Success stories of how Tungaloy’s sales representatives have worked closely with customers towards machining success.

DoMultiRec Contributes to Highly Efficient Machining of Large Machine Parts and Structural Components

Featured company

Kakiuchi Co., Ltd.

Salesman

Kenichi Nakayama

- Country

- Japan

Need for a multi-functional tool that can perform various operations on large machine parts and structural components

Kakiuchi, headquartered in Kouchi Prefecture, Japan, is a comprehensive manufacturer of industrial machines. The company not only assembles machine parts but also handles designing and production of their components. With a wide variety of machines including multi-axis machines, double-column machining centers, horizontal boring machines, and CNC vertical lathes, they are well-known for their exceptional operations on large machine parts and structural components.

The company often needs to machine custom-made products, so a versatile tool that can handle multiple operations like drilling, shoulder milling, and pocketing, comes in very handy.

On a freezing day in February of 2022, members of Kakiuchi sat in front of us with grim faces.

Competitor’s multi-purpose cutter became discontinued

The company used a multi-functional cutter made by a different cutting tool producer, but they decided to stop manufacturing it. In search for a substitution, Kakiuchi consulted us for some advice.

They used the competitor’s tool to drill and counterbore a casted component with a curved surface.

To find the best tool for the job, the company had already tried testing different cutting tool manufacturers’ items. Unfortunately, they faced some problems and none of the tools met their requirements.

- The cutter body broke from poor chip evacuation during the drilling operation.

- The central insert of the drill chipped or broke during the entry into the curved casted surface. Hence, the machine needed to be frequently stopped to change the insert and the operator had to closely monitor it with manual feed.

- The counterbored hole was going to be used for coupling, but the bottom of the hole was not flat and couldn’t be sealed properly.

- Productivity decreased as cutting parameters had to be reduced to machine the component in the required quality.

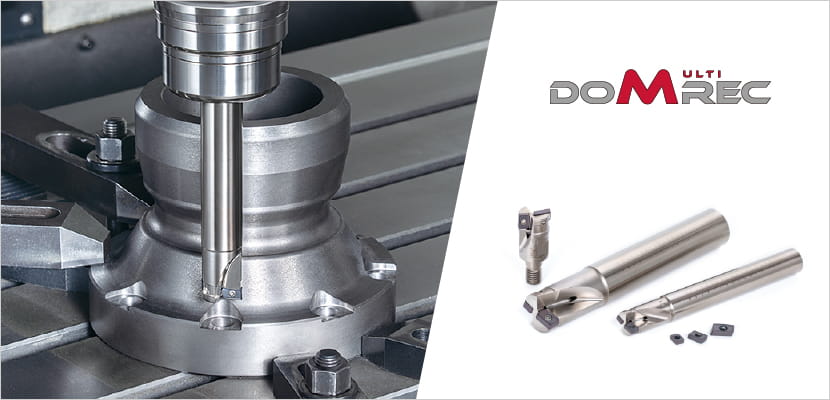

DoMultiRec increased machining efficiency and offered excellent surface finish

After carefully listening to all the challenges the customer faced, our sales representative with almost 40 years of experience in Tungaloy, knew exactly what tool to recommend – DoMultiRec.

Our DoMultiRec, the cutter series well-known for its multi-functional characteristic, is capable of drilling as well as shoulder milling with a single tool. Our research and development team also carefully designed the inserts’ cutting edges to maximize their strength during machining operations. Furthermore, the center cutting edge makes the bottom of the hole close to being flat.

The customer nervously tested DoMultiRec with lower cutting parameters at first but soon realized our inserts were tough enough to increase the cutting conditions. DoMultiRec exceeded their expectations and produced the necessary finished surfaces efficiently, which led Kakiuchi engineers to quickly decide applying it for their production.

Summary of improvements brought by DoMultiRec

-

Reduced the frequency of insert exchange with strong center cutting edge

Even during the entry to curved casted surface, DoMultiRec’s strong central cutting edge remained undamaged. The operator no longer needed to worry about sudden insert fractures and could run the machine unmanned. As a result, the company could use the manpower elsewhere, leading to improved production efficiency.

-

Highly efficient machining operations

DoMultiRec’s outstanding chip formation and evacuation during drilling, combined with high tool rigidity, made stable machining possible. The customer was able to increase the cutting parameters, and the overall productivity improved.

-

Excellent surface finish on the bottom of the hole during counterboring

The counterbored hole’s bottom very close to being flat could be perfectly sealed, which was exactly what the customer needed.

The future endeavors

Currently, DoMultiRec is installed on almost every machine the company owns, and we are excited to see our products contribute to their production. They recently consulted us for cutters with φ32mm to cover a large portion of their machining operations. To further support their need, we have started to work with our research and development team to design a new product.

Now that Kakiuchi could efficiently machine their components with DoMultiRec, their next goal is to increase the usage of tools with internal coolant system to shorten machining time and prolong insert tool life.

Tungaloy will continue working closely with our customers to solve problems that are on the surface as well as to find places for improvement to help maximize their productivity.

Featured Product

Multifunctional milling cutter with center cutting edge

DoMultiRec

All-round cutter with center cutting capability provides ultimate machining versatility