Iwaki, September 2021 — Tungaloy unveils AddForceCut deep grooving and parting-off tool system that maximizes tool stability.

Using a single-ended insert and secure insert self-clamping system, AddForceCut improves chip control and evacuation during deep grooving and parting off operations.

The use of a single-ended insert allows AddForceCut to groove deeper or cut off larger diameter barstock than double-ended inserts with no interference of the second cutting edge with the workpiece.

Insert stability is crucial for deep parting and grooving. Using a stable spring clamp, the insert seat is designed to hold the insert with maximum stability and reliability supporting the insert with three contact surfaces: one on the top and two on the bottom. In addition, the convexity located on the insert seat supports the insert bottom, transferring the increased cutting force into the robust section of the tool, while restraining unwanted insert movement during machining.

The silhouette of the holder’s top clamp is designed in continuation of the insert rake face profile so that the chips flow smoothly without obstruction away from the cutting point during deep grooving operations.

AddForceCut inserts are available in QGM and QGS geometries and for 2-5 mm (.079″-.197″) groove widths. QGM is a versatile geometry that provides good chip control across a wide range of material groups, while QGS has a sharp cutting edge that generates low cutting forces during grooving operations of stainless steel.

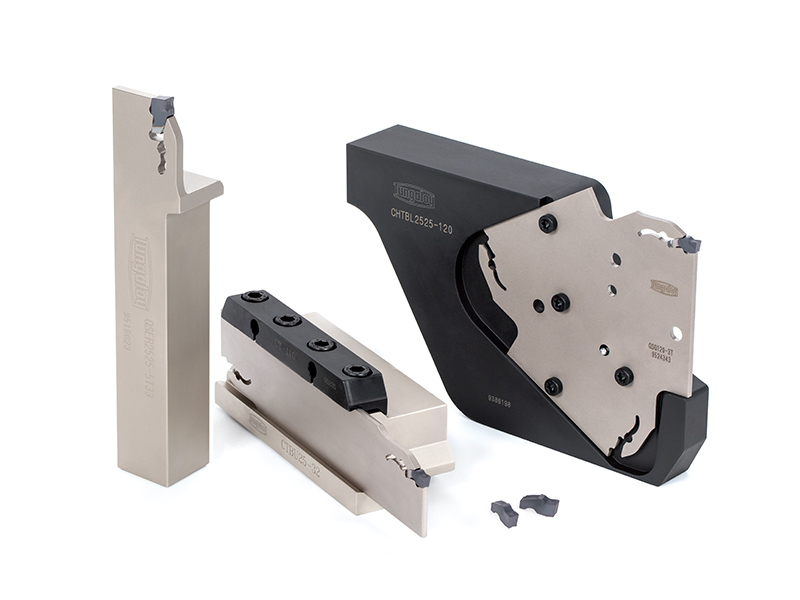

A variety of AddForceCut toolholders are available including traditional monoblock style holders for general applications, modular blades for deep grooving and parting-off applications, and vibration-free BoreMeister cutting heads for stable ID grooving of deep holes. Additionally, Tungaloy’s latest innovation TungFeed-Blade parting-off tool system offers a unique triangular modular blade for use with single-ended AddForceCut inserts. With the new robust TungFeed-Blade, AddForceCut can now boost productivity with process security, enabling cut off of barstock up to 120 mm (4.72”) diameter.