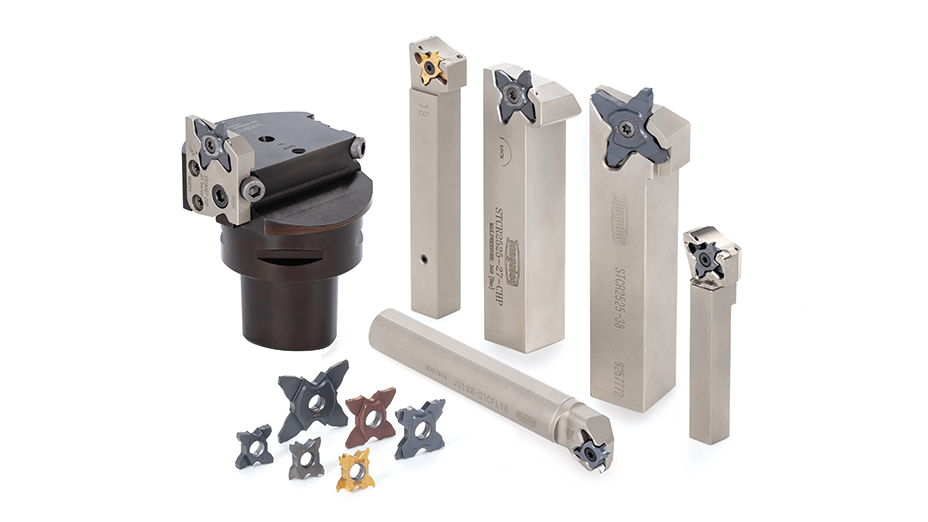

Iwaki, Japan – December 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its TetraForce-Cut series with the addition of a 16-square CHP holder designed for high-efficiency and stable grooving and parting operations in compact machining environments.

Challenges and Trends

In the field of small-part machining, high-efficiency parting and grooving in limited spaces is essential. However, the TetraForceCut series previously lacked a 16-square CHP holder optimized for small-part machining, which limited tool selection flexibility and posed challenges for machining stability. To address these Challenges and Market Conditions, we have now added a 16-square CHP holder to the lineup. This new addition delivers improved productivity and extended tool life for users in small-part machining operations.

Product Overview

TetraForce-Cut is high-precision grooving and parting tools offered by Tungaloy. Featuring economical four-corner inserts and high-rigidity toolholders, they deliver stable machining performance and high productivity.

Benefits and Features

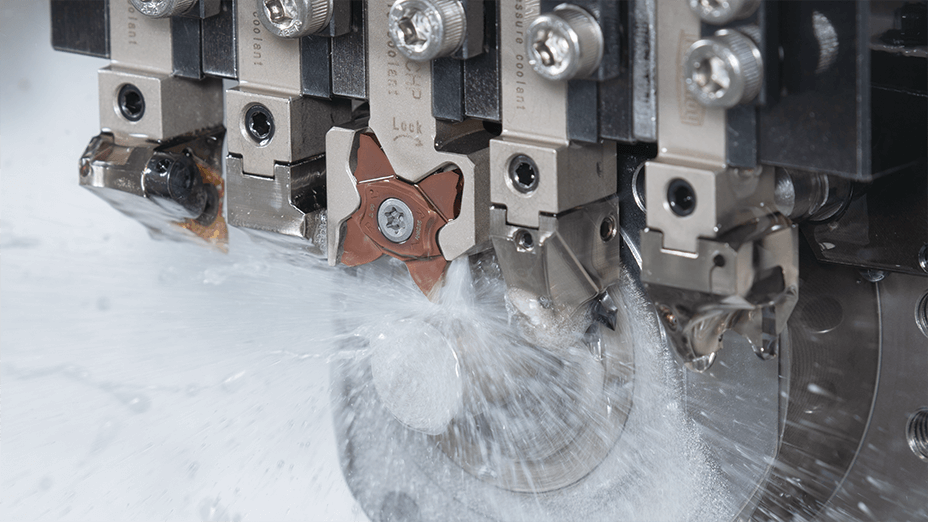

Feature 1: Enhanced Cutting Performance through Direct Coolant Supply from the Rake Face

– Direct coolant supply near the cutting edge maximizes cooling and lubrication at the cutting point

– Improved chip evacuation reduces chip tangling and clogging

– Extended tool life allows for consistent machining quality over longer periods

Feature 2: Improved Work Efficiency through Reduced Setup Time

– Direct coolant supply design eliminates the need for hose or nozzle adjustments

– Simplified setup during tool changes significantly shortens setup time

– Contributes to improved line uptime and reduced total cost