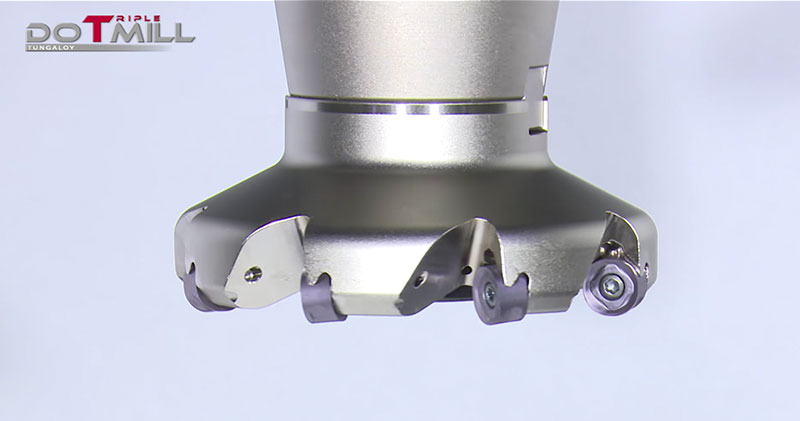

Highly-versatile face milling cutters for a wide variety of materials

DoTriple-Mill features an improved dovetail clamping structure and offers triple advantage of using square, octagonal, and round inserts in the same pocket

Applications & Features

Applications

Features

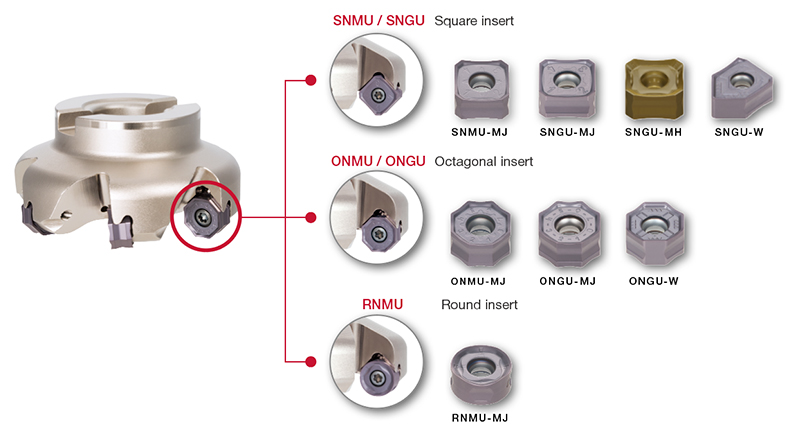

1. High Versatility

• 3 types of double sided inserts fit in the same pocket.

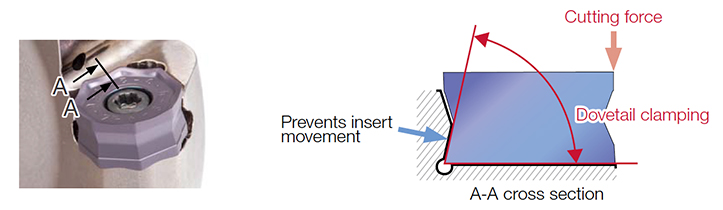

2. Rigid clamping provided with Dovetail structure

• Improved performance especially in machining high-temperature materials.

• Extended tool life.

Inserts & Grades

Inserts

SN*U

- Maximum depth of cut = 6 mm

- Cutting edge angle 45 degree on cutter body

- Suitable for a large depth of cut face milling

ON*U

- Maximum depth of cut = 3.4 mm

- Cutting edge angle 45 degree on cutter body

- High economical 16 corners inserts for face milling

RNMU

- Maximum depth of cut = 6 mm

- For high feed milling or an operation with a large depth of cut

- Lower cutting force and reduced thermal damage to the cutting edge by the helical cutting edge design

Main Grades

AH3135

![]()

![]()

- High fracture resistance

- Suitable for machining steel and stainless steel under general cutting conditions

T3225

![]()

![]()

- High chipping and fracture resistance

- Suitable for milling steel and stainless steel

T1215

![]()

- Good balance between wear and chipping resistance

- Suitable for milling cast iron

Cutter bodies

Practical examples

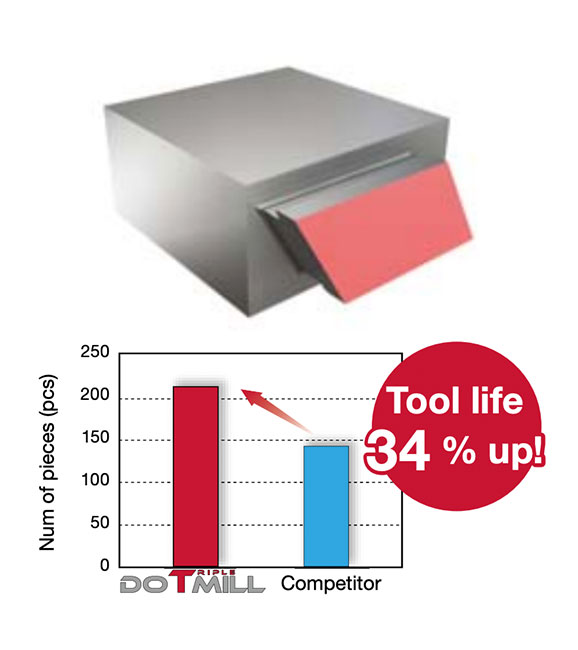

Example #1

Power Generation Industry

| Part: | Turbine blade |

| Material: | 10705BU (Stainless steel) |

| Cutter: | TASN13J100B31.7R08 (ø100, z = 8) |

| Insert: | ONGU0507ANEN-MJ |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 79 (m/min) fz = 0.10 (mm/t) Vf = 201 (mm/min) ap = 2.0 (mm) Application: Face milling (Roughing) Coolant: External Machine: Horizontal M/C, BT50 |

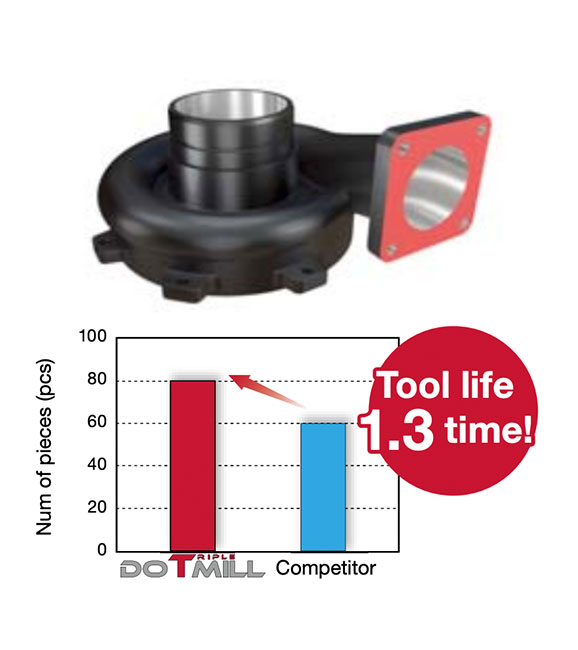

Example #2

Automotive Industry

| Part: | Turbine housing |

| Material: | GX40CrNiSiNb22-10 |

| Cutter: | TASN13M100B32.0R08 (ø100, z = 8) |

| Insert: | SNGU1307ANEN-MJ |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 94 (m/min) fz = 0.17 (mm/t) Vf = 408 (mm/min) ap = 3.5 (mm) ae = 80 (mm) Application: Face milling Coolant: External Machine: Vertical M/C |

Example #3

Automotive Industry

| Part: | Turbine housing |

| Material: | Hi Si FCD |

| Cutter: | TASN13M125B40.0R10 (ø125, z = 10) |

| Insert: | SNGU1307ANEN-MJ |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 196 (m/min) fz = 0.08 (mm/t) Vf = 400 (mm/min) ap = 1.3 (mm) ae = 100 (mm) Application: Face milling (Roughing) Coolant: External Machine: Vertical M/C, BT50 |

Standard cutting conditions

SNMU / SNGU / ONMU / ONGU

| ISO | Workpiece materials | Hardness | Priority | Grades | Chipbreaker | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|

|---|---|---|---|---|---|---|---|---|

| Low carbon steel S15C, etc. C15, etc. |

200 – 300HB | First choice | AH3225 | MJ | 100 – 250 | 0.1 – 0.5 | ||

| For wear resistance | T3225 | MJ | 200 – 350 | 0.1 – 0.4 | ||||

| High carbon and alloy steel S55C, SCM440, etc. C55, 42CrMo4, etc. |

150 – 300HB | First choice | AH3225 | MJ | 100 – 250 | 0.1 – 0.4 | ||

| For wear resistance | T3225 | MJ | 180 – 300 | 0.1 – 0.4 | ||||

| Prehardened steel NAK80, PX5, etc. |

30 – 40 HRC | First choice | AH3225 | MJ | 100 – 200 | 0.1 – 0.4 | ||

| For wear resistance | T3225 | MJ | 150 – 250 | 0.1 – 0.4 | ||||

| Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

– 200HB | First choice | AH3135 | MJ | 100 – 200 | 0.1 – 0.35 | ||

| For wear resistance | T3225 | MJ | 100 – 200 | 0.1 – 0.3 | ||||

| Cast stainless steel SCH20XNb, 1.4849, etc. |

– | First choice | T3225 | MH | 60 – 120 | 0.1 – 0.3 | ||

| For low cutting force | AH3135 | MJ | 60 – 120 | 0.1 – 0.3 | ||||

| Grey cast iron FC250, etc. 250, etc. |

150 – 250HB | First choice | AH8015 | MJ | 100 – 250 | 0.1 – 0.5 | ||

| For wear resistance | T1215 | MJ | 100 – 300 | 0.1 – 0.4 | ||||

| Ductile cast iron FCD600, etc. 600-3, etc. |

150 – 250HB | First choice | AH8015 | MJ | 80 – 200 | 0.1 – 0.5 | ||

| For wear resistance | T1215 | MJ | 100 – 300 | 0.1 – 0.4 | ||||

| Titanium alloys Ti-6AI-4V, etc. |

– 40HRC | First choice | AH3135 | MJ | 30 – 60 | 0.1 – 0.3 | ||

| For wear resistance | AH8015 | MJ | 30 – 60 | 0.1 – 0.3 | ||||

| Heat-resistant alloys Inconel718, etc. |

– 40HRC | First choice | AH8015 | MJ | 10 – 40 | 0.05 – 0.15 | ||

| For fracture resistance | AH3135 | MJ | 10 – 40 | 0.05 – 0.15 | ||||

| Hardened steel | SKD61, etc. X40CrMoV5-1, etc. |

40 – 50HRC | First choice | AH8015 | MJ | 80 – 130 | 0.05 – 0.2 | |

| For fracture resistance | AH3225 | MJ | 80 – 130 | 0.05 – 0.2 | ||||

| SKD11, etc. X153CrMoV12, etc. |

50 – 60HRC | First choice | AH8015 | MJ | 50 – 70 | 0.03 – 0.1 | ||

RNMU

| ISO | Workpiece materials | Hardness | Priority | Grades | Chip-breaker | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|

|---|---|---|---|---|---|---|---|---|

| Low carbon steel S15C, etc. C15, etc. |

200 – 300HB | First choice | AH3225 | MJ | 100 – 250 | ※ap = 6 mm : 0.1 – 0.3 ※ap = 2 mm : 0.4 – 0.8 ※ap = 1 mm : 0.8 – 1.5 |

||

| For wear resistance | T3225 | MJ | 200 – 350 | |||||

| High carbon and alloy steel S55C, SCM440, etc. C55, 42CrMo4, etc. |

150 – 300HB | First choice | AH3225 | MJ | 100 – 250 | |||

| For wear resistance | T3225 | MJ | 180 – 300 | |||||

| Prehardened steel NAK80, PX5, etc. |

30 – 40 HRC | First choice | AH3225 | MJ | 100 – 200 | |||

| For wear resistance | T3225 | MJ | 150 – 250 | |||||

| Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

– 200HB | First choice | AH3135 | MJ | 100 – 200 | ※ap = 6 mm : 0.1 – 0.25 ※ap = 2 mm : 0.3 – 0.7 ※ap = 1 mm : 0.6 – 1.3 |

||

| For wear resistance | T3225 | MJ | 100 – 200 | |||||

| Stainless cast steel SCH20XNb, 1.4849, etc. |

– | First choice | T3225 | MJ | 60 – 120 | ※ap = 2 mm : 0.2 – 0.4 ※ap = 1 mm : 0.3 – 0.8 |

||

| For fracture resistance | AH3135 | MJ | 60 – 120 | |||||

| Grey cast iron FC250, etc. 250, etc., GG25, etc. |

150 – 250HB | First choice | AH120 | MJ | 100 – 300 | ※ap = 6 mm : 0.1 – 0.3 ※ap = 2 mm : 0.4 – 0.8 ※ap = 1 mm : 0.8 – 1.5 |

||

| T1215 | MJ | 100 – 250 | ||||||

| Ductile cast iron FCD600, etc. 600-3, etc., GGG60, etc. |

150 – 250HB | First choice | AH120 | MJ | 100 – 300 | |||

| T1215 | MJ | 80 – 200 | ||||||

| Titanium alloys Ti-6AI-4V, etc. |

– 40HRC | First choice | AH3135 | MJ | 30 – 60 | ap = 1 mm : 0.15 – 0.8 | ||

| Heat-resistant alloys Inconel718, etc. |

– 40HRC | First choice | AH120 | MJ | 10 – 40 | ap = 1 mm : 0.05 – 0.3 | ||

| Hardened steel | SKD61, etc. X40CrMoV5-1, etc. |

40 – 50HRC | First choice | AH3225 | MJ | 80 – 130 | ap = 1 mm : 0.1 – 0.25 | |

| SKD11, etc. X153CrMoV12, etc. |

50 – 60HRC | First choice | AH120 | MJ | 50 – 70 | ap = 0.5 mm : 0.03 – 0.1 | ||

※ When using T3225 or T1215, decrease the feed per tooth (fz) to 80% of the abovementioned value.

For more information about this product, visit our online e-catalog or download the product report: