende Spankontrolle bei jedem Vorschub, insbesondere bei höheren Vorschüben

- Dank der reibungslosen Spanabfuhr ist Tiefbohren auch bei einem Standard-Kühlmitteldruck von 1-2 MPa (145-290 psi) möglich

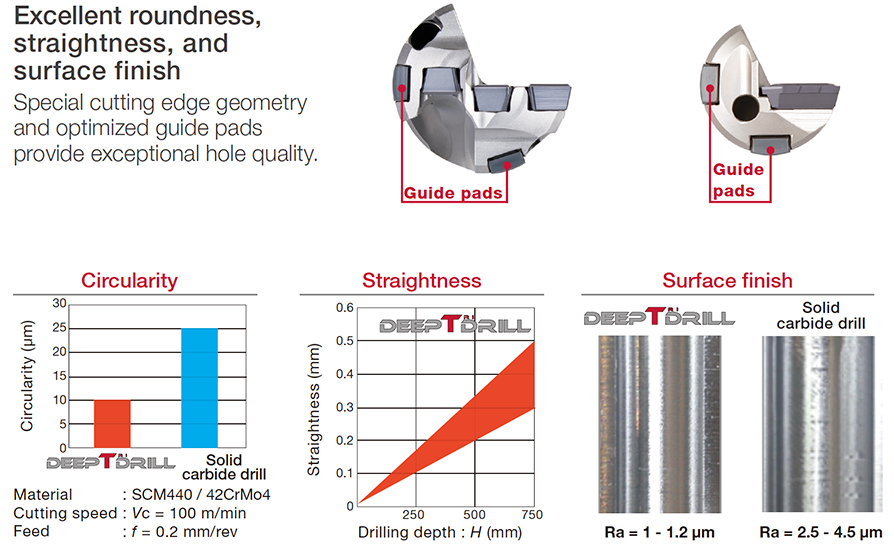

3. Ausgezeichnete Rundheit, Geradheit und Oberflächengüte

– Eine spezielle Schneidengeometrie und optimierte Führungsleisten sorgen für eine außergewöhnliche Lochqualität.

Wendeschneidplatten & Sorten

Wendeschneidplatten

TOHT-NDJ/NDL

- Wendeschneidplatte mit 3 Schneiden mit Spanbrecher

LOGT-NDJ

- Wendeschneidplatte mit 2 Schneiden mit Spanbrecher

ZSGT-NDJ

- Einseitige Wendeschneidplatte mit Spanbrecher

FBM/FBH

- Optimiertes Spanbrecherdesign für Tieflochbohren

Führungsplatte

Haupt-Sorten

AH9130

![]()

![]()

![]()

![]()

- P15 – P35 / M25 – M35 / K10 – K25 / S15 – S30

- Hohe Verschleißfestigkeit

- Entwickelt für das Bohren verschiedener Materialien

AH725

![]()

![]()

![]()

![]()

- P15 – P30 / M15 – M30 / K25 – K30 / S15 – S25

- Gutes Gleichgewicht zwischen Verschleiß- und Zerspanungsfestigkeit

- Geeignet für die Bearbeitung von Stahl und rostfreiem Stahl unter allgemeinen Schnittbedingungen

FH3125 (Für Führungsplatten)

- Erste Empfehlung

- Hohe Standzeit durch einzigartiges Substrat und Beschichtung

FH3135 (Für Führungsplatten)

- Hohe Bruchsicherheit

- Erste Wahl bei Verwendung wasserlöslicher Kühlmittel

Bohr-Körper

Allgemeines Bohren

MCTR (ø8 – ø40 mm)

– Für Drehmaschinen und Bearbeitungszentren

• L/D = 8 – 45

Praxis-Beispiele

Beispiel 1

Wärmetauscher-Industrie

| Werkstück: | Rohrbogen |

| Material: | SUS304 / X5CrNi18-9 |

| Bohrer: | MCTR20.00XM32-10 |

| Wendeschneidplatte: | TOHT090305R-NDL |

| Sorte: | AH725 |

| Schnittbedingungen: | Vc = 80 (m/min) f = 0.04 (mm/U) Vf = 53 (mm/min) H = 200 (mm) Kühlmittel: Nass Maschine: Horizontal M/C |

Beispiel 2

Werkzeug- und Formenbau

| Werkstück: | Plastikform |

| Material: | SKD61 / X40CrMoV5-1 (45 HRC) |

| Bohrer: | TRLGCH18.00X1500-36A |

| Wendeschneidplatte: | TOHT080305R-NDJ |

| Sorte: | AH725 |

| Schnittbedingungen: | Vc = 62 (m/min) f = 0.04 (mm/U) Vf = 44 (mm/min) H = 700 (mm) Kühlmittel: Nass Maschine: Horizontal M/C |

Beispiel 3

Automobilindustrie

| Werkstück: | Welle |

| Material: | SCM420H |

| Bohrer: | MCTR12.00XM20-20 |

| Wendeschneidplatte: | LOGT060204R-NDJ |

| Sorte: | AH725 |

| Schnittbedingungen: | Vc = 150 (m/min) f = 0.13 (mm/U) Vf = 517 (mm/min) øDc = 12 (mm) H = 233 (mm) Kühlmittel: Nass Maschine: Vertical M/C |

Standard-Schnittbedingungen

Bohrer-Ø : DC = ø7.94 – ø9.99 mm

| ISO | Material des Werkstücks | Spanbrecher | Sorte | Schnittgeschw. Vc (m/min) |

Vorschub f (mm/U) |

|---|---|---|---|---|---|

| Stahl mit niedrigem Kohlenstoffgehalt (C < 0,3) SS400, SM490, S25C, etc. E275A, C25, etc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | |

| Kohlenstoffstahl (C > 0,3) S45C, S55C, etc. C45, C55, usw. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.14 | |

| Niedrig legierter Stahl (C < 0,3) SCM415, 18CrMo4, etc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | |

| Legierter Stahl (C > 0,3) SCM440, SCr420, 42CrMo4, 20Cr4, etc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.14 | |

| Rostfreier Stahl (austenitisch) SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, usw. |

NDJ | AH9130 | 60 – 80 | 0.05 – 0.08 | |

| Rostfreier Stahl (martensitisch, ferritisch) SUS430, SUS416, etc. X6Cr17, X12CrS13, usw. |

NDJ | AH9130 | 60 – 80 | 0.05 – 0.08 | |

| Rostfreier Stahl (Ausscheidungshärtung) SUS630, X5CrNiCuNb16-4, etc. |

NDJ | AH9130 | 60 – 80 | 0.05 – 0.08 | |

| Grauguss FC250, GG25, 250, etc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.2 | |

| Kugelgraphitguss FCD700, 700-2, etc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.2 | |

| Aluminium-Legierungen | NDJ | AH9130 | 60 – 100 | 0.05 – 0.18 | |

| Hitzebeständige Legierungen Inconel 718, usw. |

NDJ | AH9130 | 20 – 50 | 0.04 – 0.06 | |

| Titanlegierungen Ti-6Al-4V, usw. |

NDJ | AH9130 | 30 – 60 | 0.04 – 0.1 | |

| Gehärteter Stahl ≥ 40HRC |

NDJ | AH9130 | 20 – 50 | 0.04 – 0.06 |

*Empfehlungen für Kühlschmierstoffe beim Bohren von rostfreiem Stahl:

– Öl-Kühlschmierstoff hat Vorrang.

– Wasserlöslicher Kühlschmierstoff muss einen Ölanteil von mindestens 20 % enthalten.

Bohrer-Ø : DC = ø10 – ø28 mm

| ISO | Material des Werkstücks | Priorität | Span-

brecher |

Sorte | Schnittgeschw.

Vc (m/min) |

Vorschub :f (mm/U) | |||

|---|---|---|---|---|---|---|---|---|---|

| ø10 – ø11.8 | ø11.81 – ø13.99 | ø14 – ø18 | ø18.01 – ø28 | ||||||

| Stahl mit niedrigem Kohlenstoffgehalt (C < 0,3) SS400, SM490, S25C, etc. E275A, C25, usw. |

Niedriger Vorschub | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.1 | 0.03 – 0.1 | |

| Erste Wahl | NDJ | AH9130 | 80 – 140 | 0.05 – 0.08 | 0.05 – 0.1 | 0.06 – 0.12 | 0.08 – 0.16 | ||

| Kohlenstoffstahl (C > 0,3) S45C, S55C, etc. C45, C55, usw. |

Niedriger Vorschub | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.1 | 0.03 – 0.12 | |

| Erste Wahl | NDJ | AH9130 | 80 – 140 | 0.05 – 0.14 | 0.05 – 0.16 | 0.07 – 0.18 | 0.08 – 0.2 | ||

| Niedrig legierter Stahl (C < 0,3) SCM415, 18CrMo4, etc. |

Niedriger Vorschub | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.12 | 0.08 – 0.1 | |

| Erste Wahl | NDJ | AH9130 | 80 – 140 | 0.05 – 0.08 | 0.05 – 0.1 | 0.06 – 0.12 | 0.08 – 0.16 | ||

| Legierter Stahl (C > 0,3) SCM440, SCr420, 42CrMo4, 20Cr4, etc. |

Niedriger Vorschub | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.1 | 0.03 – 0.12 | |

| Erste Wahl | NDJ | AH9130 | 80 – 120 | 0.05 – 0.14 | 0.05 – 0.16 | 0.07 – 0.18 | 0.08 – 0.2 | ||

| Rostfreier Stahl (austenitisch) SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, usw. |

Niedriger Vorschub | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.06 | 0.03 – 0.06 | |

| Erste Wahl | NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.05 – 0.12 | ||

| Rostfreier Stahl (martensitisch, ferritisch) SUS430, SUS416, etc. X6Cr17, X12CrS13, usw. |

Niedriger Vorschub | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.06 | 0.03 – 0.06 | |

| Erste Wahl | NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.05 – 0.12 | ||

| Rostfreier Stahl (Ausscheidungshärtung) SUS630, X5CrNiCuNb16-4, etc. |

Niedriger Vorschub | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.06 | 0.03 – 0.06 | |

| Erste Wahl | NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.05 – 0.12 | ||

| Grauguss FC250, GG25, 250, etc. |

Niedriger Vorschub | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.15 | 0.05 – 0.18 | |

| Erste Wahl | NDJ | AH9130 | 80 – 140 | 0.05 – 0.2 | 0.05 – 0.25 | 0.05 – 0.25 | 0.05 – 0.3 | ||

| Kugelgraphitguss FCD700, 700-2, etc. |

Niedriger Vorschub | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.15 | 0.05 – 0.18 | |

| Erste Wahl | NDJ | AH9130 | 80 – 140 | 0.05 – 0.2 | 0.05 – 0.25 | 0.05 – 0.25 | 0.05 – 0.3 | ||

| Aluminium-Legierungen | Niedriger Vorschub | NDL | AH725 | 80 – 160 | – | – | 0.03 – 0.15 | 0.03 – 0.15 | |

| Erste Wahl | NDJ | AH9130 | 100 – 200 | 0.05 – 0.18 | 0.05 – 0.2 | 0.08 – 0.22 | 0.1 – 0.25 | ||

| Hitzebeständige Legierungen Inconel 718, usw. |

Niedriger Vorschub | NDL | AH725 | 20 – 50 | – | – | 0.03 – 0.06 | 0.03 – 0.08 | |

| Erste Wahl | NDJ | AH9130 | 20 – 50 | 0.04 – 0.06 | 0.04 – 0.08 | 0.04 – 0.08 | 0.04 – 0.1 | ||

| Titanlegierungen Ti-6Al-4V, usw. |

Niedriger Vorschub | NDL | AH725 | 30 – 60 | – | – | 0.03 – 0.1 | 0.03 – 0.12 | |

| Erste Wahl | NDJ | AH9130 | 30 – 60 | 0.04 – 0.1 | 0.05 – 0.13 | 0.05 – 0.13 | 0.05 – 0.15 | ||

| Gehärteter Stahl ≥ 40HRC |

Niedriger Vorschub | NDL | AH725 | 40 – 100 | – | – | 0.03 – 0.08 | 0.03 – 0.08 | |

| Erste Wahl | NDJ | AH9130 | 50 – 100 | 0.04 – 0.06 | 0.04 – 0.08 | 0.04 – 0.08 | 0.04 – 0.1 | ||

Beim Querlochbohren unter niedrigen Vorschubbedingungen wird die Verwendung von NDL-Spänebrechern empfohlen.

*Empfehlungen für Kühlschmierstoffe beim Bohren von rostfreiem Stahl:

– Öl-Kühlschmierstoff hat Vorrang.

– Wasserlöslicher Kühlschmierstoff muss einen Ölanteil von mindestens 20 % enthalten.

Bohrer-Ø : DC = ø28.01 – ø40 mm

| ISO | Material des Werkstücks | Priorität | Zentrum | Mittel | Außen | Cutting speed Vc (m/min) |

Vorschub f (mm/U) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Span-

brecher |

Sorte | Span-

brecher |

Sorte | Span-

brecher |

Sorte | ø28.01 – ø40 | ||||

| Stahl mit niedrigem Kohlenstoffgehalt (C < 0,3) SS400, SM490, S25C, etc. E275A, C25, usw. |

Niedriger Vorschub | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| Erste Wahl | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.25 | ||

| Kohlenstoffstahl (C > 0,3) S45C, S55C, etc. C45, C55, usw. |

Niedriger Vorschub | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.12 | |

| Erste Wahl | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.3 | ||

| Niedrig legierter Stahl (C < 0,3) SCM415, 18CrMo4, etc. |

Niedriger Vorschub | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| Erste Wahl | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.25 | ||

| Legierter Stahl (C > 0,3) SCM440, SCr420, 42CrMo4, 20Cr4, etc. |

Niedriger Vorschub | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.12 | |

| Erste Wahl | G | AH725 | G | AH725 | G | AH725 | 80 – 120 | 0.1 – 0.3 | ||

| Rostfreier Stahl (austenitisch) SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, usw. |

Niedriger Vorschub | G | AH8015 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| Erste Wahl | G | AH8015 | G | AH8015 | G | AH8015 | 60 – 100 | 0.1 – 0.15 | ||

| Rostfreier Stahl (martensitisch, ferritisch) SUS430, SUS416, etc. X6Cr17, X12CrS13, usw. |

Niedriger Vorschub | G | AH8015 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| Erste Wahl | G | AH8015 | G | AH8015 | G | AH8015 | 60 – 100 | 0.1 – 0.15 | ||

| Rostfreier Stahl (Ausscheidungshärtung) SUS630, X5CrNiCuNb16-4, etc. |

Niedriger Vorschub | G | AH8015 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| Erste Wahl | G | AH8015 | G | AH8015 | G | AH8015 | 60 – 100 | 0.1 – 0.15 | ||

| Grauguss FC250, GG25, 250, etc. |

Niedriger Vorschub | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.14 | |

| Erste Wahl | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.35 | ||

| Kugelgraphitguss FCD700, 700-2, etc. |

Niedriger Vorschub | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.14 | |

| Erste Wahl | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.35 | ||

| Aluminium-Legierungen | Niedriger Vorschub | G | AH725 | DL | AH725 | G | AH725 | 80 – 160 | 0.03 – 0.2 | |

| Erste Wahl | G | AH725 | G | AH725 | G | AH725 | 100 – 200 | 0.1 – 0.3 | ||

| Hitzebeständige Legierungen Inconel 718, usw. |

Niedriger Vorschub | G | AH8015 | DL | AH725 | G | AH725 | 20 – 50 | 0.03 – 0.08 | |

| Erste Wahl | G | AH8015 | G | AH8015 | G | AH8015 | 20 – 50 | 0.06 – 0.13 | ||

| Titanlegierungen Ti-6Al-4V, usw. |

Niedriger Vorschub | G | AH725 | DL | AH725 | G | AH725 | 30 – 60 | 0.03 – 0.1 | |

| Erste Wahl | G | AH725 | G | AH725 | G | AH725 | 30 – 60 | 0.1 – 0.18 | ||

| Gehärteter Stahl ≥ 40HRC |

Niedriger Vorschub | G | AH8015 | DL | AH725 | G | AH725 | 40 – 100 | 0.03 – 0.1 | |

| Erste Wahl | G | AH8015 | G | AH8015 | G | AH8015 | 50 – 100 | 0.06 – 0.13 | ||

Beim Querlochbohren unter niedrigen Vorschubbedingungen wird die Verwendung von DL-Spänebrechern empfohlen.

*Empfehlungen für Kühlschmierstoffe beim Bohren von rostfreiem Stahl:

– Öl-Kühlschmierstoff hat Vorrang.

– Wasserlöslicher Kühlschmierstoff muss einen Ölanteil von mindestens 20 % enthalten.

Weitere Informationen zu diesem Produkt finden Sie in unserem Online-Katalog oder im Produktbericht, den Sie herunterladen können:

e-Catalog

- Haupt-Broschüre: PDF (deutsch)

Erweiterungen:

Führungsplatte