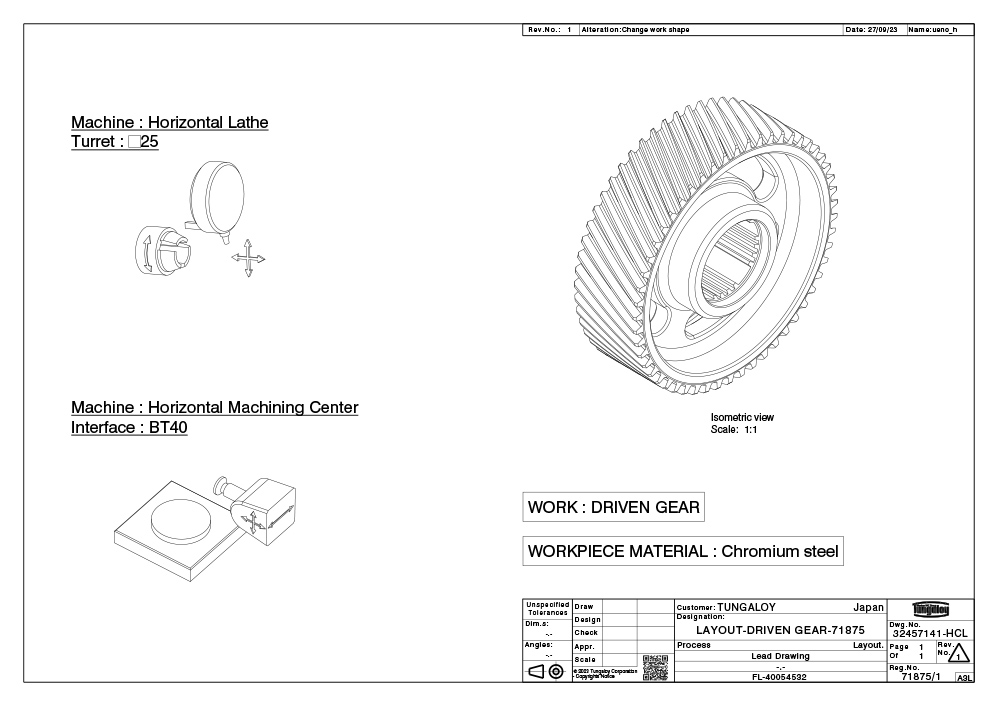

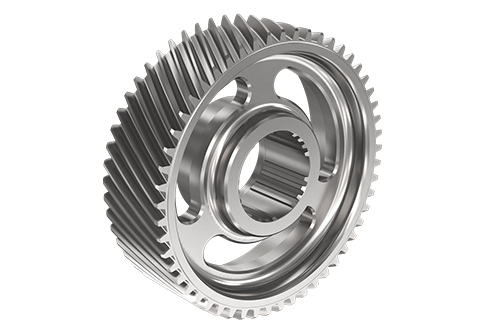

Automotive – Angetriebenes Zahnrad

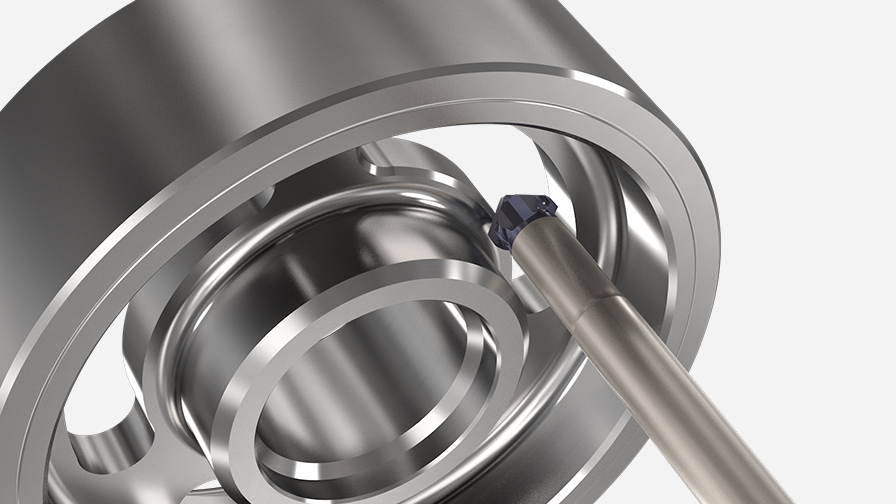

Angetriebenes Zahnrad, bezeichnet, wie der Name schon sagt, ein Zahnrad in einem Mechanismus, das Kraft empfängt.

In der Regel erhält es seine Leistung vom „Antriebszahnrad“ und überträgt diese auf andere Teile der Maschine oder des Mechanismus. Zahnräder, die auch als Zahngetriebe bezeichnet werden, übertragen Kraft durch das Ineinandergreifen ihrer Zähne – eine Bewegung, die für unzählige mechanische Geräte und Anlagen entscheidend ist. Dieser präzise Prozess der Kraftübertragung kann jedoch nur mit den richtigen Bearbeitungstechniken erreicht werden.

Bei der Herstellung von Zahnrädern werden häufig relativ weiche Werkstoffe wie kohlenstoffarmer Stahl verwendet. Solche Werkstoffe können bei der Zerspanung lange, kontinuierliche Späne erzeugen, die sich in den Werkzeugen verfangen und den ordnungsgemäßen Transport des Werkstücks behindern können.

Eine effektive Späneabfuhr trägt zur Stabilisierung des Prozesses bei, erhält die Qualität des angetriebenen Zahnrads und verbessert die Produktionseffizienz. Eine genaue und effiziente Bearbeitung unterstützt die wichtige Rolle des angetriebenen Zahnrads und ist der Schlüssel zur Maximierung der Leistung der gesamten Maschine.

Werkzeugkonzepte

- Die Anwendung des Drehens mit hohem Vorschub (Hinterdrehen) mit AddMultiTurn ermöglicht eine hocheffiziente Bearbeitung.

- Erzielen Sie eine hocheffiziente Bearbeitung mit der hohen Steifigkeit von AddForceCut auch bei langen Auskragungen.

- Steigert die Produktivität durch die schnellen Werkzeugwechsel des TungMeisters.

Besonderer Prozess

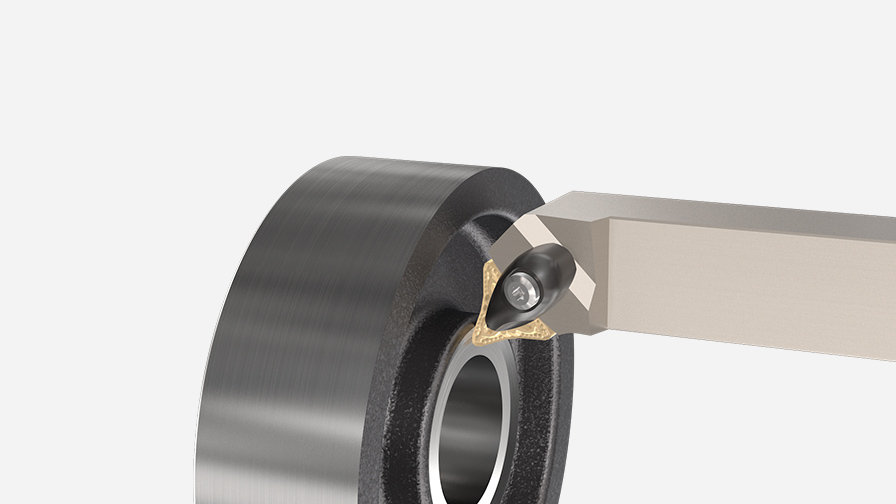

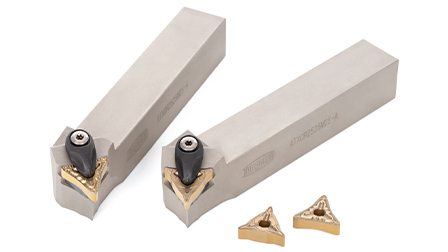

Prozess 1: Außen- und Plandrehen Schlichten

Nutzen

- Die Kantengeometrie mit hohem Vorschub beim Hinterdrehen ermöglicht hocheffiziente Bearbeitungen, die herkömmliche ISO-Werkzeuge bei Drehbearbeitungen um etwa 200 % übertreffen.

- Bei der Schruppbearbeitung, wo eine hohe Bearbeitungseffizienz erforderlich ist, wird das Hinterdrehen eingesetzt, bei der Schlichtbearbeitung, wo die Oberflächenrauheit kritisch ist, das Vorderdrehen. Durch den effizienten Einsatz von zwei Arten von Schneidkanten je nach Bearbeitungsbedingungen und Anwendung wird die Produktivität verbessert.

- Das Y-PRISM-Klemmsystem für Wendeschneidplatten, das für seine Einzigartigkeit und Robustheit bekannt ist, gewährleistet eine hervorragende Klemmsteifigkeit. Diese Eigenschaft ermöglicht eine stabile multidirektionale Bearbeitung und erleichtert eine hocheffiziente Bearbeitung.

6C-TOMG-TM

- Wirtschaftlich mit einer doppelseitigen 6-Ecken-Spezifikation.

- Die Sorte T9215 gewährleistet eine außergewöhnliche Verschleiß- und Bruchfestigkeit bei der Stahldrehbearbeitung und bietet eine hervorragende Leistung.

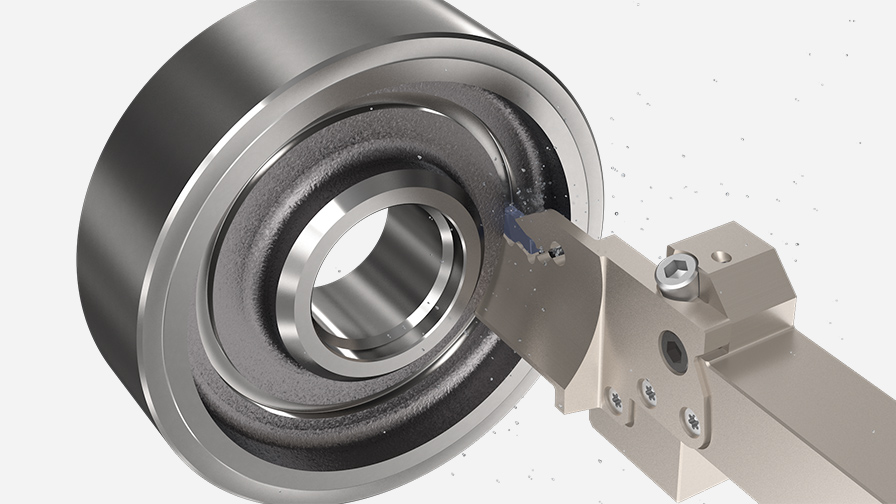

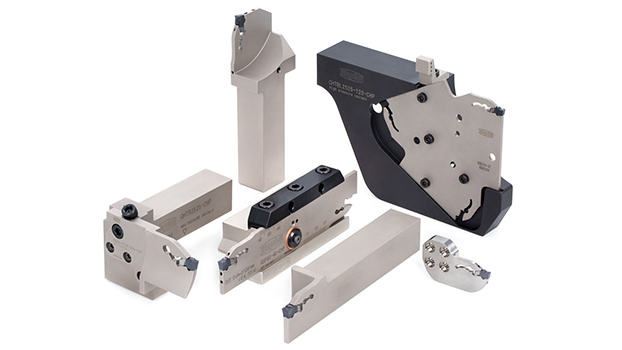

Prozess 2: Planstechen Schlichten

Nutzen

- Verwenden Sie einen hochfesten Halter mit erhöhter Dicke auf der Rückseite der Wendeschneidplatte. Ermöglicht sicheres Planstechen bei tiefen Nuten.

- Feste Klemmung durch optimal positionierte Klemmschrauben. Hohe Werkzeugsteifigkeit sorgt auch beim Planstechen und Querfeed-Bearbeitung für hervorragende Stabilität.

- Sicherstellung der Kühlmittelzufuhr zur Nut während der Bearbeitung zur Förderung der Spanabfuhr. Erreicht eine stabile Bearbeitung.

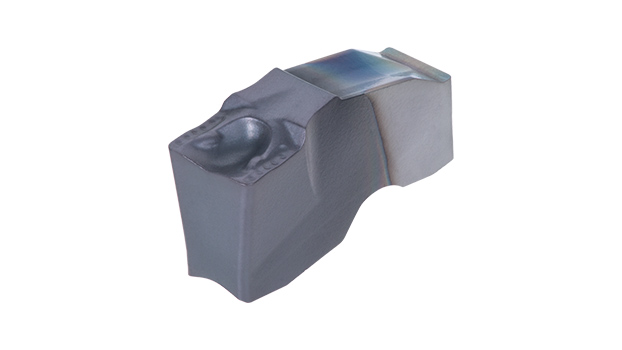

QTX Spanbrecher

- Dank einer optimierten Position der Vorsprünge ist der Spanbrecher in der Lage, die Späne zu erfassen und bildet bei jedem Vorschub ideale Locken.

- Der konkave Teil in der Mitte des Brechers komprimiert die Spanbreite. Die Verschmälerung der Spänebreite verbessert die Späneabfuhr.

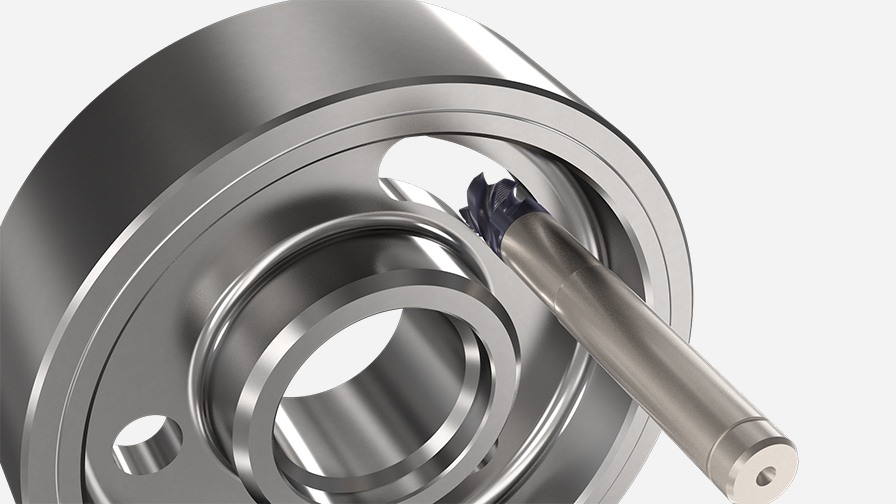

Prozess 3: Nutenfräsen Schlichten

Nutzen

- Die Schruppkante weist eine wellenförmige Schruppschneide auf und hat einen kleineren Außendurchmesser als die Schlichtkante. Mit dieser Spezifikation lassen sich Schlichtoberflächen erzielen, die denen von Vierkantfräsern gleichwertig sind, während die hohe Produktivität aufgrund der schwingungsdämpfenden Eigenschaften von Schruppfräsern erhalten bleibt.

- Drastische Reduzierung der Maschinenstillstandszeiten durch die Austauschbarkeit der Köpfe. Es ist keine Einstellung des Überstands oder ähnlicher Aufgaben erforderlich, da lediglich der Kopf ausgetauscht werden muss.

![]()

VEE-C Kopf

- Ein vielseitiges Material mit scharfer Schneidleistung und langer Standzeit.

- Starke Beschichtung auf scharfen Kanten mit hoher Haftung und ausgezeichneter Kantenfestigkeit.

Prozess 4: Anfasen Schlichten

Nutzen

- Durch den Einsatz eines VCW-Kopfes, der neben der Oberflächenfase auch eine Rückfase ermöglicht, können sowohl die Vorder- als auch die Rückseite mit dem gleichen Werkzeug bearbeitet werden, was zur Werkzeugkonsolidierung beiträgt.

- Drastische Reduzierung der Maschinenstillstandszeiten durch die Austauschbarkeit der Köpfe. Es ist keine Einstellung des Überstands oder ähnlicher Aufgaben erforderlich, da nur der Kopf ausgetauscht werden muss.

- Hohe Reproduzierbarkeit und Präzision durch beidseitige Begrenzung von Kegel und Planfläche.

![]()

VCW-02 Kopf

- Ein vielseitiges Material mit scharfer Schneidleistung und langer Standzeit.

- Starke Beschichtung auf scharfen Kanten mit hoher Haftung und ausgezeichneter Kantenfestigkeit.